Silicone sealants are built to last—often too well. I’ve seen cases where leftover silicone from previous projects, product maintenance, or mold-making processes caused major headaches. Whether you’re working with glass, plastic, or metal, removing cured silicone isn’t easy.

Here’s the good news: with the right chemical solvents, you can break down even the most stubborn silicone sealant safely and efficiently. In this guide, I’ll walk you through the most effective chemical options, including industrial-grade isopropyl alcohol, potassium hydroxide, and commercial removers like Digesil or UltraClean™. You’ll also get tips on mechanical techniques, safety precautions, and when to use each method.

Let’s explore how to remove silicone the smart way.

What is the best solvent for dissolving silicone?

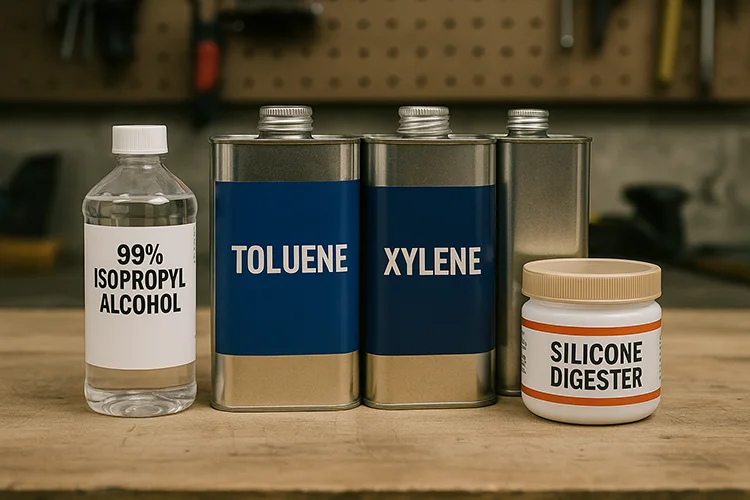

If you’re searching for a strong and reliable silicone solvent, start with industrial-grade isopropyl alcohol (99%). It’s effective for softening silicone—especially when combined with heat or scraping tools.

Other top contenders include:

- Toluene and xylene – Powerful hydrocarbon solvents used in heavy-duty industrial cleaning.

- Mineral spirits – A gentler option, better suited for delicate surfaces.

- Digesil – A commercial silicone digester, highly effective on cured sealants.

Always wear gloves and ensure proper ventilation when using any of these chemicals.

Chemical Solvent Comparison Table

| Solvent | Effectiveness | Best For | Safety Notes |

|---|---|---|---|

| Isopropyl Alcohol (99%) | ★★★★☆ | General removal | Skin-safe, flammable |

| Toluene/Xylene | ★★★★★ | Industrial use | Toxic, wear full PPE |

| Mineral Spirits | ★★★☆☆ | Light-duty projects | Mild fumes, test surface first |

| Digesil | ★★★★★ | Cured silicone removal | Follow product-specific guidelines |

| Siloxane-based Removers | ★★★★★ | Glue residues, RTV silicone | Requires controlled use |

What chemical dissolves silicone completely?

For complete breakdown, the most effective method involves a base solution of potassium hydroxide (KOH) or sodium hydroxide (NaOH) mixed with IPA. This forms a chemical bath that disrupts silicone’s polymer chains.

You can also use siloxane-based solvents such as UltraClean™ or VeriClean™, which follow the “like dissolves like” principle—ideal for removing RTV silicone and industrial coatings.

Caution: These chemicals are highly reactive and best suited for trained professionals or controlled lab environments.

Does acetone dissolve silicone?

Not quite. Acetone can swell silicone, making it easier to scrape off, but it won’t fully dissolve it. It’s helpful as a surface prep tool or for removing thin films, but for full removal, xylene or KOH is better.

Important: Acetone is flammable and harsh on plastics. Use sparingly and avoid it on sensitive components.

What helps dissolve silicone besides chemicals?

Sometimes chemicals alone aren’t enough. Here’s what else helps:

- Heat guns or hair dryers: Soften the silicone for easier peeling or scraping.

- Plastic or metal scrapers: Use gently to avoid damaging the substrate.

- Methylated spirits or vinegar: These can loosen uncured or semi-cured silicone.

Best for: Window trims, electronics, or delicate household areas where solvent use is limited.

What is the best silicone remover for industrial use?

If you’re in a factory or lab setting, Digesil is my go-to. It’s a catalytic remover that breaks down silicone’s Si-O (silicon-oxygen) bonds quickly and cleanly.

Other professional options include:

- NOVOCS solvents (by Smooth-On) – Ideal for molds and prototypes

- Techspray G3 Blue Shower – Used in electronics and maintenance cleaning

These products are engineered for fully cured silicone in high-volume or precision applications.

Can silicone remover sprays work on sealant?

Yes—but with limits. Most consumer-grade silicone remover sprays work by softening the silicone so you can peel or scrape it off. Examples include:

- WD-40 (low effectiveness)

- Selleys Silicone Remover

- HG Silicone Sealant Remover

They’re best for bathrooms, kitchens, and DIY projects—not industrial-strength removal.

What is a silicone digester and how does it work?

A silicone digester is a chemical agent that specifically targets and breaks Si-O bonds within cured silicone. It transforms the normally stubborn rubbery material into a more manageable gel-like form.

Commonly used in:

- Manufacturing lines (e.g., cleaning excess sealant from jigs)

- Laboratories (equipment maintenance)

- Prototyping workshops (removal of RTV mold layers)

Reminder: These chemicals are aggressive—always read and follow safety instructions.

Is silicone sealant removable without damage?

Yes, if you follow the right steps:

- Score the silicone with a utility knife to open up the surface

- Apply solvent (IPA, Digesil, or xylene) to penetrate

- Use heat to soften particularly tough areas

- Scrape gently with a plastic or metal blade

This approach works well on glass, tile, stainless steel, and even some plastics (with testing).

Final Thoughts: Use the Right Tool for the Job

Silicone may be tough, but with the right solvent—whether it’s IPA, Digesil, or a KOH solution—removal is completely achievable. Don’t forget that surface compatibility and safety precautions matter just as much as solvent strength.

Need help sourcing high-performance silicone components or replacing old seals? Contact us at Kinsoe for expert guidance.