Introduction

Seals might be small, but in mechanical systems, they play a massive role. Whether it’s in a car engine, a food processing line, or a complex aerospace application, seals are what keep fluids in, contaminants out, and systems running efficiently. Yet, I’ve seen too many engineers and buyers overlook one critical decision—choosing between rubber and metal seals.

An incorrect seal choice can lead to devastating outcomes: from minor fluid leaks and reduced system efficiency to complete mechanical failures or costly downtime. Sometimes the issue is underperformance from a poorly matched material. Other times, it’s a case of over-specification—using a high-cost metal seal where a basic rubber one would’ve sufficed.

That’s why I wrote this article. Whether you’re sourcing parts for an industrial application, designing a consumer product, or simply trying to understand which sealing solution fits best, my goal is to guide you clearly through the trade-offs. By the end, you’ll have the clarity and confidence to choose the right seal—based on your real application needs, not just guesswork.

Let’s start by understanding what makes rubber and metal seals so fundamentally different.

Understanding the Two Types of Seals

There are many types of seals, but rubber seals and metal seals are the two most commonly compared types. Understanding their respective materials and performance is the first step in selection.

What Are Rubber Seals?

Rubber seals are flexible components made from various elastomeric materials. The most common include:

- NBR (Nitrile Butadiene Rubber) – excellent resistance to oil and fuel

- EPDM (Ethylene Propylene Diene Monomer) – outstanding weather, ozone, and water resistance

- FKM (Fluoroelastomer, e.g., Viton®) – strong chemical and high-temperature resistance

- Silicone Rubber – heat-stable, food-safe, and highly flexible at low temperatures

Rubber seals are valued for their elasticity, ease of installation, and cost-effectiveness. They conform well to surface irregularities, making them suitable for dynamic and static sealing alike. You’ll often find them in gaskets, O-rings, tubing ends, and molded components.

In general, if your application requires flexibility, moderate temperatures, and ease of replacement, rubber seals are a dependable go-to.

What Are Metal Seals?

Metal seals are engineered for extreme conditions where elastomers might fail. Typical materials include:

- Stainless Steel (304, 316) – corrosion-resistant, widely used

- Inconel® – a nickel-chromium alloy for ultra-high temperature and pressure resistance

- Copper or Aluminum – softer metals for crush-type gaskets in static sealing

These seals are built to withstand temperatures over 500 °C, intense pressure, and corrosive chemicals. They don’t deform easily and require precision machining to function properly.

Metal seals excel in harsh environments, such as vacuum chambers, high-pressure steam systems, and aerospace engines. But they also demand tighter tolerances and professional installation.

Comparison Table: Rubber vs. Metal Seals

When choosing between rubber and metal seals, it’s not just a matter of material—it’s about performance trade-offs. Here’s a clear side-by-side comparison to help you quickly evaluate which type suits your needs:

| Feature | Rubber Seals | Metal Seals |

|---|---|---|

| Temperature Range | -50 °C to 150 °C (up to 300 °C with FKM) | 200 °C to 600 °C+, depending on metal type |

| Pressure Tolerance | Moderate (up to 10 MPa) | Very high (100 MPa or more in some designs) |

| Elasticity | High – flexible and forgiving | Low – rigid, requires precise fit |

| Chemical Resistance | Varies by elastomer (e.g., FKM for fuels) | Excellent with corrosive fluids and gases |

| Installation Ease | Simple, fits minor misalignments | Requires clean surfaces and preload |

| Maintenance | Easy to replace, low cost | Long life, but more complex to replace |

| Cost | Low to moderate | High (material + machining) |

| Common Uses | Automotive, appliances, HVAC, water systems | Aerospace, nuclear, steam, vacuum equipment |

Tip: Think of rubber seals as generalists—flexible, easy, and economical. Metal seals are specialists—tough, precise, and made for the extremes.

Selection Criteria: When to Choose What

Choosing between rubber and metal seals comes down to matching the seal to your real-world application. Here’s how I evaluate the decision across four core criteria:

Temperature and Pressure Conditions

If your application involves elevated heat or pressure, the material’s performance envelope is critical.

- Rubber seals typically perform well up to 150 °C, with specialty options like FKM or silicone pushing that to around 250–300 °C.

- Metal seals dominate in extreme settings, often handling 500 °C or more and withstanding very high internal pressures, such as in steam systems, jet engines, or reactors.

Rule of thumb: If your seal will see over 200 °C or high pressure spikes, metal is likely the safer choice.

Chemical Compatibility

The medium your seal contacts—whether gas, oil, acid, or water—matters as much as temperature.

- Rubber seals come in a range of chemistries. For instance:

- EPDM resists water and steam but degrades in oils.

- FKM handles fuels and solvents well but not steam.

- Metal seals work well with corrosive chemicals, aggressive gases, and in vacuum conditions where outgassing is a concern.

Always check chemical compatibility charts—or better, consult your supplier—to avoid material breakdown and leakage.

Installation and Tolerances

The skill level and precision of your assembly line will influence the best choice.

- Rubber seals are forgiving. Their compressibility compensates for misalignments or surface imperfections.

- Metal seals need clean, flat surfaces and specific preload forces. Improper installation can cause permanent leaks.

If field repairs or manual assembly are expected, rubber is often more practical.

Maintenance Expectations

Think about how often the seal will need inspection or replacement—and the cost of downtime.

- Rubber seals wear faster, especially under heat or chemical stress, but they’re cheap and easy to replace.

- Metal seals last longer and can survive repeated thermal cycles, but replacement is costly and labor-intensive.

For temporary or mid-duty systems, rubber may be enough. For mission-critical systems, metal’s longevity pays off.

Common Use Cases

To help you visualize the differences, here are examples of where rubber and metal seals excel—and when a hybrid approach makes the most sense.

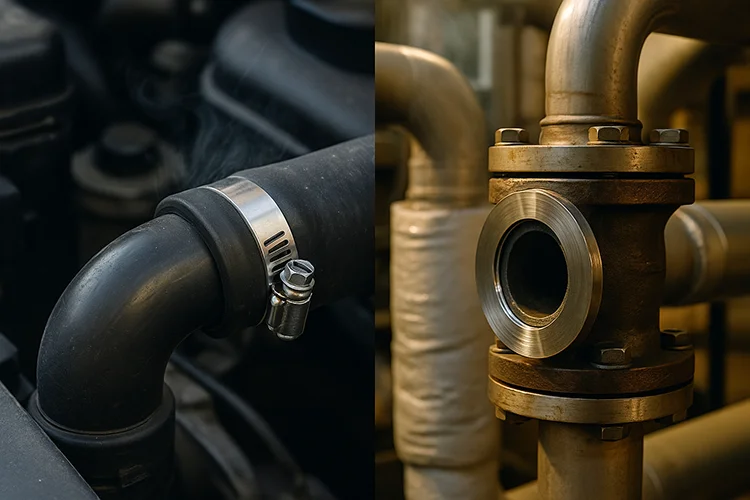

Rubber Seals in Everyday Systems

Rubber seals are everywhere in consumer and industrial products. For example:

- Automotive cooling systems rely on EPDM O-rings and gaskets to seal water pumps and radiators. These seals must handle fluctuating temperatures, pressure pulses, and long-term exposure to coolant fluids.

- Pneumatic actuators often use NBR seals to contain compressed air. Their flexibility ensures tight sealing even under repetitive motion.

These examples show how rubber seals offer sufficient performance at a manageable cost, especially when conditions stay within moderate ranges.

One of my clients in the HVAC industry once reduced costs by 30% simply by switching from over-engineered metal seals to high-temp rubber in their rooftop units.

Metal Seals in Extreme Environments

In contrast, metal seals thrive in high-demand, mission-critical environments:

- Jet engines use Inconel metal seals to maintain integrity at temperatures exceeding 600 °C and high altitudes where pressure differentials are extreme.

- Steam valves in power plants rely on stainless steel or copper seals to endure decades of cyclic thermal stress without failure.

- Semiconductor vacuum systems depend on metal C-rings to ensure hermetic sealing under ultra-high vacuum and chemically reactive conditions.

These examples underscore why metal seals are indispensable in aerospace, energy, and precision manufacturing sectors.

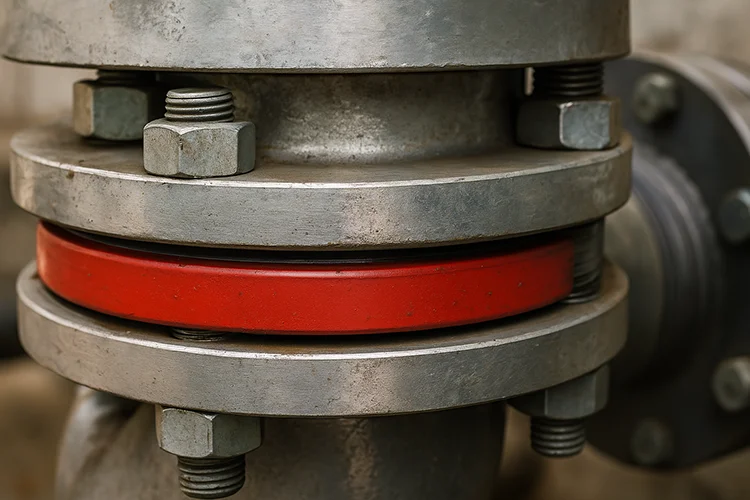

Hybrid Solutions: The Best of Both Worlds?

Some applications use rubber-coated metal seals to combine elasticity and rigidity. For instance:

- Compressor housings often use metal gaskets coated with FKM or silicone to handle both structural force and slight misalignments.

- Oil & gas flange connections benefit from the chemical resistance and sealing forgiveness of hybrid seals, especially during field maintenance.

Tip: If you’re torn between durability and ease of use, hybrid seals may offer the most balanced solution.

FAQs

Still unsure about rubber vs. metal seals? Here are the most common questions I hear—and the answers that can help you make smarter decisions.

Can metal seals replace rubber in every scenario?

Not really. While metal seals offer superior durability and resistance, they’re not suitable for every application. For example, if your system requires flexibility, quick replacement, or low assembly cost, rubber seals are often the better fit. Metal seals require precise installation and don’t compress like rubber, making them less ideal for irregular surfaces or quick maintenance scenarios.

Are rubber-coated metal seals the best of both worlds?

In many cases, yes. Rubber-coated metal seals combine a metal core’s structural strength with a rubber layer’s sealing flexibility. This makes them perfect for high-pressure flange joints, engine components, or where vibration and misalignment are concerns. However, they still come at a higher cost than pure rubber seals and may not be necessary for low-stress applications.

How do I test compatibility or failure risks?

There are three reliable methods:

- Chemical compatibility charts: These indicate how different seal materials respond to fluids, temperatures, and pressures.

- Finite Element Analysis (FEA): For critical designs, FEA simulations can predict seal deformation, contact pressure, and fatigue life.

- Field testing: Install seals in real-world conditions and inspect for swelling, cracking, or leakage after exposure cycles.

Expert tip: When in doubt, ask your supplier for material samples and run a short-term test on your actual equipment.

Conclusion

Choosing the right seal isn’t just a technical detail—it’s a strategic decision that affects performance, reliability, and cost. I’ve seen teams overengineer with expensive metal seals when a durable rubber option would’ve worked just fine. I’ve also seen critical systems fail because the seal couldn’t handle the heat, pressure, or chemicals involved.

Here’s the bottom line:

- Use rubber seals when flexibility, easy installation, and moderate performance are enough.

- Choose metal seals when facing extreme heat, pressure, or aggressive chemicals.

- Consider hybrid seals when you need a bit of both—durability with forgiveness.

If you’re unsure, never guess. Even a small mismatch between seal material and application can lead to big losses.

Need help choosing the right seal for your system? At Kinsoe, we specialize in both molded rubber and custom sealing solutions. Reach out to discuss your application—I’ll help you match the right material to your real-world needs.