I. Introduction

Rotating seals play a critical role in the performance and reliability of industrial equipment. From pumps and compressors to agitators and gearboxes, these components are responsible for preventing fluid leakage along rotating shafts. Whether it’s keeping lubricants in or contaminants out, the integrity of a rotary seal determines both the operational stability and safety of machinery.

However, there’s a hidden enemy working against every rotating seal—wear. Friction, pressure, and aggressive chemicals constantly attack sealing materials, slowly degrading their surface and reducing their effectiveness. If the wrong material is chosen, this degradation happens faster than expected, leading to premature failure, leakage, and unplanned maintenance. I’ve seen this unfold in real-world cases, where seals in hydraulic pumps fail in less than a month simply because the compound wasn’t compatible with the oil or the operating temperature.

Wear resistance isn’t just a “nice-to-have”—it’s essential. It directly affects the lifecycle cost of a machine, influencing downtime, part replacements, and labor expenses.

Industries like oil and gas, chemical processing, pharmaceuticals, automotive, and water treatment all rely heavily on rotating seals. And yet, many professionals still underestimate the impact that material selection has on seal performance.

That’s exactly why I wrote this article.

My goal is to provide a clear, professional guide that helps engineers, product designers, procurement managers, and maintenance specialists select the right wear-resistant material for their rotary seals. By integrating real user concerns from search trends—such as chemical compatibility, temperature resistance, or friction damage—I want to bridge the gap between technical knowledge and practical decision-making.

If you’re struggling with frequent seal replacements, unexplained system leaks, or customer complaints about durability—this guide is for you.

Let’s walk through the environmental factors, material types, and evaluation criteria that will help you choose better—and save more.

II. Understanding the Operating Environment

2.1 Temperature Range

One of the most critical factors in choosing seal materials is temperature tolerance. Rotating seals often operate in systems where temperatures can soar due to internal heat generation or external environmental conditions. I’ve worked with clients in food processing and automotive industries where sustained exposure to 150°C+ conditions caused elastomers to harden, crack, or lose flexibility.

When seals are exposed to elevated or fluctuating temperatures, thermal expansion becomes a problem. Materials with high coefficients of thermal expansion may deform or lose their dimensional stability, causing misalignment and leakage. Additionally, prolonged heat exposure can lead to thermal aging, reducing mechanical strength and accelerating wear.

On the flip side, extreme cold can make certain materials brittle, leading to cracks under mechanical stress. This is especially relevant in aerospace, outdoor mechanical systems, and refrigerated environments.

Key takeaway:

Choose materials like FKM (Viton) or high-performance thermoplastics (e.g., PEEK) for high-temperature use, and avoid low-grade rubbers that degrade quickly under thermal stress.

2.2 Operating Pressure

Rotating seals are often subjected to high internal pressures, especially in pumps, compressors, and hydraulic systems. Under these conditions, seal materials are prone to deformation, extrusion, and creep.

If the selected material lacks the structural strength to resist pressure, it may extrude into the gap between the shaft and housing, leading to severe wear or complete seal failure. I’ve seen PTFE-based seals in low-pressure settings perform well, but in high-pressure applications without backup rings, they often suffer from permanent deformation.

Compression set—the material’s ability to return to its original shape after being compressed—is another key concern. A poor compression set means the seal will not rebound properly, resulting in permanent gaps and leakage.

Key takeaway:

For high-pressure environments, prioritize materials with low compression set and high tensile strength, such as filled PTFE, PU, or reinforced thermoplastics.

2.3 Chemical Compatibility

Chemical exposure is a silent killer of sealing materials. If your rotary seal contacts oils, fuels, coolants, acids, or cleaning agents, chemical compatibility becomes non-negotiable.

One client in the chemical industry once replaced nitrile rubber (NBR) seals with FKM in all mixing units after repeated failures due to swelling and softening. The problem? NBR couldn’t handle aromatic hydrocarbons and acidic by-products, resulting in loss of sealing function within weeks.

Chemical attack can manifest as:

- Swelling, which causes seal misfit.

- Cracking or hardening, which breaks the dynamic seal.

- Embrittlement, especially under combined chemical and heat exposure.

Key takeaway:

Always consult chemical compatibility charts. FKM and PTFE are your safest bets for harsh chemical environments.

2.4 Rotational Speed and Friction

As the shaft rotates, it creates friction at the seal interface. High-speed rotation results in frictional heat, which contributes to wear, softening, and sometimes even thermal decomposition of the material.

Materials like PTFE and UHMWPE are valued here for their exceptionally low coefficients of friction, which minimize heat buildup. By contrast, high-friction materials like natural rubber are poor choices for fast-moving shafts.

High speeds can also disrupt the formation of hydrodynamic lubrication—a thin fluid film that reduces direct contact between the seal and shaft. Without it, dry sliding accelerates wear.

Key takeaway:

For high-RPM applications, go with low-friction polymers or elastomers optimized for dynamic sealing.

2.5 Shaft Surface and Hardware Considerations

Even the best seal material can fail if the hardware isn’t compatible. Shaft surface roughness, hardness, and finish all influence how effectively a seal will perform—and how fast it will wear out.

If the shaft is too rough, it acts like sandpaper against the seal. Too smooth, and it may prevent proper lubrication film formation. I often recommend a Ra (roughness average) between 0.2 to 0.8 μm for rotary shafts, depending on the seal type.

Shaft hardness is also important. If it’s softer than the seal, metal surface galling or seal cutting may occur. If it’s too hard or improperly finished, it can wear down the seal quickly.

Key takeaway:

Always consider the seal-shaft interface as a system, not just the material alone. Surface finish, hardness, and tolerance all impact wear resistance.

III. Common Wear-Resistant Materials for Rotary Seals

3.1 PTFE (Polytetrafluoroethylene)

PTFE is one of the most widely used materials for rotary seals, and for good reason. Its ultra-low coefficient of friction makes it ideal for high-speed applications where frictional heat is a concern. It also offers exceptional chemical resistance, standing up to nearly all industrial solvents, acids, and fuels without breaking down.

However, PTFE is not without its limitations. Pure PTFE is relatively soft and prone to creep under continuous pressure. That means over time, it can deform permanently, especially if not supported by backup rings. To counteract this, PTFE is often blended with fillers like glass fiber, carbon, or bronze to increase wear resistance and structural stability.

Use case example:

I once worked with a pharmaceutical equipment manufacturer who switched from elastomeric seals to glass-filled PTFE for a centrifugal mixer. The result was a 4x increase in seal life due to reduced chemical attack and improved dynamic wear resistance.

Summary:

- Pros: Low friction, excellent chemical resistance, wide temperature range.

- Cons: Creeping under pressure, brittle at low temperatures without reinforcement.

3.2 Polyurethane (PU)

Polyurethane has earned its place in abrasive environments. It offers outstanding abrasion and tear resistance, making it a solid choice for rotary seals exposed to particulate-laden media such as slurry, sand, or dust. Its high tensile strength and good rebound characteristics allow it to maintain shape under pressure, reducing the risk of extrusion.

That said, PU is vulnerable to hydrolysis—a chemical breakdown that occurs in hot, wet conditions. It also has a moderate chemical resistance profile, so it’s not suitable for systems that handle aggressive fuels or solvents.

Use case example:

A mining operation switched from NBR to PU seals in their slurry pumps and saw a significant reduction in downtime from abrasive wear.

Summary:

- Pros: Exceptional wear resistance, tough and flexible, great for dirty environments.

- Cons: Poor hydrolysis resistance, not ideal for high-temperature or chemical-rich applications.

3.3 Nitrile Rubber (NBR) and Hydrogenated NBR (HNBR)

NBR is perhaps the most common elastomer used in rotary sealing due to its affordability and oil resistance. It’s well-suited for general-purpose sealing in hydraulic and pneumatic systems. However, its temperature range is limited (usually up to 100°C), and it is susceptible to ozone and UV degradation.

HNBR is a more advanced version of NBR, created through hydrogenation. It offers improved thermal stability, chemical resistance, and mechanical strength, making it more suitable for demanding environments without a dramatic increase in cost.

Use case example:

In automotive power steering systems, HNBR seals are preferred over NBR due to their resistance to high-temperature oil and ozone exposure.

Summary:

- Pros (NBR): Cost-effective, flexible, good oil resistance.

- Pros (HNBR): Higher durability, better heat and chemical tolerance.

- Cons: Both degrade under ozone and sunlight unless specially formulated.

3.4 Fluoroelastomer (FKM/Viton)

FKM, commonly known by the trade name Viton, is a premium sealing material designed for extreme chemical and thermal environments. It handles temperatures up to 200°C, and resists aggressive fluids like automotive fuels, hydraulic oils, and corrosive chemicals.

However, FKM is expensive—often 2 to 4 times the cost of standard elastomers. It may also harden at low temperatures, reducing elasticity and sealing efficiency in cold environments.

Use case example:

An aerospace client replaced EPDM seals with FKM in fuel handling systems. Despite the cost, the switch eliminated chemical swelling issues and cut down maintenance by 60%.

Summary:

- Pros: Excellent chemical and thermal resistance, stable under aggressive conditions.

- Cons: High cost, potential rigidity at sub-zero temperatures.

3.5 High-Performance Thermoplastics (e.g., UHMWPE, PEEK, Vespel)

For the most demanding environments—think aerospace, medical, or chemical reactors—thermoplastics like UHMWPE, PEEK, and Vespel offer a combination of superior wear resistance, dimensional stability, and mechanical strength. These materials can operate in dry environments, vacuum systems, and high-pressure chemical applications.

While these options are not elastomers, they’re often used as the dynamic face in composite seal designs, paired with a softer backup material.

Use case example:

In semiconductor wafer processing, PEEK seals were selected to handle aggressive plasma and high vacuum with minimal outgassing and wear.

Summary:

- Pros: Excellent performance in extreme environments, low outgassing, very low wear rates.

- Cons: High material and processing cost, not suitable for elastic sealing by themselves.

IV. Common Issues Identified in Practice and SERP

4.1 Localized Heat and Wear

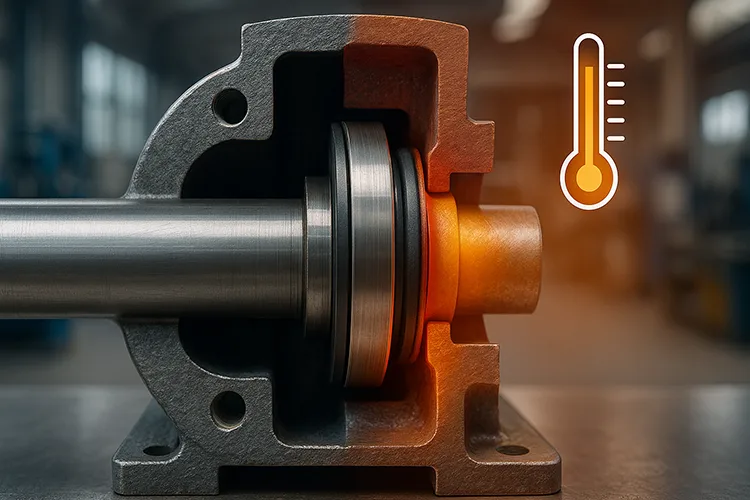

One of the most frequently encountered issues in rotary sealing is localized heating. This occurs when friction is concentrated at specific points on the sealing surface—typically due to shaft misalignment, poor lubrication, or surface irregularities. As temperature builds up, the material softens or degrades, accelerating wear.

In some applications I’ve reviewed, technicians noticed blistering or cracks forming around the seal lip, particularly in high-speed systems with insufficient cooling. This is a telltale sign of thermal fatigue.

Search insight:

Queries like “why does my seal keep burning out?” or “seal lip melting on shaft” point directly to this problem.

Key advice:

Use low-friction materials (PTFE, UHMWPE), and verify shaft alignment and lubrication before blaming the material itself.

4.2 Material Creep and Deformation

Creep is a silent failure mode. Over time, under continuous pressure and heat, certain materials like PTFE or soft elastomers gradually deform. This permanent shape change reduces sealing force, causing micro-leakage or even seal blow-out.

This problem is common in long-cycle or standby equipment, where the seal remains compressed for extended periods without movement. In one case, a client using unsupported PTFE seals in a gear pump experienced sudden leaks after two months—due to extrusion and loss of compression.

Search insight:

Phrases like “seal compression set issue” or “how to avoid PTFE seal deformation” suggest this is a common user pain point.

Key advice:

For high-load applications, always consider filled PTFE or use materials with low compression set like HNBR or FKM.

4.3 Shaft Surface Compatibility

A well-designed seal can still fail if paired with the wrong shaft finish or hardness. If the shaft is too rough, it acts like sandpaper; if too smooth, it might not retain the lubrication film. Poor surface compatibility causes uneven wear, seal cutting, or even dynamic leakage.

In one industrial mixer application I reviewed, seals failed repeatedly despite using high-quality materials. The root cause? A repaired shaft with inconsistent surface finish, causing accelerated lip wear and improper lubrication retention.

Search insight:

Common searches like “best shaft finish for rotary seal” or “seal wears out shaft too quickly” reveal this as a frequently misunderstood factor.

Key advice:

Follow surface roughness guidelines (Ra 0.2–0.8 μm) and ensure shaft hardness is matched to the seal material to minimize mutual wear.

4.4 Tribocorrosion and Galling

In environments where both mechanical wear and chemical corrosion are present, tribocorrosion can severely damage seals. This is especially risky in metal-to-metal interfaces, where galling (adhesive wear) can occur due to sliding contact under load.

I’ve seen this in stainless steel equipment used in marine settings—where saltwater and sliding motion led to a combination of wear and corrosion, drastically shortening the life of metal-reinforced seals.

Search insight:

Queries like “seal surface corrosion due to friction” or “galling in dynamic sealing applications” are indicators of this issue.

Key advice:

Use non-metallic or coated interfaces, and consider corrosion-resistant thermoplastics or ceramic coatings when operating in harsh chemical or salt-laden environments.

4.5 Chemical and Ozone Degradation

Materials like NBR or standard PU can degrade quickly when exposed to ozone, UV light, or chemical vapors. This degradation typically manifests as cracking, brittleness, or swelling. Even in indoor environments, certain cleaning agents or lubricants can initiate this damage.

In outdoor hydraulic units, I’ve seen NBR lip seals harden and crack in under three months due to ozone exposure from ambient air pollution.

Search insight:

Terms like “why does rubber seal crack outdoors?” or “elastomer seal swollen by oil” point to this recurring problem.

Key advice:

Choose ozone-resistant materials like EPDM or chemically stable compounds like FKM and avoid using NBR in exposed or chemical-rich environments without validation.

4.6 Mechanical Misalignment and Vibration

Finally, mechanical issues like shaft misalignment or excessive vibration can cause seal distortion, especially in rotary lip seals. This may result in irregular wear, seal rotation in housing, or complete failure due to dynamic instability.

A construction equipment client once reported that their shaft seals “spun inside the housing.” Investigation revealed significant misalignment under load, causing the seal to dislodge and rotate with the shaft.

Search insight:

Users often search for “seal spinning in bore” or “rotating shaft causing seal failure” when dealing with this hidden defect.

Key advice:

Always validate housing tolerances, include anti-rotation features, and assess vibration profiles when selecting or installing rotary seals.

V. Material Selection Criteria and Evaluation

5.1 Key Performance Metrics

To choose the right wear-resistant material for rotary seals, we need to move beyond brand familiarity and start evaluating quantifiable metrics. Here are the core factors I always consider when advising clients or developing a custom seal:

- Wear Resistance Index: Tests like ASTM D3702 (rotating friction and wear testing) or pin-on-disk methods simulate real dynamic wear. The lower the volume loss, the better the material.

- Hardness (Shore A or D): While harder materials usually last longer, they may compromise flexibility and sealing pressure. You need a balance—too soft, and you get creep; too hard, and you risk poor sealing contact.

- Coefficient of Friction: This affects how much heat is generated during operation. PTFE scores low (good), while rubber and PU may generate more heat unless modified.

- Compression Set: This tells you how well a material rebounds after being compressed. High compression set means the seal may lose shape and fail under static pressure.

- Chemical Resistance: Refer to chemical compatibility charts from reputable sources or use standardized test results (ASTM D471).

- Thermal Aging: Long-term resistance to heat is measured by weight loss, shrinkage, or changes in durometer after extended high-temp exposure (ASTM D573).

Summary:

A seal’s success depends on how well the material resists wear, heat, compression, and chemical attack—not just how it performs on day one.

5.2 Cost and Processability Considerations

Performance is key, but cost still matters—especially for large-volume applications or consumer-grade equipment. Here’s how I break down the cost-benefit balance:

- Material Cost: Thermoplastics like PEEK or filled PTFE are far more expensive than NBR or PU. FKM lies somewhere in the middle.

- Processing Cost: Materials that are difficult to mold, extrude, or machine will increase your tooling and manufacturing expenses. For instance, silicone rubbers are easy to process but not ideal for high-wear environments.

- Field Replaceability: A slightly more expensive material that extends service life can reduce labor costs, downtime, and inventory complexity.

One of my clients in the heavy machinery sector chose a higher-grade HNBR over NBR. The initial cost increased by 20%, but they recovered it in under three months due to reduced maintenance cycles.

Summary:

Don’t just look at per-unit price—evaluate total cost of ownership, including downtime, labor, and part longevity.

5.3 Dual-Material and Composite Options

Sometimes, no single material can do it all. That’s when composite seals come into play—pairing a hard, wear-resistant material with a softer, elastic backup.

- Hard-Soft Combinations: For instance, a PEEK or filled PTFE dynamic face bonded to an FKM or EPDM base provides both wear resistance and sealing flexibility.

- Nano-Fillers: Adding nanoclays, carbon nanotubes, or aramid fibers can significantly enhance mechanical strength and wear without compromising flexibility.

- Laminated Fabrics: In high-speed or abrasive environments, PTFE-laminated fabrics or aramid-reinforced elastomers can offer extended durability.

I recently supported a project in which Vespel was used as a contact face, backed by an HNBR body. This hybrid design successfully operated under both extreme heat and mechanical load in a gas turbine accessory.

Summary:

Explore multi-material architectures when a single material fails to meet all operational needs. These designs offer flexibility, durability, and tailored performance.

VI. Selection Strategies and Optimization

6.1 Application-Specific Recommendations

Choosing the right wear-resistant material isn’t about picking the most advanced option—it’s about matching material capabilities to your application’s actual conditions. That’s why I often use a material-environment matching matrix to guide decisions. Here are a few practical examples:

| Application Environment | Recommended Material | Reason |

|---|---|---|

| High-speed compressor (clean, dry gas) | Filled PTFE | Ultra-low friction, handles dry running well |

| Hydraulic cylinder (medium oil pressure, 80°C) | HNBR | Good oil and temperature resistance at moderate cost |

| Slurry pump (abrasive particles, medium pressure) | Polyurethane (PU) | Superior abrasion resistance, maintains seal under pressure |

| Food-grade rotating equipment | UHMWPE or PTFE (FDA-approved) | Inert, cleanable, low friction |

| Chemical reactor with mixed solvents | FKM or PEEK | High chemical and thermal resistance |

Tip: When in doubt, prioritize the dominant failure factor—whether it’s temperature, pressure, abrasion, or chemical exposure—and build your selection around that.

6.2 Testing and Validation

No matter how good a material looks on paper, real-world testing is the ultimate proof. That’s why I strongly advocate pre-deployment validation through controlled testing environments.

Recommended test types:

- Friction-Wear Test (ASTM D3702 or pin-on-disk): Simulates actual sliding conditions and wear rate.

- Thermal Aging Test (ASTM D573): Exposes materials to prolonged high temperature to assess degradation.

- Chemical Immersion Test (ASTM D471): Evaluates swelling, weight change, or hardness shift after exposure to fluids.

- Dynamic Bench Simulation: A real shaft-load-speed-temperature setup that mimics the operating system to track real seal performance over time.

In one project with a packaging machine OEM, lab testing revealed that their go-to NBR seal failed chemically in just 48 hours when exposed to a newly adopted cleaning fluid. A quick test saved them from a costly mass recall.

Summary:

Testing validates assumptions and provides data to avoid expensive errors. Never skip validation, especially for mission-critical applications.

6.3 Case Studies

Sometimes the best lessons come from real-world failures—and wins. Here are two that changed the way my clients approached material selection:

Case Study 1: Hydraulic System Failure with NBR

A construction equipment supplier used standard NBR seals in mobile hydraulic cylinders. After repeated complaints of leaks and downtime, we discovered that NBR was hardening due to fluid oxidation and ambient heat. Switching to HNBR not only solved the problem but also extended seal life by 3x, reducing maintenance callouts by over 50%.

Case Study 2: Slurry Pump Success with PU

A client in the ceramic industry constantly replaced rubber seals due to abrasive wear from fine clay particles. We trialed cast polyurethane seals, which resisted particle erosion far better. Over 6 months, seal replacement intervals jumped from 2 weeks to 3 months—saving time and cost.

These examples underscore a key truth:

“The best seal material is not the most expensive one—it’s the one proven to last in your conditions.”

VII. Conclusion

7.1 Key Takeaways

Selecting wear-resistant materials for rotating seals isn’t a guessing game—it’s a decision that requires technical awareness, application insight, and real-world validation. As I’ve illustrated throughout this guide, the right material can significantly extend seal life, reduce maintenance, and boost system reliability, while the wrong one can quietly sabotage your entire setup.

Here’s a recap of what truly matters:

- Wear resistance isn’t isolated—it interacts with pressure, temperature, chemical exposure, and shaft surface quality.

- Each material has strengths and limitations. PTFE excels in friction control, PU in abrasion, FKM in chemical and heat resistance, and HNBR in balanced performance.

- Environmental understanding and testing are key to matching materials with actual operating conditions.

- Cost should be evaluated across the product lifecycle, not just in per-unit pricing.

7.2 Long-Term Impact

I’ve seen firsthand how thoughtful material selection transforms operations. Better seals reduce unplanned downtime, lower total cost of ownership, and increase customer satisfaction. They also improve worker safety and environmental containment—critical in sectors like food processing, pharmaceuticals, and oil & gas.

And in an age where efficiency and reliability are competitive advantages, getting the seal material right isn’t just smart—it’s strategic.

“A good seal does its job quietly. A failed seal shouts in leaks, heat, and halted machines.”

7.3 Final Recommendations

Before finalizing any sealing solution:

- Always consult technical data sheets and compare chemical and thermal resistance charts.

- Engage with trusted seal manufacturers or material experts early in the design phase.

- Consider using test labs or simulation benches to validate performance before scaling.

- Refer to standards like ASTM D2000, ISO 3601, and DIN 3760 for compatibility and material classification.

At KINSOE, we’ve helped clients across industries—from automotive to chemical processing—optimize their sealing systems with the right material choices. If you’re facing recurring seal failures or planning a new product launch, feel free to reach out.