1. Introduction

Have you ever wondered what exactly sponge foam is made of? Whether you’re holding a kitchen sponge, walking on cushioned floor mats, or sealing a window with rubber gaskets, sponge foam is all around us—but few people know how it’s actually made.

I used to think sponge foam was just “puffed-up rubber.” But after years in the rubber manufacturing industry, I’ve come to realize it’s much more complex. Sponge foams are crafted from a variety of polymers, each selected based on performance needs like cushioning, insulation, chemical resistance, or thermal stability. From car seats to electrical insulators, the type of material used can dramatically change how sponge foam behaves.

In this article, I’ll break down everything I’ve learned about what sponge foam is made of—from the base materials like polyurethane and silicone to the additives and blowing agents that give it its cellular structure. I’ll also show you how to match the right material to your application, and what to watch out for in terms of safety and sustainability.

2. What is Sponge Foam?

Sponge foam is a lightweight, compressible material created by introducing gas bubbles into a polymer base, forming a cellular structure. It’s often confused with solid rubber or traditional plastic foam, but its unique spongy texture and resilience make it a distinct category of material used across countless industries.

At its core, sponge foam is engineered for cushioning, sealing, insulating, and absorbing shock or sound. What makes it special isn’t just the base material—it’s how that material is expanded into a foam through chemical or physical processes. The result? A flexible, often squishy material that returns to shape after compression.

There are two main categories:

- Open-cell foam: where cells are interconnected, allowing air or liquid to pass through

- Closed-cell foam: where cells are sealed, offering better insulation and moisture resistance

Sponge foam isn’t just soft—it’s smartly engineered for specific performance needs. You’ll find it in automotive gaskets, electronics housing, footwear padding, HVAC seals, and even food-grade environments depending on the material used.

Now that we’ve covered the basics, let’s explore the core materials that sponge foam is made of.

3. Main Materials Used in Sponge Foam

When it comes to sponge foam, the base polymer determines how it performs under pressure—literally. Different applications demand different properties like softness, durability, temperature resistance, or chemical stability. That’s why manufacturers use a range of materials to meet those needs. Below are the five most common sponge foam types I’ve encountered in my years working with industrial buyers and product developers.

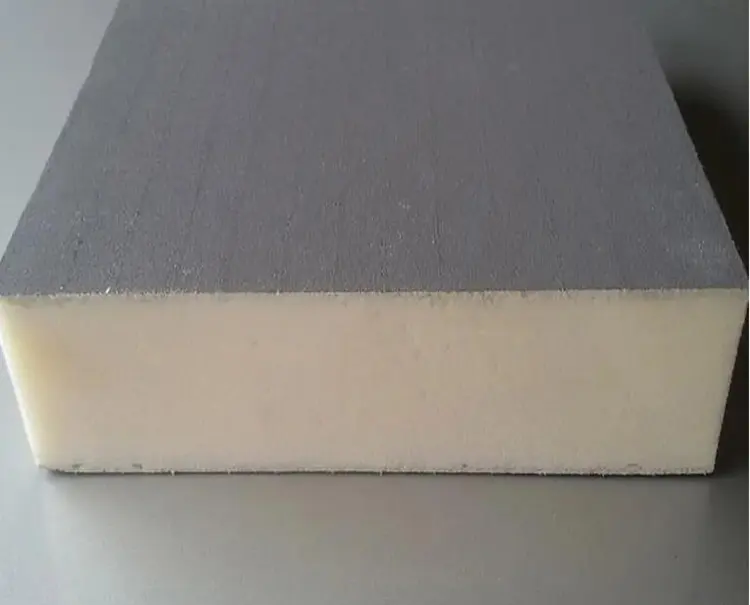

pu foam insulation board

3.1 Polyurethane (PU) Foam

Polyurethane is one of the most widely used sponge foam materials, and for good reason. It’s versatile, affordable, and can be tailored to either flexible or rigid forms.

- Properties: Lightweight, resilient, good energy absorption

- Uses: Furniture cushions, automotive interiors, packaging inserts, acoustic panels

- Pros: Low cost, customizable density, soft touch

- Cons: Limited UV and chemical resistance

“PU foam is ideal when comfort and flexibility matter more than chemical durability.”

3.2 Polyethylene (PE) Foam

PE foam is known for being denser and more rigid than PU. It has excellent water resistance and shock-absorbing properties.

- Properties: Closed-cell, water-resistant, chemically inert

- Uses: Sports padding, packaging, flotation devices, insulation

- Pros: Durable, moisture-proof, good thermal insulation

- Cons: Less flexible than PU, more expensive

If you need something that resists water, PE foam is a top contender.

EVA Foam

3.3 EVA Foam (Ethylene Vinyl Acetate)

EVA combines the flexibility of rubber with the toughness of plastic. It’s lightweight, durable, and can be foamed into both soft and firm densities.

- Properties: Soft, flexible, weather-resistant

- Uses: Yoga mats, shoe soles, knee pads, sporting goods

- Pros: UV resistance, shock absorption, vibrant coloring

- Cons: Can degrade under prolonged heat exposure

EVA strikes the perfect balance between comfort and ruggedness for lifestyle and consumer products.

Natural latex sponge

3.4 Natural Rubber and Latex Foam

Made from tree sap or synthetic latex, these foams are known for their bounce, comfort, and eco-friendly appeal.

- Properties: High elasticity, breathable, biodegradable

- Uses: Mattresses, cushions, ergonomic supports

- Pros: Natural origin, excellent rebound, hypoallergenic variants

- Cons: Can degrade over time, sensitive to oils

Latex foam is a popular choice for sustainable product lines.

![]()

Silicone spong tubing

3.5 Silicone Foam

Silicone sponge foam is the premium choice when it comes to heat resistance, chemical stability, and longevity.

- Properties: High-temperature resistance, inert, closed-cell or open-cell

- Uses: Aerospace seals, electronic gaskets, high-temp insulation

- Pros: Withstands extreme temperatures (-60°C to 230°C), non-toxic, long-lasting

- Cons: Higher cost, specialized processing

“When durability under harsh conditions is non-negotiable, silicone foam delivers unmatched performance.”

Each material comes with trade-offs, so choosing the right one depends entirely on the application. Next, I’ll dive into how additives and blowing agents influence the foam’s structure and performance.

4. Additives and Blowing Agents

While base materials like polyurethane or silicone define the foam’s core properties, it’s the additives and blowing agents that give sponge foam its signature softness, structure, and extra features. These ingredients control everything from flame resistance to how large or small the foam cells are. Let me break this down for you.

4.1 Chemical Additives for Performance

Sponge foam isn’t made of just one ingredient. Manufacturers often incorporate various performance-enhancing additives to tailor the foam for specific applications:

- Flame retardants: Improve fire resistance for automotive and aerospace uses

- Color pigments: Allow easy color-coding in industrial or consumer products

- UV stabilizers: Help prevent degradation from sunlight exposure

- Antimicrobial agents: Useful for medical or food-contact applications

- Plasticizers: Increase softness and flexibility in rigid foams

- Fillers: Lower cost and adjust density without affecting performance

“Additives fine-tune the material, turning basic foam into application-ready engineering.”

4.2 Blowing Agents and Cell Structure Formation

Blowing agents are what make foam… foam. They’re substances—either chemical or physical—that create gas bubbles during the manufacturing process, forming the sponge-like texture.

There are two major types:

- Physical blowing agents: Include gases like nitrogen or carbon dioxide injected into the material

- Chemical blowing agents: React chemically to release gas during the curing or heating process

Depending on how these agents are used, the foam can form:

- Open-cell structures: Soft, breathable, and compressible

- Closed-cell structures: Dense, waterproof, and more rigid

Control over blowing agents equals control over how the foam feels and functions.

In short, the secret sauce in sponge foam manufacturing lies in these additives and agents. They determine not just how the foam looks, but how it performs in real-world use. Up next, let’s talk about one of the most important distinctions in sponge foam: the difference between open-cell and closed-cell structures.

5. Differences Between Open-Cell and Closed-Cell Foams

One of the most crucial decisions when selecting sponge foam is whether you need open-cell or closed-cell structure. While the base material sets the foundation, the cell structure defines how the foam behaves in real-world applications.

Open-Cell Foam

Open-cell foam features interconnected air pockets, which allow air, water, and sound to pass through easily.

- Texture: Soft, compressible, breathable

- Applications: Acoustic insulation, soundproofing, cushions, sponges

- Advantages: Lightweight, sound-absorbing, excellent flexibility

- Disadvantages: Poor water and vapor resistance

“Think of open-cell foam like a sponge—it breathes, absorbs, and cushions with ease.”

It’s often used in environments where ventilation, sound absorption, or softness is more important than water resistance.

Closed-Cell Foam

Closed-cell foam, on the other hand, has sealed gas pockets, making it denser and more resistant to external factors.

- Texture: Firm, resilient, waterproof

- Applications: Sealing gaskets, thermal insulation, flotation devices

- Advantages: Water-resistant, strong structure, better thermal insulation

- Disadvantages: Less breathable, heavier, higher cost

“Closed-cell foam is your go-to for moisture resistance and structural integrity.”

It’s ideal for outdoor, industrial, or harsh environments where exposure to water, temperature swings, or mechanical stress is expected.

Choosing between open-cell and closed-cell foam isn’t just about softness—it’s about what the material needs to do. The right structure can dramatically affect product performance, durability, and user experience.

Next, I’ll explore how each foam material aligns with different real-world applications—so you can see which fits your needs best.

6. Environmental and Safety Considerations

In today’s global market, buyers and manufacturers can’t afford to ignore environmental and safety issues—especially when sponge foam is used in sensitive applications like medical equipment, children’s products, or food processing. Over the years, I’ve seen how these factors can make or break a procurement decision, especially for companies prioritizing compliance and sustainability.

6.1 Non-Toxicity and Certifications

Not all sponge foams are created equal when it comes to health and safety. The chemical composition—including residual monomers, plasticizers, or flame retardants—can influence toxicity levels.

To ensure safety, look for materials that meet international standards:

- RoHS (Restriction of Hazardous Substances): Common in electronics and automotive parts

- REACH compliance: EU regulation that restricts hazardous substances

- FDA-grade foams: Required for food-contact and medical applications

- UL 94 certification: Verifies flame retardancy in foams for electronics or appliances

“Ask your supplier for certification documents. It’s not just about specs—it’s about responsibility.”

Silicone foam, for example, is often preferred in medical and food industries due to its non-toxic and hypoallergenic properties.

6.2 Recyclability and Sustainability

Foam production can be energy-intensive, and not all materials are easy to recycle. That said, there are increasingly eco-conscious options on the market:

- Natural latex foam: Biodegradable and derived from renewable resources

- Recyclable PE and PU foams: Often reusable in packaging or insulation

- Low-VOC (Volatile Organic Compound) formulations: Reduce air pollution during use and disposal

More manufacturers are now shifting toward green blowing agents and solvent-free formulations to meet stricter environmental regulations.

Choosing sponge foam isn’t just a technical decision—it’s an ethical one too.

With certifications and environmental standards becoming critical to global supply chains, understanding these considerations helps you source smarter and build trust with end users. Up next, I’ll show you how to make the right material choice based on your specific application needs.

7. How to Choose the Right Sponge Foam Material

If you’re a product designer or sourcing manager, choosing the right sponge foam isn’t just about picking what’s available—it’s about matching material performance to application demands. After working with dozens of industries, I’ve developed a straightforward way to guide material selection using three key filters: function, environment, and compliance.

Step 1: Define the Function

What should the foam do?

- Cushioning or softness needed? → Go for PU or latex foam

- Structural support with impact resistance? → Consider EVA or PE foam

- Sealing or gasketing in high temperatures? → Choose silicone foam

Always start by identifying what you need the foam to achieve physically.

Step 2: Assess the Environment

Where will the foam be used?

- Wet or humid conditions? → Use closed-cell PE or silicone foam

- Outdoor or UV exposure? → Look for EVA or UV-stabilized PU

- Contact with chemicals or oils? → Silicone or chemical-resistant PE is ideal

Environmental stressors are often what cause foam failure—so don’t overlook them.

Step 3: Check Compliance Needs

Any industry-specific standards?

- Medical or food applications? → FDA-grade silicone or latex foam

- Electronics or appliances? → UL 94 certified flame-retardant PU or silicone

- EU/Global markets? → Look for REACH and RoHS compliance

“Certifications aren’t just about ticking boxes—they ensure long-term compatibility and trust.”

Quick Comparison Table

| Requirement | Best Material |

|---|---|

| Soft cushioning | PU Foam, Latex Foam |

| Water resistance | PE Foam, Silicone Foam |

| Heat resistance | Silicone Foam |

| Eco-friendly options | Natural Latex, EVA |

| High-impact durability | EVA Foam, PE Foam |

| Regulatory compliance | FDA Silicone, RoHS PU |

Matching the right foam with the right application isn’t guesswork—it’s strategy. The right material can extend product life, reduce warranty claims, and improve end-user satisfaction.

Now, let’s wrap it all up with a clear summary and final takeaways.

8. Conclusion

Sponge foam may look simple on the surface, but behind its soft texture lies a world of engineered complexity. From polyurethane and EVA to silicone and natural rubber, each material is selected for a reason—whether it’s for comfort, durability, water resistance, or compliance with strict industry standards.

Throughout my years working with clients across automotive, consumer goods, and industrial manufacturing, I’ve seen how a well-informed foam choice can mean the difference between product success and failure. A material that performs well in a shoe sole might completely fall short in a high-temperature sealing application. That’s why understanding the composition, structure, and regulatory impact of sponge foam is more than useful—it’s essential.

To recap, here’s what you should remember:

- PU foam offers softness and affordability for general-purpose use.

- PE foam delivers durability and moisture resistance.

- EVA foam excels in flexible, impact-heavy environments.

- Latex foam provides natural cushioning and eco-friendliness.

- Silicone foam stands unmatched for extreme conditions and safety-critical uses.

- Additives and blowing agents are key to tuning performance and structure.

- Open-cell vs. closed-cell structure changes everything about how foam behaves.

- Certifications matter when entering regulated or international markets.

My advice? Always start with your application’s demands—then choose the material that aligns technically and ethically.

If you are looking for more expert guidance on materials or need help finding the right foam or rubber component, please contact us directly. Together, we can make smarter, safer material choices.

Reference: