I. Introduction

Have you ever wondered what keeps critical industrial systems running smoothly behind the scenes? From transferring hazardous chemicals to powering pneumatic tools and handling food-grade liquids, industrial hoses are the unsung heroes of modern manufacturing. I’ve seen countless cases where the right hose prevented catastrophic failures—and unfortunately, cases where poor selection led to costly downtime or safety hazards.

Industrial hoses play a vital role in fluid transfer, air delivery, chemical handling, and more. They are the flexible connectors that maintain flow and pressure across a wide range of applications. But choosing the wrong type can compromise safety, reduce efficiency, and inflate maintenance costs.

This guide is designed for procurement professionals, engineers, and maintenance managers who need a clear understanding of hose types and their applications. Whether you’re sourcing hoses for automotive, food processing, or chemical plants, I’ll walk you through every key factor—from material selection to best practices for management.

Here’s what you’ll gain: a deep dive into industrial hose categories, application examples, common pitfalls, and decision-making tools to help you choose the best solution for your specific needs.

II. Overview of Industrial Hose Categories

1. Definition of Industrial Hose

Industrial hoses are designed to handle demanding environments far beyond the capabilities of their domestic counterparts. They differ in pressure tolerance, size range, and material diversity, enabling them to transport liquids, gases, and even solid materials under extreme conditions. Unlike garden hoses or household tubing, industrial hoses must withstand factors like high pressure, vacuum, chemical exposure, and abrasive media—all while maintaining flexibility and durability.

At KINSOE, we’ve developed hoses for everything from food-grade silicone tubing used in beverage processing to reinforced EPDM hoses that handle hot water in automotive applications. This breadth reflects the diverse requirements across industries.

2. Classification by Material

a. Rubber Hoses

Rubber hoses are renowned for flexibility and excellent temperature resistance. Common materials include:

- EPDM: Outstanding heat and weather resistance, ideal for hot water and steam.

- NBR (Nitrile): Superior oil and fuel resistance, widely used in automotive and industrial oil transfer.

- SBR (Styrene-Butadiene Rubber): Cost-effective for air and water delivery with moderate resistance to abrasion.

b. PVC Hoses

PVC hoses are lightweight, economical, and offer good chemical resistance, making them ideal for non-critical applications. However, they are limited by lower temperature and pressure ratings and are more prone to kinking in cold environments.

c. Metal Hoses

Constructed from stainless steel or other alloys, metal hoses excel in extreme temperature and high-pressure applications. Their superior durability makes them suitable for chemical plants and high-heat environments, though they lack the flexibility of rubber and composite alternatives.

d. Composite Hoses

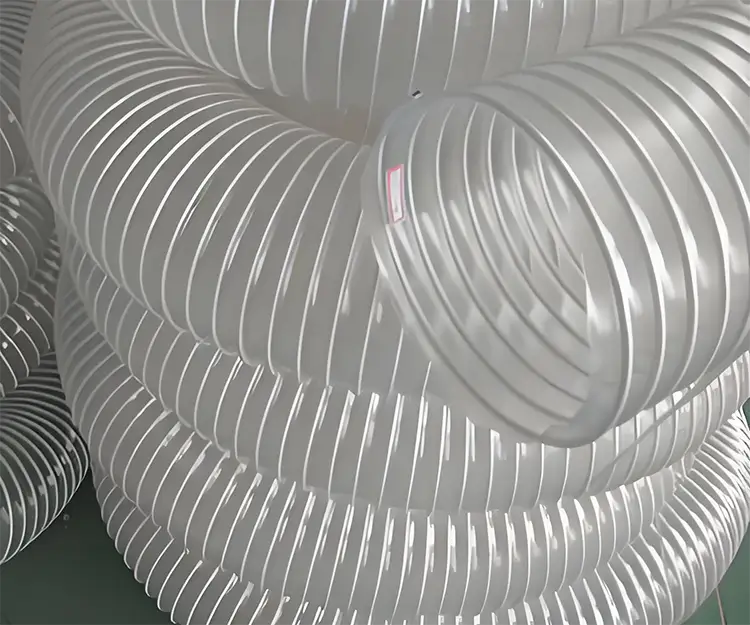

Composite hoses feature multi-layer construction with inner and outer layers of different materials, reinforced with wire helixes. They are the preferred choice for handling aggressive chemicals and hydrocarbons in industries like petroleum refining.

e. Silicone and Specialty Polymer Hoses

Silicone hoses provide high heat resistance and flexibility, making them ideal for food-grade and pharmaceutical applications. Specialty polymers like PTFE offer outstanding chemical resistance for highly corrosive environments.

3. Classification by Function

a. Air and Pneumatic Hoses

Used in compressed air systems and pneumatic tools, these hoses require excellent flexibility and kink resistance.

b. Chemical Transfer Hoses

Engineered to safely handle acids, solvents, and hazardous fluids, often with reinforced layers to prevent leaks.

c. Water and Steam Hoses

Capable of enduring high temperatures and pressures for steam cleaning and hot water delivery.

d. Food and Beverage Hoses

FDA-compliant and sanitary, these hoses are critical for transporting consumables without contamination.

e. Oil and Fuel Hoses

Specialized for refueling systems and industrial oil transfer, with materials like nitrile rubber for oil resistance.

f. Material Handling Hoses

Designed for bulk transfer of abrasive powders, grains, and pellets, requiring abrasion-resistant linings.

g. Exhaust and Ventilation Hoses

Flexible ducting solutions to handle fumes, smoke, and ventilation in confined spaces.

III. Key Factors in Selecting Industrial Hoses

Choosing the right industrial hose isn’t just about matching size and color—it’s about ensuring performance, safety, and longevity in demanding environments. Over the years, I’ve seen how overlooking just one factor—like chemical compatibility—can lead to costly system failures.

Here’s what I always recommend considering:

1. Operating Conditions

- Temperature Range: Select a hose material that can tolerate the minimum and maximum temperatures of your application without cracking or softening. For example, silicone hoses excel at high temperatures, while PVC struggles in freezing conditions.

- Pressure Ratings: Always verify the hose’s working and burst pressure. Using a hose beyond its rated pressure is a leading cause of unexpected failure.

- Media Compatibility: Consult chemical resistance charts to ensure the hose material won’t degrade or react with the substances it carries. EPDM, for instance, resists steam but not petroleum-based products.

2. Mechanical Requirements

- Flexibility and Bend Radius: A hose with poor flexibility might kink or collapse, leading to restricted flow or damage. Check the manufacturer’s recommended minimum bend radius.

- Abrasion and Wear Resistance: Applications like material handling demand hoses with reinforced abrasion-resistant linings.

- Vacuum Resistance: For suction applications, ensure the hose is reinforced to handle vacuum pressure without collapsing.

3. Environmental Considerations

- UV, Ozone, and Weather Exposure: Outdoor applications require hoses with UV and ozone resistance (EPDM and certain silicones perform well here).

- Indoor vs. Outdoor Use: Consider additional protection like hose covers or shielding if exposed to harsh environmental factors.

4. Standards and Certifications

For critical industries, compliance is non-negotiable. Look for hoses certified to:

- FDA (Food and Beverage)

- ISO (General Industrial Standards)

- SAE (Automotive)

- EN (European Norms for industrial hoses)

Pro Tip: Always consult with your supplier for the most current certification status to avoid surprises during audits or inspections.

IV. Common Problems in Industrial Hose Applications

Even the best industrial hose can fail prematurely if misapplied or poorly maintained. Over time, I’ve seen how small oversights—like ignoring bend radius or using the wrong fitting—can escalate into major system failures. Understanding common issues and their solutions is key to preventing downtime and accidents.

1. Hose Failure Causes

a. Chemical Incompatibility

When a hose material is incompatible with the media it carries, swelling, cracking, or softening can occur. For example, using EPDM with petroleum products often results in rapid degradation.

b. Excessive Pressure

Exceeding the hose’s rated pressure can lead to bursting or rupture, posing serious safety hazards. It’s crucial to account for pressure spikes during operation, not just average working pressure.

c. Abrasion and External Damage

Hoses exposed to rough surfaces, sharp edges, or high traffic areas can suffer from external wear. Over time, this can weaken the hose wall and lead to leaks or blowouts.

d. Improper Installation and Bend Radius Violations

Kinking, twisting, or bending hoses beyond their recommended radius can cause internal damage and restricted flow. Poor installation practices are a major contributor to early hose failure.

2. Preventive Measures

- Regular Inspection and Maintenance

Set up a proactive schedule to check for signs of wear, bulges, cracks, or leaks. - Proper Storage and Handling

Store hoses in a cool, dry place away from direct sunlight and chemicals. Avoid hanging hoses on small-diameter hooks that could cause deformation. - Training for Installation Best Practices

Ensure all personnel understand correct fitting techniques, bend radius requirements, and how to avoid over-tightening connections.

“Most industrial hose failures aren’t due to manufacturing defects—they’re the result of improper use and maintenance.”

V. Case Studies and Application Examples

Seeing real-world applications is one of the best ways to understand how different industrial hoses perform under demanding conditions. Here are three cases where careful hose selection made all the difference.

1. Automotive Manufacturing: Air and Fuel Hose Systems

In an automotive plant, compressed air systems and fuel transfer lines are critical for assembly line operations. Initially, the plant used standard rubber hoses for air tools, which suffered frequent cracks due to heat from nearby welding stations.

Solution: The team switched to high-temperature resistant EPDM air hoses with reinforced braiding. This eliminated downtime caused by air leaks and improved tool efficiency, saving an estimated $50,000 annually in maintenance costs.

2. Food Processing: Food-Grade Hose Selection

A food processing company faced challenges maintaining hygiene standards because their PVC hoses were prone to microbial growth and cracking under steam cleaning.

Solution: They adopted platinum-cured silicone hoses, which are FDA-compliant and resistant to high-temperature sanitization. This change not only improved product safety but also reduced hose replacement frequency by 30%.

3. Chemical Plants: Composite Hoses for Hazardous Fluids

A chemical plant handling aggressive solvents and acids experienced hose failures due to chemical attack on the inner lining of their existing rubber hoses.

Solution: Engineers switched to composite hoses with multiple chemical-resistant layers and a wire helix for structural strength. This upgrade improved safety by preventing leaks and met stringent environmental compliance standards.

Key Insight: These examples show how matching a hose’s material and design to its environment can extend service life and avoid costly mistakes.

VI. Comparative Analysis of Hose Types

With so many industrial hose options available, it can feel overwhelming to choose the right one. That’s why I always recommend breaking it down into a side-by-side comparison. This helps you quickly assess which hose best fits your specific requirements.

1. Tabular Comparison: Materials vs. Applications

| Hose Type | Durability | Flexibility | Temperature Range | Chemical Resistance | Cost | Typical Applications |

|---|---|---|---|---|---|---|

| Rubber (EPDM, NBR) | High | Excellent | -40°C to +150°C | Moderate (media-specific) | $$ | Air, water, steam, oil, fuel transfer |

| PVC | Moderate | Good | -10°C to +60°C | Moderate | $ | Light-duty air, water, food-grade transfer |

| Metal (Stainless) | Very High | Low | -200°C to +600°C | Excellent | $$$$ | High-temp, high-pressure, chemical transfer |

| Composite | High | Moderate | -40°C to +180°C | Excellent | $$$ | Aggressive chemicals, petroleum products |

| Silicone | Moderate | Excellent | -60°C to +230°C | Good | $$$ | Food & beverage, pharmaceutical, HVAC |

Bold key point:

This table highlights how no single hose fits every application—you need to balance cost, performance, and compliance with industry standards.

2. Decision-Making Framework

Here’s a simple checklist to guide your selection:

- What media will the hose carry? (Check chemical compatibility charts)

- What temperature range is required? (Consider peaks, not just averages)

- Will it face high pressures or vacuum? (Match working/burst pressure ratings)

- Indoor or outdoor use? (Think UV, ozone, and weather resistance)

- Are there industry certifications needed? (FDA, SAE, ISO, EN compliance)

- How important are flexibility and weight? (Critical for handheld or mobile systems)

Pro Tip: When in doubt, consult your supplier for application-specific recommendations. At KINSOE, we help clients evaluate these factors with real-world performance data.

VII. Best Practices for Industrial Hose Management

Once the right industrial hose is installed, proper management is crucial to maximize its lifespan and ensure consistent performance. I’ve seen how simple practices can double a hose’s service life—and how neglect can lead to sudden failures. Here’s how you can stay ahead.

1. Installation Tips

- Correct Fitting Selection: Always use fittings compatible with the hose material and pressure rating to avoid leaks or pull-outs.

- Avoid Twisting and Over-Tightening: Improper torque can damage hose ends or cause cracks at connection points.

- Respect Bend Radius: Install hoses with gentle curves instead of sharp bends to prevent kinking and internal damage.

Quote Box:

“A well-installed hose is half the battle won in preventing premature failure.”

2. Maintenance and Inspection

- Regular Checks: Inspect hoses for cracks, bulges, leaks, or signs of wear at least monthly—more often in critical systems.

- Cleaning Procedures: For food-grade and chemical hoses, follow recommended cleaning protocols to avoid material degradation.

- Replacement Indicators: Watch for stiffening, discoloration, or changes in flexibility, which signal aging hoses.

3. Lifespan Optimization

- Storage Guidelines: Store hoses in a cool, dry, and UV-protected area, coiled loosely on large-diameter reels to prevent kinks.

- Preventive Replacements: Don’t wait for failure—schedule replacements based on manufacturer recommendations and usage intensity.

By integrating these best practices, companies can reduce unplanned downtime, minimize safety risks, and extend hose life—saving both time and money.

VIII. Conclusion

Selecting and managing industrial hoses isn’t just a technical task—it’s a strategic decision that impacts your entire operation. From automotive plants to chemical processing facilities, the right hose ensures safety, efficiency, and cost control.

In this guide, I’ve walked you through:

- The diverse types of industrial hoses and their unique applications.

- Key factors to consider when selecting a hose for your system.

- Common issues and preventative measures to avoid costly failures.

- Real-world case studies showing how proper hose selection can transform operations.

- Best practices to extend hose lifespan and maintain peak performance.

Remember: Every application is unique. Temperature, pressure, chemical compatibility, and environmental exposure all play a role in determining the best solution.

If you’re unsure which hose suits your needs, I encourage you to consult with an experienced supplier. At KINSOE, we specialize in custom rubber hoses and tubing solutions for industries ranging from automotive to food processing. Our team can help you navigate complex requirements and ensure you get the right hose for your specific application.