I. Introduction

When I first visited a heating plant years ago, I noticed an alarming amount of condensation dripping from uninsulated pipes. The energy waste was staggering. This isn’t uncommon—many facilities unknowingly lose heat and face moisture-related issues simply because they selected the wrong insulation material. The outer sponge insulation layer on a heating pipe isn’t just a cosmetic covering. It’s the first line of defense against heat loss, surface burns, condensation, and even environmental damage.

At Kinsoe, I’ve worked with clients across HVAC, industrial steam systems, and district heating who struggled with insulation failures before switching to the right material. This experience showed me that choosing the right sponge insulation material can dramatically improve energy efficiency, extend system lifespan, and reduce maintenance costs.

In this guide, I’ll break down the different types of sponge insulation materials, their strengths and weaknesses, and the critical factors you need to consider. Whether you’re an industrial buyer, HVAC engineer, or maintenance manager, you’ll gain a clear roadmap for selecting the best option for your application.

Here’s what you can expect: a deep dive into material types like NBR/PVC foam, EPDM foam, silicone sponge, and PE foam, plus a practical comparison table, expert tips, and common pitfalls to avoid.

II. What Is a Sponge Insulation Layer?

1. Definition and Purpose

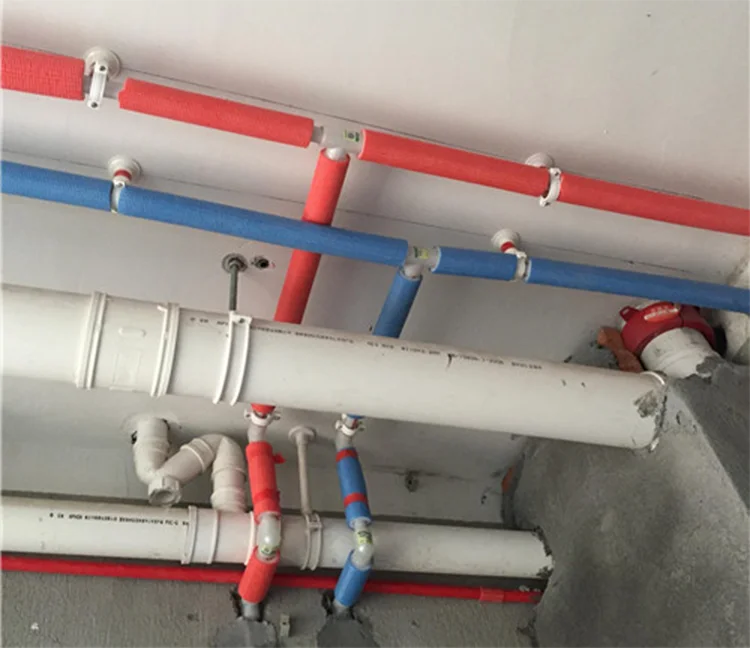

The sponge insulation layer is a flexible, closed-cell material that wraps around heating pipes to serve as a thermal barrier. Its primary role is to reduce heat loss, helping maintain the desired temperature within the pipes while improving overall energy efficiency. Beyond that, it also lowers the external surface temperature of pipes, minimizing the risk of burns for anyone working nearby.

But its benefits don’t stop there. A well-chosen sponge insulation layer protects pipes from environmental damage such as moisture ingress, UV exposure, and even mechanical impacts. This added layer of protection is especially crucial for systems exposed to outdoor conditions or harsh industrial environments.

At Kinsoe, I’ve seen how a robust insulation layer prevents long-term issues like corrosion under insulation (CUI) and contributes to smoother, uninterrupted operations in both industrial and residential systems.

2. Common Applications

Sponge insulation layers are widely used across industries. Here are some of the most common applications I’ve worked on:

- District Heating Systems: To maintain thermal efficiency over long pipe networks.

- Industrial Steam Pipelines: Protecting high-temperature steam lines from rapid heat loss and surface condensation.

- Hot Water Supply Lines: Ensuring consistent delivery temperatures in commercial and residential setups.

- HVAC Systems: Insulating chilled and hot water pipes to avoid energy waste and condensation-related damage.

These applications illustrate how versatile and essential sponge insulation is in modern heating systems. Choosing the right material for each of these use cases, however, requires a deeper understanding of their unique characteristics.

IV. Key Factors to Consider When Choosing Insulation Material

1. Temperature Resistance

The first question I always ask clients is: What’s the maximum and minimum temperature your pipes will face? Insulation failure often occurs when materials are pushed beyond their thermal limits. For example, using PE foam on a steam pipe operating at 120°C will almost certainly lead to softening and collapse. Always match the insulation’s temperature range to the system’s operating conditions.

2. Environmental Conditions

Will your pipes be indoors or exposed to harsh outdoor environments? Outdoor installations require materials with excellent UV and ozone resistance, like EPDM or silicone sponge. Without this, insulation can crack, harden, and fail prematurely. For indoor use in controlled environments, NBR/PVC foam often suffices.

3. Fire Resistance

Safety regulations increasingly demand flame-retardant materials. Check for compliance with standards like UL 94 or ASTM E84. Closed-cell silicone sponge, for example, provides superior flame resistance and low smoke emission, making it ideal for sensitive or regulated facilities.

4. Moisture and Vapor Resistance

Condensation inside insulation is a silent destroyer, leading to corrosion under insulation (CUI). Materials with a closed-cell structure—such as NBR/PVC and EPDM—are excellent at resisting moisture ingress. I recommend adding a vapor barrier for systems prone to temperature fluctuations.

5. Durability and Lifespan

In high-traffic or industrial areas, mechanical damage is a real threat. Silicone sponge and EPDM excel here due to their superior toughness and aging resistance. These materials maintain their integrity for years, reducing maintenance costs.

6. Budget Considerations

While PE foam may seem attractive for its low cost, it’s often a false economy for high-performance systems. Investing in higher-grade materials like EPDM or silicone may have a higher upfront cost but yields long-term energy savings and reduced replacement frequency.

Kinsoe Tip: Don’t just consider material cost. Factor in installation, energy efficiency, and replacement cycles to calculate the real total cost of ownership.

V. Material Comparison Table

To help you quickly evaluate the options, here’s a side-by-side comparison of the most common sponge insulation materials:

| Feature | NBR/PVC Foam | EPDM Foam | Silicone Sponge | PE Foam |

|---|---|---|---|---|

| Max Temperature | ~105°C | ~150°C | ~230°C | ~90°C |

| UV Resistance | Low | Excellent | Excellent | Poor |

| Flexibility (Low Temp) | Good | Moderate | Excellent | Good |

| Moisture Resistance | Excellent | Excellent | Excellent | Moderate |

| Fire Resistance | Moderate | Good | Excellent | Poor |

| Cost | $$ | $$$ | $$$$ | $ |

| Typical Applications | HVAC | Solar, Outdoor | Extreme Environments | Residential |

This table highlights the trade-offs between cost and performance. For most indoor HVAC systems, NBR/PVC foam is often sufficient. For outdoor or high-temperature applications, EPDM and silicone sponge clearly stand out. And while PE foam has its place in low-cost residential settings, it shouldn’t be your choice for industrial-grade systems.

Kinsoe Recommendation: When in doubt, prioritize durability and temperature range. The extra investment upfront often pays for itself in fewer failures and lower energy bills.

VI. Installation and Maintenance Tips

Selecting the right material is only half the battle. Proper installation and regular maintenance are equally critical to ensure your insulation performs as intended.

1. Choose the Right Form

Sponge insulation typically comes in pre-slit tubular sleeves or rolls for on-site wrapping. For straight runs and uniform diameters, pre-slit sleeves save time and labor. For irregular shapes or retrofits, rolls offer greater flexibility.

2. Add Protective Jackets for Outdoor Use

If you’re using NBR/PVC foam outdoors, always install an outer protective jacket made of aluminum, PVC, or UV-resistant coatings. This extra layer shields against sunlight, rain, and mechanical wear, extending the insulation’s lifespan.

3. Regular Inspections Are a Must

Even the best materials degrade over time. I recommend periodic inspections to check for:

- Cracks or splits in the insulation.

- Signs of moisture ingress or condensation.

- Areas where protective jackets may have loosened.

Addressing these issues early prevents bigger problems like corrosion under insulation (CUI) or thermal inefficiency.

Kinsoe Tip: Train your maintenance team to recognize early warning signs and establish a schedule for insulation audits—especially in high-temperature and outdoor systems.

VII. Common Mistakes to Avoid

Over the years at Kinsoe, I’ve seen too many projects compromised by simple oversights in insulation selection. Here are the most frequent mistakes I warn my clients about:

1. Using Low-Cost PE Foam on High-Temperature Pipes

PE foam’s attractive price tag can be tempting, but placing it on pipes exceeding its 90°C limit leads to rapid degradation and energy loss. Always check the maximum service temperature of your chosen material.

2. Skipping UV Protection for Outdoor Installations

NBR/PVC foam may perform well indoors, but without a UV-resistant outer jacket, it will crack and crumble under sunlight exposure. For outdoor systems, either use EPDM or silicone sponge, or add a protective layer.

3. Ignoring Local Fire Codes

Some projects fail inspections simply because their insulation material didn’t meet required flame retardancy standards. Be sure to verify compliance with UL 94, ASTM E84, or your region’s equivalent codes.

4. Overlooking Vapor Barriers in Humid Environments

In systems where condensation is likely, omitting a vapor barrier leads to moisture ingress and hidden corrosion. Closed-cell insulation helps, but in extreme cases, an additional vapor barrier is essential.

Kinsoe Reminder: Cutting corners on material choice or installation often leads to higher costs in repairs and energy bills. It’s not worth the risk.

VIII. Kinsoe Recommendations

At Kinsoe, we’ve helped countless customers navigate the maze of insulation materials to find the ideal fit for their systems. Based on our experience, here are my tailored suggestions:

HVAC Pipes (Indoor)

For most commercial and residential HVAC systems, NBR/PVC foam strikes a good balance between cost and performance. Its flexibility and ease of installation make it a go-to choice—just remember to add a protective jacket if any sections are exposed to sunlight.

Industrial Heating Systems (Outdoor)

For outdoor pipelines, especially in solar heating or district heating networks, EPDM foam offers superior UV and weather resistance. It handles higher temperatures and lasts longer in demanding environments.

Food-Grade and Cleanroom Applications

When hygiene and extreme temperature resistance are critical, I recommend silicone sponge. Its non-toxic properties and wide service range (-60°C to +230°C) make it perfect for pharmaceutical, food processing, and high-performance industrial systems.

Kinsoe Advice: If your system involves extreme temperatures or strict regulatory standards, don’t hesitate to invest in premium materials like silicone sponge. The long-term reliability and reduced maintenance justify the higher initial cost.

Silicone sponge tubing

IX. Conclusion

Choosing the right sponge insulation material for heating pipes isn’t just a technical decision—it’s an investment in your system’s efficiency, safety, and longevity. From NBR/PVC foam for standard HVAC setups to silicone sponge for extreme environments, each material has its place. The key is aligning your choice with your system’s temperature range, environmental exposure, and compliance requirements.

At Kinsoe, I’ve seen firsthand how the right material prevents energy loss, reduces maintenance headaches, and ensures peace of mind for years to come.

Don’t leave your insulation to chance. Contact Kinsoe today for expert advice and high-quality sponge insulation solutions tailored to your needs.