Introduction

Sponge rollers may seem like minor components, but they’re essential for accurate and reliable label application. In many labeling machines, consistent label adhesion depends less on automation speed and more on the quality of contact during application. That’s where sponge rollers come in.

In this quick guide—alongside a short video demonstration—I’ll walk you through how sponge rollers function inside automatic labeling systems and why factors like material and compression force can make or break labeling performance.

What Is a Sponge Roller?

A sponge roller is a cylindrical, soft-compression roller designed to press adhesive labels firmly onto product surfaces. It’s also referred to as a rubber sponge roller, label applicator roller, or sponge pressure roller. These rollers are typically made from:

- Natural rubber sponge – for general-use applications

- Polyurethane (PU) foam – for better wear resistance and rebound

- Silicone sponge – for high-temperature or sensitive surface applications

The roller’s job is to conform to varying product shapes while applying enough pressure to activate the adhesive and eliminate bubbles or misalignment.

How It Works in Labeling Machines

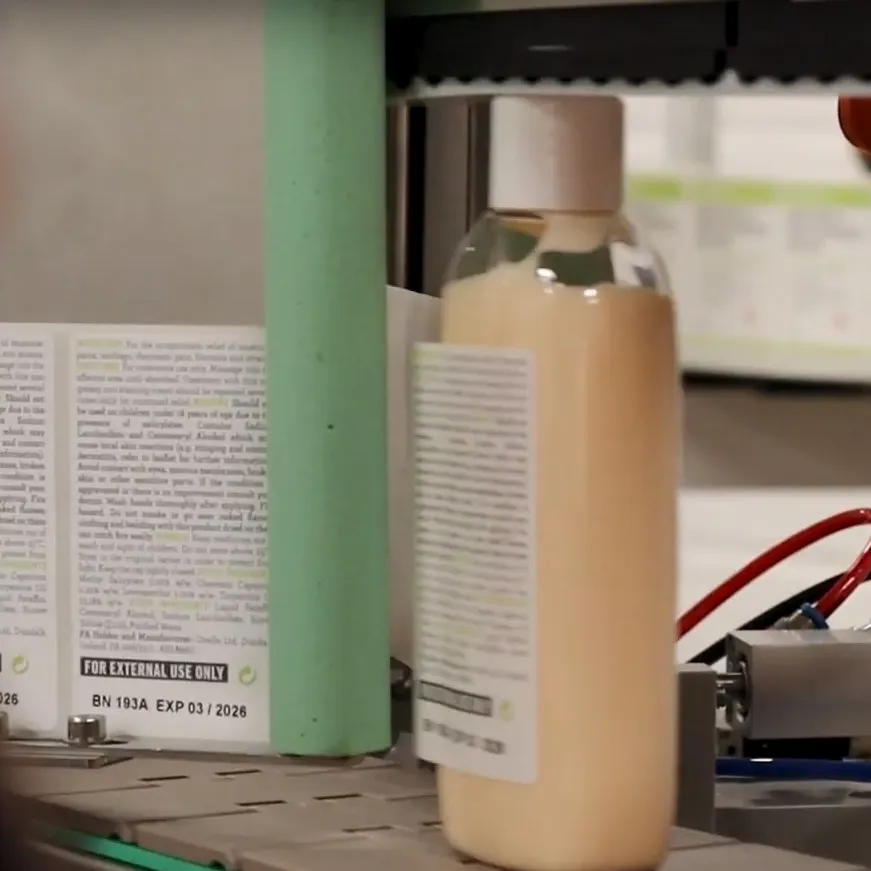

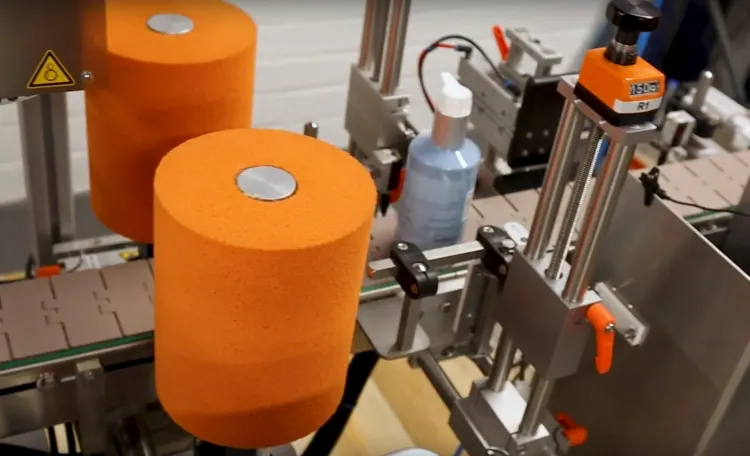

Inside an automatic labeling machine, the sponge roller rotates in sync with the conveyor or product movement. As the label is dispensed from the applicator head, the roller presses the label onto the product’s surface.

This pressure must be light yet firm—enough to bond the adhesive evenly across curved or flat surfaces without damaging the product or distorting the label. The roller compresses slightly upon contact, helping it conform to surface contours while pushing out air to prevent bubbling or wrinkling.

Key Functions and Benefits

Sponge rollers play several vital roles in ensuring high-speed, consistent label application:

- Applies uniform pressure to activate adhesives effectively

- Conforms to irregular surfaces, making it ideal for rounded bottles, tubes, or custom packaging

- Reduces label defects, such as folds, creases, or lifted edges

- Operates smoothly at high speeds without compromising label placement

“The right roller ensures that even the fastest production lines achieve clean, wrinkle-free label application.”

What Affects Sponge Roller Performance?

Not all sponge rollers perform equally. Several factors can significantly affect the final labeling result:

- Material type: Natural rubber, PU foam, and silicone each offer different levels of durability, rebound, and temperature resistance

- Hardness (Shore A): Softer rollers (lower Shore A) offer better conformity, while harder ones offer longer wear

- Surface condition: Worn or flattened rollers reduce label accuracy and should be replaced regularly

- Roller alignment: Even slight misalignment can cause label slippage, tilting, or incomplete adhesion

Video Demonstration

Watch this short demo to see a sponge roller in action inside a working labeling machine.

Tip: Pay attention to how the roller presses down precisely after the label touches the product surface. Notice the even, bubble-free application.

Conclusion

Although often overlooked, sponge rollers are critical for accurate, high-speed labeling. Their compressibility, surface grip, and material properties all contribute to how well a label adheres to a product. Selecting the right sponge roller—and maintaining it properly—can help reduce labeling errors, improve throughput, and ensure a professional appearance on every product.