I. Introduction

When it comes to valves, I’ve learned that the choice between a soft seal and a hard seal can make or break system performance—whether it’s in a home water line or a high-pressure industrial pipeline. Many people think a valve is just a valve, but the seal inside is what truly determines how reliably it will operate over time. Pick the wrong type, and you could be facing unnecessary downtime, costly repairs, or even safety hazards.

In my years at Kinsoe, I’ve worked with customers from food processing plants to oil refineries, and I’ve seen firsthand how the right seal selection can optimize both efficiency and lifespan. In this article, I’ll break down what soft and hard seals are, how they differ in terms of structure, materials, and performance, and when each one is the better choice.

Here’s what we’ll explore together:

- What soft and hard seals are

- Their performance differences and common applications

- Real-world examples and practical selection tips

By the end, you’ll be able to make a more informed choice—whether you’re a procurement manager, product designer, or simply someone who wants to understand what’s happening inside the valves you rely on every day.

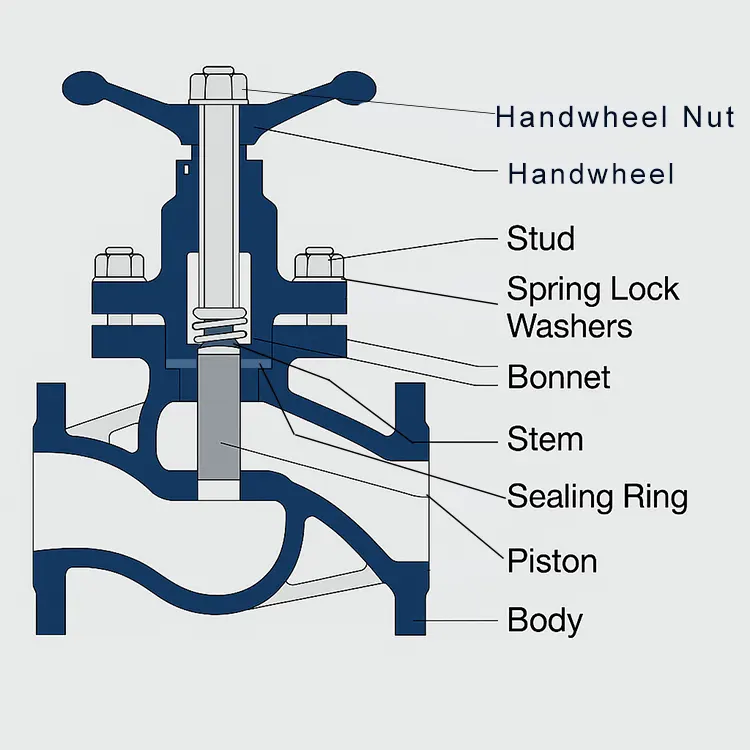

II. What Is a Valve Seal?

From my perspective, a valve seal is the unsung hero inside any valve system. It’s the component responsible for ensuring a tight closure between the valve’s moving parts—usually the disc or ball—and its stationary seat. Without a proper seal, the controlled medium, whether it’s water, steam, gas, or chemicals, would simply leak past the closure point.

At its core, the valve seal has two main jobs:

- Keep the medium contained – preventing leaks that can cause performance losses, contamination, or safety hazards.

- Maintain operational safety and efficiency – ensuring that the system delivers consistent pressure, flow, and quality without interruptions.

To make this easier to picture, I often compare a valve seal to the rubber gasket in a kitchen pressure cooker. Without that gasket, steam would escape, cooking times would be inconsistent, and the food might never reach the right texture. Or think about the flexible rubber seal on your refrigerator door—without it, cold air leaks out, energy is wasted, and the fridge can’t keep food fresh.

In industrial systems, the stakes are even higher. A well-chosen seal can save thousands in energy costs, reduce downtime, and even prevent dangerous leaks. This is why understanding the different seal types—soft and hard—is so important before making a purchase decision.

III. Understanding Soft Seals

When I talk about soft seals, I’m referring to sealing structures where one of the contact surfaces is made from a nonmetallic material such as rubber, PTFE, or other plastic composites. This design creates a metal-to-nonmetal interface, which is inherently more flexible and forgiving than a metal-to-metal connection.

Structure and Materials

Soft seals use elastomeric or polymer materials that can compress slightly to fill in micro-gaps or surface imperfections on the sealing face. Common choices include:

- Rubber (EPDM, NBR, silicone) for elasticity and cost-effectiveness

- PTFE (Teflon) for excellent chemical resistance

- Plastic composites for tailored performance in specific applications

Key Advantages

- Excellent sealing performance – With their flexibility, soft seals can achieve near-zero leakage, even in low-pressure systems.

- Lower manufacturing cost – Materials are generally less expensive, and machining requirements are less demanding.

- Ease of replacement – Damaged seals can be swapped out quickly without complex tools or specialized skills.

Limitations

- Lower temperature and pressure tolerance – Soft seals typically can’t handle extreme heat or high-pressure conditions.

- Wear and aging – Over time, exposure to chemicals, UV, or mechanical stress can cause hardening, cracking, or swelling.

- Chemical sensitivity – Certain solvents or aggressive media can degrade seal materials faster.

Common Applications

I often recommend soft seals for:

- Drinking water systems where hygiene and leak prevention are key

- HVAC equipment for reliable low-pressure operation

- Food and beverage processing where easy maintenance is valued

- Low to medium pressure pipelines handling clean, non-abrasive fluids

In short, soft seals are the go-to for situations where precision sealing at lower pressures is more critical than extreme durability.

IV. Understanding Hard Seals

Hard seals, in contrast, are built for strength and endurance. They feature metal-to-metal contact—both sealing surfaces are typically made from materials such as stainless steel, brass, or high-performance alloy steels. These seals rely on precision machining and surface hardness to achieve their sealing performance, rather than material flexibility.

Structure and Materials

Hard seals are all about rigidity and precision. The sealing faces are carefully ground and lapped to achieve a tight fit, often with tolerances within microns. Common materials include:

- Stainless steel for corrosion resistance and strength

- Alloy steel for high mechanical performance

- Hardened brass or bronze for specific industrial needs

Key Advantages

- High temperature and pressure resistance – Ideal for extreme operating environments where soft seals would quickly fail.

- Excellent durability – With proper maintenance, hard seals can last significantly longer, even in abrasive or corrosive media.

- Resistance to deformation – The rigid surfaces maintain their shape under heavy loads and rapid pressure changes.

Limitations

- Higher cost and production complexity – Requires precision manufacturing, specialized equipment, and skilled labor.

- Slightly lower sealing performance compared to soft seals – Achieving zero leakage can be more challenging without perfect surface alignment.

- Skilled maintenance needed – Servicing hard seals often demands experienced technicians and specialized tools.

Common Applications

I often recommend hard seals for:

- Power generation systems dealing with high-pressure steam

- Oil and gas pipelines where both high pressure and harsh media are present

- Industrial chemical processing where resistance to corrosion and abrasion is crucial

- High-temperature steam systems that require consistent performance in extreme heat

In short, if you need a seal that can survive hostile conditions without losing shape or performance, a hard seal is often the right choice—even if it comes with higher upfront costs.

V. Soft Seal vs Hard Seal: Key Differences

From my experience, choosing between a soft seal and a hard seal isn’t about which is “better” in general—it’s about which is better for your specific operating conditions. The table below summarizes the main differences I’ve observed in real-world applications:

| Aspect | Soft Seal | Hard Seal |

|---|---|---|

| Sealing Performance | Excellent, zero leakage possible | Good, but depends on precision |

| Temperature Range | Low to medium | Wide (including high/extreme) |

| Pressure Tolerance | Low to medium | Medium to high |

| Durability | Shorter lifespan | Longer lifespan |

| Maintenance | Easy to replace | Requires skilled maintenance |

| Cost | Lower | Higher |

What I want buyers to understand is this: A well-made soft seal can outperform a poorly made hard seal in many cases. The reverse is also true—if your application demands extreme heat, high pressure, or abrasive media, even the best soft seal will fail faster than a properly engineered hard seal.

This is why it’s crucial to align your seal selection with the actual working environment, rather than simply picking based on price or what’s in stock.

VI. How to Choose the Right Seal

Over the years, I’ve found that the most economical valve seal is the one that perfectly matches the application requirements—not necessarily the cheapest or the most expensive option. A seal that’s well-suited to your operating conditions will last longer, require less maintenance, and reduce unexpected downtime, ultimately saving far more than it costs upfront.

By Operating Temperature

- Soft seals excel in normal temperature ranges, typically from ambient to moderately elevated temperatures.

- Hard seals are essential when operating in high or extreme temperatures, where elastomer-based materials would degrade rapidly.

By Pressure Level

- For low to medium pressure systems, soft seals often deliver excellent performance without unnecessary cost.

- For high-pressure systems, hard seals are the safer, longer-lasting choice.

By Medium Type

- Soft seals work best with clean, non-abrasive fluids like potable water, compressed air, or certain food-grade liquids.

- Hard seals are better for abrasive slurries, corrosive chemicals, or media with high solid content.

By Maintenance Capability

- If your facility has limited technical expertise, soft seals are easier to replace and maintain.

- If you have skilled technicians and want maximum service life, hard seals can be a wise investment.

Case Study Examples

- Water Treatment Plant – A client chose soft seal butterfly valves for low-pressure clean water distribution. They enjoyed quick replacements, low costs, and excellent leak prevention.

- Chemical Refinery – Another client selected hard seal ball valves for handling high-pressure corrosive gas. The initial investment was higher, but the valves have run reliably for years without major servicing.

The takeaway here is clear: The best valve seal isn’t defined by its price tag—it’s the one engineered for your actual operating conditions.

VII. Procurement Insights

When advising procurement managers, I always stress that cost and performance must be evaluated together. Choosing a valve seal solely because it’s the cheapest option often leads to higher life-cycle costs—more frequent replacements, increased downtime, and even potential safety risks.

Balance Between Cost and Performance

A low-cost seal that fails prematurely will cost more in the long run than a higher-quality option that lasts years. The total cost of ownership should include not just the purchase price, but also installation, maintenance, downtime, and potential system damage.

Importance of Supplier Quality

From my experience, a well-made soft seal can outperform a poorly made hard seal, and vice versa. That’s why supplier reliability is critical. Look for manufacturers who:

- Have in-house quality control systems

- Perform material testing and verification

- Hold relevant industry certifications (such as ISO or API)

Long-Term Reliability

A valve seal that operates flawlessly for years reduces the need for emergency orders, lowers labor costs, and ensures consistent system performance. In industries like food processing or oil and gas, reliability also means compliance with strict safety and quality standards.

Vendor Selection Tip

When sourcing seals, I recommend partnering with suppliers who can provide technical consultation and customization. At Kinsoe, for example, we work closely with buyers to analyze application parameters before recommending materials and designs. This prevents mismatches that can shorten a seal’s lifespan or compromise safety.

Ultimately, the smartest procurement decision is one that delivers consistent performance, safety, and value over the entire service life of the seal.

VIII. Conclusion

In my experience, both soft and hard seals have their rightful place in valve applications. Soft seals shine when you need exceptional sealing performance at low to medium pressures, especially in clean or hygienic environments. Hard seals, on the other hand, are the champions of durability in extreme conditions—high temperatures, high pressures, and abrasive or corrosive media.

The most economical choice isn’t determined by initial cost, but by how well the seal meets your actual application requirements. When you select the right seal, you gain longer service life, fewer breakdowns, and more predictable maintenance schedules—benefits that pay off year after year.

As a supplier who has worked with industries from food processing to oil and gas, I know that the right decision starts with understanding your operating conditions in detail. That’s why I encourage buyers to seek expert advice before making a final choice.

If you’re evaluating valve sealing options and want recommendations tailored to your needs, I invite you to connect with Kinsoe. Our team can help you assess your application, choose the right material, and ensure your investment delivers maximum performance and reliability.

Related Articles

- Valve Sealing Guide: Types, Materials & Best Practices

Learn more about valve seal types, materials, and best practices to fully understand the application points of soft and hard seals. - Types of Rubber Seals by Shape, Material, and Use

A systematic breakdown of different rubber seal shapes, materials, and applications, offering practical insights for selecting soft seal materials. - O-Rings vs. Gaskets: What’s the Difference?

A comparison of the structure and sealing principles of O-rings and gaskets to help you understand the performance differences between various sealing components in real-world applications.