Intro

Condenser and chiller tubes gradually lose efficiency as biofouling, slime, and soft scaling accumulate on their inner walls. These deposits increase energy consumption, widen approach temperature, and degrade cooling performance.

An Automatic Tube Cleaning System (ATCS) uses circulating sponge balls to clean tubes continuously and online—without shutting down the chiller. This article explains how the loop works, when ATCS is the right choice, its benefits and limitations, and how to choose the correct sponge balls and dosing strategy.

For a broader overview of sponge cleaning ball applications, see the main pillar:

https://www.kinsoe.com/sponge-cleaning-balls-fast-buyers-guide/

For sizing rules, refer to the Sizing Guide:

https://www.kinsoe.com/sponge-ball-sizing-guide/

What Is ATCS? (30-Second Definition)

An Automatic Tube Cleaning System (ATCS) is a closed-loop cleaning system that continuously circulates sponge balls through condenser or chiller tubes to keep heat-transfer surfaces clean while the system is running. Instead of stopping equipment for mechanical cleaning, ATCS performs gentle, ongoing wiping that prevents biofilm and soft-scale buildup.

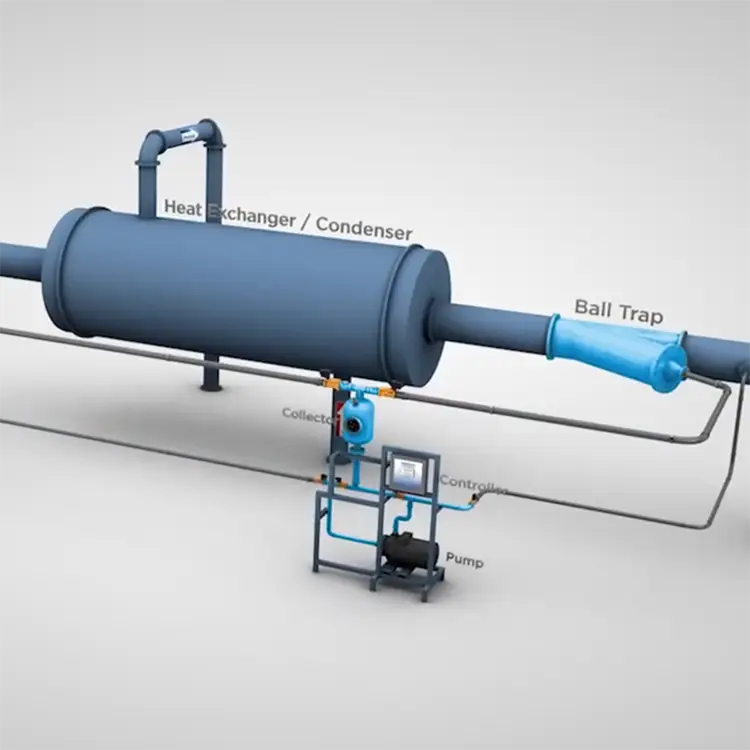

A typical ATCS includes:

- Ball injectors that release sponge balls upstream

- Tube bundle where balls perform the wiping action

- Outlet strainers/collectors that capture the balls

- Recirculation piping + pump/control valves that return balls to the injector

Ball performance depends heavily on material, cell structure, and hardness, which are explained here:

https://www.kinsoe.com/sponge-ball-materials-hardness/

Correct ball diameter requires sizing to the tube’s actual I.D.:

https://www.kinsoe.com/sponge-ball-sizing-guide/

How the Loop Works (Step-by-Step)

An ATCS loop is simple but highly effective when properly tuned. Each cycle sends sponge balls through the condenser/chiller tubes, wipes the interior surface, and returns them for repeated use.

1. Injection — Balls Enter the System

Sponge balls are introduced just upstream of the condenser or chiller tube bundle.

The system’s injector meters the balls at a controlled frequency (e.g., every few minutes or based on load conditions).

Correct ball size ensures they compress slightly for consistent wall contact:

https://www.kinsoe.com/sponge-ball-sizing-guide/

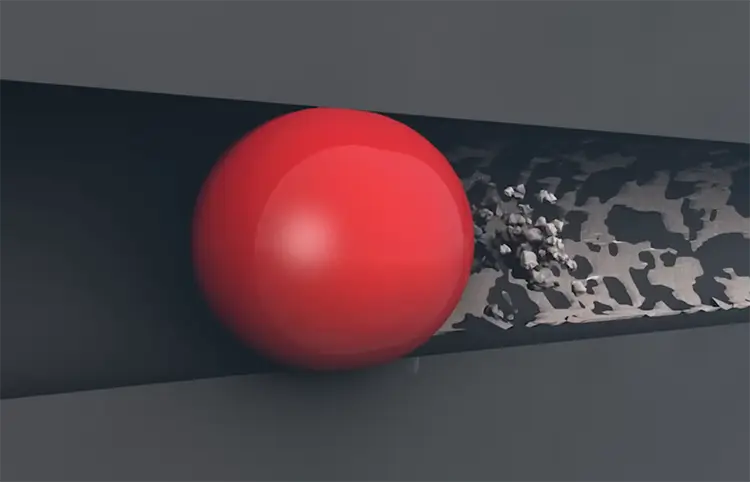

2. Transit & Wiping — Cleaning Inside the Tubes

As chilled water (or condenser water) pushes the balls through the tubes, each ball:

- Compresses slightly against the tube wall

- Removes biofilm, slime, and soft-scale deposits

- Maintains stable heat-transfer performance

- Moves smoothly due to the tube’s straight geometry and low-friction interior

Wiping aggressiveness depends on hardness and surface finish of the sponge ball.

Ball material/cell/hardness reference:

https://www.kinsoe.com/sponge-ball-materials-hardness/

3. Capture — Strainers Collect the Balls

At the condenser outlet, specially designed strainers catch the sponge balls without restricting water flow.

The system ensures 100% ball capture to prevent downstream carryover.

4. Recirculation — Balls Return to the Injector

A recirculation piping loop and pump return the captured balls to the injector for the next cycle.

This creates a continuous cleaning loop where balls cycle through the system multiple times per hour, depending on fouling severity and dosing strategy.

Surface Variants That Influence Performance

ATCS sponge balls come in different outer textures to match fouling conditions:

- Smooth → Light biofilm

- Fine ridged → Slime, early soft scale

- Abrasive ring → Light mineral scale (use cautiously with tube material)

Hardness selection affects both wiping strength and passability.

For detailed dosing and surface selection:

https://www.kinsoe.com/atcs-ball-selection-dosing/

When to Use ATCS (Decision Criteria)

ATCS is not required for every condenser or chiller system—but in the right environments, it protects heat-transfer efficiency far better than periodic manual cleaning. Use the following criteria to determine whether ATCS is the right solution for your plant.

1. High-Fouling Water Sources

ATCS is especially valuable when the cooling medium has high biological activity or suspended solids, such as:

- Warm seawater

- River or lake water

- Cooling tower water with organic load

- High TDS sources prone to soft-scale formation

These conditions cause rapid biofilm growth that can reduce heat-transfer efficiency within days, making continuous online cleaning ideal.

2. Long Runtime or High Load Operation

If your condensers or chillers run for long periods between shutdowns—common in:

- Commercial buildings

- District cooling

- Industrial plants

- Power generation

—ATCS helps maintain stable performance without interrupting operation for mechanical cleaning.

3. Tight Energy KPIs or High Electricity Costs

Facilities focused on energy efficiency benefit from ATCS because:

- Clean tubes reduce approach temperature (ΔT)

- Improved ΔT increases COP and reduces kW/ton

- Even small improvements yield large savings when chillers run continuously

If your energy team tracks KPIs aggressively, ATCS helps keep your metrics stable.

4. Tube Material & Geometry Compatibility

ATCS is ideal when:

- Tubes are straight, smooth, and full-length

- Tube sheets and support plates offer clear passage

- No unexpected restrictions or sharp interior transitions exist

Ball passability is determined by correct size and hardness:

https://www.kinsoe.com/sponge-ball-sizing-guide/

https://www.kinsoe.com/sponge-ball-materials-hardness/

5. When Manual Cleaning Is Too Disruptive

If physical tube brushing requires:

- Coordination with shutdowns

- Labor-intensive disassembly

- High downtime costs

…ATCS becomes a practical, continuous alternative for maintaining tube cleanliness between major cleanings.

Say “next” to continue to Benefits (Skimmable Bullets).

Benefits (Skimmable Bullets)

ATCS delivers several operational, financial, and maintenance advantages, especially in environments with high fouling rates. Here are the key benefits at a glance:

✔ 1. No Shutdowns Required

ATCS cleans tubes while the chiller or condenser is running.

This eliminates the need for frequent mechanical cleaning, which normally requires stopping the equipment.

✔ 2. Stable Heat-Transfer Performance

Clean tubes maintain consistent:

- Approach temperature (ΔT)

- COP / kW-TR (overall chiller efficiency)

- Heat-exchanger performance under varying loads

The system continually removes fresh layers of slime before they can develop into harder scale.

✔ 3. Reduced Reliance on Chemicals

While ATCS does not replace all chemical treatment, it can significantly reduce:

- Biofilm formation

- Frequency of certain scale-inhibition treatments

- Overall chemical consumption in high-fouling systems

This also reduces environmental impact and improves operator safety.

✔ 4. Predictable, Preventive Maintenance

Continuous wiping prevents the typical performance dip that occurs between manual cleanings.

This makes maintenance more predictable and reduces:

- Emergency cleanings

- Unplanned shutdowns

- Rush labor or overtime costs

✔ 5. Lower Operating Costs

Because clean tubes require less energy to remove heat, ATCS typically lowers:

- Electricity costs

- Cooling water pumping load

- Energy waste from fouled heat-exchanger surfaces

Plants with high electricity rates often see fast ROI.

✔ 6. Gentle, Non-Abrasive Tube Care

With correct sizing and hardness (Soft/Medium), ATCS sponge balls:

- Do not damage tube walls

- Provide safe, uniform wiping

- Extend tube life by reducing corrosion-promoting fouling layers

Correct ball selection:

https://www.kinsoe.com/atcs-ball-selection-dosing/

Limitations & What ATCS Doesn’t Do

ATCS is extremely effective at preventing biofilm and soft-fouling buildup, but it’s not a universal cleaning solution. Understanding its limitations helps you set realistic expectations and choose the right combination of ball type, dosing frequency, and supplemental maintenance.

❌ 1. ATCS Cannot Remove Heavy, Hard Mineral Scale

If tubes already contain thick calcium-based scale, silica deposits, or hard crystalline layers, ATCS will not remove them.

These require:

- Mechanical brushing

- Chemical descaling

- High-pressure cleaning

ATCS is meant for continuous prevention, not one-time deep cleaning.

❌ 2. Incorrect Ball Sizing or Dosing Causes Poor Results

ATCS performance depends entirely on proper setup. Incorrect sizing or dosing can cause:

- Carryover (balls not fully captured)

- Poor wiping

- Flow imbalance

- Premature ball wear or shrinkage

Sizing rules:

https://www.kinsoe.com/sponge-ball-sizing-guide/

Ball selection & dosing:

https://www.kinsoe.com/atcs-ball-selection-dosing/

❌ 3. System Requires Routine Strainer Maintenance

Strainers must be:

- Checked regularly

- Cleared of debris

- Verified for 100% ball capture

If strainers clog or lose efficiency, the entire ATCS loop becomes unreliable.

❌ 4. ATCS Does Not Replace Major Shut-Down Cleaning

Even with ATCS, systems still require:

- Periodic inspections

- Occasional mechanical cleaning

- Water-quality management

ATCS reduces frequency—but does not eliminate the need for deeper maintenance.

❌ 5. Ball Shrinkage & Wear Must Be Monitored

ATCS sponge balls shrink over time due to:

- Temperature cycles

- Chemical exposure

- Mechanical compression

Shrunken balls lose wiping contact and must be replaced.

Lifespan guidance:

https://www.kinsoe.com/sponge-ball-temperature-reuse/

❌ 6. Requires Tube Geometry Compatibility

If tubes have:

- Severe bends

- Unexpected restrictions

- Damaged tube sheets

- Protruding welds

Balls may struggle or wear prematurely. Geometry must be verified before installation.

Troubleshooting rare stuck/slow movement:

https://www.kinsoe.com/sponge-ball-troubleshooting/

Ball Choices for ATCS (Snapshot)

Choosing the right sponge balls is the core of ATCS performance.

ATCS environments are very different from concrete pipeline cleaning—tubes are smooth, narrow, and high-flow, which means ball selection must prioritize passability, gentle wiping, and predictable compression.

Here’s a quick snapshot of how to choose correctly.

1. Cell Structure — Closed-Cell or Fine Open-Cell

Most ATCS systems use:

- Closed-Cell Balls

- Minimal water absorption

- Stable shape and compression

- Ideal for smooth condenser/chiller tubes

- Best for biofilm/slime control

- Fine Open-Cell Balls

- Slightly higher conformity

- Useful when tubes have light surface irregularities

- Still stable enough for recirculation loops

Avoid coarse open-cell structures—they can deform excessively and lose wiping precision.

Material/cell interaction guide:

https://www.kinsoe.com/sponge-ball-materials-hardness/

2. Hardness — Soft or Medium

Hardness determines wiping aggressiveness and risk of blockage.

- Soft

- Highest passability

- Ideal for systems with delicate or narrow tubes

- Best choice for high-cycle ATCS loops

- Medium

- Balanced wiping pressure

- Helps remove more stubborn biofilm

- Still safe for long-term operation

- Hard

- Rarely used in ATCS

- Only for verified straight-tube geometries with persistent fouling

- Must be carefully sized (+5–10% oversize maximum)

Hardness sizing rules:

https://www.kinsoe.com/sponge-ball-sizing-guide/

3. Surface Finish — Match to Fouling Type

ATCS balls come with specialized surface textures:

- Smooth Surface

- Best for thin biofilm, slime prevention

- Low wear on the tube interior

- Fine Ridged Surface

- Slightly stronger wipe

- Good for early-stage soft-scale or biofouling

- Abrasive Ring Surface (use sparingly)

- For light mineral deposits

- Must match tube material compatibility

- Best used temporarily, not continuously

More details and dosing strategy:

https://www.kinsoe.com/atcs-ball-selection-dosing/

4. Material Choice — Rubber vs. PU

- Rubber

- Softer compression

- Very stable pass-through

- Widely used for general ATCS cleaning

- Polyurethane (PU)

- Longer wear life

- Holds shape well under repeated cycles

- Excellent for warmer water or abrasive conditions

Both materials work as long as size + hardness are correct.

5. Key ATCS Ball Selection Principles

- Always size to the actual tube I.D., not nominal

- Avoid overly aggressive hardness

- Match surface texture to fouling type

- Verify tube geometry (straight + clean transitions)

- Replace balls when shrinkage reduces wiping effectiveness

Integrating ATCS Into Operations

Installing ATCS is only the first step—its real value comes from proper dosing, continuous monitoring, and simple routine maintenance. This section shows how operators integrate ATCS into daily plant workflows.

1. Dosing Strategy — Cycles per Hour & Ball Quantity

ATCS does not run balls constantly. Instead, dosing is based on:

- Fouling severity

- Water source (e.g., seawater vs. cooling tower water)

- Chiller/condenser load profile

- Tube material & size

Typical starting points:

- 1–4 cycles per hour

- 1 ball per tube (varies by manufacturer)

- Adjust based on approach temperature (ΔT) trends and fouling rate

For precise dosing ranges and examples:

https://www.kinsoe.com/atcs-ball-selection-dosing/

2. Monitoring System Performance

Operators monitor several KPIs to measure ATCS effectiveness:

- Approach temperature (ΔT)

A stable or decreasing ΔT indicates good tube cleanliness. - kW/ton (COP)

Cleaner tubes mean less energy consumption per ton of cooling. - Differential pressure (ΔP)

Sudden increases may indicate biofilm formation, scale, or strainer clogging. - Chilled-water return temperature trends

Early performance drift often signals fouling before operators feel the impact.

Regular tracking of these metrics provides actionable feedback on dosing frequency and ball selection.

3. Routine Maintenance

ATCS requires minimal but essential upkeep:

- Strainer cleaning

Remove debris that may trap balls or reduce capture efficiency. - Ball inspection

Look for shrinkage, surface wear, or hardness changes.

Lifespan and temperature effects:

https://www.kinsoe.com/sponge-ball-temperature-reuse/ - Recirculation pump check

Ensure consistent flow for stable ball return. - Logbook updates

Daily or weekly entries: dosing cycles, ball replacement count, ΔT trends.

4. Coordinating ATCS With Plant Conditions

ATCS settings may change with:

- Seasonal load variations

- Cooling-tower water changes

- Sudden biofouling spikes (storms, algae blooms)

- Chiller shutdown schedules

Operators often increase dosing frequency ahead of summer peaks and reduce it during low-load periods.

5. Integration With Chemical Treatment

ATCS works best when combined with:

- Basic corrosion inhibitors

- Tower water treatment

- Occasional manual descaling (for hard-scale-prone systems)

ATCS reduces chemical reliance—but does not eliminate the need for a balanced water treatment program.

Quick Implementation Checklist

Use this checklist to verify that your ATCS system is correctly configured before starting continuous online tube cleaning. It ensures proper ball selection, safe operation, and reliable cleaning performance.

✔ Tube Geometry & Internal Diameter Confirmed

- Actual tube I.D. measured (not nominal size)

- Straight tube geometry verified

- No unexpected restrictions, dents, or sharp edges

- Support plates and tube sheets checked for smooth transitions

Sizing rules:

https://www.kinsoe.com/sponge-ball-sizing-guide/

✔ Water Quality Profile Reviewed

Understand the fouling tendency of your cooling water source:

- Biofouling (slime, algae)

- Soft scale (calcium, magnesium)

- Suspended solids (silt, organics)

- Seawater or brackish sources

This determines the ball surface finish and hardness needed.

✔ Correct Ball Selection Completed

- Material: Rubber or PU

- Cell Structure: Closed-cell or fine open-cell

- Hardness: Soft or Medium (default for ATCS)

- Surface Type: Smooth, ridged, or abrasive-ring

- Diameter: Slight oversize for gentle compression

Selection details:

https://www.kinsoe.com/sponge-ball-materials-hardness/

✔ Initial Dosing Plan Set

- Starting cycles per hour (1–4 typical)

- Number of balls per tube or per loop

- Adjustments planned based on ΔT, COP/kW-TR, and ΔP readings

Full dosing guidance:

https://www.kinsoe.com/atcs-ball-selection-dosing/

✔ Monitoring & Maintenance Ready

- Baseline KPIs recorded

- Strainers cleaned and functioning

- Pump return loop verified

- Logbook set up for tracking:

- Dosing cycles

- Ball replacements

- ΔT & ΔP trends

- Any anomalies

FAQ

Can ATCS replace chemical treatment?

Not entirely. ATCS significantly reduces biofilm and slime, which can lower the need for certain chemical treatments—but it does not eliminate scaling chemistry or corrosion control. Water chemistry still determines how much chemical support is required.

How often do the sponge balls circulate?

It depends on fouling severity, tube diameter, and load conditions. Many systems run 1–4 cycles per hour, but the exact dosing strategy is covered here:

https://www.kinsoe.com/atcs-ball-selection-dosing/

Will sponge balls get stuck in the tubes?

It’s rare in ATCS because tubes are smooth and straight. Sticking only occurs when:

- Balls are incorrectly sized,

- Hardness is too high, or

- Tube geometry has unexpected restrictions.

If issues occur, see the troubleshooting guide:

https://www.kinsoe.com/sponge-ball-troubleshooting/

Conclusion — Optimize Your ATCS Performance with the Right Sponge Balls

ATCS works best when sponge balls are correctly matched to your tube I.D., water quality, and fouling characteristics. If you want a precise recommendation for your condenser or chiller system, share the following details:

- Tube I.D. (actual, not nominal)

- Water source (cooling tower, seawater, river, etc.)

- Fouling type (biofilm, slime, soft scale)

- Chiller/plant load profile

- Desired wiping strength (gentle, standard, aggressive)

We’ll help you select the ideal material, cell structure, hardness, surface type, and diameter.

Ready to Source ATCS Sponge Balls?

Explore our product page:

👉 Sponge Cleaning Balls (Kinsoe Rubber)

https://www.kinsoe.com/product/rubber-sponge-cleaning-balls/

Want the Full System Overview?

Start with the guide’s table of contents page.:

👉 Sponge Cleaning Balls: Fast Buyer’s Overview

https://www.kinsoe.com/sponge-cleaning-balls-fast-buyers-guide/

Related posts

- Materials & Hardness → https://www.kinsoe.com/sponge-ball-materials-hardness/

- Sizing Guide → https://www.kinsoe.com/sponge-ball-sizing-guide/

- ATCS Ball Selection & Dosing → https://www.kinsoe.com/atcs-ball-selection-dosing/

- Temperature & Reuse → https://www.kinsoe.com/sponge-ball-temperature-reuse/

- Troubleshooting → https://www.kinsoe.com/sponge-ball-troubleshooting/