1. Introduction

Polyurethane foam cylinders are widely used across industrial machinery, automotive systems, HVAC equipment, construction, electronics, and even sensitive instrumentation. Their unique combination of lightweight structure, excellent damping, progressive compression, and customizable density makes them one of the most versatile components for vibration control, shock absorption, alignment, spacing, and noise reduction.

In many engineering projects, designers do not search for “polyurethane foam cylinders” as a material—but instead search for solutions to specific problems: rattling issues, vibration transfer, impact protection, thermal bridging, or assembly clearance. This is why understanding the applications of PU foam cylinders is more valuable than simply knowing their material characteristics.

This article provides a comprehensive examination of how polyurethane foam cylinders work across multiple industries, which problems they solve, and how engineers should choose the right configuration for each scenario.

If you are unfamiliar with what a polyurethane foam cylinder is or how it is structured, you may start with the foundational article:

👉 What Is a Polyurethane Foam Cylinder?

https://www.kinsoe.com/what-is-polyurethane-foam-cylinder/

2. Why Polyurethane Foam Cylinders Are Ideal for Multi-Industry Use

2.1 Key Functional Strengths

Polyurethane foam cylinders excel in applications where the following functions are required:

- Vibration damping

They convert kinetic energy into heat through microcellular deformation. - Shock absorption

Their progressive compression curve prevents hard impacts and reduces peak forces. - Noise reduction

The foam structure minimizes sound transmission and resonance. - Alignment & spacing

Foam cylinders provide soft contact points that compensate for tolerances. - Thermal & acoustic insulation

Foam prevents cold bridging and reduces airborne noise in HVAC and building systems. - Weight reduction

Compared to metal springs or rubber blocks, PU foam cylinders are lighter and easier to handle.

2.2 Open-Cell vs Closed-Cell Relevance by Application

- Open-cell PU foam

Best for damping and noise reduction. Used in most machinery and automotive cases. - Closed-cell PU foam

Better when water resistance or temperature insulation is required (e.g., HVAC duct systems).

Both structures are used across industries depending on the operating environment and performance requirements.

3. Industrial Machinery & Equipment

Industrial machinery is one of the most common domains where polyurethane foam cylinders are used. Their ability to soften impacts and stabilize movement makes them essential components in many automated systems.

3.1 Linear Motion Damping

Examples:

- CNC machine axes

- Automated guided robots

- Multi-axis actuators

In these systems, foam cylinders function as end-stop buffers, preventing metal-to-metal collision and reducing mechanical stress.

Benefits:

- Smooth deceleration

- Reduced noise

- Lower maintenance cost

3.2 Shock Absorption in Moving Assemblies

PU cylinders act as energy absorbers in:

- Conveyor stops

- Pick-and-place actuators

- Packaging machinery

- Industrial arm collisions

The foam provides progressive deformation, which protects components that repeatedly strike or compress during operation.

3.3 Vibration Reduction for Equipment

PU cylinders serve as:

- Motor mounts

- Pump and compressor isolators

- Anti-vibration spacers between metal panels

They reduce transmitted vibration to reduce fatigue, structural wear, and noise.

3.4 Benefits for Industrial Designers

- Customizable hardness for precise damping

- Consistent cycling performance

- Lightweight versus rubber/metal alternatives

- Ability to tune the compression profile

This makes PU cylinders ideal for medium- to high-cycle automation environments.

4. Automotive & Transport

Automotive engineers value polyurethane foam cylinders due to their quiet operation, lightweight nature, and ability to eliminate small rattles and resonance.

4.1 Cushioning for Latches, Covers & Hinged Components

Examples:

- Door panels

- Glove boxes

- Sunshades

- Storage compartments

- Center console covers

PU cylinders help eliminate squeaks and rattles (NVH management), providing a soft stop during opening/closing.

4.2 Vibration Isolation for Small Motorized Parts

Applications:

- Cooling fans

- Miniature blowers

- Servo motors

- Electric actuators

These components often generate high-frequency vibration. Foam cylinders provide a soft isolation interface that prevents vibration from transferring to surrounding structures.

4.3 Car Refrigerators & Portable Appliances

Cylinders are used as:

- Vibration cushions

- Spacers

- Alignment guides

- Anti-rattle pads

Small appliances in automotive environments benefit greatly from lightweight damping components.

4.4 Why PU Foam Works So Well in Vehicles

- Quiet compression (essential for NVH control)

- Excellent elasticity

- Strong fatigue resistance

- Fully customizable shapes

These features make PU foam cylinders superior to EVA or PE in most automotive cases.

5. HVAC & Air Handling Systems

The HVAC industry uses polyurethane foam cylinders extensively for vibration, acoustic, and spacing functions.

5.1 Vibration Damping for Fans & Blowers

Foam cylinders often sit under or around:

- Blower housings

- Squirrel-cage fans

- Air handler assemblies

They prevent direct metal contact and reduce vibration conducted into the duct system.

5.2 Acoustic & Thermal Control

Foam cylinders serve as:

- Acoustic spacers

- Anti-vibration mounts

- Duct stabilization supports

PU foam improves noise control by disrupting vibration pathways and softening mechanical contact points.

5.3 Seal & Support Functions for HVAC Components

They are used in:

- Pipe saddles

- Duct connectors

- HVAC casing support

- Vibration isolation of small appliances (e.g., mini chillers, dehumidifiers)

5.4 Why PU Foam Performs Well in HVAC

- Excellent sound damping

- Good thermal insulation

- Non-metallic (no corrosion)

- Moisture-resistant options available

For many HVAC engineers, PU foam cylinders offer an efficient and economical method for system noise reduction.

6. Construction & Building Services

Foam cylinders are commonly integrated into architectural and structural installations to improve comfort, reduce noise, and absorb vibration.

6.1 Soundproofing & Acoustic Buffering

Used as:

- Ceiling isolation mounts

- Wall panel dampers

- Door-frame soft spacers

These applications help prevent structure-borne noise from traveling through walls and floors.

6.2 Thermal & Vibration Breaks

Foam cylinders are placed between:

- HVAC pipes and walls

- Metal frames

- Building services and structural elements

They break thermal pathways and provide vibration isolation simultaneously.

6.3 Floor & Wall Mechanical Buffers

Foam cylinders serve as:

- Mechanical stoppers

- Expansion gap buffers

- Shock-absorbing end stops for movable frames

These uses improve safety while protecting building materials.

7. Electronics, Appliances & Sensitive Equipment

Highly sensitive electronics benefit from components that prevent vibration and absorb shock without adding weight.

7.1 Anti-Vibration Support

Examples:

- PCB-mounted motors

- Cooling fans

- Micro compressors

The soft, progressive damping of PU cylinders protects fragile components.

7.2 Shock Absorption for Portable Devices

Used inside:

- Medical devices

- Portable instruments

- Test equipment

- Handheld appliances

They protect components from accidental drops or impact.

7.3 Appliance-Level NVH Control

In refrigerators, air purifiers, washing machines, and small compressors, cylinders:

- Absorb vibration

- Reduce noise

- Improve stability

They are ideal for quiet operation in household and commercial environments.

8. Packaging, Transportation & Logistics

PU foam cylinders are widely used in protective packaging.

8.1 Dynamic Shock-Absorbing Pads

For:

- Heavy instruments

- Automotive parts

- Electronics

- Industrial tools

Foam cylinders absorb impact energy during drops or transport shocks.

8.2 Load Spacers & Stabilizers

They prevent:

- Vibration movement

- Part shifting

- Collision damage

Reusable foam cylinders are valued for cost-saving and long-term durability in packaging systems.

9. How to Choose the Right Cylinder for Each Application

This section provides an overview; for deeper engineering details, see the full selection guide:

👉 https://www.kinsoe.com/polyurethane-foam-cylinder-selection-guide/

9.1 Density Selection by Industry

- Automotive interior: 200–300 kg/m³

- HVAC: 250–350 kg/m³

- Heavy industrial machinery: 350–600 kg/m³

Higher density increases load-bearing capability and stiffness.

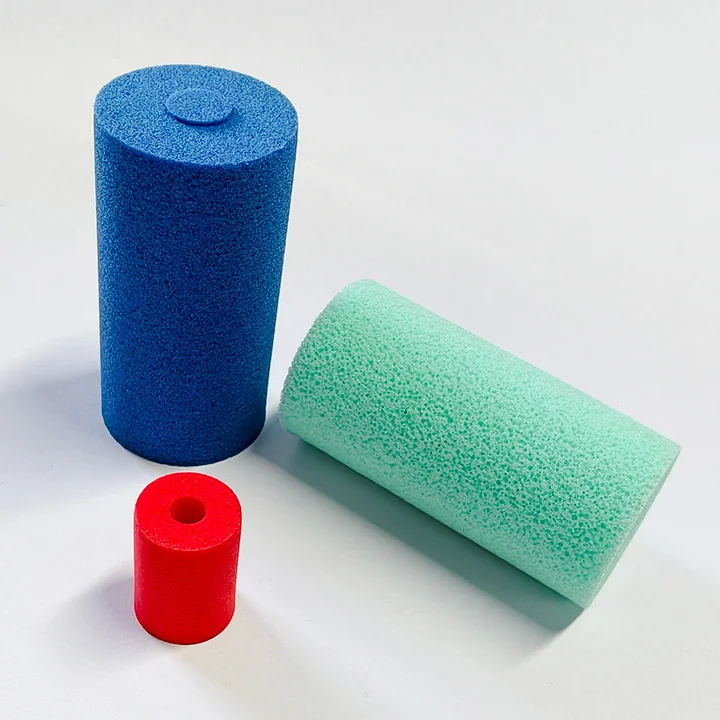

9.2 Solid vs Hollow Designs

- Solid cylinders:

Best for impact zones or direct compression. - Hollow cylinders:

Better progressive damping, lighter, mountable over shafts, ideal for HVAC or electronics.

9.3 Environmental Considerations

Evaluate:

- Ambient temperature

- Moisture exposure

- UV exposure

- Chemical/oil exposure

These factors determine whether PU, silicone foam, or NBR foam is more suitable.

10. Why PU Foam Cylinders Outperform Other Materials

For a full comparison, read:

👉 Polyurethane vs Other Foam Materials

https://www.kinsoe.com/polyurethane-vs-other-foam-cylinders/

Against EVA & PE

- PU is more durable

- Better fatigue resistance

- Greater density range

Against Silicone Foam

- More cost-effective

- Higher abrasion resistance

- Silicone only needed for high temperatures

Against Rubber / Metal Dampers

- Lighter

- Quieter

- More progressive compression

11. When Should You Use PU Foam Cylinders?

11.1 Ideal Scenarios

- When vibration must be controlled

- When noise is unacceptable

- When the system cannot tolerate metal-to-metal contact

- When lightweight solutions are required

- When components need tolerance compensation

11.2 When a Different Material Might Be Better

- High heat → silicone

- Heavy oil exposure → NBR foam

- High structural loads → rubber/metal hybrid

12. What Buyers Should Prepare for Custom Projects

12.1 Essential Data

- Load profile

- Compression target

- Operating temperature

- Dimensions

- Frequency of cycle

12.2 OEM Customer Notes

- Color coding for hardness

- Adhesive requirements

- Fire-resistance needs

- Consistency specifications (QC)

Knowing these details helps Kinsoe provide accurate recommendations and create efficient prototypes.

13. Summary: Why PU Foam Cylinders Drive Performance Across Industries

Polyurethane foam cylinders provide:

- Strong vibration damping

- Effective shock absorption

- Noise reduction

- Lightweight, non-metallic performance

- Adaptability to nearly any industrial or consumer application

Across five major industries and over twenty use cases, PU cylinders consistently outperform simpler foam, rubber pads, or metal dampers where quiet, soft, progressive compression is required.

14. Recommended Next Steps

Learn More About PU Foam Cylinders

- What they are →

https://www.kinsoe.com/what-is-polyurethane-foam-cylinder/ - Compare materials →

https://www.kinsoe.com/polyurethane-vs-other-foam-cylinders/ - Engineering selection →

https://www.kinsoe.com/polyurethane-foam-cylinder-selection-guide/

View the Product Page

Request Samples or Custom Solutions

Send your drawings, performance requirements, or industry use case to Kinsoe.

Our engineering team will help you select or design the ideal cylinder for your project.

Article B is complete.

Shall I begin Article C next?