1. Introduction

1.1 Why Material and Structure Shape Performance

In my work helping automation engineers optimize gripping performance, I’ve seen that suction cups rarely fail randomly. Instead, they fail because the material or structure doesn’t match the real-world surface conditions. Foam cups work extremely well on rough or porous surfaces, while rubber cups dominate on smooth, rigid parts. Bellows cups excel in speed and compensation but struggle with porosity.

Choosing the right suction cup is not about “which one is better,” but rather choosing the right tool for the right job. You can find a deeper overview of surface behavior in Foam Suction Cups for Rough and Oily Surfaces, where I break down leakage mechanisms and surface challenges in detail.

1.2 What This Article Covers

In this material guide, I explain:

- Structural differences between foam, rubber and bellows cups

- When each type performs best in different automation scenarios

- In-depth comparison of NR, EPDM, NBR, silicone and PU

- Practical rules so you can quickly select the right material

For overall sizing and hardness selection guidance, you may refer to

How to Select the Right Foam Suction Cups, which complements the material-focused content in this article.

2. Structural Comparison: Foam vs Rubber vs Bellows

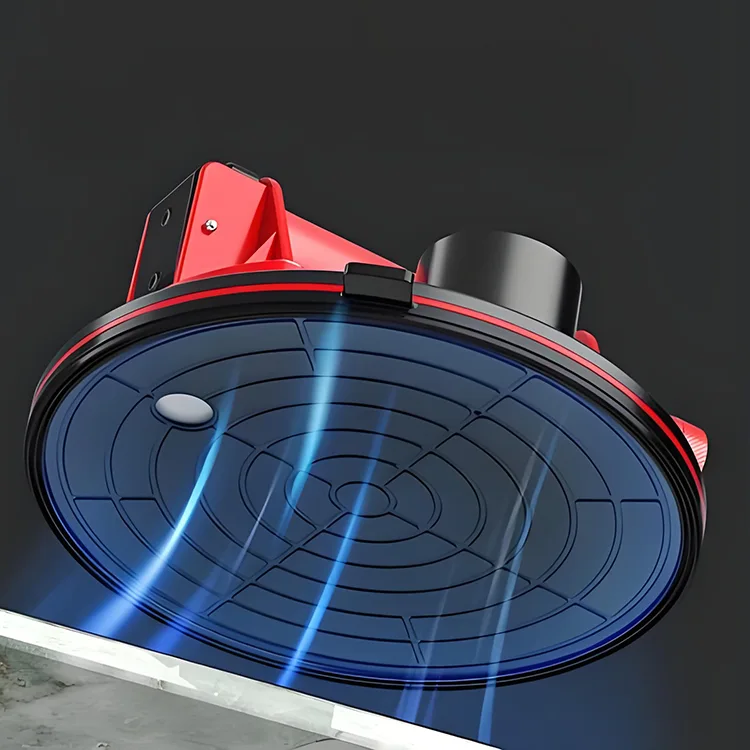

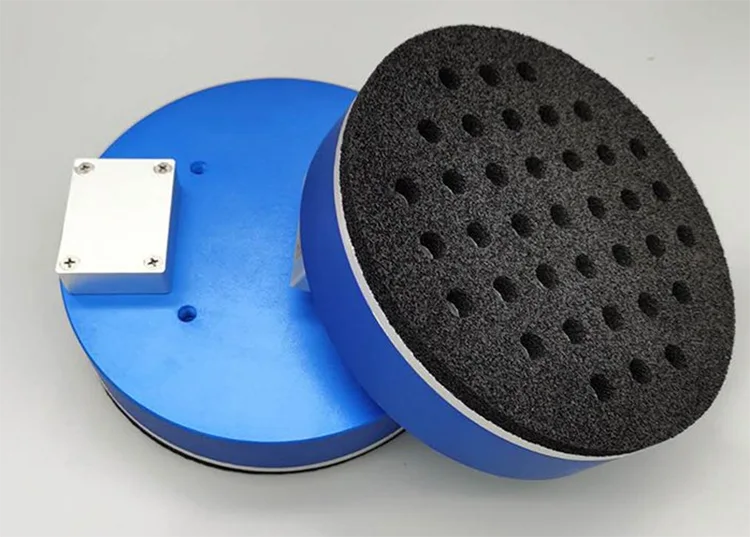

2.1 Foam Suction Cups

Foam suction cups feature an open-cell or fine-cell structure that fills micro-gaps on textured, porous or uneven surfaces. This makes them ideal for corrugated boxes, MDF panels, textured plastics and surfaces that rubber cups cannot seal. Because foam tolerates controlled leakage, it performs best when matched with high-flow vacuum systems.

If you’d like to understand why these surfaces cause leakage, you can continue with

Foam Suction Cups for Rough and Oily Surfaces, which explains each surface type in detail.

2.2 Solid Rubber Suction Cups

Solid rubber cups are engineered for smooth, flat, non-porous surfaces such as polished plastics, clean metals or coated glass. They create an almost airtight seal and generate higher ultimate vacuum than foam. However, they are less adaptable to height variation and lose performance quickly when the surface contains texture or porosity.

2.3 Bellows Cups

Bellows cups include a flexible stem that compensates for motion and vertical displacement. They are excellent for high-speed picking, curved surfaces, and applications requiring rapid compression and decompression. However, because they still rely on solid rubber for sealing, they remain unsuitable for porous or dusty materials.

2.4 Comparison Table

| Feature | Foam Cups | Rubber Cups | Bellows Cups |

|---|---|---|---|

| Surface Adaptability | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

| Rough/Porous Sealing | ★★★★★ | ★☆☆☆☆ | ★★☆☆☆ |

| Marking Risk | ★★★★★ Low | ★★☆☆☆ Medium | ★★★☆☆ |

| Durability | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Cost | Medium | Low | Medium |

| Ideal Use Case | Rough/uneven surfaces | Smooth, rigid surfaces | Fast pick-and-place, curved parts |

For industry-specific examples of how these structures behave, you can explore

Foam Suction Cup Applications in Industry.

3. When Foam Cups Outperform Rubber

3.1 Rough Cartons and Recycled Paper Surfaces

In packaging and e-commerce logistics, recycled cartons often have deep texture and porous fiber layers. Solid rubber cups leak instantly on these surfaces, whereas foam compresses into the texture and forms a micro-conformity seal. This directly improves cycle stability and reduces drop-offs.

More details on this surface type can be found in

Foam Suction Cups for Rough and Oily Surfaces.

3.2 Textured Plastics and Molded Parts

Grooves, embossed textures and ribbed patterns are common in molded plastic components. Foam compensates for these irregularities, creating a more secure seal than rubber. This makes foam ideal for decorative plastics, appliance housings and consumer goods.

3.3 Dusty or Slightly Contaminated Surfaces

Rubber cups struggle when dust, sawdust, paper fibers or machining debris interrupt the seal. Foam cups tolerate small particle contamination better because the open-cell structure absorbs minor debris without collapsing sealing performance.

3.4 Delicate or High-Gloss Surfaces

For coated electronics, glossy housings or decorative finishes, foam provides a softer and more uniform contact surface. Silicone foam is especially effective for preventing micro-scratches and surface marks.

3.5 Shape or Height Variations

When part dimensions vary slightly—or when surfaces are bowed, curved or warped—foam compensates by compressing into height variations. This improves stability in applications such as MDF handling, uneven wood panels and mixed packaging.

For more technical insights on dealing with uneven or porous surfaces, see

Foam Suction Cups for Rough and Oily Surfaces.

4. When Rubber or Bellows Still Perform Better

4.1 Smooth, Non-Porous Surfaces

For perfectly smooth materials—such as coated glass, polished stainless steel, or glossy plastic—solid rubber suction cups consistently achieve a stronger airtight seal than foam. Rubber simply generates higher ultimate vacuum when surface conditions are ideal. If your operation involves precision lifting of smooth, rigid materials, rubber remains the more reliable choice.

For understanding when diameter and hardness decisions affect sealing stability, you can refer to

How to Select the Right Foam Suction Cups.

4.2 Ultra-Fast Cycle Times

Bellows suction cups are the best option for high-speed pick-and-place systems. Their flexible stems absorb motion and offer fast vertical compensation, making them ideal for robotics, packaging lines, and high-frequency handling. While foam provides superior sealing on irregular surfaces, it cannot match the response speed of bellows cups on smooth parts.

4.3 Environments With High Wear or Abrasion

In extremely abrasive environments—such as handling rough metal edges, sharp plastic gates, or abrasive composite sheets—solid rubber (especially PU rubber) may outlast foam. While PU foam is durable, it can still wear faster than solid compounds when the surface is harsh enough. For more information on wear patterns and lifespan, you can continue with

Foam Suction Cup Life, Maintenance and Cost.

4.4 Very Heavy Loads With Small Contact Area

When the load is heavy but the gripping area is small, solid rubber offers a firmer interface. Foam compresses under weight, which may reduce the sealing margin on small surfaces. In these cases, rubber cups provide a more rigid, stable contact point.

If you need help making this choice based on real load conditions,

How to Select the Right Foam Suction Cups provides rules for load, diameter and safety factor calculations.

5. Material Guide for Foam Suction Cups

5.1 NR (Natural Rubber)

Natural rubber foam provides excellent elasticity and adaptability. It is ideal for handling cartons, printed materials, wood panels and textured plastics. NR foam forms strong micro-conformity seals but is not suitable for oily or high-temperature environments.

For understanding how NR performs under wear and long-term use, see

Foam Suction Cup Life, Maintenance and Cost.

5.2 EPDM

EPDM foam is the most weather-resistant option, offering strong resistance to ozone, UV and moisture. This makes it a reliable choice for environments with humidity, steam, or outdoor operation. EPDM is commonly used in applications involving environmental exposure and in automated systems near water or washing processes.

5.3 NBR

NBR foam is the best choice for oily environments. It resists swelling and maintains sealing performance even when exposed to lubricants, cutting fluids and oily residues. It is widely used in automotive components, machined metal parts and oil-exposed production lines.

5.4 Silicone

Silicone foam is the top performer for delicate surfaces and high-temperature environments. It resists heat, prevents marking, and maintains consistent compression characteristics across a wide temperature range. It is ideal for electronics, coated housings, displays and decorative surfaces.

5.5 PU (Polyurethane)

PU foam delivers the highest abrasion resistance among all foam materials. It withstands repeated scraping, rough textures and high cycle rates, making it the best choice for MDF, rough wood, particle board, abrasive plastics or aggressive packaging lines.

For durability comparisons across these materials,

Foam Suction Cup Life, Maintenance and Cost provides detailed wear analysis.

6. How to Match Material to Environment

6.1 Temperature

For high-temperature applications—such as electronics assembly, curing lines or heated conveyors—silicone foam performs best. It maintains stability when NR or EPDM may soften or degrade. PU also performs well across a wide temperature range for general industrial use.

6.2 Oils and Chemicals

Oil exposure requires NBR foam. It maintains shape and sealing strength even in the presence of cutting fluids and lubrication oils. Silicone and NR may swell in oily environments, reducing performance. For more field examples of handling oily surfaces, you may refer to

Foam Suction Cups for Rough and Oily Surfaces.

6.3 Outdoor Exposure

For surfaces exposed to sunlight, humidity or outdoor environments, EPDM is the preferred option due to its strong resistance to UV, ozone and moisture. It ensures longer life where other materials age prematurely.

6.4 Abrasion and High Load Cycles

When handling materials such as MDF, abrasive plastics or rough composites, PU foam significantly increases service life. Its durability reduces replacement frequency and lowers total operating cost. More insights about lifespan under heavy wear can be found in

Foam Suction Cup Life, Maintenance and Cost.

7. Practical “If X, Choose Y” Guide

7.1 If the surface is rough or porous → Soft or medium NR foam

For corrugated cartons, recycled boxes, MDF, particle board, or textured plastics, soft or medium NR foam provides the best micro-gap sealing. It adapts to inconsistent textures, reducing leakage. For more detailed rough-surface behavior, you can refer to

Foam Suction Cups for Rough and Oily Surfaces.

7.2 If the surface is oily → NBR foam

NBR foam is the correct choice when handling oily machined parts, automotive components or metal surfaces with lubrication. It resists swelling and maintains sealing strength. You can explore practical oily-surface scenarios in

Foam Suction Cups for Rough and Oily Surfaces.

7.3 If the part is delicate → Soft silicone foam

For coated panels, high-gloss housings, displays or decorative items, soft silicone foam eliminates marking and distributes pressure safely. This guidance complements the delicate-surface handling tips described in

How to Select the Right Foam Suction Cups.

7.4 If the application is high-wear → PU foam

For abrasive plastic parts, MDF, sanded boards or rough surfaces, PU foam delivers superior durability. If you want to understand how material choice affects service life, continue with

Foam Suction Cup Life, Maintenance and Cost.

7.5 If the environment is outdoors → EPDM foam

When sunlight, humidity or ozone exposure is present, EPDM foam provides stable long-term performance. Combining this with correct hardness and diameter selection (as described in

How to Select the Right Foam Suction Cups) ensures better sealing reliability.

8. Matching Material and Structure for Real Applications

8.1 Packaging Line Example

In e-commerce or parcel-handling systems, cartons vary widely in porosity and surface texture. A medium-hard NR foam suction cup with a wide diameter significantly improves grip stability. This aligns closely with the industry cases discussed in

Foam Suction Cup Applications in Industry.

8.2 Automotive or Machining Example

When handling oily machined parts or automotive components, NBR foam paired with proper filtration ensures slip-free operation. This is especially relevant if you operate in an environment similar to the oily-surface case studies in

Foam Suction Cups for Rough and Oily Surfaces.

8.3 Electronics Example

Electronics and appliance components often have delicate, high-gloss surfaces. Ultra-soft silicone foam provides safe, clean handling without risk of marks. If you need to size silicone cups correctly for these parts,

How to Select the Right Foam Suction Cups offers practical sizing rules.

8.4 Furniture and Wood Example

Wood panels, MDF and decorative boards present challenges from dust to uneven texture. Medium-density foam offers both dust tolerance and stable sealing performance. For more guidance on these industry surfaces, refer to

Foam Suction Cup Applications in Industry.

9. Conclusion

Foam, rubber, and bellows suction cups each excel under different conditions—and throughout this guide, the pattern is clear: performance is determined by how well material and structure match the real surface, environment, and motion of your application.

Foam suction cups stand out on rough, porous, dusty, uneven, or delicate surfaces, where micro-gap sealing and compliance matter more than achieving a perfect vacuum. Rubber cups remain the best solution for smooth, rigid, non-porous parts, while bellows cups deliver advantages in high-speed systems requiring height compensation. Within foam solutions, material choice—NR, EPDM, NBR, silicone, or PU—further determines resistance to oil, heat, abrasion, weathering, and surface marking.

In practice, reliable gripping comes from evaluating:

- Surface texture and porosity

- Environmental exposure (oil, heat, UV, moisture)

- Load weight and contact area

- Cycle speed and wear expectations

When these factors are aligned correctly, suction cups stop being a weak point—and start becoming a stable, predictable part of the automation system.

If your application involves non-standard surfaces, mixed materials, or demanding operating conditions, customization is often the fastest path to stability and lower total cost.

For tailored material selection, foam structure, hardness, and dimensions, you can visit our product page here:

👉 https://www.kinsoe.com/product/custom-foam-suction-cups/

Selecting the right suction cup once—correctly—will always outperform repeated replacements and troubleshooting later.