Foam vs. Traditional Rubber Suction Cups: Material Options and When to Use Each

Compare suction cups for automation—learn when to use foam, rubber, or bellows based on surface, speed, and wear.

For over 10 years, I’ve been in the trenches of the rubber and plastics industry—first in sales, where I learned all about pricing battles, distribution headaches, and what really keeps customers up at night.

These days, I’ve shifted gears to become a solutions-driven product manager. Cutting through the noise to play “matchmaker” between projects and the perfect materials. Be the translator between technical specs and real-world needs.

You know what I’ve learned? Customers don’t need more suppliers—they need partners who can actually fix things. That’s why I’m here sharing what I know.

Compare suction cups for automation—learn when to use foam, rubber, or bellows based on surface, speed, and wear.

Get precise with foam suction cup sizing, materials, and vacuum tuning—plus tips from real automation applications.

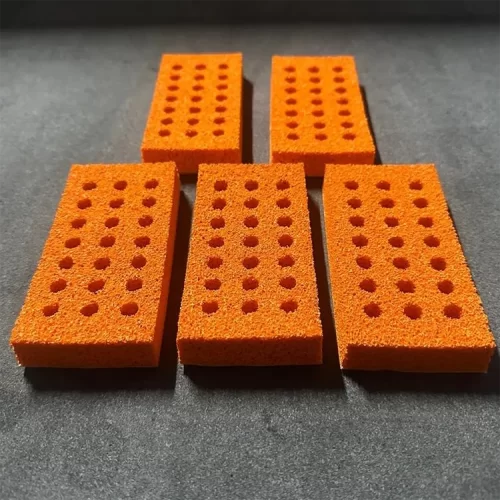

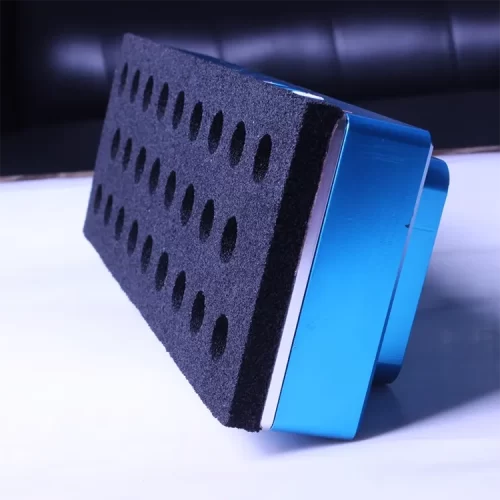

Foam suction cups solve gripping issues on rough, porous, and oily surfaces by boosting vacuum flow and contact area.

Learn the key factors that determine suction cup life—from material to maintenance—and how to reduce cost over time.

Rubber cups not working? Foam suction cups improve grip on porous, dusty, and curved surfaces—here’s how by industry.

A practical troubleshooting guide for foam suction cups—diagnose drop-offs, slow pick-up, surface marking, and vacuum overload, with proven fixes for stable automation.

A practical guide to foam suction cups—how they work, where they outperform rubber cups, and how to select the right size, material, and hardness for reliable automation.

A practical application-focused guide showing how polyurethane foam cylinders are used in machinery, robotics, vehicles, HVAC systems, construction, and energy absorption projects.

A complete guide explaining what polyurethane foam cylinders are, how they’re made, their core properties, and why they’re used in vibration damping, cushioning, insulation, and industrial applications.

A detailed engineer-oriented selection guide covering density ranges, hardness levels, compression behavior, load-bearing requirements, tolerances, lifespan, and design considerations for polyurethane foam cylinders.

A comparison guide evaluating polyurethane foam cylinders against EVA, NBR, silicone, and PE foam, helping engineers and buyers understand performance, damping, cost, and durability differences.

A practical ATCS selection guide: match sponge ball surface type and hardness to fouling mode, set a sensible dosing plan, and monitor KPIs to optimize performance and lifespan.

Share your queries to get professional help.