Introduction

Have you ever wondered how modern sealing strips manage to combine rigidity with flexibility in a single profile? In industrial and automotive applications, sealing strips play a critical role in protecting interiors from dust, water, noise, and vibration. But as design requirements grow more complex, manufacturers like us at KINSOE have turned to advanced production techniques to meet these demands.

One such innovation is co-extrusion—a process that allows multiple materials to be fused into a single, seamless profile. This technology is transforming how sealing solutions are designed and applied, offering both functional and economic advantages.

In this article, I’ll give you a technical yet practical guide to understanding co-extrusion. We’ll explore how it works, why it’s so valuable in sealing strip production, and the challenges and future trends shaping its evolution. Whether you’re a buyer, product manager, or simply curious about advanced rubber engineering, you’ll find insights here that help you make better decisions.

Here’s what you can expect: I’ll break down the core technology, dive into real-world applications, and share best practices from our two decades of experience at KINSOE.

1. What Is Co-Extrusion?

1.1 Definition and Working Principle

Co-extrusion is a manufacturing process that enables two or more materials to be extruded simultaneously through a single die to form a unified profile. This technique allows each material to retain its unique physical properties while being bonded together into one seamless structure.

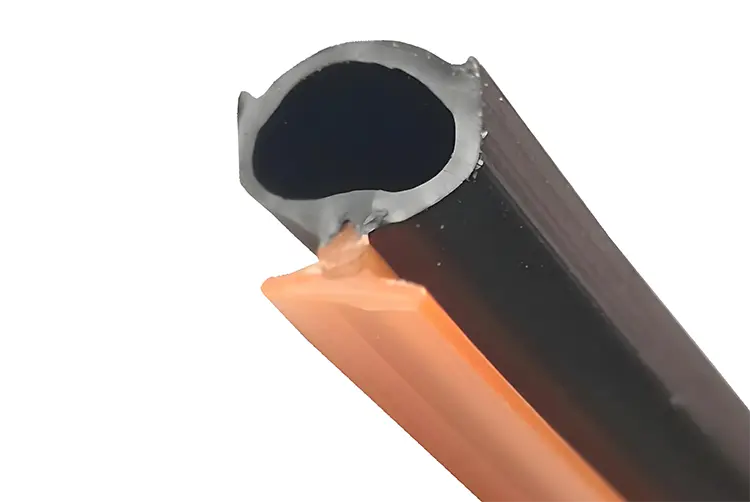

Unlike single-material extrusion, which produces profiles from only one type of rubber or polymer, co-extrusion combines materials such as solid EPDM for rigidity and sponge EPDM for flexibility in a single run. The result is a composite sealing strip with tailored characteristics, such as a firm base for mounting and a soft bulb for effective sealing.

The process involves multiple extruders feeding into a specially designed die, where their flows converge and form the desired cross-sectional shape. Precise control of temperature, pressure, and flow rates ensures proper bonding and consistent dimensions.

Diagram suggestion: A simple illustration showing two extruders feeding different materials into a co-extrusion die, merging into a single sealing strip profile.

This seamless integration not only improves functionality but also enhances the aesthetic quality of the final product by eliminating the need for adhesives or mechanical joining.

1.2 Why Co-Extrusion Is Used in Sealing Strips

So why has co-extrusion become a game-changer in sealing strip manufacturing? The answer lies in its ability to combine different material properties within a single profile, which traditional extrusion or assembly methods can’t achieve as efficiently.

For instance, a co-extruded car door seal might feature:

- A rigid EPDM base to ensure strong gripping on the metal flange.

- A soft sponge bulb to provide excellent compression and sealing against water, air, and noise.

This eliminates the need for secondary processes like bonding or mechanical fasteners, streamlining production and improving long-term durability.

Moreover, co-extrusion helps:

- Reduce production costs by minimizing assembly steps.

- Enhance design flexibility, allowing for more complex cross-sections.

- Improve product performance, with each material optimized for its functional role.

By leveraging this technology, we at KINSOE can deliver custom sealing solutions that meet demanding industrial and automotive standards while keeping production efficient and cost-effective.

2. Co-Extruded Sealing Strips: Materials and Structures

2.1 Common Materials

Choosing the right materials is critical in co-extrusion because each layer serves a distinct purpose in the final sealing strip. At KINSOE, we commonly work with:

- EPDM (Ethylene Propylene Diene Monomer): Available in both solid and sponge forms, EPDM is valued for its excellent weather, ozone, and temperature resistance. It’s ideal for outdoor automotive and industrial applications.

- TPE (Thermoplastic Elastomer): Offers the flexibility of rubber with the processability of plastics, making it a popular choice for dual-material profiles.

- PVC (Polyvinyl Chloride): Often used for rigid components due to its cost efficiency and moderate chemical resistance.

- Silicone: Chosen for high-temperature environments or applications requiring food-grade compliance.

When designing co-extruded strips, material compatibility is paramount. Improper pairing can lead to poor adhesion, thermal mismatch, or premature failure. To address this, we use tie layers or adhesion promoters to ensure a strong bond between layers.

Key insight: Multi-material co-extrusion isn’t just about combining any two materials—it’s about engineering them to work together seamlessly under real-world conditions.

2.2 Typical Composite Structures

Co-extruded sealing strips come in various composite structures, each designed to meet specific functional requirements. The most common configurations include:

- Solid + Sponge: Using the same base material (like EPDM) but with different densities. The solid part provides structural support, while the sponge section offers superior compressibility for effective sealing.

- Dual-Material Profiles: Combining two distinct materials, such as a rigid TPE for gripping strength and a soft EPDM or PVC for flexibility and sealing.

- Multi-Hardness Profiles: Achieving zones of varied hardness within the same material to optimize different parts of the strip for grip, sealing, or cushioning.

Diagram suggestion: Cross-sectional views showing

- a solid base with a sponge bulb,

- a dual-material profile (rigid + flexible),

- a triple-zone design with hard, medium, and soft segments.

These designs allow manufacturers like KINSOE to deliver sealing strips that perform multiple functions—gripping, sealing, damping vibration, and even aesthetic finishing—all in one streamlined product.

3. Applications in Automotive and Industry

3.1 Automotive Applications

In the automotive sector, co-extruded sealing strips are essential for creating durable and multi-functional seals. Common uses include:

- Car Door Seals: Featuring a rigid EPDM base for secure attachment to the metal flange and a soft sponge bulb that compresses to prevent air and water ingress.

- Window Channel Guides: Providing a smooth, low-friction path for glass movement while offering weather resistance.

- Trunk Seals: Designed to maintain consistent compression and rebound over years of opening and closing cycles.

These applications not only improve the vehicle’s noise, vibration, and harshness (NVH) characteristics but also contribute to energy efficiency by ensuring airtight sealing.

Real-world insight: At KINSOE, we’ve supplied co-extruded automotive seals that meet OEM standards for luxury car brands, where performance and aesthetics are equally critical.

3.2 Industrial Applications

Co-extruded sealing strips aren’t limited to automotive use—they’re equally vital across industrial sectors. Typical applications include:

- HVAC Duct Connectors: Combining a rigid edge for mounting with a flexible sealing surface that accommodates movement and thermal expansion.

- Building Window and Door Seals: Offering superior weather resistance and thermal insulation by integrating soft sealing zones and firm gripping bases.

- Specialized Equipment Enclosures: Providing dust, water, and chemical resistance for sensitive machinery or electronics.

These solutions help industries meet increasingly stringent environmental and performance standards while simplifying installation processes.

Practical benefit: By using co-extruded strips, industrial clients can reduce part counts and assembly time, leading to faster production and lower total costs.

3.3 Case Studies

To illustrate the benefits of co-extrusion, let me share two real-world examples:

Case 1: Automotive Door Seal for Extreme Weather

A European car manufacturer faced issues with water leakage in cold climates. We developed a co-extruded EPDM seal combining:

- A dense EPDM base for strong attachment to the door frame.

- A microcellular sponge bulb for superior compression and recovery, even at sub-zero temperatures.

Result: The redesigned seal reduced warranty claims by 35% within the first year.

Case 2: HVAC Flexible Duct Connector

An HVAC system supplier needed a connector that was easy to install yet could withstand constant vibration. We created a dual-material profile with:

- Rigid PVC edges for bolt-down installation.

- Soft TPE center to absorb vibration and seal air leaks.

Result: Installation time dropped by 20%, and product lifespan increased by 40%.

These cases highlight how co-extrusion isn’t just a manufacturing choice—it’s a strategic design tool to meet demanding application needs.

4. Advantages of Co-Extrusion

4.1 Design Flexibility

One of the most compelling advantages of co-extrusion is its unparalleled design flexibility. With this process, we can engineer sealing strips that integrate multiple material properties into a single, continuous profile.

This allows us to:

- Create complex cross-sections that combine rigid and soft zones for gripping and sealing.

- Embed features like lips, fins, or bulbs without secondary operations.

- Tailor profiles for unique customer requirements, from automotive flanges to industrial equipment enclosures.

Key point: Co-extrusion eliminates the need for adhesives or mechanical fasteners between components, reducing potential failure points and improving long-term reliability.

4.2 Performance Optimization

Co-extruded sealing strips aren’t just about clever designs—they deliver tangible performance improvements. By combining materials with complementary properties, we achieve:

- Enhanced sealing performance: Soft sponge sections conform to irregular surfaces, ensuring airtight and watertight seals.

- Noise and vibration reduction: Integrated flexible zones act as dampers, improving acoustic comfort in vehicles and reducing equipment noise in industrial settings.

- Durability under dynamic conditions: Co-extruded profiles maintain their shape and functionality even under repeated compression, temperature fluctuations, or exposure to chemicals.

This level of performance would be difficult—if not impossible—to achieve with single-material profiles or post-assembly methods.

4.3 Cost Efficiency

Another major advantage of co-extrusion is cost efficiency, both in production and end-use applications.

Here’s how it helps:

- Reduced Assembly Steps: Since multiple materials are combined in a single extrusion run, there’s no need for gluing, welding, or mechanical joining afterward.

- Lower Material Waste: Precise die design and controlled extrusion processes minimize excess material and scrap.

- Streamlined Supply Chain: Customers receive a ready-to-install product, cutting down on secondary processing and inventory costs.

At KINSOE, we’ve seen clients achieve up to 15% cost savings when switching from assembled multi-part seals to our co-extruded solutions—without compromising quality or performance.

5. Challenges in Co-Extrusion

5.1 Material Compatibility Issues

While co-extrusion offers impressive advantages, it also comes with technical challenges. The most critical is material compatibility.

Two different materials may:

- Fail to bond properly, leading to delamination under stress or temperature changes.

- Exhibit differential shrinkage during cooling, creating internal stresses that distort the profile.

- Have mismatched thermal expansion rates, which can cause cracking or warping over time.

To address these issues, manufacturers like KINSOE often use adhesion promoters or tie layers—special intermediate materials designed to improve bonding between incompatible polymers.

Takeaway: Successful co-extrusion depends on careful selection and formulation of materials that work together in both processing and real-world conditions.

5.2 Process Control Difficulties

Precision is everything in co-extrusion. Even slight variations in processing parameters can lead to defects such as:

- Density inconsistencies between solid and sponge layers, resulting in uneven compression or sealing performance.

- Foaming and curing issues in sponge zones, where improper control can create weak spots or surface imperfections.

- Flow imbalances between materials, causing distortion at the interface or die swell that alters the profile’s intended shape.

At KINSOE, we overcome these challenges by using advanced extrusion lines with real-time monitoring for temperature, pressure, and flow rates. Fine-tuning these parameters ensures each layer maintains its integrity and the finished product meets strict dimensional tolerances.

5.3 Tooling and Design Limitations

Another key challenge in co-extrusion lies in tooling and profile design. Because different materials flow at different rates and viscosities, the die must be engineered to accommodate:

- Die swell: The tendency of materials to expand after exiting the die, which can distort cross-sectional dimensions.

- Interface distortion: Uneven convergence zones can lead to surface defects or weak bonding at material boundaries.

- Surface quality issues: Such as streaks or rough textures where materials meet.

To minimize these risks, we at KINSOE rely on 3D CAD simulations during die design. This allows us to predict flow behaviors, balance channel geometries, and ensure smooth transitions between materials—all before actual production begins.

6. Solutions and Best Practices

6.1 Material Formulation Optimization

One of the most effective ways to address co-extrusion challenges is through material formulation optimization. At KINSOE, we carefully select polymers and additives to ensure:

- Strong interlayer adhesion: Using adhesion promoters or tie layers when materials have different chemical natures.

- Consistent curing rates: So that both solid and sponge sections set uniformly without creating internal stresses.

- Thermal compatibility: Matching materials with similar expansion rates to avoid delamination or warping.

By fine-tuning these formulations, we can create co-extruded sealing strips that perform reliably even in demanding applications like automotive doors or industrial enclosures.

6.2 Die Design Considerations

A well-designed die is the backbone of successful co-extrusion. To achieve precise and defect-free profiles, we at KINSOE focus on:

- Flow Channel Balancing: Ensuring both materials reach the convergence zone at the same rate and pressure to avoid distortion.

- Smooth Convergence Zones: Preventing turbulence where materials meet, which can cause weak bonding or surface streaks.

- Thermal Management: Incorporating heating and cooling zones in the die to maintain optimal viscosity for each material.

These design considerations, combined with advanced simulation tools, allow us to produce complex profiles with minimal trial-and-error on the production floor.

6.3 Process Parameter Control

Precision in process parameters is critical for ensuring the quality of co-extruded sealing strips. At KINSOE, we maintain tight control over:

- Temperature: Keeping each material within its ideal processing range to prevent degradation or incomplete curing.

- Pressure: Balancing pressure across all extrusion channels to avoid uneven flow and distortion.

- Extrusion Speed: Adjusting line speeds to synchronize material delivery and prevent interface defects.

We also employ automated monitoring systems to detect variations in real-time. This enables quick corrections, reducing the risk of costly defects and ensuring every meter of extrusion meets stringent quality standards.

6.4 Quality Inspection Techniques

Even with optimized materials and processes, rigorous quality inspection is essential to guarantee performance. At KINSOE, our inspection practices include:

- Cross-Sectional Analysis: Cutting and analyzing samples to verify uniformity, bonding strength, and dimensional accuracy.

- Compression and Rebound Testing: Ensuring the sponge sections provide consistent sealing under repeated compression.

- Surface Defect Checks: Identifying visual flaws such as streaks, voids, or rough textures at material interfaces.

- Adhesion Testing: Confirming that multi-material bonds can withstand thermal cycling and mechanical stresses.

These quality checks help us deliver co-extruded sealing strips that not only meet but exceed the expectations of industrial and automotive clients.

7. Future Trends in Co-Extrusion

Looking ahead, co-extrusion technology is evolving to meet the growing demands for sustainability, performance, and design innovation. Key trends include:

- Lightweight and Eco-Friendly Materials: Development of bio-based elastomers and recyclable polymers for greener sealing solutions.

- Advanced Die Design and Automation: Use of AI-driven simulation tools and smart extrusion lines for greater precision and reduced downtime.

- Multi-Material Recycling: Techniques to recover and reuse co-extruded waste, supporting circular manufacturing models.

At KINSOE, we’re actively investing in these innovations to help our clients stay ahead in industries where sealing solutions are critical for energy efficiency, environmental compliance, and product longevity.

Conclusion

Co-extrusion has transformed the way sealing strips are designed and manufactured, offering unmatched design flexibility, performance optimization, and cost efficiency. From automotive door seals that withstand extreme climates to industrial gaskets that simplify installation, the advantages of this technology are clear.

But achieving these benefits requires more than just machinery—it demands expertise in material science, precision engineering, and process control. That’s where KINSOE stands out. With over 20 years of experience, we provide custom co-extruded solutions that meet the stringent requirements of diverse industries.

If you’re looking for innovative sealing solutions tailored to your application, I encourage you to contact us today. Together, we can engineer a co-extruded profile that delivers performance and value for your project.

(FAQ)

Q1: What is co-extrusion in sealing strips?

Co-extrusion is a process where two or more materials are extruded together to form a single sealing strip. It allows combining rigid and flexible zones in one profile for enhanced performance and design flexibility.

Q2: Why is co-extrusion used in automotive sealing?

Co-extrusion enables car door and window seals to have a rigid base for secure attachment and a soft bulb for effective sealing against noise, water, and dust.

Q3: What materials are used in co-extruded sealing strips?

Common materials include solid and sponge EPDM, TPE, PVC, and silicone. Material selection depends on durability, flexibility, and environmental resistance needs.

Q4: What are the advantages of co-extrusion for industrial applications?

Co-extrusion reduces assembly steps, enhances sealing performance, and allows custom multi-material profiles for HVAC, building, and equipment seals.

Q5: What challenges does co-extrusion solve?

It eliminates adhesives or fasteners, streamlines production, improves sealing under dynamic conditions, and meets demanding OEM standards.