Introduction

When I first started working with rubber materials, I was overwhelmed by how many types of elastomers there were—each with its own trade-offs, specifications, and ideal use cases. Whether you’re designing a new gasket, sourcing tubing, or selecting seals for industrial equipment, choosing the wrong elastomer can mean premature failure, unnecessary costs, or regulatory setbacks.

The reality is, most buyers and even product designers get elastomer selection wrong. I’ve seen people overspecify, picking a high-end material when a basic rubber would do just fine. On the flip side, some cut corners, only to find the seals degrade within weeks due to oil exposure, UV, or temperature swings.

That’s why I created this guide—for product managers, procurement teams, engineers, and curious newcomers who want a reliable reference point when dealing with rubber components. Whether you’re buying from a supplier like Kinsoe or developing your own formulations, understanding the fundamentals of elastomers is the first step toward better product design and smarter sourcing.

Here’s what you’ll learn in this guide:

- What elastomers are and how they behave under stress

- The difference between thermoset and thermoplastic rubbers

- A detailed review of over a dozen common materials

- Comparison tables to help you spot trade-offs at a glance

- Key criteria for choosing the right material

- 4 case studies to help you avoid common mistakes

Let’s start from the basics.

What Is an Elastomer?

At its core, an elastomer is a polymer with viscoelasticity—meaning it behaves both like a viscous fluid and an elastic solid. Think of how a rubber band stretches under force and returns to its original shape when released. That’s elastic recovery, and it’s one of the defining features of elastomers.

From a molecular perspective, elastomers are composed of long polymer chains that are lightly cross-linked. These cross-links act like springs, allowing the material to deform under stress and then snap back. The amount and type of cross-linking determines the final properties: hardness, flexibility, thermal stability, and more.

“Elastomers are the reason your car tires grip the road, your blender doesn’t leak, and your smartwatch feels soft but durable on your wrist.”

But not all elastomers are created equal. In fact, the first major divide you’ll encounter is between two families:

Thermoset vs. Thermoplastic Elastomers

Thermoset Elastomers

Thermosets are cured (vulcanized) rubbers that undergo an irreversible chemical reaction during processing. Once set, they can’t be remelted or reshaped.

- Strengths: Excellent temperature resistance, mechanical strength, and chemical stability.

- Weaknesses: Not recyclable, more complex to mold.

- Examples: Natural rubber, EPDM, NBR, silicone, FKM.

Thermoplastic Elastomers (TPEs)

TPEs are physically cross-linked and can be melted, reshaped, and recycled like plastics. They offer soft-touch feel and flexible processing options.

- Strengths: Recyclable, easy to process, often lighter.

- Weaknesses: Lower temperature and chemical resistance than thermosets.

- Examples: TPE-S (styrenic), TPE-U (polyurethane), TPE-V (vulcanized blends).

Choosing between these two depends on your product’s lifecycle, performance needs, and regulatory constraints. Don’t worry—I’ll break down both categories in depth in the sections ahead.

Thermosetting elastomers

Thermoset Elastomers: In-Depth Material Guide

When it comes to industrial-grade performance, thermoset elastomers are the go-to choice. Their irreversible curing process makes them more resistant to heat, chemicals, and mechanical stress. Below is a breakdown of the most widely used thermoset rubber types, so you can compare their strengths and choose wisely for your application.

1. Natural Rubber (NR)

Natural rubber is the original elastomer, harvested from the latex sap of rubber trees. It’s still widely used today for its exceptional elasticity and low cost, especially in dynamic applications.

- Pros: Excellent tensile strength, flexibility, and rebound resilience. Affordable and easy to process.

- Cons: Poor resistance to ozone, UV, oil, and weathering. Limited chemical compatibility.

- Temperature Range: -50°C to 90°C

- Applications: Tires, vibration mounts, adhesives, shock absorbers.

Use it when: Cost and stretch are more important than chemical or outdoor resistance.

NBR Rubber

2. Styrene-Butadiene Rubber (SBR)

SBR is the most common synthetic rubber and often used as a cost-effective substitute for natural rubber with improved abrasion resistance.

- Pros: Good wear resistance, stable pricing, widely available.

- Cons: Weak against oil, ozone, and heat; requires additives for weather durability.

- Temperature Range: -40°C to 100°C

- Applications: Shoe soles, conveyor belts, brake components, insulation.

Use it when: You need decent mechanical properties at scale—but not in oil or outdoor conditions.

NBR rubber O-ring

3. Nitrile Rubber (NBR)

NBR is the oil- and fuel-resistant workhorse of the rubber world. If your product touches petroleum, this is usually your first stop.

- Pros: Excellent resistance to oil, fuel, and grease; good mechanical strength.

- Cons: Poor ozone and weather resistance without additives.

- Temperature Range: -30°C to 120°C

- Applications: Fuel hoses, O-rings, gaskets, seals for hydraulic and pneumatic systems.

Use it when: Your part faces hydrocarbons, industrial fluids, or regular mechanical stress.

4. Hydrogenated Nitrile Butadiene Rubber (HNBR)

HNBR is a next-generation version of NBR, created by hydrogenating its molecular structure to improve heat and chemical resistance.

- Pros: Outstanding resistance to oil, ozone, aging, and elevated temperatures; higher mechanical strength and abrasion resistance than standard NBR.

- Cons: More expensive; limited flexibility at very low temperatures.

- Temperature Range: -40°C to 150°C

- Applications: Automotive timing belts, fuel system components, industrial seals, and oilfield applications.

Use it when: NBR isn’t tough enough—especially for high-temperature and chemically demanding environments.

5. Butyl Rubber (IIR)

Butyl rubber stands out for its extremely low gas permeability, making it ideal for airtight and vacuum applications.

- Pros: Excellent airtightness, good weather and chemical resistance, high damping capacity.

- Cons: Poor resistance to petroleum oils and low rebound resilience.

- Temperature Range: -55°C to 125°C

- Applications: Tire inner liners, pharmaceutical stoppers, shock mounts, vacuum sealing.

Use it when: You need to seal gases or maintain internal pressure over long periods.

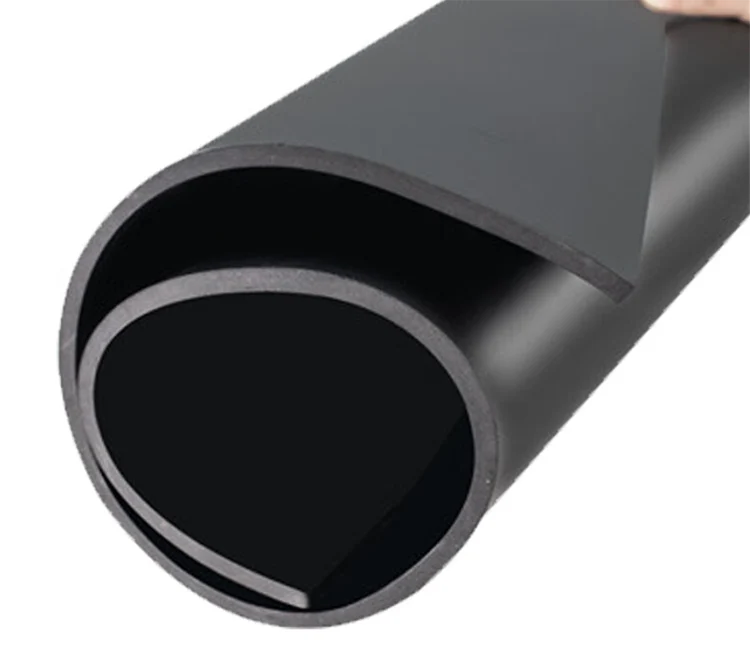

EPDM foam self-adhesive board

6. EPDM (Ethylene Propylene Diene Monomer)

EPDM is a versatile synthetic rubber known for its superior resistance to weathering, ozone, UV, and steam.

- Pros: Great for outdoor and high-moisture environments, excellent dielectric properties.

- Cons: Not compatible with petroleum oils or fuels.

- Temperature Range: -50°C to 150°C

- Applications: Roof membranes, automotive weather seals, HVAC gaskets, electrical insulation.

Use it when: Your product needs long-term exposure to sun, water, or steam without cracking or degradation.

7. Neoprene (Polychloroprene, CR)

Neoprene is a well-rounded general-purpose rubber offering a balanced mix of flame resistance, oil tolerance, and weather durability.

- Pros: Resists moderate oils, ozone, UV, and flame; good mechanical properties and moderate flexibility.

- Cons: Not ideal for strong acids, fuels, or high-temperature demands.

- Temperature Range: -40°C to 120°C

- Applications: Gaskets, wetsuits, HVAC seals, vibration isolators, cable jackets.

Use it when: You need a dependable material with moderate oil and weather resistance—especially for outdoor or industrial settings.

![]()

Silicone sponge tube

8. Silicone Rubber (VMQ)

Silicone rubber is known for its exceptional flexibility in extreme temperatures and excellent biocompatibility, making it ideal for both industrial and consumer-grade applications.

- Pros: Handles extreme heat and cold, physiologically inert, excellent dielectric properties.

- Cons: Low tear and tensile strength, prone to swelling in oils and solvents.

- Temperature Range: -60°C to 230°C

- Applications: Kitchenware, medical tubing, electronics seals, lighting gaskets.

Use it when: You need high temperature or cold resistance, or your product is used in food, medical, or clean environments.

9. Fluorosilicone Rubber (FVMQ)

Fluorosilicone combines the thermal range of silicone with enhanced chemical resistance—especially against fuels and oils.

- Pros: Resists jet fuels, oils, solvents, and extreme temperatures; maintains flexibility in cold conditions.

- Cons: Lower mechanical strength and higher cost than standard silicone.

- Temperature Range: -60°C to 200°C

- Applications: Aerospace fuel systems, turbocharger hoses, high-end automotive seals.

Use it when: Your application requires both wide temperature tolerance and fuel/oil exposure.

10. Fluorocarbon Rubber (FKM / Viton®)

FKM—also known by the trade name Viton®—is a high-performance elastomer prized for its resistance to heat, chemicals, and aggressive fluids.

- Pros: Exceptional resistance to high temperatures, fuels, hydraulic fluids, and most chemicals; low compression set; long service life.

- Cons: Poor low-temperature flexibility; significantly more expensive than general-purpose rubbers.

- Temperature Range: -20°C to 250°C

- Applications: Automotive fuel systems, chemical plant equipment, oil and gas seals, aerospace components.

Use it when: You’re dealing with hot, corrosive, or chemically aggressive environments and need long-term durability.

FFKM rubber O-ring

11. Perfluoroelastomer (FFKM)

FFKM is the elite of all elastomers—engineered to survive the most extreme chemical and thermal conditions imaginable.

- Pros: Nearly universal chemical resistance; withstands the highest temperatures of any rubber; excellent sealing reliability under harsh conditions.

- Cons: Extremely expensive; limited mechanical strength.

- Temperature Range: -15°C to 327°C

- Applications: Semiconductor manufacturing, pharmaceutical processing, aerospace propulsion, ultra-clean or ultra-aggressive chemical systems.

Use it when: Failure is not an option—especially in mission-critical environments like cleanrooms, high-purity chemical transfer, or deep-space technology.

Thermoplastic elastomers

Thermoplastic Elastomers (TPEs): In-Depth Material Guide

While thermoset rubbers dominate in extreme industrial conditions, thermoplastic elastomers (TPEs) offer unique benefits: they’re lighter, recyclable, easier to process, and available in soft-touch grades. TPEs are perfect for consumer goods, flexible parts, and quick prototyping. Here’s a breakdown of the six major TPE types you need to know:

1. TPE-S (Styrenic Block Copolymers)

TPE-S is the most commonly used soft plastic elastomer. It’s formed from block copolymers like SBS and SEBS that give a rubber-like feel with excellent elasticity and touch.

- Pros: Soft, skin-safe, easily colored, recyclable, great for overmolding on hard plastics.

- Cons: Limited thermal resistance, not suitable for chemically aggressive environments.

- Temperature Range: -30°C to 70°C

- Applications: Toothbrush grips, toys, wearable bands, packaging.

Use it when: A soft-touch, flexible, low-cost solution is needed—especially in consumer-facing products.

2. TPE-O (Olefin-based Elastomers)

TPE-O blends polyolefins (like polypropylene) with elastomeric phases to deliver a low-density, weather-resistant rubber.

- Pros: Lightweight, good fatigue resistance, UV stable, halogen-free.

- Cons: Lower elasticity and recovery than other TPEs; weak oil resistance.

- Temperature Range: -60°C to 100°C

- Applications: Automotive trims, interior panels, household appliance seals.

Use it when: You want a durable, light, and weather-tolerant elastomer for structural or decorative parts.

3. TPE-U (Polyurethane-based)

TPE-U, or TPU (thermoplastic polyurethane), is known for its excellent toughness, abrasion resistance, and elasticity. It bridges the gap between rubber flexibility and plastic durability.

- Pros: High tensile strength, superior wear and cut resistance, oil and grease resistant, good transparency options.

- Cons: Sensitive to hydrolysis and UV unless stabilized; more difficult to process than other TPEs.

- Temperature Range: -40°C to 120°C

- Applications: Industrial wheels, protective cases, cable sheathing, sporting goods.

Use it when: Your application needs rugged durability, especially in dynamic, high-friction environments.

4. TPE-E (Polyester-based)

TPE-E (also called COPE or thermoplastic polyester elastomer) delivers spring-like resilience and strong resistance to heat and chemicals.

- Pros: Excellent mechanical strength, good dimensional stability, long flex life, resists oils and fuels.

- Cons: Costlier than TPE-S or TPE-O; not as soft; less flexible at cold temperatures.

- Temperature Range: -50°C to 150°C

- Applications: Conveyor belts, precision gears, clips, automotive underhood components.

Use it when: Your product needs elastic strength combined with thermal and chemical stability—especially in engineering-grade applications.

5. TPE-V (TPV: Vulcanized Rubber + PP Blend)

TPE-V, or thermoplastic vulcanizate, is a blend of dynamically vulcanized rubber particles (usually EPDM) within a polypropylene matrix—combining true rubber performance with thermoplastic processability.

- Pros: High elasticity, excellent aging and weather resistance, good oil tolerance, can replace EPDM in many cases.

- Cons: More expensive than basic TPEs; heavier than TPE-O or TPE-S.

- Temperature Range: -60°C to 135°C

- Applications: Automotive seals, bellows, electrical enclosures, appliance gaskets.

Use it when: You want near-EPDM performance but need injection molding and recyclability benefits.

PEBA plastic pellets

6. TPE-A (Polyamide-based, e.g., PEBA)

TPE-A is based on polyamide chemistry (like PEBA) and offers a premium feel, outstanding low-temperature flexibility, and excellent energy return.

- Pros: Maintains flexibility in sub-zero temperatures, strong rebound, good chemical resistance, luxurious surface finish.

- Cons: Expensive; may not be suitable for mass-market applications.

- Temperature Range: -40°C to 120°C

- Applications: Ski boots, performance sportswear, medical devices, luxury consumer electronics.

Use it when: You’re designing premium products that require high elasticity, cold resistance, and tactile excellence.

Thermoset Elastomer Comparison Table

Here’s a side-by-side breakdown to help you quickly compare the most common thermoset rubbers. Use this table when evaluating trade-offs in performance, cost, and operating conditions.

| Material | Strengths | Weaknesses | Temp Range | Applications | Cost Level |

|---|---|---|---|---|---|

| NR | Elastic, low cost | Poor weather resistance | -50~90°C | Tires, mounts | $ |

| SBR | Abrasion resistance | Poor chemical resistance | -40~100°C | Conveyor belts, soles | $ |

| NBR | Oil/fuel resistant | Poor ozone resistance | -30~120°C | Fuel systems, seals | $$ |

| HNBR | Oil + heat + ozone resistant | Higher cost | -40~150°C | Automotive seals | $$$ |

| IIR | Low gas permeability | Poor oil resistance | -55~125°C | Tire inner liners | $$ |

| EPDM | UV/ozone/waterproof | Not oil resistant | -50~150°C | Roof seals, HVAC | $$ |

| CR (Neoprene) | Flame, oil, ozone resistant | Moderate heat resistance | -40~120°C | Gaskets, wetsuits | $$ |

| VMQ (Silicone) | Extreme heat/cold, inert | Low tear strength | -60~230°C | Food, electronics | $$$ |

| FVMQ | Fuel + heat + cold resistant | Lower mechanical strength | -60~200°C | Aerospace, fuel seals | $$$$ |

| FKM | Heat + chemical resistance | Expensive, poor cold flex | -20~250°C | Automotive, chemical plants | $$$$ |

| FFKM | Ultimate chem/temp resistance | Extremely expensive | -15~327°C | Semiconductor, pharma | $$$$$ |

Pro tip: Start by narrowing your selection by temperature and chemical resistance. Then weigh performance needs against your project’s budget.

Thermoplastic Elastomer (TPE) Comparison Table

Use this table to compare the six major TPE types by their core characteristics, cost, and application fit. It’s a quick reference for designers and buyers trying to balance performance, flexibility, and manufacturability.

| Material | Strengths | Weaknesses | Temp Range | Applications | Cost Level |

|---|---|---|---|---|---|

| TPE-S | Soft-touch, recyclable | Heat-limited | -30~70°C | Grips, toys, consumer goods | $ |

| TPE-O | Lightweight, weatherproof | Less elastic | -60~100°C | Interior trims, basic seals | $ |

| TPE-U | Tough, oil resistant | Sensitive to hydrolysis | -40~120°C | Wheels, cable jackets, sports gear | $$ |

| TPE-E | Spring-like, heat resistant | Limited chemical resistance | -50~150°C | Gears, clips, moving parts | $$ |

| TPE-V | Rubber-like, durable | Costlier than basic TPEs | -60~135°C | Seals, bellows, industrial gaskets | $$$ |

| TPE-A | Cold-flexible, premium feel | Expensive | -40~120°C | Medical, sports, luxury products | $$$$ |

Remember:

- If recyclability and softness are key, TPE-S is your go-to.

- For rugged and weather-tough parts, TPE-V or TPE-U might serve better.

- TPE-A is best reserved for premium-grade applications where aesthetics and performance both matter.

5 Key Factors to Consider When Choosing Elastomers

Choosing the right rubber isn’t just about ticking boxes on a datasheet. It’s about aligning material behavior with your product environment, lifespan, and performance expectations. Here are the five most important factors I evaluate when helping clients select elastomers:

1. Working Temperature

Is your product sitting in a refrigerated lab, or mounted under a car hood at 200°C?

- Low-temp flexibility is critical for outdoor or cold-climate applications (e.g., EPDM, TPE-A).

- High-temp endurance matters for engine bays, ovens, or electronics (e.g., FKM, silicone, FFKM).

Rule of thumb: Never push a material to its upper temperature limit—leave a 10–15°C safety margin.

2. Chemical Exposure

What will the elastomer come into contact with—fuel, grease, acids, detergents, or just water?

- NBR and FKM are great for oils and fuels.

- EPDM handles steam and water well, but fails with oil.

- FFKM is the nuclear option when almost nothing else works.

Pro tip: Always cross-check chemical resistance charts from material suppliers. One solvent can ruin everything.

3. Movement or Compression

Is the rubber sealing a static joint or flexing with every use?

- Static seals tolerate harder, less flexible rubbers.

- Dynamic seals require fatigue resistance, low compression set, and elasticity (e.g., silicone, TPE-E, NR).

Key metric: Compression set—how much the material loses shape over time under load.

4. Regulatory Requirements

Will the product touch food? Be implanted in the body? Used in electrical devices?

- Look for FDA, UL 94, RoHS, REACH, NSF, ISO 10993 as needed.

- Silicone and FKM often meet biocompatibility or food-grade standards.

- For electrical insulation, EPDM or silicone are preferred.

Don’t skip certifications—they’re often legally required for sale in specific industries.

5. Cost vs. Performance

Don’t overspec. Don’t underspec. Balance is everything.

- Too cheap, and you risk failures, leaks, or customer complaints.

- Too premium, and you burn through your margin without added value.

Smart choice: Use EPDM instead of FKM for outdoor applications where oil resistance isn’t needed. Or downgrade from FFKM to HNBR when full chemical resistance isn’t required.

“The best elastomer is the one that meets your needs—no more, no less.”

Case Studies

Sometimes, the best way to understand elastomer selection is to walk through real-world decision points. These examples are based on actual conversations I’ve had with product engineers and sourcing teams, and they illustrate how material properties directly affect performance, cost, and long-term reliability.

EPDM vs. NBR for Weather Sealing

A client needed rubber seals for a generator housing used outdoors. The original design called for NBR due to its oil resistance—but field failures occurred because the seals cracked after prolonged sun exposure.

- Problem: NBR doesn’t resist ozone or UV well.

- Solution: Swapped to EPDM, which resists weather and water but isn’t suitable for oil.

Takeaway: Always consider environmental exposure first—even before chemical compatibility.

Neoprene vs. Silicone in Wearable Products

One R&D team working on a fitness tracker used Neoprene for wrist contact because it was cheaper and durable. But users reported skin irritation and discomfort over time.

- Problem: Neoprene can leach additives and doesn’t breathe well.

- Solution: Replaced with medical-grade silicone, which is inert, soft, and biocompatible.

Takeaway: For skin contact and comfort, always prioritize material safety and softness—even at a higher cost.

![]()

Silicone watch strap

When HNBR Is Worth the Upgrade from Standard NBR

An automotive supplier was seeing premature cracking in NBR seals exposed to both heat and ozone under the hood.

- Problem: Standard NBR couldn’t handle the combined thermal and oxidative stress.

- Solution: Upgraded to HNBR, extending service life by over 3x.

Takeaway: If you’re combining heat, oil, and outdoor use, HNBR pays for itself quickly.

Choosing Between TPE-V and TPE-U in Automotive Parts

A parts buyer had to choose between TPE-V and TPE-U for underbody cable boots. Both met flexibility and oil resistance specs.

- Consideration: TPE-U offered higher abrasion resistance, but TPE-V had better long-term UV and ozone stability.

- Final choice: TPE-V, due to the exposed location and long outdoor lifespan.

Takeaway: Sometimes both options are viable—your environment and longevity goals tip the scale.

Summary

Navigating the world of elastomer materials can feel overwhelming—especially with the dozens of rubber types, acronyms, and technical trade-offs. But by understanding how performance factors align with real-world use, you can make confident, cost-effective choices that improve your product’s reliability and user satisfaction.

Here’s what I want you to remember:

- Start with the environment—temperature, chemicals, movement, and exposure dictate 80% of material success.

- Thermosets (like EPDM, NBR, and FKM) are best for high-performance, permanent-use cases.

- Thermoplastics (like TPE-V or TPE-U) offer recyclability, ease of molding, and are ideal for consumer goods and modular parts.

- Don’t assume “premium” means better—choose the material that fits your specific application needs.

Whether you’re a sourcing manager evaluating a supplier, a designer testing prototypes, or simply new to elastomers, making the right material choice means fewer failures, smoother production, and happier end users.

Ready to find the right rubber for your project?

At Kinsoe, we specialize in custom rubber solutions—from extrusion-grade EPDM to injection-molded silicone and advanced thermoplastics. With 20+ years of experience and a full in-house lab, we help product teams around the world develop high-performance seals, hoses, and gaskets tailored to real-life demands.

Get in touch today for expert support in selecting and customizing elastomers for your application.

References: