Introduction

Have you ever ordered an EPDM sealing strip, only to find it’s the wrong shape, too soft, or impossible to install? You’re not alone. With dozens of profiles, materials, and mounting styles to choose from, even experienced engineers or buyers can feel overwhelmed. Whether you’re trying to stop a cold draft from a window, reduce vibration in a car door, or keep moisture out of an outdoor electrical box, one wrong choice could lead to poor performance—or even product failure.

EPDM sealing strips are some of the most versatile and widely used sealing materials in the world. Thanks to their excellent weather resistance, flexibility, and durability, they’re found everywhere from car doors to HVAC systems. But not every EPDM strip works for every application.

In this article, I’ll break down the major types of EPDM sealing strips, explain how to choose the right one step by step, and give you real-world examples to make the decision-making process simpler and more reliable. If you’re a DIY homeowner, a car repair enthusiast, a product designer, or part of an industrial procurement team, this guide is for you.

1. What Is EPDM Rubber and Why It’s Ideal for Sealing

1.1 Core Properties

EPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber compound engineered for outdoor and sealing performance. What makes it so effective? It all comes down to its chemical resistance and flexibility.

- Weather and UV resistance: EPDM doesn’t crack or degrade easily under sunlight, ozone, or extreme outdoor exposure.

- Low-temperature flexibility: It stays elastic even in freezing conditions down to –40°C.

- Non-toxic and aging-resistant: It’s safe for use in HVAC and household applications and maintains its integrity over time.

- Working temperature range: From –40°C to +120°C, making it suitable for most climate zones and environments.

However, EPDM is not suitable for contact with oils, fuels, or petroleum-based solvents. If your application involves hydrocarbons, consider using NBR (Nitrile) or FKM (Viton) instead.

“EPDM is the gold standard for weather sealing, but not for oil sealing.”

1.2 Where It’s Commonly Used

Thanks to its robust profile, EPDM is used across industries and everyday products. You’ve likely encountered it in one of these forms:

- Automotive: Door, trunk, hood seals, and vibration damping strips

- Construction: Window and door weatherstripping in buildings

- Bathroom products: Shower glass door seals and anti-leak edges

- Electrical enclosures: To protect against dust, water, and humidity

- HVAC systems: Duct connections, vibration joints, and insulating seals

At KINSOE, we’ve supplied custom EPDM strips to clients in automotive assembly lines, prefab housing units, and even food equipment manufacturers—each requiring a slightly different profile and hardness.

2. Types of EPDM Sealing Strips

EPDM sealing strips are not one-size-fits-all. They come in a variety of shapes, internal structures, and installation methods. Understanding these differences is critical for making the right choice.

2.1 By Shape (Profile)

Each shape is designed for a specific sealing challenge. Here are the most common:

- D-Shape: Semi-circular cross-section. Excellent for compressive sealing on flat surfaces like doors and cabinets.

- P-Shape: Offers both cushioning and sealing. Often used on car doors for noise and vibration control.

- E-Shape: Combines multiple contact points. Great for water sealing in windows and cabinets.

- U-Shape / Edge Trim: Slides onto sharp edges like glass or metal. Often used for edge protection and sealing.

- O-Ring Cord: Circular cord cut to length for custom gasket applications.

- H-Shape: Designed to join two panels, such as glass partitions.

- Custom Profiles: At KINSOE, we produce tailored designs using 3D CAD and extrusion tooling based on customer specs.

“The shape of your EPDM strip should match both your sealing surface and the compression force available.”

2.2 By Material Structure

Not all EPDM is created equal. The internal structure determines its compression and resilience:

- Solid EPDM: Dense and durable. Best for applications requiring shape retention and structural integrity.

- Sponge EPDM (foam): Softer, compressible, and great for sealing uneven or irregular gaps.

- Dual Durometer: Combines a rigid base with a soft sealing bulb. Offers both secure mounting and effective sealing.

2.3 By Mounting Method

How you install the strip impacts both performance and ease of use:

- Self-adhesive: Comes with a peel-and-stick backing. Perfect for quick installs on clean, smooth surfaces.

- Push-on / Edge grip: Friction-based installation. Ideal for sealing around metal or plastic edges.

- Clip-on with metal insert: Reinforced with embedded steel clips for strong grip on automotive or industrial edges.

- Groove-inserted seals: Designed to fit into a molded groove. Common in window frames and enclosures.

Selecting the right combination of profile, structure, and mounting style ensures reliable sealing and long-term performance.

3. How to Choose the Right EPDM Sealing Strip

Choosing the right EPDM strip isn’t about picking the thickest or the cheapest—it’s about fit, function, and environment. Here’s a step-by-step approach I use when helping clients choose at KINSOE.

3.1 Step 1: Define Your Environment

- Indoor or Outdoor? Outdoor use demands UV and weather resistance—EPDM is ideal here.

- Temperature extremes? Make sure the range (–40°C to +120°C) fits.

- Oil or fuel exposure? Avoid EPDM. Use NBR or FKM instead for those conditions.

“If your application touches oil, EPDM is not the right choice—go nitrile instead.”

3.2 Step 2: Identify the Application Use Case

Here’s a quick reference based on common problems:

| Problem | Recommended EPDM Strip |

|---|---|

| Cold air leaking from door | D-shape adhesive-backed foam |

| Car door vibration noise | P-shape solid strip |

| Sharp metal edge on glass | U-shape edge trim |

| Cabinet water leakage | E-shape sponge strip |

| Joining glass panels | H-shape or custom profile |

3.3 Step 3: Choose the Right Profile

Match the seal to the surface type and compression gap:

- Flat door = D-shape

- Panel joints = H-shape

- Edge coverage = U-shape

Make sure the seal compresses enough to close the gap, but not so much that it deforms permanently.

3.4 Step 4: Pick the Right Structure (Solid vs. Sponge)

| Feature | Solid EPDM | Sponge EPDM |

|---|---|---|

| Durability | High | Medium |

| Compression | Low | High |

| Fit on uneven surfaces | Poor | Excellent |

| Best for | Structural sealing | Gap filling/sealing |

Sponge is more forgiving. Solid lasts longer under load. Dual-durometer gives you both.

3.5 Step 5: Select Mounting Style

- Peel-and-stick: Fast install, ideal for home and light-duty use

- Push-on / Clip-on: Firm hold for vehicle and industrial edges

- Groove-inserted: Sleek and secure, but needs a compatible frame

Choose based on your installation tools, surface, and how often you may need to replace the strip.

3.6 Step 6: Check the Durometer (Hardness)

Shore A hardness determines feel and compression:

- 30–40 Shore A: Soft, great for delicate seals

- 60–70 Shore A: Standard for most door and window applications

- 80+ Shore A: Rigid, for structural or load-bearing contact

Tip: If you’re sealing a metal door with minimal flex, go harder. For an uneven plastic edge, go softer.

4. Case Examples

To make this guide more practical, here are four real-world scenarios I’ve personally helped clients solve using the right EPDM sealing strip. These examples demonstrate how matching profile, structure, and installation method leads to better performance and customer satisfaction.

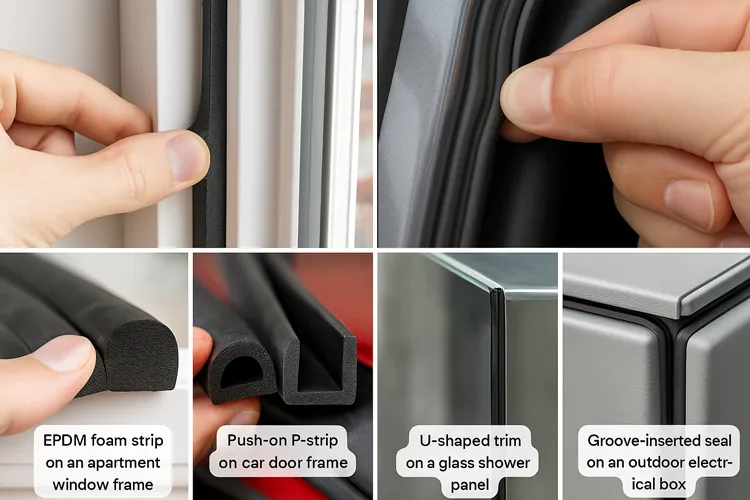

Case 1: Drafty Apartment Window Fix

A homeowner contacted us frustrated about cold air leaking through the gaps in his apartment’s aluminum sliding windows. After reviewing photos and measuring the gap (~3 mm), we recommended a D-shape EPDM foam strip with self-adhesive backing.

- Why it worked: The D-shape provided consistent compression, and the foam structure accommodated uneven window gaps.

- Result: Improved thermal insulation and reduced heating costs in winter.

Case 2: Used Car Trunk Leak

A car repair shop faced recurring customer complaints about rainwater leaking into the trunk of a used sedan. The original seal had hardened and shrunk.

- Solution: A P-shape solid EPDM strip, push-on style, selected for durability and vibration resistance.

- Result: Watertight seal restored, with no return issues after three months.

Case 3: DIY Shower Glass Edge Protection

A DIY enthusiast building a custom walk-in shower needed a seal to prevent water from seeping between glass panels and tile edges.

- Recommendation: A U-shape edge trim with sponge core, easy to press onto the glass panel without tools.

- Result: Sleek finish and effective splash control, installed in under 10 minutes.

Case 4: Garage Electrical Box Weather Seal

An industrial buyer needed to protect outdoor electrical enclosures installed on a new warehouse exterior wall. The goal was to prevent dust and rain intrusion.

- Our approach: A groove-inserted solid EPDM seal, cut to length, with medium hardness for consistent pressure sealing.

- Outcome: Passed IP65 water ingress testing with zero modification to the original box design.

“The best sealing performance often comes from selecting the simplest profile that fits correctly—nothing more, nothing less.”

5. Frequently Asked Questions (FAQs from SERP and Forums)

Over the years, I’ve answered hundreds of customer questions about EPDM sealing strips. Here are the top ones people ask—answered clearly and practically.

Q1. Can EPDM withstand sun exposure?

Yes. EPDM is one of the most UV-resistant rubber types available. It resists cracking, chalking, and degradation under long-term sun and ozone exposure, making it ideal for outdoor applications like windows, solar panel mounts, and RV doors.

Q2. Is EPDM rubber waterproof?

Absolutely. EPDM has excellent water resistance and is widely used for weatherproofing applications such as garage doors, car trunks, and window seals. However, make sure the installation surface is clean and dry to ensure a tight fit or proper adhesive bonding.

Q3. How do I know what size EPDM strip I need?

Measure the gap you want to seal and the surface area available for mounting. Then match it with the uncompressed height of the EPDM strip. Most foam profiles compress 25–50% under pressure. It’s best to test with a sample strip when available.

“Always measure both the gap and the compression range—not just one or the other.”

Q4. Can I install it myself?

Yes. Many EPDM sealing strips—especially self-adhesive and push-on types—are designed for easy DIY installation. Just clean the surface, peel, and stick. For industrial installs, clip-on or groove-mounted styles may require basic tools or a jig.

Q5. What if I need an oil-resistant rubber strip?

EPDM is not compatible with petroleum oils or fuels. For oil resistance, use NBR (nitrile rubber) or FKM (Viton) instead. These materials are specifically designed to resist swelling, degradation, and hardening in contact with oils and solvents.

Conclusion

Choosing the right EPDM sealing strip doesn’t need to be overwhelming. Once you clearly define the environment, understand the application, and match it with the right profile, structure, and installation method, you’ll drastically improve the performance and longevity of your seal.

Here’s a quick recap of what we’ve covered:

- EPDM rubber offers excellent weather resistance, flexibility, and UV protection—but it’s not oil-compatible.

- You can choose from various shapes (D, P, U, etc.), structures (solid, sponge, dual), and mounting styles (self-adhesive, clip-on, groove-inserted).

- The key to success is in the details: measure your gaps, consider the compression needed, and match the durometer to your use case.

At KINSOE, we help customers worldwide—from DIYers sealing windows to engineers designing next-gen enclosures—find the exact strip they need. Don’t hesitate to ask for samples or custom profiles if the standard shapes don’t fit your application.

“The right seal doesn’t just block air or water—it protects your design, improves efficiency, and reduces long-term cost.”

References: