1. Introduction

1.1 Why Rubber Seals Matter

When I first started working with extruded rubber seals, I was surprised by how underestimated their role often is. Yet, a single sealing failure can bring an entire system to its knees.

Take construction projects for example—poor-quality window or curtain wall seals can lead to water ingress, mold growth, and expensive remediation. In automotive design, a faulty door seal might seem minor until you hear wind noise howling down the highway, or worse, experience water leaks that damage electronics. These aren’t rare incidents—they’re everyday consequences of sealing oversight.

In essence, extruded rubber seals play a silent but crucial role in maintaining environmental integrity, mechanical performance, and long-term reliability across industries.

1.2 Why Extrusion?

Now, why choose extrusion over other processing methods like molding or injection? The answer lies in its unique advantages.

Extrusion allows for continuous production of complex cross-sectional profiles—something not easily achieved with molding. That means I can produce long, seamless seals with varied geometries efficiently, without sacrificing dimensional accuracy. Compared to injection molding, which is better suited for discrete parts, extrusion excels in cost-efficiency and flexibility when producing linear or coiled rubber components.

Whether I need a hollow seal for sound insulation, a dense strip for pressure resistance, or a dual-material profile for hybrid functionality—extrusion gives me that design freedom.

And when I combine it with post-processing like cutting, splicing, or adhesive lamination, I unlock a whole new world of customized sealing solutions.

2. Material Selection: Core Properties and Application Scenarios

2.1 Common Rubber Materials Compared

When choosing the right material for extruded rubber seals, the first question I always ask is: What kind of environment will this seal face? Different materials offer distinct advantages, and selecting the wrong one can lead to early failure, safety issues, or costly recalls.

Here’s how I typically break it down:

- EPDM (Ethylene Propylene Diene Monomer)

EPDM is my go-to for outdoor applications. It offers excellent UV resistance, ozone resistance, and weather durability. That’s why it’s commonly used in building facades, window frames, and automotive door seals. - Silicone Rubber

If temperature extremes are a concern—especially in appliances or electronics—then silicone is the clear winner. It maintains elasticity from -60°C to +200°C, making it ideal for oven seals, lighting enclosures, and medical equipment. - NBR (Nitrile Butadiene Rubber)

For oil resistance, NBR outperforms most general-purpose rubbers. I use it in fuel system components, industrial equipment, and hydraulic seals where contact with lubricants and hydrocarbons is expected. - Neoprene (CR)

Neoprene is the best pick when flame retardancy and moderate chemical resistance are required. You’ll find it in fire doors, marine seals, and HVAC gaskets. - TPE/TPV (Thermoplastic Elastomers/ Vulcanizates)

These modern alternatives are recyclable and allow for co-extrusion with rigid plastics. They’re increasingly favored in eco-conscious designs such as car trims, sliding window seals, and appliance gaskets.

2.2 Modified Materials and Additives

Sometimes the base rubber just isn’t enough. That’s where additives come in.

- UV stabilizers: Prolong service life under sun exposure.

- Abrasion-resistant coatings: Reduce wear in sliding applications.

- Conductive fillers: Provide EMI shielding for electronics.

I’ve used these modifications to create custom solutions—like a conductive silicone strip for LED housings, or a coated EPDM gasket for dynamic door frames in public transport.

2.3 Material Selection Decision Tree

To simplify material choice, I rely on a decision matrix based on four primary factors:

| Condition | Recommended Material |

|---|---|

| Outdoor + UV Exposure | EPDM |

| High Temperature | Silicone |

| Oil/Fuel Contact | NBR |

| Flame Resistance | Neoprene (CR) |

| Recyclability | TPE / TPV |

This structured approach helps me avoid trial-and-error and ensures that every extrusion job starts on the right footing.

3. Structure and Design: How to Match Requirements

3.1 Cross-Section Shape Design

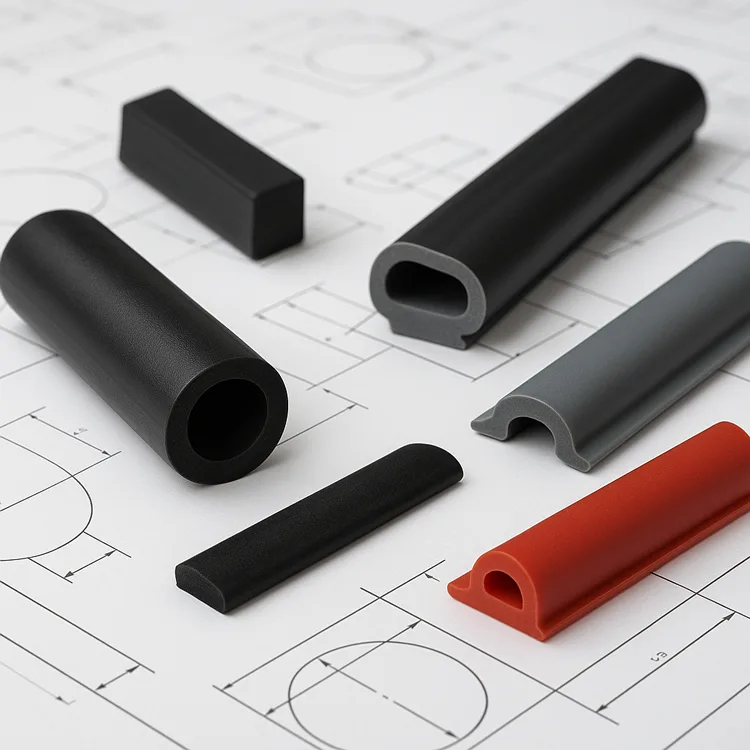

When it comes to extruded rubber seals, shape isn’t just form—it’s function. Over the years, I’ve found that the right cross-sectional design can make or break a seal’s performance.

- Hollow Profiles

These are my preferred choice for vibration damping and sound insulation. Their compressibility allows for energy absorption and sealing flexibility, especially useful in automotive cabins and HVAC ducting. - Solid Profiles

I turn to solid rubber when strength and rebound resilience are crucial. These are ideal for compression seals in static joints, such as building expansion joints or pressure vessel flanges. - Lip or Flange Profiles

These offer dynamic sealing capabilities, conforming to irregular surfaces while maintaining a tight barrier. I often recommend them for sliding windows, refrigeration doors, and automotive glass.

Each geometry serves a purpose. The right design increases sealing reliability, while the wrong one causes leaks, noise, or early wear.

3.2 Key Performance Parameters

Material and shape alone aren’t enough. I always evaluate three critical properties when designing or choosing a seal:

- Compression Set

This tells me how much a rubber will recover after being compressed. A low compression set (ideally <20%) ensures the seal maintains its shape over time, especially in door gaskets and clamps. - Tensile Strength

Especially important in applications where the seal may be stretched or pulled during installation. I look for >7 MPa for robust, high-stress environments. - Hardness (Shore A)

Shore A 40–70 is the sweet spot for most extruded seals. Lower hardness improves flexibility (great for curves), while higher hardness increases stability (ideal for rigid frames).

3.3 Functional Design Add-Ons

Beyond basic sealing, today’s rubber seals need to serve multiple roles. I’ve worked on custom profiles with added features such as:

- Self-adhesive backing: Speeds up installation on doors and windows. Great for DIY or fast production lines.

- Magnetic inserts: Used in refrigerator doors or cleanroom panels where snap-fit sealing is essential.

- Conductive paths: Integrated into silicone to provide EMI shielding in electronics housings.

It’s not just about sealing anymore—a modern extruded rubber profile can be multifunctional, aesthetic, and installation-friendly.

4. In-Depth Industry Applications

One of the most exciting parts of working with extruded rubber seals is seeing how widely and creatively they’re used. From high-rise buildings to EV battery packs, these seals are quietly protecting systems we depend on every day.

4.1 Construction Industry

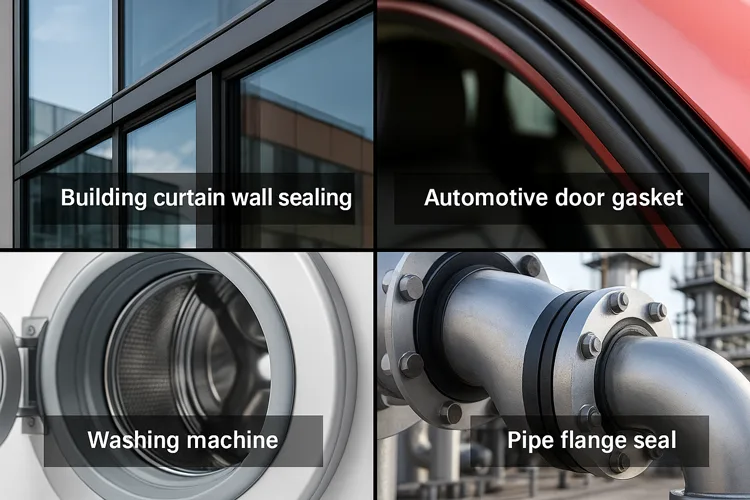

In construction, sealing is about more than weather protection—it’s about longevity and energy efficiency.

- Curtain Wall Joints: I’ve supplied EPDM seals for glazed façades where they prevent water ingress and thermal bridging. Proper profile selection here reduces HVAC load and ensures compliance with building envelope standards.

- Aluminum Door & Window Seals: A good seal must withstand temperature swings, UV exposure, and mechanical wear. In this case, I often recommend co-extruded profiles: a soft bulb for compression and a rigid spine for secure mounting.

4.2 Automotive Industry

The demands in automotive sealing are rapidly evolving, especially with the rise of electric vehicles.

- EV Battery Pack Seals: These must handle coolant exposure, ensure air-tightness, and remain flexible during thermal cycling. For this, I’ve worked on custom silicone or TPV extrusions, incorporating dual-durometer sections for varying compressive force zones.

- Door and Trunk Seals: These combine aesthetic finish with high functionality—blocking noise, dust, and water. I often work with OEMs to tweak the lip geometry or add flocked surfaces for better wear resistance.

4.3 Home Appliances and Electronics

Precision is critical in consumer products. A minor gap can mean leakage, short circuits, or customer complaints.

- Washing Machine Door Gaskets: These seals face constant flexing and moisture. I use mildew-resistant, high-rebound silicone in these applications, often incorporating a textured sealing surface for better grip.

- Enclosure Gaskets (IP Seals): For cabinets and control panels, I recommend sponge rubber or co-extruded dense/sponge hybrids. They compress easily, provide excellent rebound, and help meet IP66/IP67 ratings for water and dust resistance.

4.4 Industrial Sector

In heavy-duty environments, sealing isn’t optional—it’s vital to safety and performance.

- Pipe Flange Seals: I’ve worked with EPDM and NBR extrusions that resist aggressive chemicals and temperature swings, especially in water treatment or chemical plants.

- Chemical Resistance Applications: For pump housings or drum closures, we’ve engineered gaskets using fluoroelastomer-modified rubber, combining extrusion efficiency with precision tolerances and compliance to ASTM D2000.

5. Purchasing Guide: Avoiding Pitfalls and Optimizing Costs

Over the years, I’ve learned that even the best-designed seal can fail if procurement isn’t handled strategically. Whether you’re sourcing for a construction project or a new appliance line, here are the critical factors I consider when selecting and managing extruded rubber seal suppliers.

5.1 Key Points for Supplier Evaluation

Choosing a capable supplier isn’t just about price—it’s about reliability, traceability, and engineering support. Here’s my checklist:

- Certifications: I always look for suppliers with ISO 9001 and ASTM compliance, especially for regulated industries like automotive or electronics.

- Production Capacity: If a supplier can’t commit to consistent lead times, it’s a red flag. I prefer manufacturers with in-house extrusion, cutting, and post-processing to avoid outsourcing delays.

- Customization Ability: For projects with non-standard geometries or special materials (like FDA-grade silicone or flame-retardant TPV), the supplier must offer design support and prototyping.

At Kinsoe, for example, we provide 3D CAD replication and ±0.05mm tolerance precision, which allows our clients to scale from sample to mass production without surprises.

5.2 Cost Optimization Strategies

While quality is non-negotiable, there are ways to make smarter material and design choices without compromising performance.

- Material Substitution: I’ve helped clients replace EPDM with TPV in certain window systems to cut material costs by 10–15%, while maintaining UV resistance and flexibility.

- Simplified Profiles: Reducing the number of lobes, undercuts, or functional zones in the cross-section can improve extrusion stability and reduce tooling costs.

- Co-Extrusion Efficiency: Instead of bonding two parts later, co-extruding hard and soft sections in one pass improves labor efficiency and reduces part failures during assembly.

5.3 Common Issues and How to Fix Them

I’ve encountered many avoidable problems in the field. Here are the top three—and how I typically solve them:

- Stickiness or Aging: Often due to improper material formulation or poor storage. Upgrading to peroxide-cured silicone or adding anti-aging agents can prevent this.

- Installation Failures: Seals falling off? It’s likely the wrong adhesive or substrate prep. I recommend testing multiple adhesive types under actual environmental conditions.

- Dimensional Inconsistency: This usually comes from lack of process control or poor die maintenance. I always advise using laser-based inline inspection systems for critical tolerances.

Ultimately, smart buying isn’t just about cost savings—it’s about long-term reliability and peace of mind.

6. Installation and Maintenance

Even the best-designed and highest-quality rubber seal will underperform if it’s installed incorrectly or poorly maintained. Over time, I’ve realized that installation and upkeep are often overlooked, yet they’re essential to the seal’s lifecycle.

6.1 Installation Methods

Different mounting environments require different approaches. Here are the most common methods I use and where they work best:

- Slot/Channel Fit

This is ideal for architectural and automotive applications where the seal is inserted into an aluminum or plastic groove. It allows for easy replacement and excellent alignment. A slightly oversized profile ensures a snug, vibration-resistant fit. - Pressure-Sensitive Adhesive (PSA) Backing

Popular in doors, windows, and appliances. I often recommend 3M adhesive for its superior durability and temperature resistance. But be careful—surface preparation is everything. Cleaning with isopropyl alcohol and ensuring a dust-free environment is critical for long-term adhesion. - Mechanical Fastening (Screw-In or Clip-On)

Used in high-load or industrial scenarios where mechanical security is needed. For example, large cabinet enclosures or HVAC housings benefit from screw-fixed gaskets that can endure mechanical stress and pressure variation.

Each method has trade-offs in cost, labor, and performance. I always guide my clients to choose the one best aligned with their application conditions.

6.2 Maintenance Tips for Longevity

To extend service life and avoid unexpected failures, here’s the maintenance routine I follow and recommend:

- Regular Surface Cleaning

Use neutral-pH cleaners or isopropyl alcohol. Avoid petroleum-based solvents—they degrade rubber over time. - Inspect Corners and Joints

Most failure points happen at corners or splice joints. A quarterly visual inspection can catch hardening, cracking, or peeling before it becomes a system-level problem. - Environmental Monitoring

In extreme environments (e.g., outdoor façades or chemical plants), I advise annual material testing for tensile strength and compression set to ensure long-term reliability. - Replace on Deformation

If a seal no longer rebounds after compression or shows permanent flattening, it’s time for a replacement—even if no visible cracks exist. Performance is already compromised.

I often tell clients: a $2 seal can protect a $2 million system—if maintained properly.

7. Future Trends and Innovations

The world of extruded rubber seals isn’t static. As industries evolve, so do the performance expectations placed on these “silent protectors.” Here’s what I see on the horizon—and how I’m preparing for it.

7.1 Material Innovation

Demand for sustainable and smarter materials is reshaping the rubber industry.

- Bio-Based Rubber

Instead of petroleum-based compounds, manufacturers are exploring plant-derived alternatives like natural latex hybrids and soybean oil-based rubbers. These are increasingly used in green building certifications and eco-label-compliant products. - Self-Healing Coatings

Imagine a door seal that recovers from small cuts or abrasions on its own. This is no longer science fiction. I’ve seen prototypes with embedded microcapsules that release a bonding agent when ruptured, allowing minor damage to self-repair—ideal for high-wear environments.

7.2 Process Upgrades

On the manufacturing side, automation and precision control are driving huge improvements.

- 3D-Printed Tooling

Traditional die making is slow and costly. Now, I can 3D-print prototype dies in just a few hours, allowing for rapid iteration and design validation. This shortens lead times and reduces development costs. - Inline Laser Inspection

Real-time dimension control during extrusion ensures every meter meets spec. With ±0.05 mm precision, I can confidently promise consistent quality across high-volume production runs. - Smart Extrusion Lines

With IoT integration, machines now self-adjust extrusion parameters based on feedback loops. This minimizes scrap and increases energy efficiency.

7.3 Evolving Industry Demands

As new industries emerge, so do novel sealing challenges:

- Lightweighting for Electric Vehicles (EVs)

Weight reduction is a major design focus. This means thinner seals, co-extruded multi-functional profiles, and tighter dimensional tolerances. I’ve already helped EV clients switch from solid EPDM to hollow TPV profiles, saving over 20% in part weight. - Miniaturization in Electronics

Smaller devices need ultra-precise, low-compression seals that still block dust and moisture. Sponge silicone in micro-extrusions is becoming a staple. - Hybrid Architectural Systems

More buildings now use mixed-material frames (e.g., wood + aluminum). This requires seals with dual compatibility, often using co-extruded profiles that accommodate differential thermal expansion.

If there’s one thing I’ve learned, it’s that the humble rubber seal is evolving fast—and keeping up is key to staying competitive.

8. Conclusion

After years of working with extruded rubber seals across a wide range of industries, one thing has become crystal clear to me: there is no one-size-fits-all solution. The best seal isn’t the most expensive one, nor the most technically advanced—it’s the one that best matches the application’s exact needs.

Whether it’s choosing between EPDM and silicone, deciding on a hollow or solid profile, or selecting the right installation method, successful sealing always starts with understanding the environment, mechanical demands, and cost-performance balance.

From skyscrapers and cleanrooms to electric vehicles and appliances, extruded rubber seals quietly ensure safety, efficiency, and durability. And as industries grow smarter and greener, these components will continue to evolve in step—through better materials, tighter tolerances, and more efficient production.

Here’s my advice: match your sealing solution to your real-world needs—not just technical specs. Over-engineering wastes money. Under-engineering risks failure.

If you’re unsure where to start, I recommend consulting:

- Third-party testing labs (e.g., for Shore A, tensile, or migration tests)

- Standards bodies like ASTM, ISO, and UL for performance criteria

- Reputable manufacturers who offer not just rubber but engineering guidance

At Kinsoe, I work closely with engineers and procurement specialists worldwide to provide customized sealing solutions—from material selection to tooling, prototyping, and delivery. If you’d like to explore options or troubleshoot an issue, don’t hesitate to reach out.

References: