Introduction

When it comes to high-performance sealing materials, two names often come up: Fluororubber (FKM) and Perfluoroether Rubber (FFKM). While both are part of the fluoroelastomer family, their chemical composition, temperature and chemical resistance, mechanical properties, applications, and cost

FKM is a partially fluorinated rubber widely used for its resistance to fuel, heat, and a broad range of chemicals. FFKM, on the other hand, is a fully fluorinated perfluoroelastomer designed for the harshest operating environments on Earth—think semiconductor cleanrooms, aggressive chemical processing, and aerospace propulsion systems.

So why does this distinction matter?

Selecting the right elastomer is critical to preventing seal failure in extreme temperature or chemically aggressive conditions. A misstep could mean premature degradation, costly downtime, or catastrophic leakage. That’s why product designers, engineers, and procurement specialists alike must understand when to choose FKM—and when to invest in FFKM.

In this article, I’ll walk you through a detailed comparison of FKM and FFKM across seven dimensions: their molecular makeup, temperature resistance, chemical resilience, mechanical performance, applications, cost, and more. You’ll come away with a clear understanding of which material best fits your project’s demands.

Let’s begin with their chemical structure—the foundation of their performance differences.

1. Chemical Composition and Structure

1.1 FKM: Partially Fluorinated Fluoroelastomer

FKM, commonly known under brand names like Viton®, is a fluoroelastomer composed of fluorinated monomers such as vinylidene fluoride (VDF), hexafluoropropylene (HFP), tetrafluoroethylene (TFE), and occasionally perfluoromethylvinylether (PMVE). These monomers form a polymer chain that contains both carbon–fluorine (C–F) and carbon–hydrogen (C–H) bonds.

The inclusion of hydrogen in the backbone makes FKM more susceptible to chemical degradation than FFKM, but it also makes the material easier and more economical to process. Depending on the formulation, FKM typically contains 60% to 70% fluorine by weight, giving it good resistance to heat, oils, and many chemicals.

Key takeaway: FKM strikes a balance between chemical resistance, thermal stability, and manufacturing cost, which is why it’s widely adopted across automotive, aerospace, and industrial sectors.

1.2 FFKM: Fully Fluorinated Perfluoroelastomer

FFKM is engineered for environments where no compromise is acceptable. Its polymer backbone is fully saturated with fluorine atoms, meaning there are no C–H bonds present. This complete fluorination grants the material near-total chemical inertness and outstanding thermal resistance.

What sets FFKM apart further is its use of fluorinated ether side chains, which not only improve low-temperature flexibility but also enhance long-term chemical stability under extreme exposure. The fluorine content in FFKM can exceed 75–80%, making it the most chemically resistant elastomer available today.

Quote box:

“FFKM is to elastomers what platinum is to metals—rare, expensive, but unmatched in performance.”

In short: FKM is a tough, fuel-resistant workhorse. FFKM is a chemical tank built for the most punishing environments imaginable.

2. Temperature Resistance

2.1 FKM

One of FKM’s strongest assets is its ability to maintain performance under elevated temperatures. Standard grades of FKM operate effectively from -25°C up to +230°C, with some special formulations pushing the upper limit to around 250°C. This makes it a preferred choice for automotive engine compartments, aerospace fuel systems, and industrial equipment exposed to moderate heat.

However, sustained exposure beyond 230°C can lead to hardening, embrittlement, and eventual seal failure. While FKM does handle short bursts of higher temperatures, its performance begins to degrade when held at extreme heat over time.

Bold point: FKM is well-suited for most high-temperature industrial uses, but it’s not built for prolonged ultra-high-heat environments.

2.2 FFKM

FFKM takes heat resistance to an entirely different level. Thanks to its fully fluorinated backbone and engineered side chains, FFKM elastomers can withstand continuous use from -55°C up to +327°C, with some specialty grades rated as high as 350°C.

Even under these extreme conditions, FFKM retains its elasticity, sealing force, and dimensional stability, making it indispensable in aerospace propulsion systems, high-temperature chemical reactors, and semiconductor fabrication where thermal cycles are aggressive and constant.

Quote box:

“If your system runs hot and failure is not an option, FFKM is the seal material of choice.”

In summary: FKM offers reliable high-temperature performance for most industries, but when the heat turns extreme, FFKM stands alone.

3. Chemical Resistance

3.1 FKM

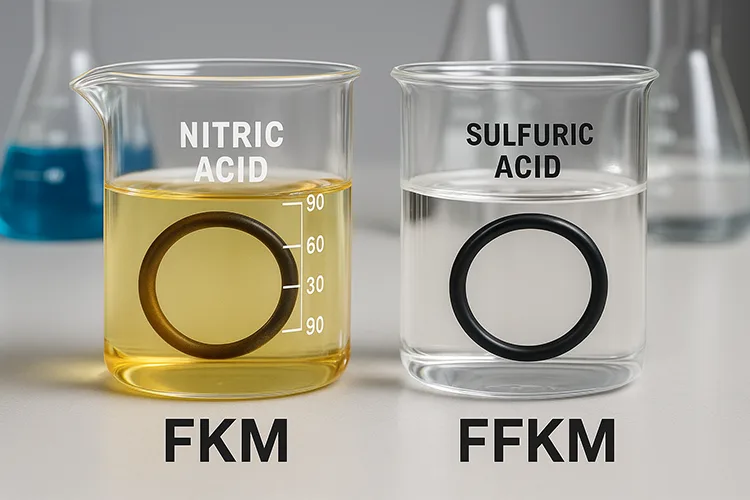

FKM is known for its excellent resistance to a broad range of chemicals, especially hydrocarbons. It performs well in contact with fuels, mineral oils, synthetic lubricants, acids, and many aliphatic and aromatic solvents. This versatility explains its widespread use in the automotive, aerospace, and oil & gas sectors.

However, there are limitations. FKM is not compatible with highly polar solvents such as ketones, esters, and low-molecular-weight ethers. It also degrades in contact with strong oxidizing agents and highly concentrated organic or inorganic acids like nitric or fuming sulfuric acid.

Key point: FKM is chemically resilient for general industrial use, but it cannot withstand the most aggressive or reactive substances.

3.2 FFKM

FFKM, in contrast, delivers near-universal chemical resistance. Its molecular design allows it to remain stable and elastic in the presence of:

- Strong acids (e.g., nitric, sulfuric, hydrofluoric)

- Organic solvents (ethers, ketones, esters, amines)

- Oxidizers, steam, and even plasma environments

This resistance extends to ultra-clean and corrosive environments like semiconductor wafer etching, chemical vapor deposition (CVD), and pharmaceutical manufacturing—where even microscopic contamination or swelling can be catastrophic.

Quote box:

“FFKM is one of the few elastomers that can survive in chemical baths that would destroy most rubbers in minutes.”

Bottom line: While FKM is sufficient for many applications, FFKM is the go-to material when chemical resistance must be absolute and uncompromising.

4. Mechanical Properties and Durability

4.1 FKM

From a mechanical standpoint, FKM offers a strong balance of elasticity, toughness, and compression set resistance. It maintains flexibility across a wide range of operating temperatures and exhibits good resistance to swelling and deformation, even in chemically active environments.

That said, FKM’s mechanical durability begins to decline when subjected to prolonged exposure to very high temperatures, aggressive media, or high dynamic loads. Over time, you may observe compression set (loss of sealing force), cracking, or hardening, especially if the compound is not correctly matched to the service conditions.

Highlight: FKM’s durability is dependable in moderately harsh environments but must be matched to its chemical and thermal limitations.

4.2 FFKM

FFKM is engineered for longevity under the harshest conditions. Its superior compression set resistance ensures that seals maintain their shape and performance—even after thousands of hours in extreme chemical and thermal environments. It also boasts low outgassing, a critical requirement for vacuum systems and cleanrooms.

What’s more, FFKM demonstrates excellent dimensional stability, making it ideal for precision sealing in high-purity or high-pressure systems. Whether under static load, mechanical vibration, or thermal cycling, FFKM components last significantly longer than most other elastomers.

Quote box:

“In mission-critical systems, seal failure isn’t just inconvenient—it’s catastrophic. That’s where FFKM proves its worth.”

Conclusion: FKM provides solid mechanical performance for general applications, but FFKM outlasts and outperforms when stress, heat, and chemicals are all in play simultaneously.

5. Applications

5.1 FKM

Thanks to its well-rounded performance, FKM is widely used in industrial, automotive, and aerospace sectors where strong resistance to heat and chemicals is required—but not at the extreme levels FFKM is designed for.

Common FKM applications include:

- Automotive fuel systems: O-rings, fuel injector seals, and crankshaft gaskets

- Aerospace fuel handling systems: Static and dynamic seals exposed to jet fuels and hydraulic fluids

- General industrial sealing: Gaskets and profiles used in pumps, valves, and compressors in contact with oils, lubricants, and mild acids

Key benefit: FKM delivers high value for its performance, offering a reliable sealing solution in moderately harsh environments without the cost burden of ultra-premium materials.

5.2 FFKM

FFKM’s usage is far more specialized, targeting applications where failure is unacceptable and the sealing environment is chemically or thermally extreme. Its cost is justified by its unrivaled longevity and stability.

Typical FFKM applications include:

- Semiconductor wafer processing: Dry etching chambers, plasma tools, and ultra-clean sealing systems

- Aggressive chemical reactors: Seals in systems dealing with concentrated acids, amines, and oxidizers

- Aerospace hydraulic systems: Where seals must operate across extreme altitude, temperature, and pressure ranges

- Oil & gas HPHT applications: Downhole tools, valve stem seals, and blowout preventers exposed to corrosive fluids and extreme pressure

Quote box:

“If downtime means millions lost or contamination risks human safety, then only FFKM will do.”

Conclusion: FKM is ideal for high-performance but cost-sensitive systems, while FFKM dominates in mission-critical environments where chemical purity, extreme conditions, and long service life are mandatory.

![]()

6. Cost and Availability

6.1 FKM

One of FKM greatest advantages—aside from its chemical and thermal resistance—is its cost-efficiency. As a partially fluorinated rubber, it is less expensive to produce and process than FFKM. This makes it widely accessible for both small- and large-scale applications.

- Readily available in a variety of grades, including standard, low-temperature, and high-temperature formulations

- Shorter lead times and broader supply chain support

- Cost-effective for most high-performance industrial needs without compromising reliability

Key point: FKM provides a sweet spot between performance and price—especially for industries where good-enough resistance is actually good enough.

6.2 FFKM

FFKM, by contrast, sits in the premium category. Its complex polymerization process, specialized raw materials, and limited manufacturing capacity all contribute to its significantly higher price point—often 10 to 20 times more expensive than FKM, depending on the grade and supplier.

- Longer lead times due to niche manufacturing and custom formulation

- Used primarily in mission-critical systems where failure is unacceptable

- Specialized sourcing required, with fewer global suppliers compared to standard elastomers

Quote box:

“In critical systems, you don’t pay for the material—you pay for the peace of mind it delivers.”

Bottom line: FKM is budget-friendly and broadly accessible, while FFKM is a precision investment reserved for extreme environments and sensitive operations. The price gap reflects their fundamentally different performance ceilings.

7. Summary Comparison Table

To help you quickly evaluate which material fits your application needs, here’s a side-by-side comparison of FKM and FFKM across key performance indicators:

| Feature | FKM (Fluororubber) | FFKM (Perfluoroether Rubber) |

|---|---|---|

| Fluorination Level | Partial (contains some C–H bonds) | Fully fluorinated (no C–H bonds) |

| Fluorine Content | ~60–70% | Up to ~75–80% |

| Operating Temp Range | -25°C to +230°C (up to 250°C in special grades) | -55°C to +327°C (up to 350°C in premium grades) |

| Chemical Resistance | Excellent for fuels, oils, mild acids/solvents | Near-universal, including strong acids and oxidizers |

| Mechanical Durability | Good under moderate stress | Superior in high-stress, high-purity, and high-temp use |

| Common Applications | Automotive, aerospace fuel systems, machinery | Semiconductor, oil & gas, aerospace hydraulics, reactors |

| Cost | Moderate and economical | High—used in mission-critical or ultrapure environments |

Key takeaway: FKM and FFKM serve different ends of the performance spectrum. If your application can tolerate moderate extremes, FKM is often more than sufficient. But when you’re operating at the edge of thermal and chemical limits, FFKM becomes indispensable—despite the price.

Conclusion

Choosing between fluororubber (FKM) and perfluoroether rubber (FFKM) is not just a matter of performance—it’s a matter of balancing cost, risk, and application demand.

If you’re working in an environment with moderate to high heat, exposure to fuels or lubricants, and a need for reliable sealing performance, FKM is a cost-effective and dependable choice. It’s widely available, versatile, and trusted across automotive, aerospace, and general industrial sectors.

But when your system must withstand aggressive chemicals, extreme temperatures, and zero tolerance for contamination or failure, FFKM is the elite option. Though costly, it offers unmatched chemical inertness, thermal endurance, and long-term sealing stability, making it the only viable solution for semiconductors, high-purity reactors, and HPHT energy operations.

Final verdict:

- Use FKM when performance matters—but budget still has a say.

- Use FFKM when performance is mission-critical—and nothing less will do.

The smartest engineers and buyers I work with always start with the application—not the material. Define your temperature, chemical, and mechanical needs first, and the right rubber will reveal itself.

Need help choosing the right rubber for your seals? Contact us for expert guidance and custom solutions tailored to your industry.

References: