1. Introduction

1.1 Why Applications Matter

When I work with automation engineers and production teams across different industries, I often notice one common misunderstanding:

many people assume foam suction cups behave the same way in every application.

But in reality, foam suction cups perform very differently depending on:

- the surface (rough, porous, dusty, curved)

- the material (paper, wood, plastic, glass, coated metal)

- the production environment (dust levels, oil exposure, cycle speed)

- the gripping method (single cup vs. multi-cup vs. robot EOAT)

This is why the application context determines whether a foam suction cup performs beautifully—or fails unexpectedly.

In this article, I’ll break down each major industry, explain the typical problems rubber cups encounter, and show how foam suction cups solve them with real, practical scenarios.

For a complete overview of how foam cups work and how they compare to rubber, you can refer back to the pillar guide:

➡️ Foam Suction Cups: Complete Buyer’s Guide

1.2 What This Article Covers

In this industry-focused guide, I’ll walk you through:

- The seven main industries where foam suction cups outperform rubber cups

- The typical surface types each industry deals with

- Why traditional rubber cups fail in these cases

- The exact foam cup features that solve these problems

- Real-world mini-scenarios that show how the solution works

- Internal links to deeper resources for selection, materials, and troubleshooting

You’ll find direct links to technical guides throughout this article, including:

- Selection & Sizing Guide –

➡️ https://www.kinsoe.com/select-foam-suction-cups-sizing-guide/ - Material Comparison (Foam vs Rubber) –

➡️ https://www.kinsoe.com/foam-vs-rubber-suction-cups-materials/ - Surface Challenges: Rough, Porous, Oily –

➡️ https://www.kinsoe.com/foam-suction-cups-rough-porous-oily-surfaces/

2. Packaging & Logistics

The packaging and logistics industry is where I see foam suction cups deliver some of the biggest performance improvements, simply because the materials involved—especially modern shipping cartons—are some of the hardest surfaces for rubber suction cups to handle reliably.

If your automation process involves e-commerce parcels, corrugated boxes, kraft paper, recycled cartons, or dusty packaging lines, then foam suction cups are almost always the correct choice. Here’s why.

2.1 Common Surfaces in Packaging

Packaging and logistics typically involve:

- Corrugated cartons (single wall / double wall / recycled board)

- Kraft paper boxes

- Printed boxes with heavy ink coverage

- Dusty surfaces from high-volume packing areas

- Soft or deformable cartons (variation from batch to batch)

These surfaces are inherently problematic because:

- Recycled paper is highly porous

- Double-wall cartons have deep ridges and valleys

- Dust creates fine leakage paths

- High-speed operations cause boxes to flex or collapse slightly

Rubber cups can’t maintain stable sealing under these conditions, which leads to drop-offs, misalignment, or slow pick-up times.

For a deeper look at surface challenges like porosity and dust, you can refer to:

➡️ Foam Suction Cups for Rough & Oily Surfaces

2.2 Typical Problems with Standard Rubber Cups

Across packaging lines I’ve audited, rubber suction cups consistently fail in several ways:

1) Vacuum Leakage from Porous or Rough Surfaces

Recycled cartons allow air to pass directly through the material.

Rubber cups require airtight contact—foam does not.

2) Height Variation Causes Unstable Grip

Boxes are rarely 100% uniform. Even minor variations break the seal.

3) Dust Interferes with Sealing

Dust particles get trapped between the cup lip and the box surface.

4) Misalignment & Drop-Offs at High Speed

Rubber cups “skip” across uneven carton textures, leading to inconsistent gripping.

5) Paper Fibers Get Pulled Off

Rubber lips can grab or tear the top fiber layer, damaging the box.

If you’re seeing any of these issues, the root cause is almost always a mismatch between surface characteristics and cup type—not a problem with the vacuum generator itself.

2.3 Why Foam Suction Cups Solve These Problems

Foam cups work so well in packaging because they are designed specifically for the surfaces rubber cups struggle with.

✔ Micro-gap sealing

Foam compresses into the ridges of corrugated board, creating a consistent sealing boundary.

✔ High conformity

Soft or medium-density foam adapts instantly to uneven or flexible box surfaces.

✔ Natural dust tolerance

Foam—unlike rubber—can seal even when minor dust is present.

✔ Larger stable contact area

This prevents tearing the box surface or pulling fibers.

✔ Strong performance on recycled cartons

Foam cups maintain grip even with moisture variations, recycled fibers, or inconsistent textures.

For sizing and hardness selection, see:

➡️ How to Select the Right Foam Suction Cups

2.4 Real Use Scenario — E-Commerce Parcel Pick & Place

One of my clients in a large fulfillment center was experiencing:

- 45–60 drops per shift

- Frequent vacuum alarms

- Inconsistent picking of poly-laminated cartons

- High wear on rubber cups due to rough surfaces

They switched to medium-soft NR foam cups with a larger diameter and a high-flow vacuum source.

The results:

- 92% reduction in drop-offs

- 30% faster pick-up time

- No more surface tearing

- Longer suction cup lifespan

This is extremely typical—I see similar improvements across most packaging sites that switch from rubber to foam.

If you want to find the most suitable material (NR, EPDM, NBR, silicone, PU), here’s the detailed guide:

➡️ Foam vs Rubber Suction Cups: Material Guide

3. Woodworking & Furniture Manufacturing

Woodworking and furniture factories deal with some of the most difficult surfaces in automation: MDF, particle board, plywood, veneer, sanded wood, and panels covered in dust. Among all industries I support, this is the one where rubber suction cups fail the fastest—and where foam suction cups consistently deliver dramatic improvements in stability and reliability.

If your operations involve CNC machines, panel saws, lamination lines, sanding stations, or material transfer robots, foam suction cups are almost always the right choice.

3.1 Common Surfaces in Woodworking

Typical surfaces in this industry include:

- MDF & particle board (high porosity)

- Raw wood panels

- Sanded surfaces with loose dust

- Curved or slightly bowed wood pieces

- Veneered boards

- Laminated furniture parts

- Textured decorative laminates

These surfaces have two traits that rubber cups are simply not designed for:

1) Porosity

Air passes directly through MDF and particle board—no rubber lip can seal this.

2) Dust contamination

Wood dust blocks the sealing edge, creating unpredictable leakage.

To understand why these surfaces require special handling, you can refer to the in-depth article:

➡️ Foam Suction Cups for Rough & Oily Surfaces

3.2 Challenges With Rubber Suction Cups in Woodworking

Rubber cups fail frequently in woodworking due to:

1) Porous surfaces = instant vacuum loss

Particle board and MDF behave like sponges—they allow air to flow straight through.

2) Dust clogs the sealing edge

Even a thin dust layer breaks the vacuum boundary required by rubber cups.

3) Height variation across panels

Panels can be slightly bowed, uneven, or bent from storage.

4) Slippage on laminated or veneered surfaces

Rubber cups struggle with smooth laminates and glossy coatings.

5) Overloading and wear

Wood edges can be sharp or abrasive, cutting rubber lips quickly.

If you’re experiencing slippage or drop-offs, check the symptom-based fixes in:

➡️ Foam Suction Cups Not Holding? Troubleshooting Guide

3.3 Why Foam Suction Cups Solve These Issues

Foam suction cups are the preferred solution in woodworking environments because they:

✔ Compensate for Porosity

Foam doesn’t rely on a perfect airtight lip.

Instead, it compresses into the surface and uses high-flow vacuum to maintain stability—even when air passes through the board.

✔ Handle Dust Better

Foam maintains sealing performance even with light dust contamination, unlike rubber cups.

✔ Conform to Bowed or Uneven Panels

Wood panels rarely sit perfectly flat.

Foam adjusts to these micro-height variations instantly.

✔ Provide Grip on Laminated or Glossy Panels

Medium-density foam or silicone foam improves friction without marking the surface.

✔ Withstand Abrasive Edges

Using medium or PU foam varieties offers much better durability than rubber when edges are rough.

For help choosing the right hardness/material combination, see:

➡️ How to Select the Right Foam Suction Cups

3.4 Real Use Scenario — MDF Panel Handling

One furniture manufacturer I worked with used rubber suction cups on their CNC loading/unloading system. Their problems included:

- Frequent vacuum alarms

- Panels slipping slightly during movement

- Rubber cups wearing out in 2–3 days

- Heavy dust contamination affecting sealing

- Bowed panels causing uneven gripping and misalignment

We switched them to medium-density NR foam cups in a larger diameter, supported by:

- A higher-flow vacuum source, and

- Better filtration to protect the generator from wood dust

The results were immediate:

- Zero drop-offs

- Stable pick-up even on panels with slight curvature

- Foam cup life extended by 3–4× compared to rubber

- CNC loading became smoother and faster

If you’re seeing accelerated wear or frequent replacements, you’ll find helpful guidelines in:

➡️ Foam Suction Cup Life, Maintenance & Cost

4. Electronics, Appliances & Precision Assembly

Electronics and appliance manufacturing demand extremely clean, scratch-free, and dimensionally precise handling.

From glossy plastic housings to coated metal panels and delicate internal components, these surfaces are easily damaged, and even the slightest marking can cause a part to be rejected.

Foam suction cups—especially soft and fine-cell variants—are one of the best solutions for handling sensitive electronics components without leaving marks, scratches, or deformation.

4.1 Common Surfaces in Electronics & Precision Assembly

The surfaces I typically see in electronics and appliance lines include:

- Glossy plastic housings (TV, speaker, laptop covers)

- Coated metal panels (powder-coated, anodized, painted)

- Glass touch panels and screens

- Polished decorative parts

- Anti-fingerprint or anti-scratch coatings

- Precision components requiring accurate alignment

- Small lightweight plastic parts

All these surfaces present challenges for standard rubber suction cups because:

- They are mark-sensitive

- They require precise positioning

- Their coatings are easily damaged

- They often have curved or angled geometry

- The required gripping force must be controlled carefully

If you’re unsure which foam type fits your surface, you can reference the material comparison here:

➡️ Foam vs Rubber Suction Cups: Material Guide

4.2 Challenges With Rubber Cups in Electronics

Rubber cups (even soft variants) introduce several problems that become unacceptable in precision assembly, including:

1) Visible surface marks / ring marks

Rubber can leave:

- Micro rings

- Shine marks

- Pressure spots

- Surface distortion

These marks are especially visible on glossy plastics and coated metals.

2) Scratches on delicate coatings

Rubber has a harder, less forgiving edge that can damage:

- UV coatings

- Anti-scratch films

- Decorative laminates

3) Poor grip on curved or angled surfaces

Electronics housings often feature ergonomic, curved designs.

Rubber cups lose sealing contact as the geometry changes.

4) Overly strong gripping force

Rubber cups often “over-grip,” causing micro-deformation on thin parts.

5) Alignment accuracy issues

Any minor slip during pick-and-place affects downstream assembly precision.

If you’re dealing with performance issues like slipping, marks, or misalignment, I recommend checking:

➡️ Foam Suction Cups Not Holding? Troubleshooting Guide

4.3 Why Foam Suction Cups Work Exceptionally Well Here

Foam suction cups are designed to handle these surfaces with the necessary level of care and precision.

✔ Ultra-soft compression for non-marking contact

Soft foam spreads pressure evenly without creating visible marks.

✔ Fine-cell structure for stable grip on coatings

Fine-cell silicone foam is ideal for:

- High-gloss plastics

- Powder-coated surfaces

- Coated glass

✔ Conforms to curved or complex geometry

Foam adapts to 3D shapes and multi-curvature surfaces where rubber cups lose sealing.

✔ Stable hold with controlled force

Foam distributes force more evenly, reducing deformation of thin parts.

✔ Anti-static foam options

Critical for electronics lines to prevent ESD-related failures.

If you’re selecting foam hardness/material for sensitive surfaces, you can use this guide:

➡️ How to Select the Right Foam Suction Cups (Article C)

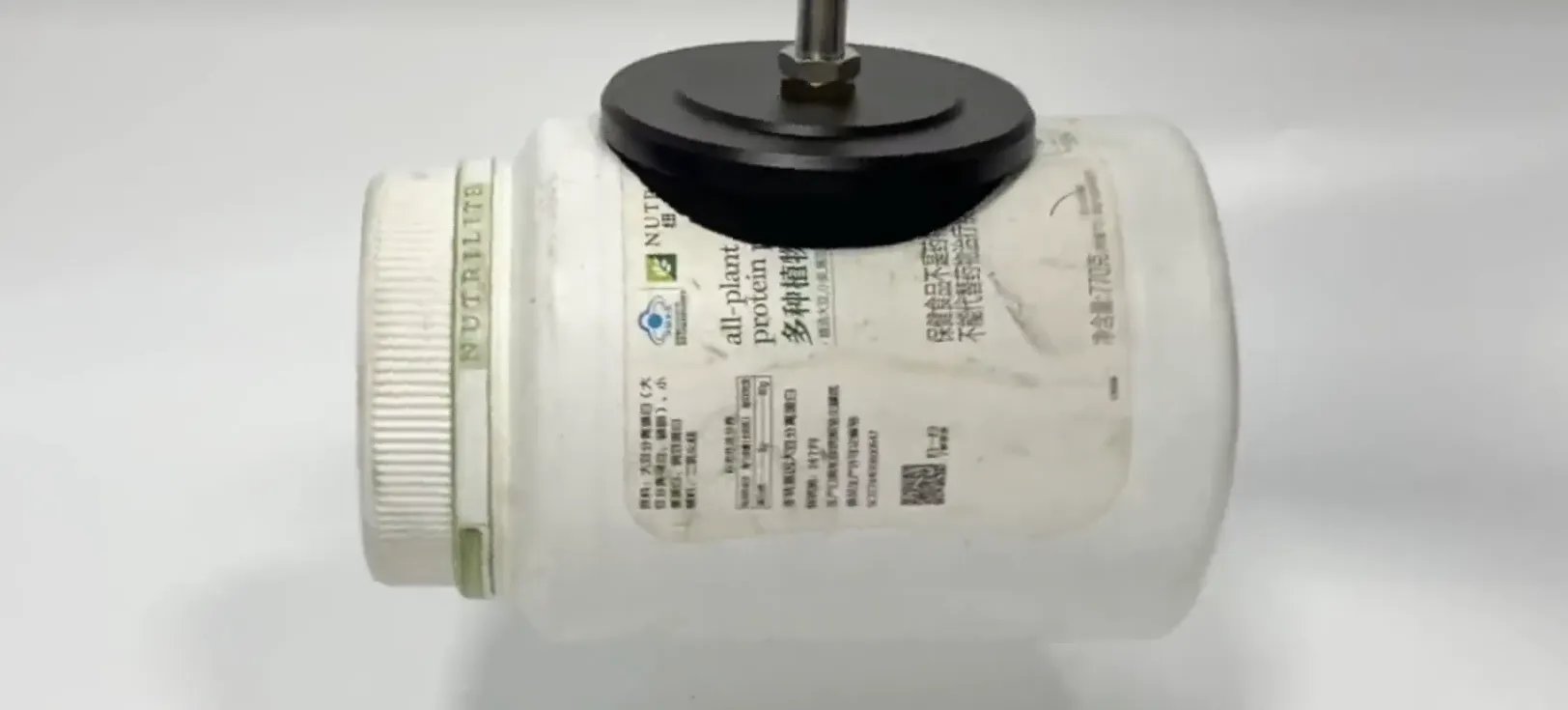

4.4 Real Use Scenario — Appliance Housing Assembly

A home appliance manufacturer I worked with had a problem:

- Rubber cups were leaving visible rings on glossy refrigerator and washer panels.

- Customers noticed these marks even after cleaning.

- The QC rejection rate was rising.

- Workers manually wiped surfaces after picking to hide the defects.

I replaced their rubber cups with ultra-soft silicone foam cups, slightly larger in diameter, along with reduced vacuum level and higher flow.

The results:

- Zero surface marks

- Faster alignment with fewer micro-adjustments

- Higher yield in downstream assembly

- No need for manual cleaning

- Better stability on curved appliance panels

For handling high-sensitivity surfaces like these, silicone foam remains my top recommendation.

For additional insights on lifespan and maintenance in clean assembly environments, visit:

➡️ Foam Suction Cup Life, Maintenance & Cost

5. Glass, Ceramics & Coated Panels

When handling glass, ceramic tiles, solar panels, or coated architectural materials, manufacturers face two critical challenges:

- The surface is fragile.

- The surface is easily marked.

In these industries, even a tiny scratch or pressure mark can render a piece unusable. That’s why foam suction cups—especially fine-cell silicone and PU variants—are a major upgrade over traditional rubber cups.

If your application involves glass lifting, decorative panel transfer, solar module handling, or ceramic tile packaging, this chapter will be especially useful.

5.1 Common Surfaces in Glass & Panel Handling

The surfaces I typically encounter in this industry include:

- Decorative glass panels

- Low-E glass

- Ceramic tiles (matte, gloss, textured)

- Coated solar panels

- Tempered glass sheets

- Laminated architectural panels

- Mirrors and reflective surfaces

- Anti-fingerprint/anti-scratch coatings

These surfaces present multiple challenges at once:

- Smooth yet micro-textured

- Highly mark-sensitive

- Often curved or slightly bent

- Sometimes powder-coated or coated with films

- Extremely fragile edges

If your surfaces are rough, porous, or oily in addition to being coated, this deeper article will help:

➡️ Foam Suction Cups for Rough & Oily Surfaces

5.2 Challenges With Standard Rubber Cups

Rubber suction cups often perform poorly with glass and coated panels because:

1) Micro-texture causes leakage

Even smooth glass can have nano-texture or coating layers that create micro gaps.

2) Rubber leaves visible pressure marks

Especially noticeable on:

- Decorative glass

- Glossy tiles

- Coated solar sheets

- Mirror panels

3) Poor conformity to bowed or uneven shapes

Large panels often have a small “crown” or bow—rubber cannot adapt to this.

4) Slippage during long horizontal transfers

Rubber can slide on smooth surfaces during movement.

5) High risk of cracking due to uneven pressure

Rigid rubber lips apply point pressure instead of distributing force evenly.

If you’re seeing cracks, marking, or slippage, troubleshooting steps are here:

➡️ Troubleshooting Guide — Foam Suction Cups Not Holding

5.3 Why Foam Suction Cups Work Better

Foam suction cups solve these problems with their compressible, adaptable structure. Here’s why they excel in glass and ceramic handling:

✔ Fine-cell foam fills microscopic texture

This helps maintain sealing even on coated, low-E, or patterned surfaces.

✔ Even pressure distribution prevents cracks

Foam compresses uniformly, reducing the risk of pressure-induced breakage.

✔ Non-marking silicone and PU options

Soft silicone foam is my top recommendation for:

- Mirror panels

- Touchscreens

- Decorative glass

- Solar panels

PU foam is excellent for:

- Ceramic tiles

- Abrasive matte surfaces

- High-speed panel lines

✔ Excellent grip on curved or bowed panels

Foam adapts to curvature, eliminating partial-seal problems that rubber cups face.

✔ Stable performance during long-distance transfer

Foam increases the friction zone, reducing slip.

If you’re unsure which foam hardness/material to choose, this guide will help:

➡️ How to Select the Right Foam Suction Cups

5.4 Real Use Scenario — Solar Panel Handling Line

A solar panel manufacturer contacted me because:

- Rubber cups were leaving visible circular marks

- Operators had to manually clean each panel

- There were occasional micro-cracks at the glass edge

- The vacuum system overheated due to leakage issues

We switched them to fine-cell silicone foam suction cups, combined with:

- A larger diameter

- Higher vacuum flow (not higher vacuum level)

- A short-hose manifold design

- Anti-static treatment where required

Results:

- Zero marking on coated surfaces

- Improved safety—no pressure spikes

- Stable pick-up even on bowed panels

- Reduced generator load and cooler operation

- Significantly faster cycle times

For related cost and maintenance considerations, see:

➡️ Foam Suction Cup Life, Maintenance & Cost

6. Logistics & E-Commerce Automation

In fast-moving logistics and e-commerce fulfillment centers, automation must deal with extreme variability—different package materials, random shapes, inconsistent surfaces, and rapid cycle times.

This environment puts tremendous pressure on suction cup performance, and it’s one of the areas where I see foam suction cups make the biggest difference in drop rates, picking stability, and long-term operational efficiency.

If you’re handling parcels, polybags, mixed packaging types, or variable incoming goods, foam suction cups may be the solution you’ve been missing.

6.1 Common Surfaces in Logistics & E-Commerce

Unlike traditional manufacturing, logistics deals with unpredictable surfaces, such as:

- Mixed material parcels (paper, plastic, laminated, bubble mailers)

- Corrugated boxes (single/double-wall, recycled, damaged)

- Polybags and mailer bags

- Shrink-wrapped parcels

- Irregularly shaped shipments

- Soft, deformable packages

- Dusty or scuffed goods from shipping routes

These surfaces create constant problems because they are:

- Not uniform

- Not always flat

- Frequently dirty or worn

- Highly porous in the case of recycled boards

- Slippery (plastic bags, shrink film)

All these factors push traditional rubber suction cups beyond their limits.

For a deeper look at how surface conditions affect sealing, refer to:

➡️ Foam Suction Cups for Rough & Oily Surfaces

6.2 Problems With Rubber Cups in Logistics

Rubber cups fail frequently in logistics for five main reasons:

1) Highly Variable Surfaces

Rubber cups need consistent flatness. E-commerce items rarely offer that.

2) Porosity in Recycled Boxes

Modern shipping boxes leak air straight through the fiber structure.

3) Polybags Collapse Under Vacuum

Rubber can cause the bag to deform or slip.

4) Dust & Scuffs Reduce Sealing

Packages that travel through warehouses accumulate fine dust and abrasion marks.

5) Speed + Variability = Wear + Drop-offs

High cycle speeds amplify any instability in vacuum gripping.

As always, if you are faced with drop-offs, slippage, or poor vacuum performance, the troubleshooting guide will help:

➡️ Foam Suction Cups Not Holding? Troubleshooting Guide

6.3 Why Foam Suction Cups Are Ideal for Logistics

Foam suction cups excel in this industry for several reasons:

✔ Maximum Adaptability

Foam adapts to:

- inconsistent packaging

- dents and folds

- rough outer surfaces

- flexible materials

✔ High Leakage Compensation

Foam can maintain grip even on porous, worn, or lightweight parcels.

✔ Stable Pick-Up on Polybags

Soft foam spreads force across a wider area, preventing deformation.

✔ Reduced Drop-Offs at High Speed

Even on 70–120 cycles/min machines, foam cups maintain excellent stability.

✔ Lower System Stress

Foam uses flow-based sealing, reducing the need for high-vacuum levels that wear generators faster.

If you need assistance selecting foam hardness, diameter, or vacuum settings for your logistics equipment, you can reference the selection guide:

➡️ How to Select the Right Foam Suction Cups (Article C)

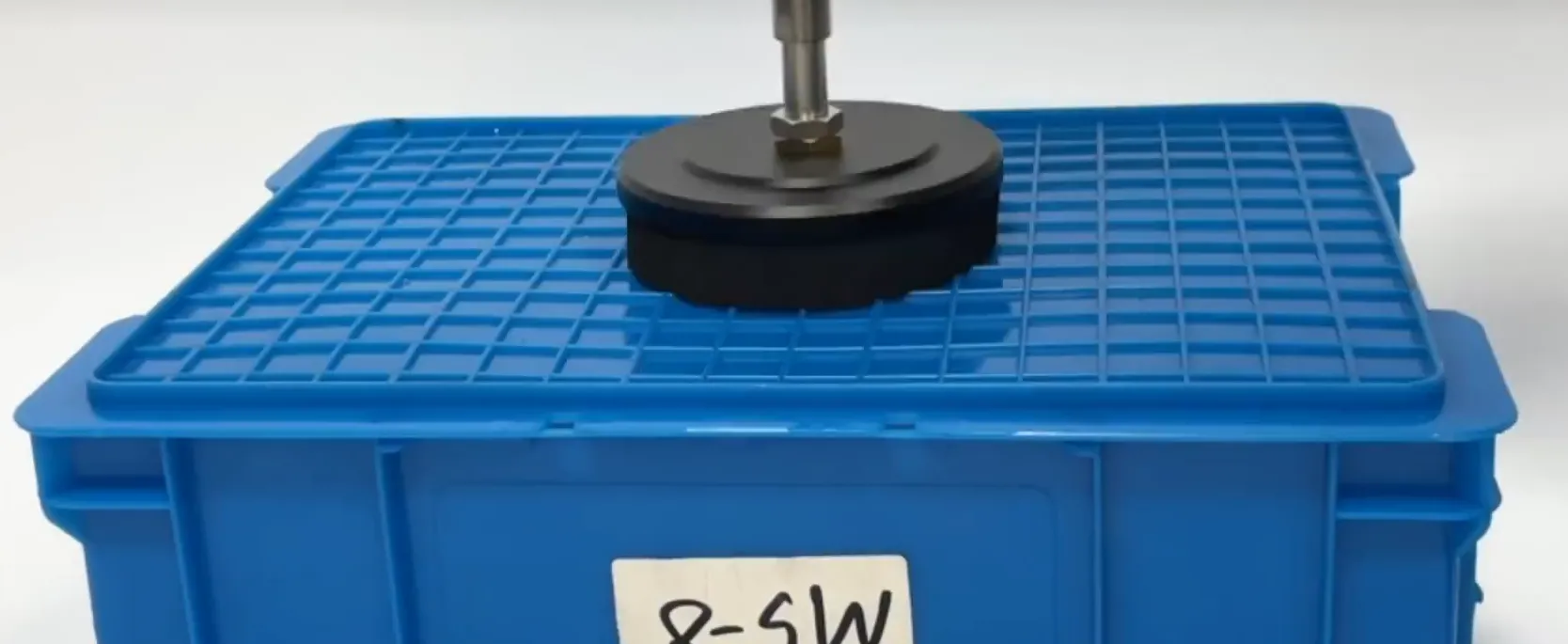

6.4 Mini Scenario — Mixed Parcel Picking for E-Commerce

One of the biggest challenges I helped solve involved an e-commerce fulfillment robot arm that needed to pick:

- Small cartons

- Polybags

- Bubble mailers

- Laminated return packages

- Oddly shaped goods

Rubber cups had:

- Daily drop-offs

- Frequent “no pick” errors

- Issues gripping polybags and bubble mailers

- Difficulty adjusting to dented cartons

- Large variations in cycle time

After switching to wide-diameter medium-soft foam cups with a high-flow vacuum ejector:

- Failure rates dropped by over 90%

- Picking became stable even with crushed or irregular packages

- Polybags could be handled without slippage

- The robot’s cycle time became more consistent

- Maintenance time reduced due to fewer vacuum alarms

For optimizing cup life and total cost in high-consumption environments like logistics, see:

➡️ Foam Suction Cup Life, Maintenance & Cost

7. Industry/Application Table

To make it easier for you to compare the behavior of foam suction cups across industries, I’ve summarized the most important insights into a clean, skimmable table.

This is the table I personally use when guiding customers during early-stage project discussions.

It shows:

- The industry

- The typical surface type

- The main handling challenge

- My recommended foam suction cup configuration

This summary also helps you quickly decide which detailed article to read next, depending on your industry.

7.1 Quick Reference Table — Where Foam Suction Cups Perform Best

| Industry | Common Surface Type | Handling Challenge | Recommended Foam Solution |

|---|---|---|---|

| Packaging & Logistics | Corrugated carton, recycled paper | Porous, rough, inconsistent height | Soft–medium NR foam + larger diameter |

| Woodworking & Furniture | MDF, particle board, dusty surfaces | Porosity, dust contamination, bowing | Medium-density NR or PU foam |

| Electronics & Appliance Assembly | Glossy plastic, coated metal, screens | Scratches, marks, alignment precision | Ultra-soft silicone or soft NR foam |

| Glass, Solar & Ceramic Panels | Coated glass, solar sheets, tiles | Micro-texture, slippage, pressure sensitivity | Fine-cell silicone or PU foam |

| E-Commerce & Parcel Automation | Mixed parcels, polybags, shrink wrap | Extreme variability, porous surfaces | Wide-diameter soft–medium foam + high flow |

| General Industrial Automation | Plastic parts, coated plates, mixed textures | Height variation, marking concerns | Medium NR foam or silicone foam depending on surface |

7.2 How to Use This Table Effectively

I recommend using this table as a diagnostic tool when starting a project.

Here’s how:

- Identify your surface type

→ rough, porous, curved, delicate, or coated - Match the challenge

→ leakage, marking, uneven height, durability, etc. - Use the recommended foam configuration

→ hardness, material, and diameter - Jump to the related article

Each link takes you directly to a detailed breakdown and scenario-based guidance.

8. Conclusion

Foam suction cups are not a “universal replacement” for rubber cups—and that’s exactly why they work so well when applied correctly. As this article has shown across packaging, labeling, woodworking, electronics, glass handling, and logistics automation, performance is driven by application context: surface condition, material sensitivity, variability, environment, and motion requirements.

Across all industries, the pattern is consistent:

- Rubber suction cups fail when surfaces are rough, porous, dusty, curved, coated, or inconsistent

- Foam suction cups succeed because they adapt—mechanically and pneumatically—to real-world surfaces

Whether it’s recycled cartons in packaging, MDF panels in woodworking, glossy housings in electronics, coated glass panels, or mixed parcels in e-commerce, foam suction cups solve problems by:

- Filling micro-gaps instead of demanding airtight contact

- Compensating for height variation and surface irregularities

- Distributing pressure evenly to avoid marking or damage

- Maintaining stable grip under high-speed, high-variability conditions

The most important takeaway is this:

There is no “best” foam suction cup—only the best match between cup design and application.

That’s why selection matters. Diameter, foam hardness, material (NR, EPDM, NBR, silicone, PU), thickness, and vacuum flow must all be chosen based on how and where the cup is used. When these factors are aligned, foam suction cups deliver dramatic improvements in stability, yield, and overall automation reliability.

Planning a new automation project, or experiencing unstable gripping issues on your existing production line? Contact us now. A well-designed foam suction cup not only improves gripping performance but also ensures stability throughout the entire production process.

Related posts

Every engineer or buyer who reads this guide will come with different priorities—some need to understand material compatibility, others want troubleshooting help, and some want to explore customization options for OEM automation.

So in this chapter, I’m providing a clear navigation hub with direct text-based hyperlinks to the exact next article you should read based on your situation.

By structuring the links this way, I help readers move naturally from problem → solution → action, which also strengthens the SEO authority of the entire cluster.

9.1 If You Want to Understand Where Foam Suction Cups Are Used

Start with real-world industry examples and problem scenarios:

➡️ Foam Suction Cup Applications in Industry

(Covers packaging, labeling, woodworking, electronics, glass, and more.)

9.2 If You Need Help Selecting the Correct Size, Hardness, or Material

Go straight to the engineering guide:

➡️ How to Select the Right Foam Suction Cups

(Complete sizing rules, diameter calculations, foam hardness selection, vacuum flow settings, and checklists.)

9.3 If You’re Comparing Foam vs. Rubber Suction Cups

See when foam is better (and when rubber still works):

➡️ Foam vs Rubber Suction Cups: Material Guide

(Includes NR, EPDM, NBR, silicone, PU comparisons, and structural differences.)

9.4 If You Handle Rough, Porous, Dusty, or Oily Surfaces

This is the most technical and surface-focused article in the series:

➡️ Foam Suction Cups for Rough & Oily Surfaces

(In-depth behavior on rough cartons, MDF, oily metal parts, dusty wood, and textured plastics.)

9.5 If You Want to Reduce Replacement Frequency and Total Cost

Learn how to extend foam cup life and optimize maintenance:

➡️ Foam Suction Cup Life, Maintenance & Cost

(Inspection routines, wear patterns, replacement intervals by industry.)

9.6 If You’re Facing Drop-Offs, Slow Pick-Up, or Vacuum Alarms

Jump straight to the troubleshooting handbook:

➡️ Foam Suction Cups Not Holding? Troubleshooting Guide

(This guide is organized by symptoms and includes diagnostic steps.)

9.7 If You’re Ready to Source or Test Foam Suction Cups

Here is the product page for your inquiry:

➡️ Custom Foam Suction Cups – Product Page

You can request engineering recommendations by sending:

- Photos of the parts and surfaces

- Load weight and cycle speed

- Vacuum pump/ejector model

- Hose length and diameter

- Environment (dust, oil, heat, humidity)

I’ll evaluate these details and recommend the ideal foam hardness, material, geometry, and vacuum configuration.