1. Introduction

In my daily work supporting automation engineers, packaging plants, and OEM integrators, I’m often asked the same question:

“Why do standard suction cups fail on rough, porous, or inconsistent surfaces?”

This guide answers that question completely. Foam suction cups are becoming essential in modern automation, and here I’ll walk you through everything: how they work, where they excel, how to choose them correctly, and how they compare to rubber and bellows cups.

Where relevant, I’ll link directly to the detailed sub-articles in this series so you can jump to the topic you need.

1.1 What This Guide Covers

- How foam cups differ from rubber cups

- Where they are used across industries

- How to size and select them

- When to switch from rubber to foam

- Troubleshooting & maintenance guidance

- Direct links to deep-dive articles for each topic

1.2 Why Foam Suction Cups Matter Today

Automation today handles more:

- Recycled cartons

- MDF and wood composites

- Textured plastics

- Delicate coated surfaces

Rubber cups can’t seal these reliably.

Foam cups can—and this guide explains why.

2. What Are Foam Suction Cups?

2.1 Basic Structure & Working Principle

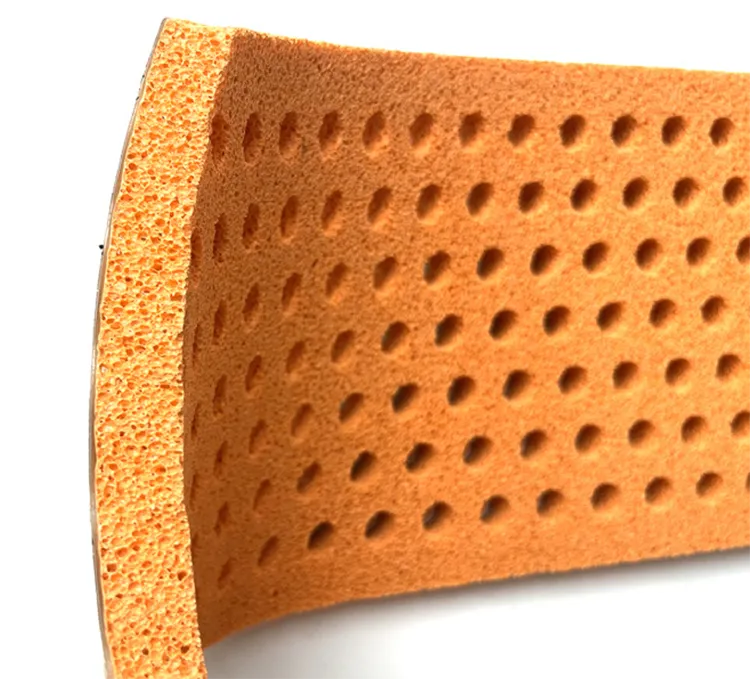

Foam suction cups combine:

- A foam layer (soft/medium/hard)

- A holder or rigid base

- A vacuum generator (pump or ejector)

The foam layer compresses and fills micro-gaps, producing grip where rubber cups fail.

For a deeper explanation of industry use cases, visit

➡️ Foam Suction Cup Applications in Industry.

2.2 How They Achieve Superior Surface Adaptability

Foam cups offer:

- Micro-gap sealing

- Significant height compensation

- Excellent conformity to rough or uneven textures

- Very low marking on delicate surfaces

2.3 When Foam Cups Are the Preferred Choice

Typical cases include:

- Corrugated or recycled cartons

- MDF, particle board, wood components

- Textured plastic housings

- Glossy, coated, or decorative surfaces

For material comparisons, see

➡️ Foam vs Rubber Suction Cups: Material Guide.

3. Key Advantages of Foam Suction Cups

3.1 Better Sealing on Rough & Porous Surfaces

Rubber cups leak instantly on porous surfaces. Foam closes gaps naturally.

3.2 More Stable Vacuum Performance

Reduced leakage = smoother pick-up and release.

3.3 Protects Delicate Surfaces

Soft foam is ideal for electronics, coated panels, and printed media.

3.4 Compensates for Height Variation

Foam adapts to inconsistent part dimensions.

3.5 Reduced Drop-Off Rates

I’ve seen failure rates drop by 80–90% after switching to foam.

If you’re dealing with drop-offs now, check

➡️ Foam Suction Cups Not Holding? Troubleshooting Guide.

4. Primary Industrial Applications

Foam suction cups are used across a wide range of automation processes. Below is a high-level overview, with a link to the deep-dive article.

4.1 Packaging & Logistics

Perfect for porous or inconsistent cartons.

4.2 Woodworking & Furniture

MDF, particle board, and dusty surfaces that rubber cannot handle.

4.3 Electronics & Precision Assembly

Delicate surfaces where marking must be avoided.

4.4 Glass, Solar & Coated Panels

Non-marking silicone foam options protect fragile surfaces.

5. How to Select Foam Suction Cups: The Fundamentals

Selecting foam cups correctly is the key to performance. For the full engineering guide (with sizing formulas and checklists), jump to:

➡️ How to Select the Right Foam Suction Cups

5.1 Choosing the Right Diameter

- Heavier loads → larger diameter

- Rough/porous surfaces → increase diameter by 20% or more

- Unstable loads → choose bigger for safety margin

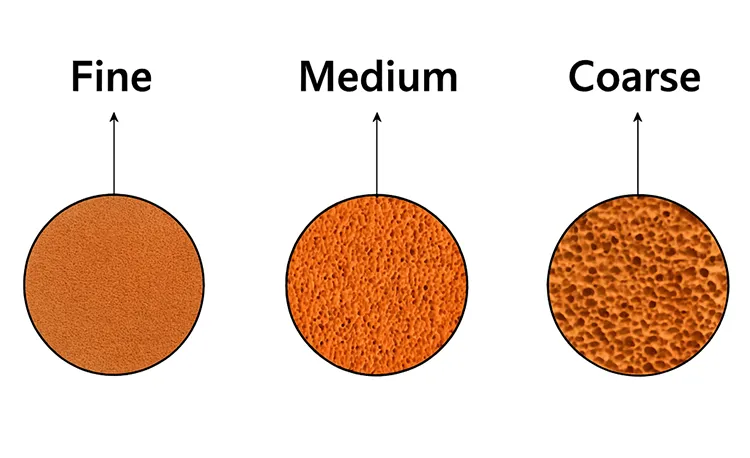

5.2 Foam Hardness Basics

- Soft foam: delicate surfaces

- Medium foam: universal choice

- Hard foam: rigid surfaces, precision positioning

5.3 Material Selection Snapshot

For quick decisions:

- NR: best adaptability, general use

- EPDM: weather/humidity resistance

- NBR: oily environments

- Silicone: high-temp & non-marking

- PU: longest wear life

Full material comparison:

➡️ Material Guide

5.4 Matching Cup to Vacuum System

Foam cups require higher flow, not deeper vacuum.

If you’re unsure how to set it up, see:

➡️ Selection & Design Guide

6. Foam Suction Cups vs. Rubber/Bellows Cups

When should you switch?

6.1 Core Differences in Structure

Foam cups compress to conform; rubber cups require smooth surfaces.

6.2 Performance Comparison Table

Foam wins on:

- Rough/porous surfaces

- Delicate surface handling

- Height variation

- Anti-marking

Rubber wins on:

- Fully smooth, non-porous materials

- Ultra-fast cycle speeds

- Heavy loads with small footprint

Detailed comparison:

➡️ Foam vs Rubber Suction Cups: Material Guide

6.3 When to Switch to Foam Cups

Switch if you see:

- Drop-offs on cartons

- Leaks on textured plastics

- Scratches on delicate products

- Failure on porous materials

If you work with rough, porous, dusty or oily surfaces, you must read:

➡️ Foam Suction Cups for Rough & Oily Surfaces

7. Common Problems & How to Prevent Them

7.1 Why Rubber Cups Fail

Rubber requires airtight contact; foam does not.

7.2 Why Foam Performs Better

Foam naturally closes gaps and tolerates leakage.

7.3 Prevention Rules

- Use correct hardness

- Oversize diameter for rough surfaces

- Apply high-flow vacuum, not high vacuum

- Clean filters and cups regularly

- Replace cups before compression set becomes permanent

If you’re troubleshooting right now:

➡️ Troubleshooting Guide

8. Conclusion

Foam suction cups are not a niche solution—they are a practical response to the realities of modern automation. As this guide has shown, most suction failures don’t come from poor vacuum systems or incorrect installation, but from a mismatch between cup type and surface condition.

If your process involves rough, porous, dusty, textured, coated, or inconsistent surfaces, foam suction cups offer clear advantages over standard rubber or bellows cups:

- Reliable sealing where rubber leaks

- Stable vacuum performance with fewer drop-offs

- Surface protection for delicate or decorative products

- Tolerance for height variation in real-world production

- Higher overall process stability, especially in packaging, woodworking, labeling, and precision handling

The key takeaway is simple:

Foam suction cups succeed because they adapt—mechanically and pneumatically—while rubber cups demand perfection.

That said, performance depends on correct selection. Diameter, foam hardness, material choice, and vacuum flow all matter. Oversizing slightly for rough surfaces, matching foam hardness to the application, and ensuring sufficient air flow will prevent most issues before they appear.

Need a Custom Solution?

In real production environments, there is rarely a one-size-fits-all suction cup. If your application involves unique surface conditions, load requirements, temperatures, or cycle speeds, customization is often the most reliable path.

If you need help selecting or customizing foam suction cups for your application, you can explore detailed specifications and request support here:

👉 https://www.kinsoe.com/product/custom-foam-suction-cups/

I work closely with automation engineers and OEMs to match suction cup design to real operating conditions—not theory. The right foam cup doesn’t just hold parts better; it stabilizes your entire process.

9. Related posts

Here are the full cluster articles for fast reference:

-

- Applications →

https://www.kinsoe.com/foam-suction-cup-applications-industries/ - Selection & Design Guide →

https://www.kinsoe.com/select-foam-suction-cups-sizing-guide/ - Material Comparison →

https://www.kinsoe.com/foam-vs-rubber-suction-cups-materials/ - Surface Challenges →

https://www.kinsoe.com/foam-suction-cups-rough-porous-oily-surfaces/ - Durability & Cost →

https://www.kinsoe.com/foam-suction-cup-lifetime-maintenance-cost/ - Troubleshooting →

https://www.kinsoe.com/foam-suction-cups-troubleshooting-guide/

- Applications →