1. Why Food-Grade & Pharma-Grade Rubber Needs Special Attention

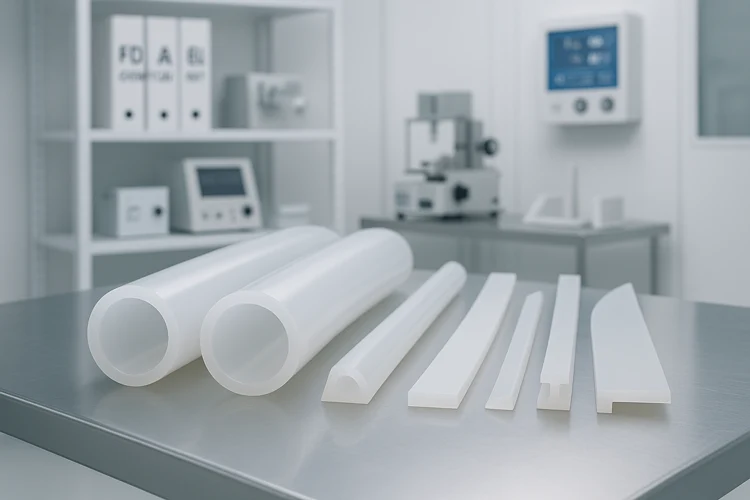

When I first started exploring rubber extrusion for regulated industries, I quickly learned that not all rubber is created equal. In food and pharmaceutical applications, even microscopic contamination or material migration can result in serious health risks, failed audits, and massive recalls.

Think about it—rubber tubing for a baby bottle, gaskets for water filtration systems, or seals in pharmaceutical filling machines. These components come into direct contact with substances consumed or injected by people. That’s why the materials and processes behind them must meet the most stringent safety standards.

Compliance is not just about passing a test; it’s about protecting consumer health and brand integrity. Regulatory bodies like the FDA (U.S.), EFSA (EU), NSF, and USP set detailed requirements for materials, migration limits, production environments, and traceability.

At KINSOE, I’ve seen firsthand how these standards impact everything from raw material selection to storage. Meeting them isn’t optional—it’s the baseline for trust, performance, and global market access.

So, how can you ensure that your extruded rubber components truly meet food-grade or pharma-grade standards?

Here’s a step-by-step approach built from real production practices and industry benchmarks.

2. Raw Material Compliance

The first and most crucial checkpoint in ensuring food-grade or pharma-grade rubber is selecting the right materials. When I work on any extrusion project for regulated industries, I always begin by verifying that every ingredient—base polymer, filler, pigment, and additive—complies with global safety standards.

Material Standards to Meet

I strictly adhere to certifications such as:

- FDA CFR 21 177.2600 – For rubber articles intended for repeated food contact in the U.S.

- EU 10/2011 – For plastic and rubber food contact materials in the European Union.

- NSF-51/NSF-61 – For components used in food equipment and drinking water systems.

- USP Class VI – For rubber materials in medical and pharmaceutical use.

Common rubber types that can meet these standards include:

| Rubber Type | Key Features | Complies With |

|---|---|---|

| Platinum-Cured Silicone | Non-toxic, odorless, heat stable | FDA, USP VI, EU 10/2011 |

| EPDM (Food Grade) | Good steam and chemical resistance | FDA, NSF-61 |

| FKM (Fluororubber) | Superior chemical resistance | FDA, some pharma-specific variants |

Choosing compliant material is non-negotiable—it’s the foundation of your entire process.

Additives and Contaminants to Avoid

I always verify that materials are free from restricted substances such as:

- Phthalates and other plasticizers (e.g., DEHP)

- Heavy metals (e.g., lead, cadmium)

- Nitrosamines

- Animal-derived ingredients (for pharma or halal/kosher needs)

Every supplier I work with is required to submit:

- Declaration of Compliance (DoC)

- Material Safety Data Sheets (MSDS)

- RoHS & REACH Reports

Without these, I simply don’t proceed.

📌 Pro Tip: Keep an internal reference sheet listing compliant rubber types and their applicable certifications—it saves hours during project qualification.

In short, material compliance isn’t just a checkbox—it’s a multi-layered validation process. Once the materials are approved, the next critical step is ensuring the production process maintains that purity. Let’s get into that next.

3. Production Process Control

Even with fully compliant raw materials, the risk of contamination remains high if the manufacturing process isn’t tightly controlled. I’ve seen excellent compounds fail final audits because of trace residues, poor cleaning protocols, or cross-contamination with industrial-grade rubbers.

So how do I ensure the extrusion process consistently meets food-grade or pharma-grade standards?

1. Cleanroom or Hygienic Workshop Management

For high-risk applications, I set up dedicated extrusion lines in isolated areas built according to GMP (Good Manufacturing Practice) guidelines. These areas are equipped with:

- HEPA-filtered ventilation systems

- Stainless steel work surfaces

- Controlled access and personnel hygiene systems

This setup helps prevent airborne particles, microbial growth, and cross-contamination.

2. Equipment Segregation and Maintenance

One golden rule I follow: no shared equipment between industrial and hygienic product lines. Even the tiniest rubber residue from a previous run can compromise safety. I also schedule:

- Regular cleaning and sterilization protocols

- Validation records after maintenance

- Tool color-coding systems to prevent mix-ups

3. Process Parameter Standardization

Food/pharma-grade rubber requires precise control of temperature, pressure, and cure time. At KINSOE, we log these variables digitally through our MES system for full traceability. Each batch includes:

- Extrusion speed

- Vulcanization profile (temperature & dwell time)

- Line pressure and vacuum consistency

Key Point: Standardization isn’t just for consistency—it’s the foundation of traceability and auditability.

4. Post-Processing Hygiene

Once extrusion is complete, I implement additional cleaning and curing to remove any volatile residues. These steps often include:

- Ethanol or purified water rinsing

- Post-cure baking (for platinum-cured silicone)

- Detergent-based degreasing

- Solvent extraction, especially for tubing used in medical devices

I also apply antistatic covers and sealed bags immediately after inspection to avoid airborne contamination.

5. Cross-Contamination Controls

To reinforce hygiene, I’ve developed tool segregation protocols, color-coded bins, and zone-based workflows. These prevent unintentional mixing of parts, tooling, or packaging across different compliance levels.

With every one of these controls, the goal is simple: protect the material’s integrity from raw compound to final packaged part. In the next step, I’ll walk you through how I validate this process through rigorous quality testing.

4. Quality Control and Testing

No matter how well I control the production environment, I never assume compliance until it’s been verified through testing. Food-grade and pharma-grade rubber components must not only be manufactured safely—they must prove their safety and functionality through documented performance and migration testing.

Here’s how I structure quality control to ensure full compliance:

1. Physical Property Testing

To confirm that the rubber maintains its integrity under mechanical stress, I run tests on each batch, including:

- Tensile strength

- Elongation at break

- Shore A hardness

- Compression set (permanent deformation)

These results are benchmarked against internal standards and regulatory requirements like ASTM D412 and ISO 37.

Every mechanical test helps ensure the product will hold up under real-world usage.

2. Migration Testing (Contact Safety)

This is the most critical aspect for materials in direct contact with food, water, or pharmaceuticals. I conduct:

- Overall Migration Limit (OML) tests – Determines total extractables in simulants

- Specific Migration Limit (SML) – For substances like plasticizers, metals, or accelerators

- Simulant compatibility testing – Using water, acidic solutions, ethanol, or oil-based liquids to reflect real usage

Migration tests follow protocols outlined in EU 10/2011, FDA 21 CFR, and NSF guidelines, often using third-party labs like SGS or Intertek.

3. Biocompatibility Testing

For pharmaceutical and medical-grade parts, I ensure that the rubber passes:

- USP Class VI – Tests for systemic toxicity, intracutaneous reactivity, and implantation safety

- ISO 10993 – Covers cytotoxicity, irritation, and sensitization for medical devices

This is mandatory for anything that touches mucous membranes, enters the body, or is used in cleanroom production.

4. Sensory and Visual Testing

Even if the material is technically safe, it won’t pass inspection if it smells bad, discolors liquids, or sheds particles. That’s why I also test for:

- Odor neutrality

- Color migration into food simulants

- Surface residue or blooming under microscope

These tests are especially important for baby products, water seals, and visible components.

Mandatory vs Recommended Testing

| Test Type | Required By Law? | Applicable Standards |

|---|---|---|

| Tensile & Hardness | Yes | ASTM, ISO |

| Migration Testing (OML/SML) | Yes | EU 10/2011, FDA, NSF |

| Biocompatibility (USP/ISO) | Case-by-case | USP Class VI, ISO 10993 |

| Sensory Testing | Recommended | Internal & customer specs |

With these layered tests, I can confirm and document that the product is not only functional and durable—but biologically and chemically safe. Next, I’ll show how I tie it all together with a solid documentation and traceability system.

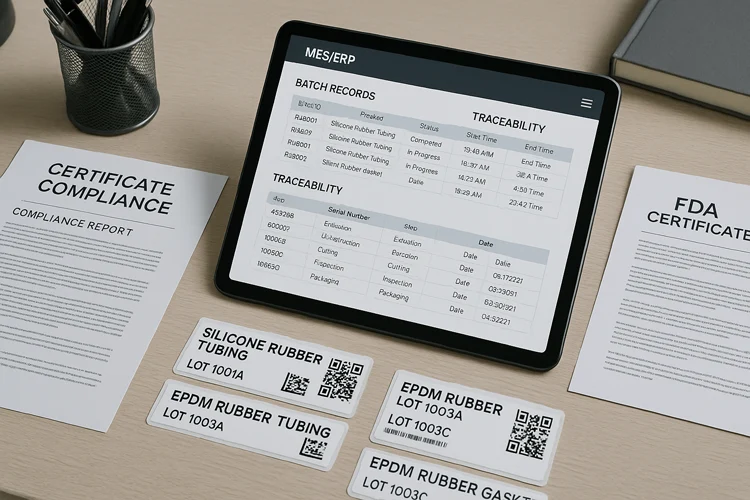

5. Documentation and Traceability

In regulated industries, quality without documentation is the same as no quality at all. Over the years, I’ve learned that even the best products can be rejected if they lack proof of compliance. That’s why at KINSOE, I’ve built a traceability system that documents every stage of production, from raw material to final shipment.

1. Batch Management

Each extrusion batch is assigned a unique traceable lot number linked to:

- Raw material supplier and formulation

- Process parameters (temperature, pressure, speed)

- In-line inspection records

- Final product identifiers (label, storage bin, pallet ID)

This allows me to trace any issue back to its source in minutes.

2. Compliance Documentation System

To support audits or customer verification, I maintain an organized library of:

- Declaration of Compliance (DoC) for each raw material and finished product

- Third-party certificates (FDA, NSF, USP, EU)

- Internal testing reports

- Customer inspection records

- SDS, RoHS, REACH documents

I’ve learned to align this documentation with customer QA templates to reduce back-and-forth and build trust quickly.

A strong documentation system is your shield during customer audits and regulatory inspections.

3. ERP/MES-Enabled Digital Records

Instead of relying on paper trails, I’ve adopted digital tracking through our ERP and MES platforms. These systems automatically:

- Link each production run to its operator, shift, and machine

- Store quality test data in the cloud

- Track customer orders against lot numbers

- Trigger alerts if a material or process deviates from specification

This not only improves accuracy but also ensures compliance with global recall requirements.

4. Retention Policy and Oversight

To meet FDA and EU regulations, I store all documentation:

- For a minimum of 5 years after product release

- Under control of a designated quality records manager

- With offsite backups for business continuity

Without this system, responding to a product complaint or recall would be chaotic.

Traceability is not just about paperwork—it’s about protecting your brand and ensuring consumer safety long after the product leaves your facility.

Next, I’ll explain how we manage global regulatory compliance and certification workflows to meet evolving market demands.

6. Regulatory Compliance and Certification Management

Staying compliant isn’t just about meeting today’s requirements—it’s about preparing for tomorrow’s. Over the years, I’ve realized that regulatory standards for food and pharmaceutical contact materials evolve frequently, and failing to keep up can mean losing market access.

To stay ahead, I’ve developed a structured approach to regulatory compliance and certification management.

1. Key Regulations by Region

Here’s a quick reference of the major food/pharma-contact rubber regulations we follow:

| Region | Regulation Name | Application Scope |

|---|---|---|

| United States | FDA CFR 21 177.2600 | Rubber articles in contact with food |

| European Union | EU 10/2011 | Food contact materials, including elastomers |

| China | GB 4806.11-2016 | Food contact rubber materials |

| Global | NSF-51 & NSF-61 | Food equipment and drinking water systems |

| Global | USP Class VI / ISO 10993 | Pharmaceutical/medical device materials |

Each market may have slight variations, but the guiding principle remains the same: verify that the material does not release harmful substances under expected conditions of use.

2. Certification Process

I break down the certification flow into three practical steps:

- Internal pre-evaluation:

- Review formulations and process records

- Perform internal migration and physical testing

- Third-party testing:

- Select labs like SGS, Intertek, or TÜV SÜD

- Conduct full migration and biocompatibility panels

- Client-facing documentation:

- Compile certificates, reports, DoC, and test summaries into a standard format

- Prepare for on-site factory audits if required by the customer

Certification is not a one-time action—it’s a continuous readiness posture.

3. Ongoing Regulation Monitoring

To ensure long-term compliance, I actively monitor updates from regulatory bodies like:

- U.S. FDA – www.fda.gov

- European Food Safety Authority (EFSA) – www.efsa.europa.eu

- NSF International – www.nsf.org

We subscribe to newsletters, attend compliance seminars, and regularly update internal specifications to match new migration limits or banned substance lists.

4. Supporting Resources

I maintain a library of:

- Regulation summaries by country/region

- Material guides mapping rubber types to allowable uses

- Testing protocol templates for new product development

By doing so, I make it easy for our internal teams—and our customers—to stay compliant without needing to be regulatory experts.

A proactive compliance strategy protects your global sales and reinforces your credibility with quality-focused clients.

Up next, I’ll walk you through how we manage storage and packaging to preserve cleanliness and ensure food-grade integrity all the way to final delivery.

7. Storage and Packaging Management

Even the best rubber component can lose its food-grade or pharmaceutical compliance if it’s mishandled during storage or packaging. That’s why I treat the post-production phase with the same rigor as manufacturing—because cleanliness and traceability don’t stop at the factory door.

1. Packaging Materials and Design

Every food or pharma-grade product I ship is double-layer packaged:

- Inner packaging: Made from food-grade polyethylene (PE) bags, sealed immediately after final QC

- Outer packaging: Corrugated cartons labeled with batch number, product name, and compliance symbols

Whenever possible, we request or provide the DoC for packaging materials themselves to ensure they meet food contact standards like EU 1935/2004 or FDA 21 CFR 177.1520.

The packaging should be as compliant and traceable as the product inside.

2. Storage Environment

Once packaged, rubber products must be stored in controlled conditions to maintain cleanliness and material properties. I apply the following rules:

- Ventilation: Warehouses are equipped with HEPA filters and airflow monitoring

- Moisture control: Humidity is kept below 60% to prevent mold or degradation

- Light shielding: UV-sensitive products are stored in shaded or opaque bins

- Temperature: Stored between 10°C–30°C to avoid premature aging or warping

Products are always arranged using the FIFO (First In, First Out) method to ensure no outdated batches remain in circulation.

3. Labeling and Identification

Each product is labeled with:

- Product name and internal item code

- Batch/lot number

- Production and expiry date

- Compliance markings (e.g., FDA-compliant, USP VI, etc.)

These labels help customers identify the part’s compliance at a glance and facilitate audits, recalls, or restocking.

In highly regulated markets, unclear or missing labels can trigger an automatic rejection or audit failure.

4. Cross-Contamination Prevention in Logistics

During shipping preparation, I make sure that:

- Food/pharma parts are kept separate from industrial-grade products

- No repacking or exposure occurs outside the controlled area

- Pallets are shrink-wrapped and sanitized before loading

If a product is headed for cleanroom integration (such as in a pharmaceutical facility), we even offer double-bagging and gamma-sterilized packaging upon request.

By enforcing these practices, I ensure that the rubber products maintain their certified cleanliness and compliance from extrusion to end-user installation. Next, I’ll walk you through how continuous improvement and feedback loops help us evolve and optimize every stage of this process.

8. Continuous Improvement and Customer Feedback Mechanism

Compliance is not a destination—it’s an ongoing journey. Over the years, I’ve learned that the only way to stay ahead of tightening regulations and rising customer expectations is to embed continuous improvement into every layer of the business.

Here’s how I maintain and enhance food-grade and pharmaceutical-grade rubber production at KINSOE:

1. Customer Complaint and Feedback Tracking

Every customer concern—no matter how small—is logged into our Quality Management System (QMS). Each case includes:

- Problem description

- Product lot number and application context

- Root cause analysis (RCA)

- Corrective and preventive actions (CAPA)

We aim to respond within 24 hours and resolve within 5 working days. This not only builds trust—it helps identify weak points in our process we may have overlooked.

2. Internal Audit System

To make sure we’re not just putting out fires, I schedule quarterly internal audits across:

- GMP workshop cleanliness

- Compliance documentation

- Employee procedures and cross-contamination safeguards

- Maintenance and calibration records

Each audit includes a non-conformity log and a follow-up verification to ensure corrective actions are not only issued, but closed.

Without internal auditing, small process drifts can accumulate into major compliance risks.

3. Employee Training Program

The people on the shop floor are the front line of compliance. That’s why I’ve built a structured training system covering:

- Regulatory updates (FDA, EU, GB, NSF, etc.)

- GMP fundamentals and hygiene practices

- Quality control procedures and inspection protocols

- Emergency recall and escalation mechanisms

New hires undergo onboarding training within 1 week, and all employees are re-certified annually.

4. Supplier Requalification and Evaluation

Vendors and raw material suppliers are re-audited annually or whenever a new regulation arises. We assess:

- DoC and certification updates

- Changes in formulations or production sites

- Responsiveness to non-conformance reports

- Consistency in delivery and communication

I believe that your supply chain is an extension of your compliance system. If one link breaks, the entire chain is at risk.

5. Data-Driven Improvement Loop

All quality metrics—complaints, audit scores, production deviations—are reviewed in monthly quality meetings. Based on trends, we implement:

- Process updates

- Design reviews

- Testing enhancements

- Tooling modifications

By doing this, we ensure that improvements are based on facts—not assumptions.

Up next, I’ll bring all of these points together with a practical summary and key takeaways to help you build or evaluate your own food/pharma-grade rubber system.

9. Conclusion: Building a Fully Compliant Rubber Extrusion Process

When I reflect on what it takes to produce food-grade or pharmaceutical-grade extruded rubber parts, one thing stands out: compliance is the result of consistency, not luck.

To truly meet FDA, EU, NSF, and USP standards, I’ve built systems that ensure every stage of the process—from raw material to delivery—is controlled, traceable, and verifiable.

Here are the essential checkpoints I never skip:

- Raw material compliance: Always choose certified rubber compounds and additives. Validate every ingredient with documentation like DoC and MSDS.

- Clean production environments: Maintain physical separation, tool control, and GMP-level hygiene to prevent contamination.

- Validated processes: Standardize your extrusion parameters, equipment cleaning routines, and post-curing protocols.

- Rigorous testing: Conduct mechanical, migration, and biocompatibility tests tailored to your market’s legal requirements.

- Full traceability: Use ERP/MES tools to link every product back to its origin and process history.

- Up-to-date certification: Stay ahead by continuously monitoring regulatory changes and maintaining current certificates.

- Controlled packaging and storage: Ensure that even after production, the product remains safe, clean, and compliant.

- Ongoing improvement: Use data, audits, and customer feedback to make your system smarter, stronger, and more compliant over time.

Prevention is cheaper than recall. And in regulated markets, prevention means process.

At KINSOE, this philosophy has enabled me to supply reliable, compliant rubber components to customers in food processing, medical equipment, and consumer health sectors across the globe. Whether you’re a buyer, engineer, or quality manager, I hope this article has given you a clear roadmap to evaluate and improve your compliance strategy.

Because when it comes to food and pharmaceutical contact materials, there are no shortcuts—only systems.