I. Introduction

Sealing rings might be small, but their role in food-related systems is anything but minor. Whether used in a home pressure cooker or an industrial bottling line, sealing rings are the frontline defense against leaks, contamination, and mechanical failure. They create a tight, reliable barrier between components, ensuring that food products remain safe, uncontaminated, and properly processed.

But here’s the catch: not all sealing materials are created equal, especially when we need them to meet two demanding criteria—food-grade safety and high-temperature resistance. A gasket that’s perfect for room-temperature bottling may degrade or leach chemicals under the intense heat of commercial cooking. And a high-heat resistant seal could still fail food safety tests if it releases odors, tastes, or non-compliant substances.

Choosing the wrong sealing ring can have serious consequences. I’ve seen applications where non-compliant materials led to flavor contamination, product recalls, and failed regulatory inspections. In other cases, seals have cracked or deformed under heat, leading to equipment damage and production downtime.

That’s why I’m writing this article—to walk you through the essential criteria, compare the most common materials used today, and share real-life applications that will help you make an informed, confident decision. Whether you’re designing kitchen equipment, selecting parts for a beverage line, or simply curious about what’s inside your espresso machine, this guide will equip you with the answers.

II. Key Requirements for Food-Grade, High-Temperature Seals

When selecting sealing rings for food applications involving heat, it’s not just about finding a material that “works.” The right choice must meet strict hygiene standards, withstand demanding temperatures, and remain reliable over time—even with repeated cleaning, pressure, or chemical exposure. Let’s break down the key requirements that define a truly suitable material.

2.1 Food Safety Standards

To qualify as food-grade, a sealing material must be non-toxic, odorless, and tasteless—even under stress or prolonged use. This means no leaching of harmful compounds, no chemical reactions with food substances, and no compromise in purity. Globally recognized certifications ensure materials meet these criteria:

- FDA (21 CFR 177.2600): The gold standard in the U.S. for rubber materials in contact with food.

- EU Regulation 1935/2004: A stringent European framework covering materials intended to come into contact with food.

- LFGB (Germany): Often considered even stricter than FDA, ensuring materials do not alter food taste or safety.

A key mistake I’ve seen in product development is assuming that all silicone or rubber parts are food-safe. They’re not. Unless specifically certified, many industrial-grade materials will fail food-contact requirements.

2.2 High-Temperature Resistance Benchmarks

Not all food applications operate at the same temperature. The sealing material must maintain its shape, elasticity, and sealing capability at the upper temperature limits of its use case. Here’s a reference for typical food-related temperature categories:

- Household cooking and baking: 180–250°C

- Pressure cookers and sterilizers: 120–140°C (with pressure)

- Industrial fryers and autoclaves: 250–300°C

A suitable sealing ring must not only resist heat but also avoid permanent deformation (compression set) or thermal breakdown. Once a seal warps, cracks, or hardens under heat, failure is just a matter of time.

2.3 Other Essential Properties

Beyond food compliance and thermal endurance, there are several performance traits that matter in real-world scenarios:

- Flexibility and Elasticity: A rigid seal can’t adapt to flange movement or thermal expansion, leading to leaks.

- Resistance to Cleaning Chemicals and Oils: Especially in industrial or commercial kitchens where strong detergents or vegetable oils are present.

- Longevity and Maintenance Needs: Some materials degrade faster with repeated heat-cool cycles. Others resist fatigue and need fewer replacements.

“A good food-grade seal isn’t just compliant—it’s dependable across dozens of cleaning cycles, thermal shocks, and exposure to fats or steam.”

Up next, we’ll look at the most common sealing materials used today and see how they stack up.

III. Common Materials Compared

Choosing the right sealing ring material starts with understanding the strengths and limitations of each candidate. Below, I’ve outlined four of the most widely used materials for food-grade and high-temperature applications—each one brings unique advantages to the table.

3.1 Silicone Rubber (VMQ)

Silicone is one of the most recognized and trusted materials in food-contact environments. It offers exceptional flexibility and remains stable in a wide temperature range, typically from -60°C to +250°C, with some high-grade variants going even higher.

Where it’s used:

You’ll find silicone rings in baking molds, pressure cooker gaskets, microwave covers, and oven door seals. It’s favored for both domestic and commercial kitchenware because it doesn’t affect taste or odor and is easy to clean.

Pros:

- Excellent thermal resistance up to 250°C

- Highly flexible and elastic, even in cold environments

- Certified food-safe (FDA, LFGB available)

- Color-customizable and non-reactive

Cons:

- Poor resistance to oils and greases

- Not suitable for continuous exposure to strong acids or fuels

- Slightly lower mechanical strength than other rubbers

“If your equipment touches baked goods, steam, or dry heat—silicone is almost always the top contender.”

3.2 PTFE (Teflon®)

Polytetrafluoroethylene, better known by its brand name Teflon, is a non-elastomeric material with one major strength: chemical and thermal resistance. PTFE operates safely up to 260°C, with very low friction and zero reactivity, making it ideal for aggressive environments.

Where it’s used:

High-end dairy systems, sterile filling lines, chemical handling in food manufacturing, and gasket coatings.

Pros:

- Outstanding chemical inertness

- Can tolerate steam, acids, and fats

- Extremely low friction (non-stick)

- Food-safe and non-contaminating

Cons:

- Lacks elasticity (not compressible like rubber)

- Prone to cold flow under load

- More expensive and harder to fabricate into flexible gaskets

“When I see sealing challenges involving aggressive cleaners, dairy acids, or extreme heat—PTFE is often the only viable option.”

3.3 FKM (Viton® – Food Grade)

Fluorocarbon rubber (FKM), also known by the trade name Viton, is a premium sealing material that combines excellent oil resistance with high-temperature stability up to 300°C in food-grade variants.

Where it’s used:

Oil fryers, deep-fat cooking equipment, food-grade pumps exposed to high temperatures and hydrocarbon-based ingredients.

Pros:

- Handles extreme heat (up to 300°C)

- Resistant to oils, fats, and some acids

- Long service life in harsh environments

- Available in FDA-compliant grades

Cons:

- Higher cost compared to silicone and EPDM

- Less flexible in cold conditions

- May be overkill for low-stress environments

“If your seal comes in contact with hot oils or operates in a demanding fryer line, FKM is the material I’d trust.”

3.4 EPDM (Food Grade)

Ethylene Propylene Diene Monomer (EPDM) rubber is commonly used in systems with steam, hot water, or mild acids. While it maxes out around 150°C, it remains affordable and easy to mold, making it a go-to for many beverage and low-heat applications.

Where it’s used:

Steam sterilizers, soda dispensers, espresso machines, dishwashers.

Pros:

- Excellent resistance to steam and water-based solutions

- Good elasticity and chemical resistance (except oils)

- Lower cost compared to FKM or PTFE

- Suitable for low-pressure and low-temp systems

Cons:

- Not suitable for oil-rich or high-heat environments

- Limited upper temperature resistance (typically ≤150°C)

“EPDM is a smart choice when dealing with hot water, steam, or beverages—but not for hot oil systems or oven use.”

IV. Common Cases

Knowing the technical specs of sealing materials is useful—but real insight comes from seeing how they perform in actual environments. I’ve worked with engineers, designers, and even home appliance developers who faced the same question: Which material works best for this application? Here’s how these materials play out in the real world.

4.1 Everyday Kitchen and Household Applications

Let’s start with what you probably have at home.

- Pressure Cookers: Most modern pressure cookers rely on silicone gaskets. Why? Because silicone handles both the elevated pressure and heat (often ~120–130°C), and doesn’t introduce odors or flavors into food. It’s also easy to remove and clean.

- Oven Doors and Bakeware: Oven door seals often use silicone or sometimes PTFE coatings in commercial settings. These seals endure dry heat and need to remain pliable without sticking or degrading.

- Espresso Machines: Internal gaskets must withstand high-pressure steam and occasional acid buildup from water impurities. Here, EPDM or silicone is typically used. EPDM offers better steam resistance, while silicone remains a favorite for flavor neutrality.

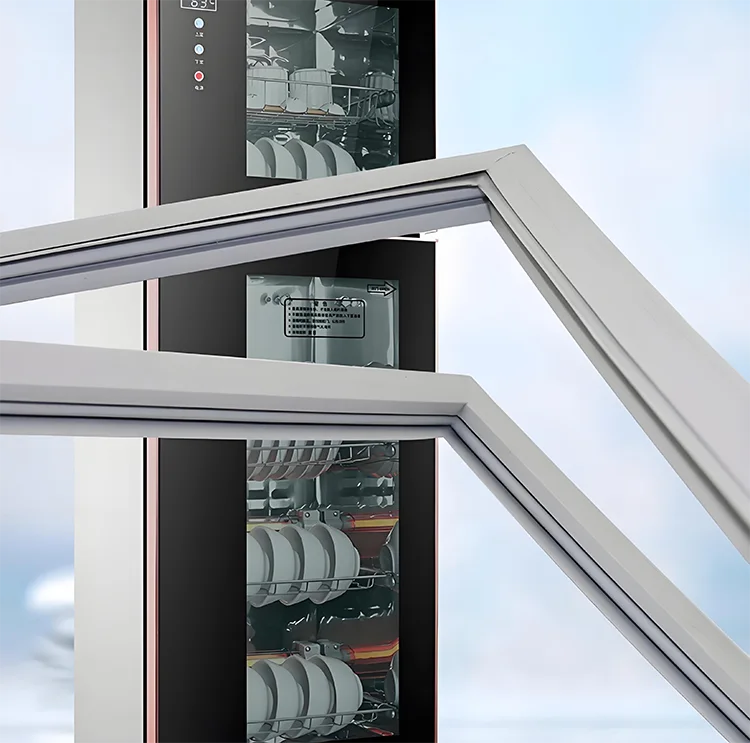

- Dishwashers: Surprisingly, dishwashers don’t get as hot as ovens or pressure cookers—maxing out around 120°C. For these, EPDM seals are standard. They handle steam and detergent exposure well, though they degrade quickly in oil-rich conditions.

“If you’ve ever had a dishwasher start leaking around the door, chances are it’s because the EPDM seal hardened or lost its elasticity over time.”

4.2 Commercial and Industrial Use Cases

Industrial food processing demands higher performance—and sometimes more specialized materials.

- Industrial Ovens: Doors of tunnel ovens or rotary rack ovens may use PTFE seals. They’re exposed to constant high heat, and PTFE’s thermal and chemical resistance make it ideal.

- Bottling Lines (Hot-Fill Juices): Juice bottling requires seals that can handle pasteurization temperatures, often over 85°C during filling. Silicone or FKM is used here. FKM offers superior resistance to acidic juice oils and elevated heat.

- Dairy Processing Systems: These systems often switch between hot water, acidic cleaners, and milk fat exposure. PTFE or EPDM is used depending on the cleaning process and contact points.

- Fryers and Food-Grade Pumps: These are some of the harshest environments for a seal. Fryers require seals to withstand direct oil exposure at temperatures close to 200–250°C. Only FKM survives long-term without swelling or cracking.

4.3 Special Environments

Some scenarios demand more than just heat resistance or food safety—they need specialized performance.

- High-Pressure Sterilizers (Autoclaves): Equipment used for sterilizing utensils or packaging materials often reaches 130–140°C under pressure. Silicone and PTFE are both used here. Silicone for flexibility, PTFE for durability.

- Breweries and Fermentation Tanks: These systems face steam, alcohol vapors, and cleaning chemicals. EPDM is a popular choice here thanks to its steam and chemical resistance, plus cost-effectiveness.

- Vegan Cheese Production (Acidic Ingredients): Acid-rich formulations can attack standard rubber. In such cases, PTFE seals are preferred for their chemical inertness and flavor neutrality.

“One customer in plant-based dairy switched from silicone to PTFE after multiple failures in an acidic mixing tank. The difference in longevity was night and day.”

Next, I’ll walk you through a practical comparison table and three key questions to help you choose the best sealing ring material for your application.

V. Decision-Making Guide: How to Choose the Right Material

With so many materials and use cases, it’s easy to feel overwhelmed. But the right choice becomes clearer when you match material capabilities to your specific operating conditions. This section offers two tools: a quick comparison table for reference and three essential questions to guide your selection.

5.1 Quick Comparison Table

| Material | Max Temp | Food Grade | Best For | Not Suitable For |

|---|---|---|---|---|

| Silicone | 250°C | ✅ | Household appliances, ovens, bakeware | Prolonged oil exposure |

| PTFE | 260°C | ✅ | Harsh chemicals, dairy, sterilization | Areas needing flexibility |

| FKM | 300°C | ✅* | Fryers, oil pumps, high-temp food lines | Cold environments, cost-sensitive applications |

| EPDM | 150°C | ✅ | Steam systems, beverage dispensers | High heat, oil or grease contact |

*Note: Not all FKM grades are food-safe—ensure FDA or EU-compliant formulations are used.

This table condenses years of practical experience. While overlaps exist (e.g., silicone and EPDM both used in beverage systems), each material has a sweet spot where it shines.

5.2 3 Questions to Ask Before Choosing

Before you settle on a sealing material, answer these three questions:

- What temperature will the seal face continuously?

This determines whether silicone or FKM is even an option. High-heat applications immediately rule out materials like EPDM. - Will it be exposed to oils, acids, or steam?

This defines chemical resistance requirements. Oils and fats point you toward FKM, while PTFE is preferred for acidic or aggressive cleaners. - Is direct food contact required?

If yes, certifications matter. Always verify that your chosen material is FDA or EU-compliant. Just because a material is used in a kitchen doesn’t mean it’s safe for food contact.

“A seal that’s perfect for a sterilizer might fail miserably in a fryer—because heat isn’t the only enemy; oil, pressure, and cleaning chemicals are just as important.”

In the next section, I’ll highlight common mistakes people make when choosing sealing ring materials—and how to avoid them.

VI. Common Mistakes to Avoid

Even seasoned engineers and product designers can fall into these traps—especially when deadlines are tight and budgets are squeezed. Choosing the wrong sealing material doesn’t always lead to immediate failure, but over time, these mistakes can result in contamination, product recalls, or costly downtime.

1. Assuming All Rubber is Food-Grade

Just because a gasket looks like silicone or EPDM doesn’t mean it meets FDA or EU standards. Many industrial rubbers contain plasticizers, curing agents, or fillers that can leach into food or emit odors. Always request material certification documents from your supplier.

“I’ve seen ‘gray market’ seals marketed as food-grade—only to fail lab tests due to excessive VOC release under heat.”

2. Choosing Silicone for Oily Environments

Silicone rubber performs poorly in oil-heavy settings. It swells, softens, and loses elasticity after repeated exposure to cooking oil or greasy environments. For these applications, FKM is a far better choice due to its resistance to hydrocarbons.

3. Ignoring Compliance Certifications

It’s not enough for a material to be safe—it must be provably safe. If your product is exported or used in commercial food systems, regulatory agencies may require documentation. Overlooking this can cause customs delays or product recalls.

- FDA-compliant isn’t the same as FDA-listed

- EU 1935/2004 requires traceability and migration testing

- LFGB compliance can be more stringent than either

4. Overlooking Cleaning Chemical Resistance

Food environments are cleaned frequently with hot water, acids, alkalis, and disinfectants. Seals that aren’t chemically resistant will degrade quickly, harden, or lose elasticity. PTFE and EPDM both handle this well, depending on the cleaner used.

“I’ve seen seals break down not during cooking, but during nightly CIP (clean-in-place) cycles—leading to unnoticed contamination risks.”

In the final section, I’ll wrap up with a recap and final recommendations to help you confidently choose the right sealing material.

VII. Conclusion

Finding the right sealing ring material for food-grade and high-temperature applications isn’t about picking the “best overall”—it’s about finding the best fit for your specific environment.

Here’s a quick recap:

- Silicone is flexible, clean, and ideal for dry heat and home appliances—but not for greasy systems.

- PTFE is unbeatable for harsh chemicals, acids, and extreme heat—but not suited for dynamic seals that require elasticity.

- FKM is the champion for oil-rich, high-temperature systems like fryers and pumps—but it comes at a higher cost.

- EPDM is perfect for steam and beverage equipment with moderate heat—but fails in oil or excessive heat exposure.

Ultimately, success comes down to understanding your operating conditions and ensuring your material choice is compliant, durable, and chemically compatible. Ask the right questions. Request certifications. Test in real-world conditions if possible.

“When in doubt, don’t just choose based on specs—match the material to your environment, and you’ll save time, money, and headaches down the road.”

If you’re still unsure, I always recommend consulting with a material engineer or rubber manufacturer who can guide you through application-specific considerations. At Kinsoe, we help our clients analyze sealing requirements across industries—from food and beverage to high-performance industrial systems—ensuring every part is tailored to perform safely and reliably.