1. Introduction

In pumps and rotating equipment, seals play a critical role in preventing fluid leakage, maintaining pressure, and protecting system components from wear. Whether it’s transporting clean water, hazardous chemicals, or abrasive slurries, the choice of seal type directly impacts operational efficiency, safety, and costs.

In industrial applications, two of the most common sealing solutions are mechanical seals and soft packing seals (also called gland packing). Each has its own strengths and limitations, making the selection process more than just a matter of price.

In this article, I’ll explain the working principles, advantages, and disadvantages of both types, as well as cost and maintenance considerations, to help you choose the right seal for your application.

2. Understanding the Basics

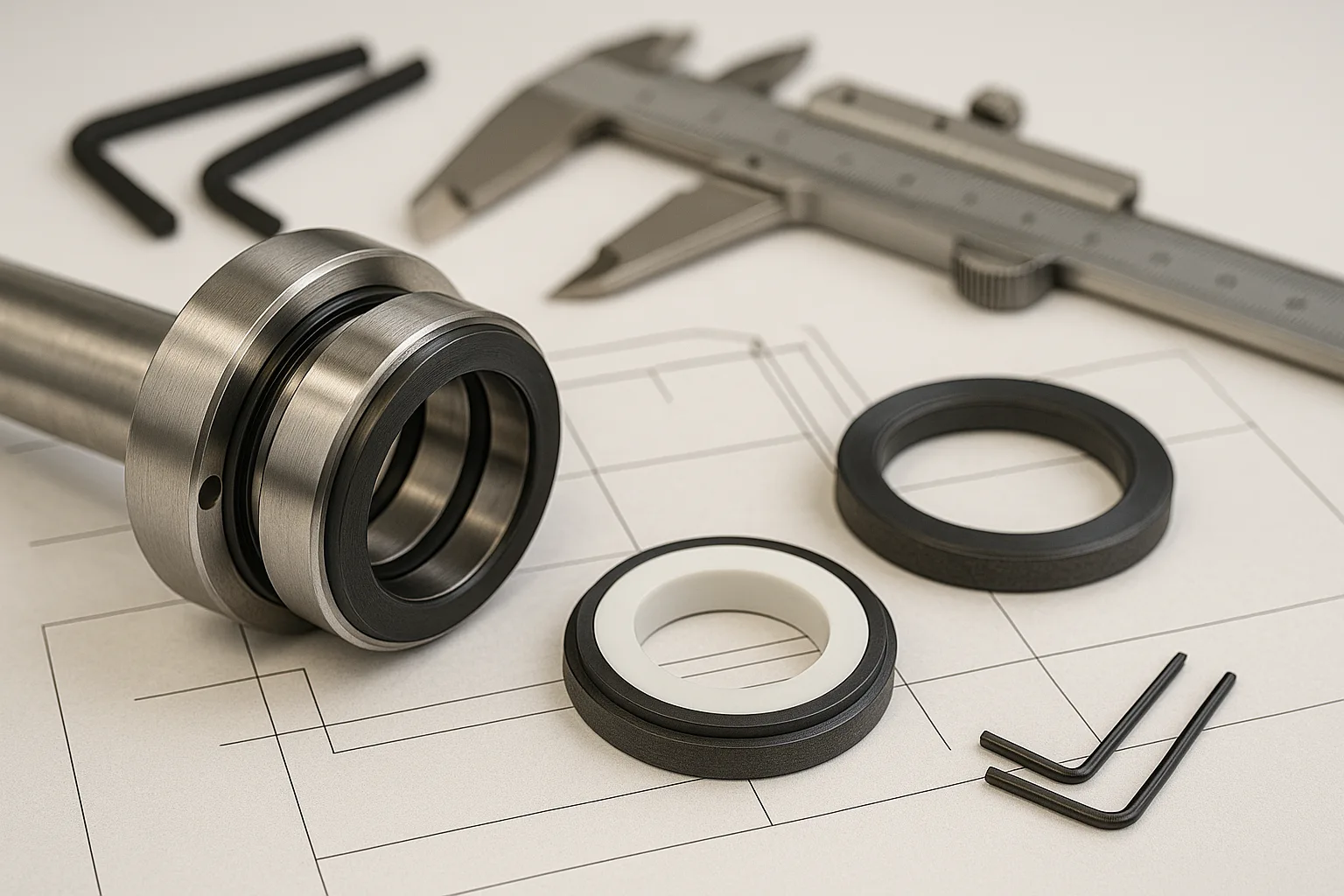

2.1 What Is a Mechanical Seal?

A mechanical seal consists of two ultra-flat surfaces—one stationary and one rotating—that press together to form a tight seal. One surface is typically mounted to the pump housing, while the other is fixed to the rotating shaft. A thin lubricating film between the faces prevents excessive wear and keeps leakage almost invisible.

Where it’s used:

-

Petrochemical plants

-

Power generation

-

Pharmaceutical and food processing industries

-

Applications requiring minimal leakage and compliance with environmental regulations

Key features:

-

Near-zero visible leakage

-

Complex design requiring precision installation

-

Works best in clean or well-flushed services

2.2 What Is a Soft Packing Seal (Gland Packing)?

A soft packing seal uses rings of braided material—such as graphite, PTFE, or aramid—compressed into a stuffing box around the shaft. Tightening the gland follower compresses the packing against the shaft sleeve, creating a sealing barrier.

Where it’s used:

-

General water services

-

Mining and slurry pumps

-

Marine applications

-

Older or lower-speed rotating equipment

Key features:

-

Allows controlled leakage to provide lubrication and cooling

-

Simple, rugged design

-

Tolerates more shaft movement than mechanical seals

3. Advantages and Disadvantages of Mechanical Seals

3.1 Advantages

-

Minimal Leakage: Excellent environmental compliance, suitable for hazardous fluids.

-

Lower Energy Loss: Less friction compared to packing seals, improving efficiency.

-

Extended Maintenance Intervals: Can run for years without replacement in clean service.

-

Standardization: Designs often comply with API 682 and ISO 21049 standards for performance and reliability.

Mechanical seals are often the go-to choice where downtime is costly and environmental control is critical.

3.2 Disadvantages

-

High Initial Cost: Can be several times more expensive than packing seals.

-

Sensitive to Conditions: Dry running, misalignment, or dirty fluids can cause premature failure.

-

Complexity: Requires skilled installation and specialized repair tools.

4. Advantages and Disadvantages of Soft Packing Seals

4.1 Advantages

-

Low Purchase Cost: Affordable and widely available.

-

Easy Installation: Can be replaced without specialized tools.

-

Misalignment Tolerance: Handles shaft deflection and vibration better.

-

Versatility: Works with abrasive fluids and slurry applications.

4.2 Disadvantages

-

Requires Continuous Leakage: Leakage is necessary for lubrication, which can lead to product loss.

-

Higher Energy Use: More friction against the shaft increases energy consumption.

-

Frequent Maintenance: Packing needs regular adjustments and more frequent replacement.

5. Cost and Maintenance Considerations

| Factor | Mechanical Seal | Soft Packing Seal |

|---|---|---|

| Initial Cost | High | Low |

| Energy Efficiency | High | Moderate to Low |

| Leakage Control | Excellent | Limited |

| Maintenance Frequency | Low | High |

| Service Life | Long (in clean service) | Short to Medium |

| Skill Required | High | Low |

Case Example:

In a clean-water pumping station, switching from soft packing seals to mechanical seals reduced maintenance downtime by 70% and saved over $15,000 annually in labor and replacement costs. However, in a slurry application at a mining site, packing seals proved more cost-effective due to the abrasive nature of the fluid, which would have worn out mechanical seals rapidly.

6. Choosing the Right Seal for Your Application

When deciding between mechanical seals and packing seals, consider:

-

Fluid Type: Hazardous or volatile fluids usually require mechanical seals; abrasive slurries often suit packing.

-

Environmental Compliance: Stricter regulations favor mechanical seals.

-

Maintenance Capabilities: If skilled labor is limited, packing seals may be easier to manage.

-

Total Cost of Ownership: Consider energy use, downtime, and environmental penalties—not just purchase price.

Industry Trends:

-

Mechanical seals dominate in petrochemical, pharmaceutical, and high-value manufacturing.

-

Packing seals remain common in water utilities, mining, and older facilities.

7. Conclusion

Both mechanical seals and soft packing seals have their place in industrial operations. Mechanical seals offer superior leakage control, energy efficiency, and long-term reliability—ideal for critical applications with stringent environmental requirements. Packing seals, on the other hand, excel in cost-effectiveness, tolerance to misalignment, and suitability for abrasive or dirty services.

The best choice depends on service conditions, available maintenance skills, and the balance between upfront cost and total operating cost.

8. References

-

API 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps

-

ISO 21049: Pump Shaft Sealing Systems for Rotating Equipment

-

EPA LDAR (Leak Detection and Repair) Guidelines

-

Manufacturer technical guides: John Crane, EagleBurgmann, Flowserve

Related Articles

Types of Rubber Seals by Shape, Material, and Use

Learn about different seal configurations, materials, and applications to broaden your understanding beyond mechanical and packing seals.

Extruded Rubber Seals: Materials, Design & Uses Guide

A practical guide to selecting materials, profiles, and designs for extruded rubber seals across various industries.

Why Rubber Seals Fail: Compression Set Explained

Understand what compression set is, why it causes seal failure, and how to prevent it through material and design choices.