Introduction

When it comes to fluid handling systems, few components are as deceptively simple yet critically important as peristaltic pump silicone tubing. This specialized tubing sits at the heart of peristaltic pump mechanisms—helping deliver fluids with exceptional precision, hygiene, and chemical safety. Whether you’re pumping nutrient media in a bioreactor, dispensing flavor syrup in a beverage machine, or running dialysis equipment in a hospital, the silicone tubing used inside the pump head is not just a passive channel—it’s an active part of the pumping process.

The unique demands placed on this tubing—constant flexing, compression, and recovery—mean that ordinary silicone tubing simply won’t do. That’s where pump-grade silicone tubing comes in: engineered for rebound resilience, biocompatibility, and clarity, it’s purpose-built for dynamic, demanding environments.

This article is for engineers designing fluidic systems, procurement professionals sourcing high-performance components, and OEM integrators looking to ensure their pumps run reliably across industries like medical, biotech, food processing, and chemical dispensing. I’ve worked with dozens of companies in these sectors, helping them match the right tubing to the right pump, and I’ve seen firsthand how critical that choice can be.

If you’re looking to understand what makes peristaltic pump silicone tubing different—and how to choose the right one—this guide will give you all the insights you need. Let’s dive in.

1. What Is Peristaltic Pump Silicone Tubing?

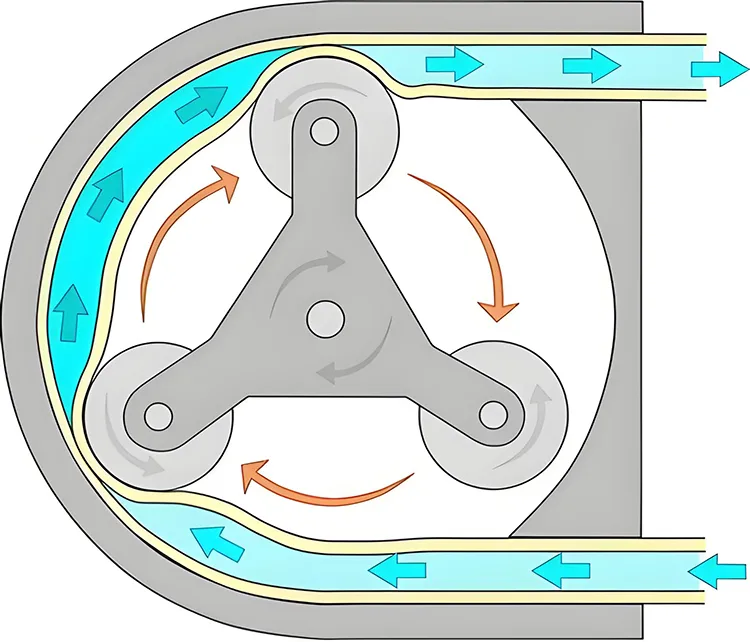

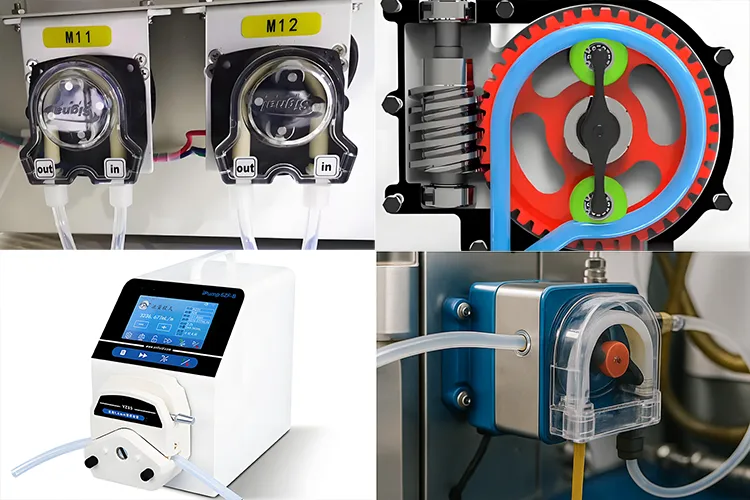

Peristaltic pump silicone tubing is a highly flexible, specially formulated type of silicone hose designed to operate inside peristaltic pump systems. Unlike traditional silicone tubing that simply transports fluid, this tubing must withstand repeated compression and relaxation as the pump rollers rotate over it—creating a pushing action that moves fluid forward without direct contact between the pump and the liquid.

In a peristaltic pump, the tubing is looped around a rotor with several “rollers” or “shoes.” As the rotor turns, the rollers squeeze the tubing at intervals, pushing the fluid inside toward the outlet. Once the roller passes, the tubing must quickly regain its shape to avoid suction loss or flow interruptions. This is where high rebound elasticity and consistent wall integrity of silicone tubing become mission-critical.

What sets peristaltic pump-grade silicone tubing apart from standard silicone tubes? First, it is often made from platinum-cured silicone, offering superior purity, biocompatibility, and lower extractables. Second, it is manufactured to precise wall thickness and Shore A hardness specifications, ensuring consistent compression response and long-term performance without premature fatigue or cracking.

“Peristaltic pump tubing isn’t just a hose—it’s a mechanical component. Its flexibility, compression set resistance, and chemical compatibility directly affect your pump’s precision and reliability.”

If you were to visualize how this tubing works inside a peristaltic pump, you’d see a constant flex-recover cycle occurring every few seconds. Over thousands of cycles, the tubing must maintain both shape and strength. That’s why not just any silicone tubing can be used—it must be engineered specifically for the job.

Peristaltic pump silicone tubing

2. Key Properties of Peristaltic Pump-Grade Silicone Tubing

When it comes to peristaltic pumps, the tubing isn’t just a passive component—it actively determines how accurately, safely, and consistently fluid is delivered. That’s why peristaltic pump-grade silicone tubing is engineered with a specific set of performance characteristics that distinguish it from general-purpose silicone hoses.

• Flexibility and Rebound Resilience

The most important property is flexibility combined with rebound resilience. The tubing must endure constant pinching and release from pump rollers. If it’s too stiff, it won’t compress easily; if it’s too soft, it may collapse or not recover its shape. High-performance silicone tubing achieves a perfect balance—soft enough to compress smoothly, but with excellent memory to spring back to its original form immediately after.

• High Clarity

Many peristaltic pump applications—especially in laboratory and medical settings—require visual inspection of the fluid path. That’s why translucency or optical clarity is a hallmark of quality tubing. Clear silicone allows operators to see bubbles, sediment, or contamination instantly, reducing operational risk.

• Biocompatibility and FDA/USP Compliance

In medical, food, and biopharma applications, safety is non-negotiable. Pump-grade silicone tubing is typically platinum-cured to reduce extractables and enhance purity. It complies with FDA 21 CFR 177.2600, USP Class VI, and ISO 10993 standards—ensuring it’s safe for human contact, ingestible fluids, or sensitive biologicals.

• Temperature and Chemical Resistance

Silicone naturally resists a wide temperature range—usually from -50°C to +200°C—making it ideal for hot-fill processes or refrigerated systems. It also offers moderate resistance to many chemicals including acids, alcohols, and bases. However, it’s worth noting that silicone has limited resistance to oils and hydrocarbons (we’ll address this further in the troubleshooting section).

• Sterilization Compatibility

Whether you’re using autoclave, gamma irradiation, or CIP/SIP (Clean-In-Place/Sterilize-In-Place) procedures, platinum-cured silicone tubing retains its mechanical and surface properties. This makes it suitable for multiple sterilization cycles—especially valuable in pharmaceutical and bioprocessing systems.

The real value of pump-grade silicone tubing lies in its ability to combine elasticity, purity, and stability in one material. That’s why it remains a preferred choice across regulated industries.

![]()

3. Typical Applications

Peristaltic pump silicone tubing plays a crucial role in a wide range of industries—anywhere that sterile, accurate, and contamination-free fluid handling is required. Because the fluid only contacts the inside of the tubing, not the pump mechanism, it’s ideal for sensitive applications. Let’s explore where and how this tubing is commonly used.

• Medical (Dialysis, Infusion)

In dialysis machines, peristaltic pumps are used to control blood and dialysate flow precisely. Here, the tubing must be biocompatible, non-leaching, and highly reliable, since any failure can pose a direct risk to patient safety. Similarly, in infusion and transfusion systems, soft and sterile platinum-cured silicone ensures smooth fluid delivery without shear damage to delicate cells.

• Biopharma (Fluid Transfer, Fermentation)

In biopharmaceutical manufacturing, peristaltic pumps with silicone tubing are used to transfer culture media, buffers, and drug formulations in a closed-loop, sterile environment. These operations demand compliance with USP Class VI and FDA standards, as well as resistance to multiple sterilization cycles. Tubing integrity here directly affects batch quality.

• Food and Beverage Dispensing

Silicone tubing approved for food contact is ideal for peristaltic systems that handle sauces, flavorings, dairy, and juice concentrates. Its non-reactivity and cleanliness mean no flavor carryover or contamination risk. In coffee machines, syrup dispensers, and filling equipment, peristaltic systems deliver metered doses with hygienic precision.

• Laboratory Dosing

In chemical and analytical labs, peristaltic tubing is used to dose, sample, and transfer precise volumes of liquid reagents. The tubing’s clarity makes it easy to track fluid flow, while its resilience ensures consistent performance even in repetitive testing scenarios.

• Ink, Chemical, and Detergent Dispensing

In commercial printers, car wash systems, and cleaning dispensers, silicone tubing handles aggressive but water-based fluids. The peristaltic mechanism allows for clean, drip-free dispensing, even of viscous or foaming liquids. Tubing choice here must consider chemical compatibility and wear resistance.

• Case Example: Pharmaceutical Filling Line

One client I worked with—a pharma OEM—used platinum-cured peristaltic tubing in a semi-automatic vial filling machine. The tubing allowed for precise dosage control while meeting GMP and sterility requirements. Its ability to withstand repeated autoclave cycles made it both cost-effective and compliant for small-batch injectable drug production.

“From hospital bedsides to biotech cleanrooms, peristaltic pump silicone tubing is trusted where cleanliness, safety, and accuracy can’t be compromised.”

4. Common User Concerns (and Solutions)

Through customer feedback, forum discussions, and real-world troubleshooting, I’ve identified the most frequent challenges people face when using peristaltic pump silicone tubing. The good news? Most of these issues can be prevented—or solved—with the right knowledge and product choice. Let’s break them down:

a. Tubing Cracking or Wearing Out Fast

Symptoms: Visible surface cracks, loss of elasticity, flow inconsistency after a short period.

Root Causes:

- Using low-quality or peroxide-cured silicone, which has higher extractables and poor durability.

- Incorrect Shore A hardness, resulting in too-soft or too-stiff tubing for the pump’s compression level.

- Wall thickness not suited to the pump head design.

Solutions:

- Use platinum-cured silicone tubing, which resists degradation and has better rebound properties.

- Match tubing Shore A hardness and wall thickness to pump roller geometry.

- Rotate tubing orientation periodically to distribute compression wear.

“Many premature failures are due to mismatched tubing—not the pump. Material and dimension precision matter.”

b. Tubing Slipping into Pump Head

Symptoms: Tubing pulls into or pops out of the rotor area during operation.

Root Causes:

- Loose fit due to wrong outer diameter (OD).

- High friction from roller head materials or aggressive fluid pressures.

- Lack of secure mounting or anchoring on inlet/outlet ends.

Solutions:

- Choose tubing with tight OD tolerance for a snug, controlled fit.

- Use barbed fittings or clamps to secure tubing in place.

- Ensure proper alignment and tensioning inside the pump cassette.

c. Pulsation and Flow Inaccuracy

Symptoms: Irregular flow, pulsation spikes, or under-dosing in precise applications.

Root Causes:

- Tubing loses shape due to fatigue or poor elasticity.

- Roller count too low, leading to higher pulsation amplitude.

- Tubing hardness not optimized for flow smoothing.

Solutions:

- Use high-rebound, platinum-cured silicone to maintain tubing form.

- Opt for multi-roller pump heads to reduce pulsation per revolution.

- Consider flow dampeners or downstream sensors if ultra-precision is needed.

d. Compatibility with Aggressive Fluids

Symptoms: Swelling, cracking, or discoloration of tubing exposed to certain fluids.

Root Causes:

- Silicone is not highly resistant to oils, fuels, and certain solvents.

- Prolonged exposure to aggressive chemicals alters tubing structure.

Solutions:

- For oil or solvent-heavy applications, consider alternative materials like PharMed®, Norprene®, or Santoprene®.

- Use hybrid pump setups with chemically compatible tubing segments.

- Always request chemical resistance charts before choosing tubing.

“Silicone is versatile—but not universal. Know your fluid’s profile before finalizing tubing selection.”

5. How to Select the Right Silicone Tubing

Choosing the right peristaltic pump silicone tubing isn’t just about diameter—it’s a combination of mechanical compatibility, chemical safety, and regulatory compliance. Over the years, I’ve helped many engineers and buyers avoid costly mistakes by focusing on a few critical parameters. Here’s what to look for:

• Inner Diameter (ID), Outer Diameter (OD), and Wall Thickness

The tubing’s ID determines flow rate, while the wall thickness affects compression behavior. If the wall is too thin, it may collapse; too thick, and it may resist compression, leading to backpressure or slippage. Most pump manufacturers specify ID × OD for optimal fit.

Tip: Always verify the pump head’s cavity design and match it with the recommended tubing geometry.

• Shore A Hardness

Shore A hardness measures the softness of the silicone. For peristaltic pumps, 50–60 Shore A is common, balancing flexibility with durability. Softer tubing may wear faster; harder tubing may not compress evenly.

• Material Certifications

Look for platinum-cured tubing with certifications such as:

- FDA 21 CFR 177.2600 for food contact safety

- USP Class VI for biocompatibility

- ISO 10993 for medical use

- RoHS and REACH compliance for chemical safety

These certifications are essential for applications in pharmaceutical, medical, food, and biotech environments.

• Pump Compatibility

Different peristaltic pumps vary in:

- Roller size and number

- Occlusion pressure

- Mounting type (cassette, continuous loop)

Always consult your pump supplier or documentation to confirm tubing type, dimension range, and performance fit.

Sample Tubing Specification Table

| Common Pump Type | Recommended ID × OD (mm) | Wall Thickness | Shore A Hardness | Remarks |

|---|---|---|---|---|

| Lab peristaltic pumps | 1.6 × 4.8 | 1.6 mm | 50–55 | Low flow, high precision |

| Medical pumps (IV) | 3.2 × 6.4 | 1.6 mm | 50–60 | Biocompatible, sterilizable |

| Food dispensing pumps | 4.8 × 8.0 | 1.6 mm | 55 | FDA food-grade |

| Industrial dosing pumps | 6.4 × 9.6 | 1.6 mm | 60 | Higher wear resistance |

“Start with your pump specs—but don’t forget to cross-check your tubing supplier’s tolerance and curing method.”

![]()

6. Comparison: Silicone vs Other Tubing Materials

Silicone is a top choice for peristaltic pumps, but it’s not the only option—nor always the best for every application. Let’s compare silicone with other commonly used pump tubing materials to help you decide which fits your needs best.

| Property | Silicone | PharMed® | Norprene® | PVC |

|---|---|---|---|---|

| Flexibility | Excellent | Good | Moderate | Moderate |

| Biocompatibility | Excellent | Excellent | Fair | Fair |

| Chemical Resistance | Moderate | Good | Good | Low |

| Lifespan in Pump | Moderate | Long | Long | Short |

| Transparency | High | Low | Opaque | Transparent |

| Sterilization Tolerance | Excellent (autoclave, gamma) | Moderate | Moderate | Low |

| Cost | Higher | Medium | Medium | Low |

Key Takeaways:

- Silicone is ideal for biomedical and food applications due to its clarity, flexibility, and sterilization resistance. It’s not ideal for oil-heavy or solvent-rich fluids.

- PharMed® tubing shines in biotech and chemical dosing, offering longer pump life and better chemical resistance, though it’s less transparent.

- Norprene® is built for industrial fluid handling, especially in harsh or high-pressure environments.

- PVC is inexpensive and easy to find, but has a short pump life, low chemical resistance, and limited compliance for regulated industries.

“Choosing tubing isn’t just about what works—it’s about what lasts, complies, and performs in your specific operating conditions.”

7. Maintenance and Tubing Life

Even the best peristaltic pump silicone tubing won’t last forever. Because the tubing is in constant contact with pump rollers, its longevity depends on a mix of factors: mechanical stress, chemical exposure, sterilization frequency, and storage conditions. Proper maintenance and timely replacement are essential to ensure pump performance and prevent contamination or failure.

• Expected Cycle Life

On average, high-quality platinum-cured silicone tubing lasts between 150 to 500 hours in a typical peristaltic pump, depending on:

- Pump speed and occlusion pressure

- Roller design and count

- Tubing wall thickness and hardness

- Operating temperature and chemical exposure

Some applications—such as continuous biotech processing or 24/7 ink dispensing—may require more frequent replacement, while others can run for weeks without issue.

• When to Replace Tubing

Don’t wait for a failure to happen. Here are clear indicators it’s time to replace the tubing:

- Visible cracking or hardening of the outer surface

- Loss of elasticity—tubing doesn’t bounce back after compression

- Flow rate drops or dosing becomes inconsistent

- Discoloration or fluid contamination inside the tube

If you operate in a regulated environment (GMP, FDA), it’s best to follow a preventive replacement schedule based on run time or batch count.

• Storage and Handling Tips

Tubing shelf life is often overlooked. Even unused tubing can degrade if stored improperly. Follow these guidelines:

- Store in a cool, dry place away from UV light

- Keep in original packaging to avoid dust and contamination

- Avoid sharp bends or compression during storage

- Check expiration or lot dates for traceability, especially in medical/pharma use

“A proactive maintenance routine saves you from pump failure, contamination risks, and emergency downtime—especially in high-stakes environments.”

8. Sourcing & Buying Tips

If you’re responsible for purchasing peristaltic pump silicone tubing—whether as a product manager, lab manager, or procurement officer—it’s not enough to simply order “silicone tubing.” The wrong choice can lead to pump failure, flow inconsistencies, or compliance issues. Here’s how to source the right tubing with confidence.

• What Specs to Request from Suppliers

When requesting quotes or samples, always provide a clear specification sheet or ask the supplier to confirm these parameters:

- Inner diameter (ID) and outer diameter (OD) tolerance

- Wall thickness suited to your pump’s compression ratio

- Shore A hardness (typically 50–60 for peristaltic applications)

- Curing method (preferably platinum-cured)

- Certifications required: FDA, USP Class VI, ISO 10993, RoHS, REACH

“The more details you provide, the better the tubing will fit your pump and your industry’s safety standards.”

• How to Evaluate Tubing Quality

Whether you’re inspecting tubing samples or reviewing documentation, focus on these quality indicators:

- Surface finish: Smooth, bubble-free interior and exterior walls

- Stretch and rebound: Should return to shape instantly when compressed

- Transparency: Uniform clarity if required for visual flow monitoring

- Documentation: Batch traceability, compliance certificates, and material safety data sheets (MSDS)

Some suppliers may offer free samples or small trial batches—this is highly recommended before committing to bulk orders.

Conclusion

Peristaltic pump silicone tubing may look simple—but as you’ve seen throughout this guide, it plays a mission-critical role in systems where hygiene, accuracy, and safety are non-negotiable. From biopharmaceuticals and medical devices to food dispensing and industrial dosing, the right tubing ensures clean flow, precise delivery, and system reliability.

What sets this tubing apart is its unique blend of properties: high flexibility, fast recovery after compression, biocompatibility, and resistance to temperature and sterilization. But not all silicone tubing is created equal. Choosing the wrong wall thickness, hardness, or curing method can shorten tubing life or even compromise your process.

That’s why I always recommend working closely with tubing experts—especially when your application involves regulated industries or custom pump heads. At Kinsoe, we specialize in platinum-cured silicone tubing engineered specifically for peristaltic pump use. Whether you need medical-grade precision, FDA compliance, or OEM-matched dimensions, we’re here to help. Contact us today for free samples, specification guidance, or bulk pricing support—we’ll make sure you get tubing that’s built to perform.

References: