Product Description

Ceramized Liquid Silicone Foam combines the flexibility and cushioning of silicone with the fireproof and insulating performance of ceramics.

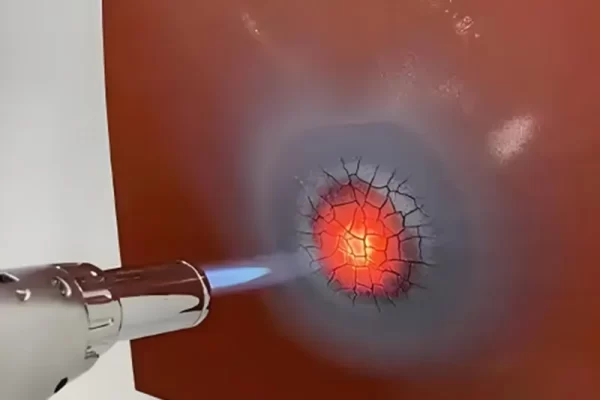

During fire exposure, the foam undergoes a ceramization reaction, forming a dense, rigid ceramic structure that maintains its shape and prevents flame penetration.

This transformation ensures continuous protection without releasing toxic smoke or halogens—meeting strict safety standards for transportation, energy, and construction industries.

Key Features

- High-Temperature Ceramization – Forms a rigid ceramic barrier when exposed to flame or heat above 500 °C, effectively blocking heat and oxygen.

- Lightweight & Low Density – Adjustable foam density (0.5–1.2 g/cm³) helps reduce system weight without compromising performance.

- Outstanding Weather & Aging Resistance – Resists UV, ozone, and outdoor exposure for long service life.

- Eco-Friendly Formulation – Free from halogens and heavy metals, compliant with RoHS and REACH regulations.

- Flexible Processing Options – Compatible with molding, extrusion, or injection molding, enabling complex custom geometries.

Technical Parameters

| Parameter | Value |

|---|---|

| Density (g/cm³) | 0.5–1.2 |

| 25% Compression Stress (kPa) | 20–50 |

| Tensile Strength (MPa) | 2.0–4.5 |

| Elongation at Break (%) | 150–300 |

| Compression Set (100 °C) | ≤ 10% |

| Water Absorption (%) | < 1.0 |

| Low-Temperature Brittleness (°C) | ≤ –50 |

| Flame Retardant Rating | UL 94 V-0 |

| Environmental Compliance | RoHS, REACH |

Performance Advantages

- Extreme Fire Resistance

The ceramized layer withstands short-term exposure above 600 °C, slowing fire propagation and maintaining structural integrity. - Dimensional Stability Under Heat

Retains form and cushioning even under continuous high-temperature conditions, preventing collapse or material failure. - Multi-Layer Thermal Protection

Acts as both heat shield and insulator, significantly reducing heat transfer during flame exposure. - Design Flexibility

Available in sheets, rolls, or custom die-cut shapes, adaptable to any insulation system, gasket, or thermal barrier.

Typical Applications

Fire Protection

- Fire-rated wall joints and cable seals

- Building insulation and fireproof fillers

New Energy Vehicles (EV & Hybrid)

- Battery-pack insulation pads

- Charging station gaskets and protective barriers

Industrial Protection

- Pipe insulation and heat-resistant sealing

- Equipment enclosures and electrical switchgear

Aerospace & Marine

- Compartment fire barriers

- Engine and exhaust insulation systems

Environmental & Quality Commitment

At Kinsoe, sustainability is integrated into every production stage.

Our ceramized silicone foams are manufactured using environmentally friendly processes, ensuring product safety for both users and the environment.

All formulations comply with RoHS, REACH, and UL94 V-0 standards, reinforcing our position as a responsible and globally trusted silicone foam manufacturer.

Why Choose Kinsoe

- Expertise in High-Temperature Materials — Over 20 years of silicone engineering and custom compounding experience.

- In-House R&D and Testing — Comprehensive performance verification for thermal stability, flame spread, and mechanical strength.

- Customizable Solutions — Tailored density, hardness, and thickness to meet your design and certification requirements.

- Global Support — Localized technical service and scalable production for OEM and project-based clients worldwide.