Key Features

- Excellent Surface Adaptability

The compressible foam structure conforms to uneven, textured, or porous surfaces, ensuring consistent vacuum sealing and minimal leakage. - High-Quality Natural Rubber Base

Standard models are made from high-elasticity natural rubber sponge, providing durability, flexibility, and long-term sealing stability. - Customizable Materials

Available in EPDM (for weather and ozone resistance), NBR (for oil resistance), Silicone (for high-temperature environments), and Polyurethane (for abrasion-resistant use). - Geometry Options

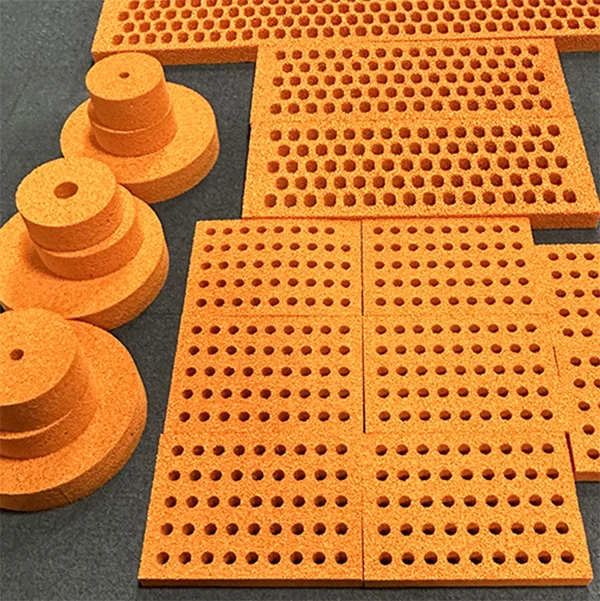

Offered in round, rectangular, oval, and special-shaped forms to fit diverse automation equipment and lifting systems. - Optional Self-Adhesive Backing

Self-adhesive foam pads can be easily installed onto vacuum plates, robotic grippers, or lifting heads without additional fixtures. - Density and Color Customization

Foam hardness, cell structure, and color can be customized to match specific performance or branding requirements. - Energy-Efficient Vacuum Sealing

Optimized foam compression reduces air leakage, allowing smaller pumps to achieve the same holding power—improving system efficiency.

Product Characteristics

| Parameter | Typical Range / Option |

|---|---|

| Material | Natural Rubber (Standard), EPDM, NBR, Silicone, PU |

| Structure | Open-cell or closed-cell sponge foam (depending on material) |

| Density | 100–600 kg/m³ (customizable) |

| Hardness | 20–70 Shore A |

| Thickness | 5–50 mm (standard 20 mm) (customizable) |

| Geometry | Round / Rectangular / Custom shapes |

| Backing Type | Plain / Self-adhesive / Threaded mount |

| Operating Temperature | –40 °C to +200 °C (depending on material) |

| Color | Black / Gray / Orange / Customized |

| Surface Finish | Smooth or micro-textured sealing face |

Application Cases

Our foam suction cups are widely used in industries that handle rough, porous, or uneven materials, including:

- Wood Industry – Secure gripping of rough-sawn wood panels, MDF boards, and plywood sheets.

- Stone & Construction Materials – Reliable sealing on marble, tiles, concrete blocks, and bricks during cutting or transfer.

- Packaging & Palletizing – Vacuum lifting of cartons, sacks, and irregular packages in automated lines.

- Metal Processing – Handling of embossed or patterned metal sheets, diamond plates, and coated panels.

- Robotics & Automation – Integration with robotic grippers and area vacuum plates for multi-surface handling.

- Glass & Composite Materials – Safe, non-marking contact for laminated, frosted, or textured surfaces.

Why Choose Kinsoe

- Tailor-Made Design — Each suction cup is engineered according to the customer’s surface characteristics, load requirements, and system design.

- Material Expertise — 20 years of experience in rubber and polymer engineering ensures precise material selection for every project.

- In-House Production — From foam fabrication to precision laser cutting, all processes are completed in-house for consistent quality.

- Global OEM Support — Serving automation, HVAC, woodworking, and construction equipment manufacturers worldwide.

Frequently Asked Questions (FAQ)

Q1: What is the difference between open-cell and closed-cell foam suction cups?

A1: Open-cell foam provides better flexibility and surface conformity, suitable for fragile or curved objects. Closed-cell foam minimizes air leakage and is ideal for rough or porous surfaces requiring strong vacuum retention.

Q2: Can Kinsoe customize the suction cup size and shape?

A2: Yes. We can produce round, rectangular, oval, or custom-shaped foam suction cups according to your drawing or application requirement.

Q3: Which material should I choose for my application?

A3:

- Natural Rubber – General use, good elasticity.

- EPDM – Outdoor/weather resistance.

- NBR – Oil and fuel resistance.

- Silicone – High-temperature stability.

- PU – Excellent wear resistance and long service life.

Q4: Can I order foam suction cups with self-adhesive backing?

A4: Absolutely. Self-adhesive options are available for easy installation on vacuum plates or robotic end effectors.

Q5: What are the typical lead times for custom orders?

A5: Standard sizes are usually shipped within 7–10 days, while customized geometries or materials may require 2–3 weeks, depending on order volume and complexity.

Product Gallery