At Kinsoe, we often work with clients seeking to optimize sealing solutions—whether to reduce costs, improve ease of maintenance, or adapt to new operating conditions. One common question we receive is whether rubber seals can replace traditional metal seals. While the idea is tempting, especially for streamlining installation or saving material costs, it’s not always straightforward.

In this article, I’ll walk you through a detailed, experience-backed guide on replacing metal seals with rubber alternatives. From feasibility to design and safety to material science, this is everything you need to consider to avoid costly mistakes—or worse, seal failures.

Feasibility First: Is Rubber a Realistic Replacement?

Before even thinking about swapping out metal for rubber, we need to determine whether the application can support the change. The physical, chemical, and mechanical differences between these two materials are substantial.

Operating Temperature Limitations

Rubber’s operating temperature range is significantly narrower than metal. For example:

- NBR (Nitrile Butadiene Rubber): typically up to 100°C

- FKM (Fluorocarbon/Viton): can go up to 250°C

- Perfluoroelastomers (FFKM): up to 300°C+ (with high cost)

Compare that with metal seals, which can withstand temperatures well above 800°C. That’s a massive difference.

🔧 Our rule at Kinsoe: If your system has transient spikes or sustained heat above 250°C, don’t even consider rubber unless using specialized elastomers—and only after extensive testing.

Pressure and PV Limitations

Rubber seals can generally handle pressures under 10 MPa without extrusion support. However, they are sensitive to high sliding speeds and pressure-velocity (PV) values, which cause heat buildup and premature aging.

In metal seals, plastic deformation handles the load. In rubber, we rely on elastic compression. This means:

- High pressure → risk of extrusion

- High speed → frictional heating → accelerated degradation

⚠️ Be especially cautious in dynamic sealing environments like pistons, shafts, or rotating assemblies.

Chemical Compatibility

Unlike metals, rubber swells or degrades when exposed to incompatible media. For example:

- NBR degrades in ketones

- FKM struggles with amines

- EPDM fails in petroleum oils

Always consult a chemical resistance chart (ASTM D471 or ISO 6072) before selecting a rubber. At Kinsoe, we maintain a database of real-world compatibility cases across industries—from food to petrochemicals.

Abrasive or Particulate Media

If your system handles slurries, powders, or particulates, think twice. Rubber wears much faster than metal. Metal is inherently abrasion-resistant; rubber needs design support (like backup rings or dust lips) to survive such environments.

Understand the Safety and Compliance Risks

One of the biggest mistakes I see in the field is underestimating the regulatory or safety implications of swapping seals.

Hazardous Media and Permeability

Rubber is more permeable than metal—period. In systems containing:

- Liquid oxygen

- Natural gas (LNG)

- Toxic or flammable chemicals

…even microscopic permeability can be a big problem.

Metal seals are often used because they eliminate vapor leakage. Switching to rubber without considering permeability could lead to ignition risks, contamination, or vapor loss.

Regulatory Requirements

Before we at Kinsoe recommend any material substitution, we verify:

- Is the system governed by API 682 (mechanical seal standard)?

- Is the pipeline compliant with ASME B31.3?

- Is rubber even permitted in this part of the system?

For example, in aerospace, defense, or nuclear sectors, rubber substitution is outright forbidden unless qualified and certified.

Fire Safety

Rubber burns—metal doesn’t. That’s a simple but vital fact. If your application involves exposure to sparks, high temperatures, or combustion risks, choose only flame-retardant rubber compounds like FKM or FFKM blends. Even then, consult with fire safety engineers.

Structural Adaptation: It’s Not Just a Drop-In Replacement

Installing a rubber seal where a metal ring once was is not as simple as matching diameters. The structure and mechanics of the sealing groove must change.

Groove and Compression Redesign

Rubber needs space to deform elastically. Metal does not.

| Parameter | Metal Seals | Rubber Seals |

|---|---|---|

| Compression Ratio | Low | 15–30% |

| Groove Shape | Sharp, defined | Rounded corners, clearance control |

| Extrusion Gap | Less critical | Must be tightly controlled |

| Installation Fit | Hard press-fit | Needs stretch and squeeze balance |

At Kinsoe, we recalculate groove dimensions using rubber-specific standards like AS 568A for O-rings. We also evaluate corner chamfers to avoid cutting the rubber during installation.

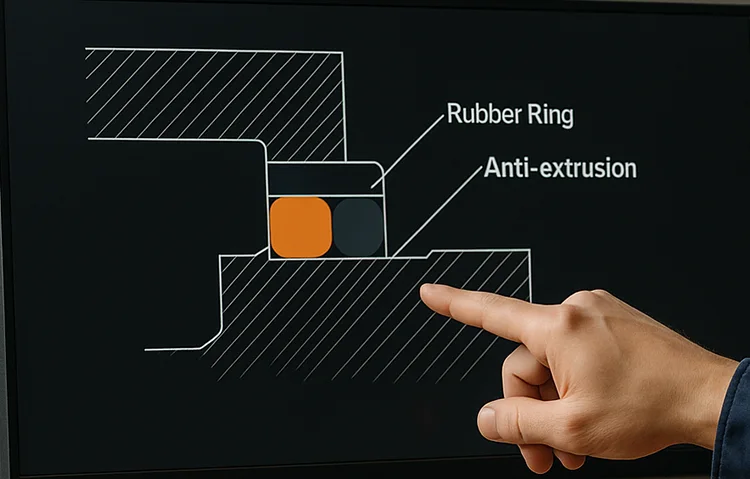

Add Anti-Extrusion Features

In higher-pressure applications, we integrate:

- PTFE backup rings

- Metal retainers

- Spring energizers

These components prevent the rubber from being pushed out of the sealing gap under pressure.

Selecting the Right Rubber Material

Rubber is not one material—it’s a family. Choosing the right type is crucial, especially when replacing metals.

Common Substitutes and Precautions

| Application Need | Rubber Material | Cautions |

|---|---|---|

| High Temp (>250°C) | FFKM | Expensive, prone to long-term degradation |

| Acid/Alkali | EPDM or FKM | Match based on pH and exposure time |

| Low Friction | PTFE-blended rubber | Risk of poor bonding or delamination |

| High Wear | PU (Polyurethane) | Avoid in hot/humid environments due to hydrolysis |

Each choice is a trade-off between cost, durability, and functionality. For instance, silicone is great for flexibility and heat but swells in oils. PU resists wear but fails in wet environments.

Special Functions

- Electrical Conductivity: For ESD-safe or explosion-proof systems, we add carbon black or metallic powder to rubber to enable conductivity.

- Vacuum Compatibility: We use low-outgassing fluororubbers for vacuum seals. Regular rubber emits vapors, contaminating vacuum chambers or optical systems.

Installation and Maintenance Tips

Replacing metal with rubber demands revised installation and upkeep practices.

Installation Techniques

- Avoid sharp tools. Use plastic or brass tools to prevent cuts.

- Apply compatible lubricants (e.g., silicone grease for NBR-safe assemblies).

- Pre-compress evenly. Rubber needs distributed pressure to function.

A common field failure we’ve seen: improper installation causes twisted seals or uneven compression—leading to leakage in days.

Lifecycle Monitoring

Rubber has a shorter lifespan than metal, especially under heat, UV, or chemical exposure. Always:

- Shorten maintenance intervals

- Inspect for hardening, cracking, or swelling

- Use leak sensors for early alerts

Remember: saving on seal costs means nothing if maintenance costs balloon later.

Typical Application Cases: When It Works—And When It Doesn’t

Here are real examples from our experience:

| Scenario | Feasible Rubber Substitution | Pitfall to Avoid |

|---|---|---|

| Water cooling system valves (low pressure) | EPDM O-rings | Avoid NBR due to ozone degradation |

| Static seals in hydraulic cylinders (<20 MPa) | PU + FKM combo | Check PU for hydrolytic stability |

| Food machinery bearing seal | Silicone (VMQ) | Swelling risk in contact with lubricants |

| Exhaust pipe flange | Graphite-filled rubber | Risk: Most rubbers fail >300°C |

Each substitution worked only after carefully redesigning the groove, evaluating the media, and selecting high-performance rubber.

Final Principles for Safe and Effective Replacement

Let me leave you with the three golden rules we follow at Kinsoe:

1. Prioritize Operating Conditions

If the temperature, pressure, or media compatibility doesn’t meet rubber standards—don’t substitute.

2. Adapt the Structure, Don’t Force a Fit

A successful replacement requires:

- Groove redesign

- Extrusion gap control

- Support structures (springs, retainers)

3. Manage the Lifecycle Proactively

Rubber seals require:

- Frequent inspection

- Leak detection systems

- Scheduled replacement

These operational costs must be factored into your ROI model.

Conclusion

Replacing a metal seal with rubber might seem like a minor modification—but it’s not. The implications span thermal, mechanical, and chemical performance, not to mention safety and regulatory compliance.

At Kinsoe, we’re here to help you evaluate whether a rubber seal is suitable—and if so, which material, groove design, and installation practices are needed for success. For critical environments like nuclear power, aerospace, or high-pressure chemical systems, metal seals remain irreplaceable.

So before making any substitution, talk to your OEM, work with experienced sealing engineers, and remember: a failed seal can cost far more than a well-chosen one.