1. Introduction: Why Rubber Bellows Matter in Industrial Design

When I first started working with rubber bellows, I was surprised by how such a simple-looking component could play such a crucial role in industrial systems. At first glance, rubber bellows may look like nothing more than flexible tubes—but in fact, they’re essential for ensuring the longevity and reliability of everything from HVAC ductwork to precision robotics.

Rubber bellows are flexible, corrugated components designed to expand, compress, and twist in response to movement or pressure. Their primary role? To isolate vibration, absorb mechanical motion, and seal out dust, water, oil, or chemicals. Without them, machines would break down more frequently due to stress, misalignment, or contamination.

The beauty of rubber bellows lies in their versatility. Whether it’s a construction HVAC contractor needing flexible duct joints, or an OEM engineer looking to protect a sensitive piston rod, bellows offer a compact, cost-effective solution. That’s why they’re used by a wide range of professionals—OEM product designers, HVAC system integrators, equipment manufacturers, and even medical device engineers.

In this article, I’ll walk you through exactly what rubber bellows are, where they’re used, how to choose the right material, and what pitfalls to avoid. Let’s start with a closer look at how they’re built and why they work so well.

2. What Are Rubber Bellows?

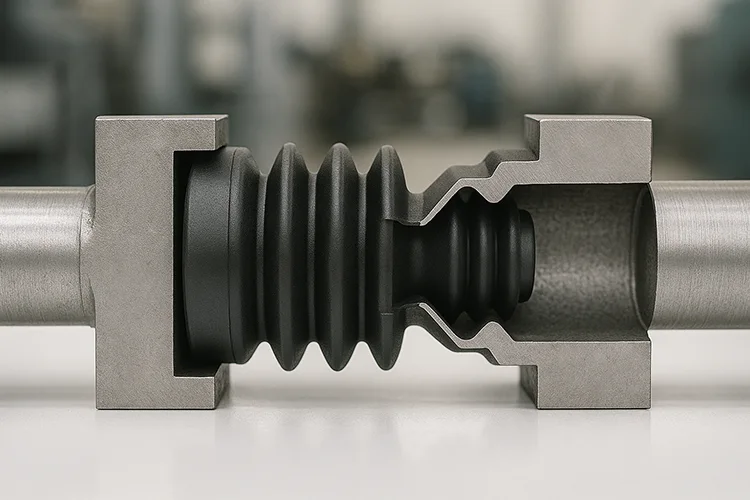

Rubber bellows are flexible, accordion-like components engineered to accommodate movement and protect sensitive parts within mechanical assemblies. Structurally, they consist of a corrugated or convoluted design that allows them to expand, contract, or flex in multiple directions without compromising the sealed environment they protect.

These components are often placed around rods, shafts, or moving joints, serving as both a mechanical buffer and a barrier against external elements. Depending on the system, bellows can be round, oval, square, or custom-molded to match complex geometries. They are typically installed via flanges, cuffs, or adhesive bonding depending on the application.

Main Functions:

- Absorbing Movement and Misalignment

They compensate for angular, axial, and lateral movement between components—particularly useful in dynamic systems or installations where exact alignment isn’t feasible. - Sealing Against Dust, Water, and Chemicals

Rubber bellows serve as the first line of defense against contamination. Whether it’s dust in a machining environment or oil in an engine bay, the bellows keep foreign material out. - Vibration Damping and Noise Reduction

By absorbing mechanical shocks and vibrations, they protect surrounding components from fatigue and reduce operating noise.

Compared to metal or fabric bellows, rubber options offer several advantages. They’re lightweight, more affordable, easier to mold into complex shapes, and require less maintenance. While metal may outperform rubber in extreme high-pressure systems, rubber bellows remain the go-to for most general-purpose sealing, protection, and motion-control applications.

3. Common Applications of Rubber Bellows

One of the most fascinating aspects of rubber bellows is their sheer range of uses across industries. Over the years, I’ve seen them integrated into countless systems—from the suspension of a delivery truck to the precision assembly line of a semiconductor factory. Let me walk you through some of the most common applications.

1. HVAC Systems

Rubber bellows are widely used as flexible duct connectors in HVAC installations. They absorb vibrations from blowers and dampen noise transmission between rigid duct sections. Their elasticity also allows for thermal expansion and contraction, reducing stress on the entire ventilation system.

Example: In a rooftop commercial HVAC setup, bellows connect metal ducts to vibrating machinery, ensuring the entire structure doesn’t rattle or crack from repeated motion.

2. Automotive Industry

In vehicles, bellows act as protective boots for shock absorbers and steering racks. These components move constantly and are exposed to dust, water, and road grime. The bellows ensure that internal seals and rods remain clean and lubricated, preventing premature wear.

Example: The rubber gaiter on a steering rack expands and contracts every time the wheel turns—keeping debris out and ensuring a longer lifespan for the internal components.

3. Machinery & Hydraulics

In heavy equipment and factory machinery, bellows are fitted over linear shafts or hydraulic pistons to prevent the ingress of particles. Even a small amount of dust can degrade performance in precision systems.

Example: CNC machines often use rubber bellows to shield the moving rails and bearings from metal shavings and coolant splashes.

4. Electronics & Cabling

Bellows serve as strain relief boots at the cable entry points of enclosures. They provide sealing and also protect wires from sharp bending and external pull force.

Example: On handheld diagnostic tools or control boxes, rubber bellows prevent cable fraying or disconnection caused by repeated flexing.

In short: if a system has movement, pressure, or a risk of contamination—there’s a good chance rubber bellows are involved. Their adaptability makes them indispensable to engineers and procurement teams alike.

4. Material Choices for Rubber Bellows (with Comparison Table)

Choosing the right material for rubber bellows is more than just picking what’s available—it’s about matching material properties with the environment, media exposure, and performance needs of your application. I’ve worked on projects where the wrong material choice led to cracking within months. So let’s break it down clearly.

Rubber bellows can be made from several elastomer compounds, each offering different temperature tolerances, chemical resistances, and mechanical properties. Below is a practical comparison table to help guide your selection:

| Material | Temp Range | Strengths | Typical Use |

|---|---|---|---|

| EPDM | -40°C to 130°C | Excellent UV & ozone resistance | HVAC duct joints, outdoor enclosures |

| Silicone | -60°C to 200°C | High-temperature & food-safe | Medical devices, lab equipment |

| NBR (Nitrile) | -30°C to 100°C | Oil, fuel, and grease resistance | Automotive boots, hydraulic covers |

| Neoprene (CR) | -35°C to 120°C | Flame retardant, weatherproof | Electrical seals, appliance parts |

Key Tips for Material Selection:

- Outdoor Exposure? Choose EPDM or Neoprene for their UV resistance and weather durability.

- High Heat Environment? Silicone performs best under extreme temperature swings, especially in lab or food processing setups.

- Oil and Chemical Exposure? NBR is your best bet in automotive or industrial fluid applications.

- Electrical Safety Needs? Neoprene’s flame resistance makes it ideal for appliance or electronic enclosures.

Remember: even the best-designed bellow can fail prematurely if the material doesn’t match the real-world environment. I always advise customers to test samples under actual conditions when in doubt. The upfront effort can save thousands in downtime or replacements later.

5. Common Failure Modes & How to Avoid Them

Despite their durability, rubber bellows can still fail—especially if misapplied or installed incorrectly. Over the years, I’ve seen some preventable mistakes lead to system failures, and I want to help you avoid those pitfalls. Here are the most common failure modes and what you can do to mitigate them.

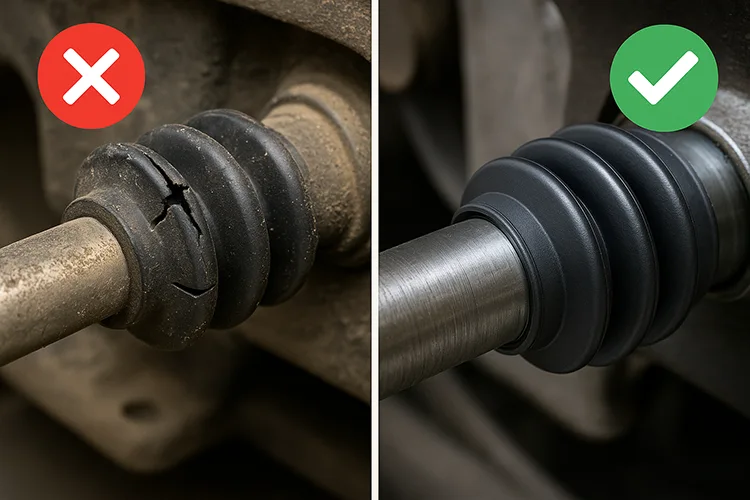

1. Cracking and Aging

Rubber exposed to harsh sunlight, ozone, or incompatible chemicals can develop surface cracks over time. This often happens when general-purpose rubber is used outdoors or near electrical discharge.

How to prevent it:

- Select materials like EPDM or Neoprene for outdoor or high-ozone environments.

- Use protective coatings or shielding if UV exposure is constant.

2. Tearing from Over-Compression

When bellows are compressed beyond their design range—or are pinched during assembly—they can tear, reducing sealing performance and structural integrity.

How to prevent it:

- Allow proper axial clearance in your design.

- Install mechanical stops or limiters to avoid over-deflection.

- Never stretch or compress the bellow to fit—it must match the installation geometry precisely.

3. Chemical Incompatibility

Exposure to incompatible fluids such as oils, acids, or cleaning agents can cause swelling, softening, or degradation of the rubber compound.

How to prevent it:

- Check the chemical compatibility of the selected rubber.

- Use NBR for oil, Silicone for food/lab, and EPDM for water and air systems.

4. Improper Installation

Incorrect mounting—such as misalignment, poor clamping, or sharp edges—can create stress points that lead to premature failure.

How to prevent it:

- Use smooth, deburred surfaces and round-edge clamps.

- Align the axis of movement carefully.

- Follow manufacturer installation guides or ask for custom flange solutions.

“A bellow’s success isn’t just in the material—it’s in the mounting, movement allowance, and the conditions it’s exposed to.”

By identifying these common problems early, you can extend service life, reduce maintenance costs, and keep your systems operating smoothly.

6. Conclusion

Rubber bellows may seem like small components, but their impact on system performance is anything but minor. They ensure reliable sealing, reduce mechanical stress, and protect equipment from environmental damage—all while being cost-effective and highly customizable. Whether you’re designing an HVAC system, automotive component, or industrial machine, choosing the right bellow type and material can greatly enhance performance and reduce downtime.

At KINSOE, we specialize in custom-molded rubber bellows tailored to your exact design and environmental requirements. With over 20 years of experience in rubber extrusion and molding, we’ve helped integrators, and engineers across various industries protect and optimize their equipment with precision-engineered rubber components.

Need help selecting the right rubber bellow for your application?

Reach out to our technical team today—we’re here to support your design process from prototype to production.