Introduction

Why Material Selection Matters in Rubber Parts

When I began working in the rubber manufacturing industry, I quickly learned that not all rubber is created equal. Choosing the wrong material might seem like a minor mistake—until it leads to a product recall, failed seal, or customer complaint. That’s why material selection isn’t just an engineering decision—it’s a business-critical one.

Rubber components play a vital role in sealing, insulation, shock absorption, and chemical protection. Whether I’m developing a rubber tube for a food processing plant or an oil-resistant gasket for a hydraulic system, the properties of the rubber I choose directly determine how the product will perform, how long it will last, and how safely it can operate.

A well-chosen rubber can withstand extreme environments and meet industry regulations. A poorly chosen one? It can crack, degrade, or fail when your customers need it most.

Common Rubber Forming Methods in Industry

To make the most of any rubber material, I first consider how it will be formed. Most of our clients come to us with a need for either extruded or molded rubber parts.

- Extrusion is ideal for continuous profiles like door seals, tubing, or edge trim. The uncured rubber is forced through a die to create a long, uniform shape that’s then vulcanized for strength and elasticity.

- Molding, on the other hand, involves shaping rubber into complex 3D forms like grommets, bumpers, or precision seals using compression, transfer, or injection molds.

Each method imposes different physical demands on the rubber—meaning some materials are better suited for extrusion, while others thrive in molding applications.

Here are the proven ways I evaluate and match rubber types to specific forming processes and application requirements. Let’s start by laying out a side-by-side comparison.

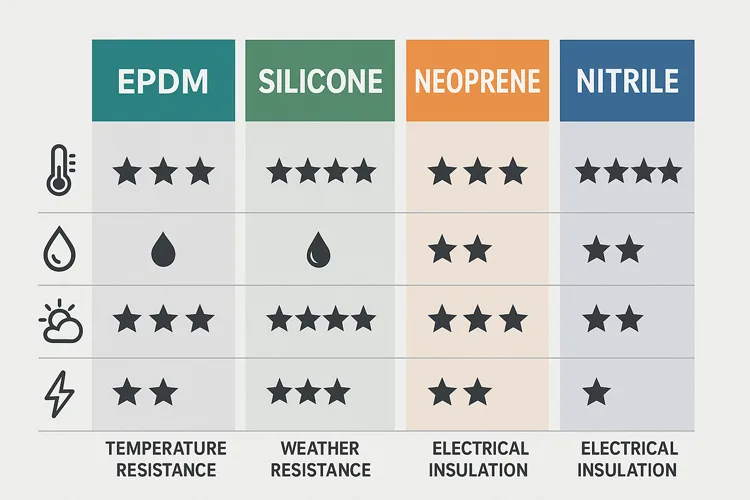

Quick Comparison Table of EPDM, Silicone, Neoprene, and Nitrile

Summary of Physical and Chemical Properties

Before diving into specific use cases, I always recommend clients review the core physical and chemical traits of each rubber material. This helps narrow down the field based on the environment the product will face. Here’s a quick overview of the four common types:

| Property | EPDM | Silicone | Neoprene | Nitrile (NBR) |

|---|---|---|---|---|

| Temperature Range | -40°C to 120°C | -60°C to 230°C | -35°C to 110°C | -30°C to 100°C |

| Oil Resistance | Poor | Poor | Moderate | Excellent |

| Chemical Resistance | Good (acids, alkalis) | Excellent (inert) | Moderate (some acids/oils) | Good (fuel, oil, grease) |

| Weather & UV Resistance | Excellent | Excellent | Good | Poor |

| Flame Retardancy | Moderate | Good | Good | Fair |

| Electrical Insulation | Good | Excellent | Moderate | Poor |

| Cost Level | Low | High | Medium | Low to Medium |

| Processability | Easy to extrude & mold | Requires careful processing | Flexible in both extrusion/molding | Molds well, extrusion less common |

EPDM is the best all-rounder for outdoor use. Silicone is unbeatable for temperature extremes and hygiene. Neoprene strikes a balance between toughness and affordability. Nitrile rules in oil-heavy environments.

This table provides a snapshot—but material selection should never be done in isolation. Up next, I’ll walk you through how to apply this knowledge to real-world forming processes.

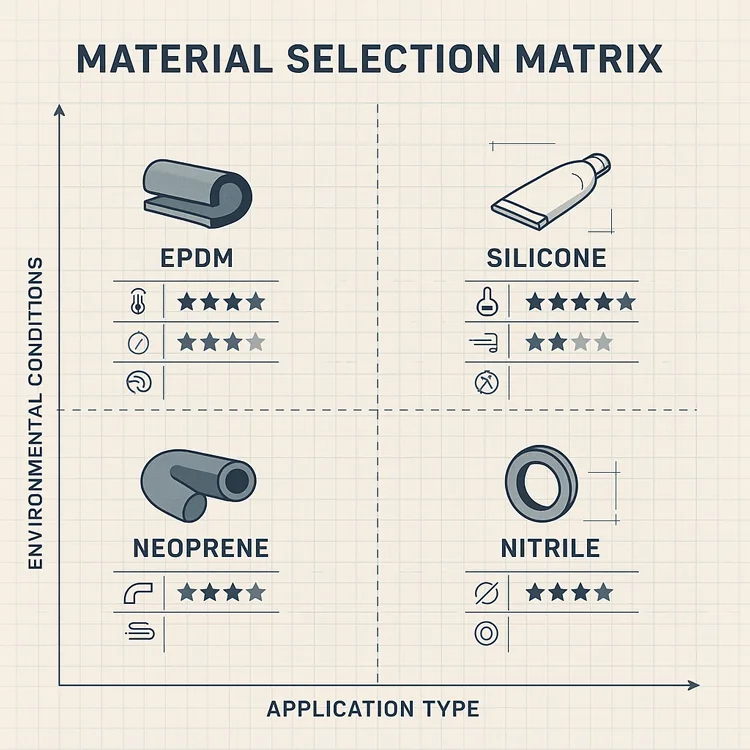

Select By Application

When it comes to selecting rubber materials for extrusion or molding, I’ve found it’s most effective to focus on the application first—then work backward to the right material. Here’s how I typically guide customers across both forming processes:

For Extruded Rubber Profiles (e.g., Seals, Tubes, Gaskets)

EPDM – The Outdoor and Weather-Resistant Choice

If you’re building something that will live outdoors—like automotive door seals or HVAC duct gaskets—EPDM is usually my first recommendation.

- Ideal Applications: Window seals, outdoor tubing, ventilation flanges

- Why It Works: EPDM resists UV, ozone, and extreme weather far better than most rubbers. It also remains flexible in cold conditions, making it ideal for climates with temperature swings.

- Cost Advantage: Among the four rubbers, EPDM is the most affordable for extrusion.

EPDM is my go-to for construction and HVAC profiles that need to endure years of sunlight and rain without cracking.

Silicone – The High-Temp and Food-Safe Performer

Silicone stands out when hygiene or heat are your top concerns. I often recommend it for the food, medical, and electronics industries.

- Ideal Applications: Food-grade tubing, medical transfer hoses, oven door seals

- Why It Works: It offers unmatched thermal resistance (up to 230°C), and it’s inert—meaning it won’t react with food or chemicals.

- Limitations: Silicone can be more expensive and softer than other rubbers, so it may not suit every structural profile.

I choose silicone extrusion when regulatory compliance and sterility can’t be compromised.

Neoprene – The Balanced Performer for Industrial Profiles

When neither extreme heat nor harsh oil exposure are present, Neoprene offers a middle-ground solution.

- Ideal Applications: Cable covers, protective edge trims, weather strips

- Why It Works: It balances physical toughness, moderate flame retardancy, and some chemical resistance.

- Processing Tip: Neoprene extrudes well into complex shapes with decent mechanical strength.

Neoprene is versatile for general industrial use—it holds up without breaking the bank.

For Molded Rubber Parts (e.g., Grommets, O-Rings, Protective Caps)

Nitrile (NBR) – The Oil-Resistant Workhorse

If your component will contact oils, fuels, or hydraulic fluids, nothing beats nitrile. It’s the most common choice in automotive and machinery applications.

- Ideal Applications: Oil seals, fuel caps, engine gaskets

- Why It Works: NBR withstands hydrocarbons without degrading, all while staying flexible.

- Cost Efficiency: It’s one of the lowest-cost moldable rubbers with reliable oil resistance.

I rarely recommend anything other than nitrile when oil exposure is a concern—it just works.

Neoprene – The Versatile Industrial Choice

Neoprene shines again in molded parts where a balance of strength, cushioning, and flame resistance is required.

- Ideal Applications: Anti-vibration pads, molded enclosures, caps

- Why It Works: It resists deformation, has good chemical stability, and holds up under physical stress.

Molded neoprene performs well in environments that demand both toughness and flexibility.

Silicone – The Premium Option for Sensitive Applications

Silicone is often my recommendation when precision and purity matter more than cost.

- Ideal Applications: Medical device components, cleanroom plugs, pharma-grade seals

- Why It Works: It’s biocompatible, elastic, and retains its shape after repeated sterilization cycles.

- Note: Silicone molded parts require careful handling during curing to avoid defects.

For pharma and healthcare, I always steer clients toward molded silicone—it’s the safest bet for compliance and safety.

![]()

How to Choose the Right Material

When customers ask me, “Which rubber should I use?” I usually turn the question back to them with a checklist. The right answer isn’t just about material properties—it’s about use environment, regulatory needs, and performance priorities.

Key Considerations for Your Clients

Before you select a rubber, you should clarify a few non-negotiables. Here’s what I guide every client to think through:

- Temperature Range

Will the product face freezing cold, dry heat, or rapid thermal changes?

Choose Silicone for extreme heat; EPDM for cold weather. - Exposure to Oils, Chemicals, or Fuels

Will the rubber touch lubricants, fuels, acids, or solvents?

Nitrile (NBR) handles oils best. Neoprene offers moderate chemical resistance. - UV, Ozone, and Weather Resistance

Is the product used outdoors or in a high-ozone environment?

EPDM and Silicone resist environmental aging exceptionally well. - Mechanical Stress and Shape Retention

Will it flex constantly, or must it hold a rigid form?

Neoprene is durable under stress. Silicone maintains shape over cycles. - Certifications or Compliance Needs

Is the product used in food, pharma, or medical applications?

Only FDA-grade Silicone meets most hygiene regulations.

Quick Tip: The more conditions a part is exposed to, the more critical material selection becomes.

Comparison Table: Application vs. Material Fit

| Industry Scenario | Best Material | Forming Method | Notes |

|---|---|---|---|

| Outdoor weather strip | EPDM | Extrusion | Excellent UV/ozone resistance, cost-effective |

| Food-grade transfer tubing | Silicone | Extrusion | FDA compliant, high-temp stability |

| Fuel tank gasket | Nitrile (NBR) | Molding | Excellent oil resistance |

| Cable entry grommet | Neoprene | Molding | Balanced performance, chemical resistance |

| HVAC vibration isolation pad | Neoprene | Molding | Tough and compressible |

| Oven door seal | Silicone | Extrusion | Withstands up to 230°C, retains flexibility |

| Engine oil seal | Nitrile (NBR) | Molding | Affordable, high-performance in lubricated zones |

This decision matrix has helped many of my clients confidently narrow their material choices. But sometimes it takes examples from their own industry to really seal the decision.

Real-World Recommendations Based on Customer Types

Over the years, I’ve worked with hundreds of buyers, engineers, and OEMs from diverse sectors. While the core rubber materials don’t change, the right choice often depends on the industry’s specific performance and regulatory needs. Here are a few real-world recommendations I frequently give to different customer types:

Construction and HVAC Manufacturers

Product examples: EPDM seals, Neoprene pipe sleeves, duct connectors

- Why EPDM? It holds up brilliantly in outdoor environments. Door and window seal buyers in the construction field usually opt for extruded EPDM for its UV resistance and flexibility, even after years of sun exposure.

- Why Neoprene? For flexible duct sleeves or insulation components in HVAC, molded or extruded Neoprene works well because of its flame resistance and toughness.

“If your products are going on rooftops, exposed to the elements, EPDM is your best friend.”

Food and Medical Equipment Buyers

Product examples: Silicone tubing, molded stoppers, sanitary gaskets

- Why Silicone? There’s no safer or more compliant material. Whether you’re extruding peristaltic pump tubing or molding caps for pharmaceutical vials, medical-grade silicone checks every box: biocompatibility, sterility, and thermal resistance.

- Bonus Tip: Always verify that your supplier can provide FDA or USP Class VI certificates when ordering for medical or food use.

“For hygienic zones, I tell clients: ‘Don’t compromise—go with certified silicone.’”

Automotive and Hydraulic System Clients

Product examples: Nitrile oil seals, Neoprene anti-vibration mounts

- Why Nitrile? It’s the industry standard for anything involving oil, grease, or fuels. Most molded engine bay components, from grommets to O-rings, are best made from NBR.

- Why Neoprene? For parts subject to motion and mechanical stress—like engine mounts or buffer blocks—Neoprene’s compression strength and moderate chemical resistance are a solid fit.

“If it touches oil or fuel, it’s NBR. If it needs to take a beating, go for Neoprene.”

These aren’t just material matches—they’re industry-proven combinations that can save time, reduce product failures, and ensure compliance from the start.

Conclusion

Choosing the Right Rubber = Long-Term Performance

Rubber parts may seem small in the scope of your overall product—but they often carry the biggest responsibility: sealing out leaks, protecting sensitive systems, or withstanding exposure to the elements. Over the years, I’ve seen how the wrong material choice leads to cracked gaskets, failed certifications, or premature replacements—all of which cost far more than a better material ever would.

That’s why I always stress: Start with your application, then choose your material accordingly.

Here’s a quick recap of what you’ve learned:

- EPDM: Best for outdoor and weather-exposed profiles.

- Silicone: Ideal for high temperatures and hygienic environments.

- Neoprene: A versatile performer in both molded and extruded forms.

- Nitrile (NBR): Unmatched when oil, grease, or fuel is involved.

Whether you’re designing HVAC seals, food-grade tubing, or automotive gaskets, there’s a perfect material match—and I’m here to help you find it.

If you’re unsure what material best suits your project, don’t hesitate to reach out. At KINSOE, we offer custom rubber extrusion and molding, backed by engineering support, regulatory expertise, and 20+ years of experience across industries.

Let’s make sure your rubber components perform—not just today, but for years to come. Contact us now for a tailored recommendation.

References: