Rubber seals are critical to product reliability, but many people overlook a hidden threat: compression deformation. Over time, seals may lose their original shape, leading to leaks and failure. In this article, I’ll explain what compression deformation is, why it matters, and how to prevent it through smart material choices and design.

Rubber compression deformation, often referred to as compression set, is the permanent change in shape that occurs when a rubber seal is subjected to a compressive force over time. This deformation reduces the seal’s ability to return to its original form after the pressure is removed. It’s a critical factor in seal failure because it compromises the seal’s elasticity, leading to leaks, loss of pressure, or contamination. Choosing the right material and design can significantly minimize this issue.

Now that we’ve defined rubber compression deformation, let’s take a closer look at why it happens, how it’s measured, and what you can do to avoid it in real-world applications.

What is Compression Deformation?

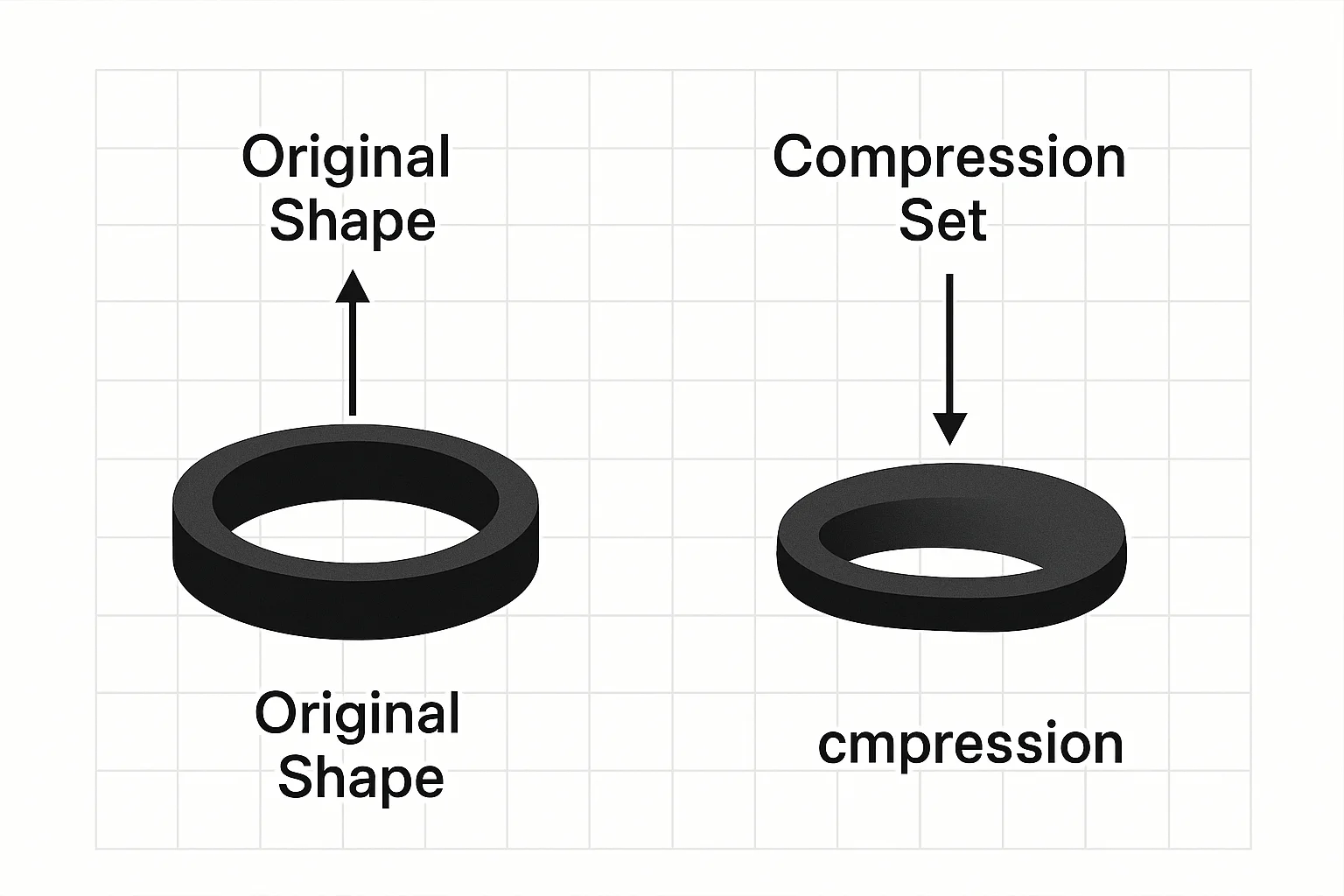

Compression deformation refers to the way rubber changes shape when a constant compressive force is applied over time. When rubber is squeezed—such as in a gasket or seal—it naturally tries to push back into its original form once the pressure is released. However, if the pressure is applied for too long, especially at elevated temperatures, the rubber may not fully recover. This permanent loss of shape is known as compression set.

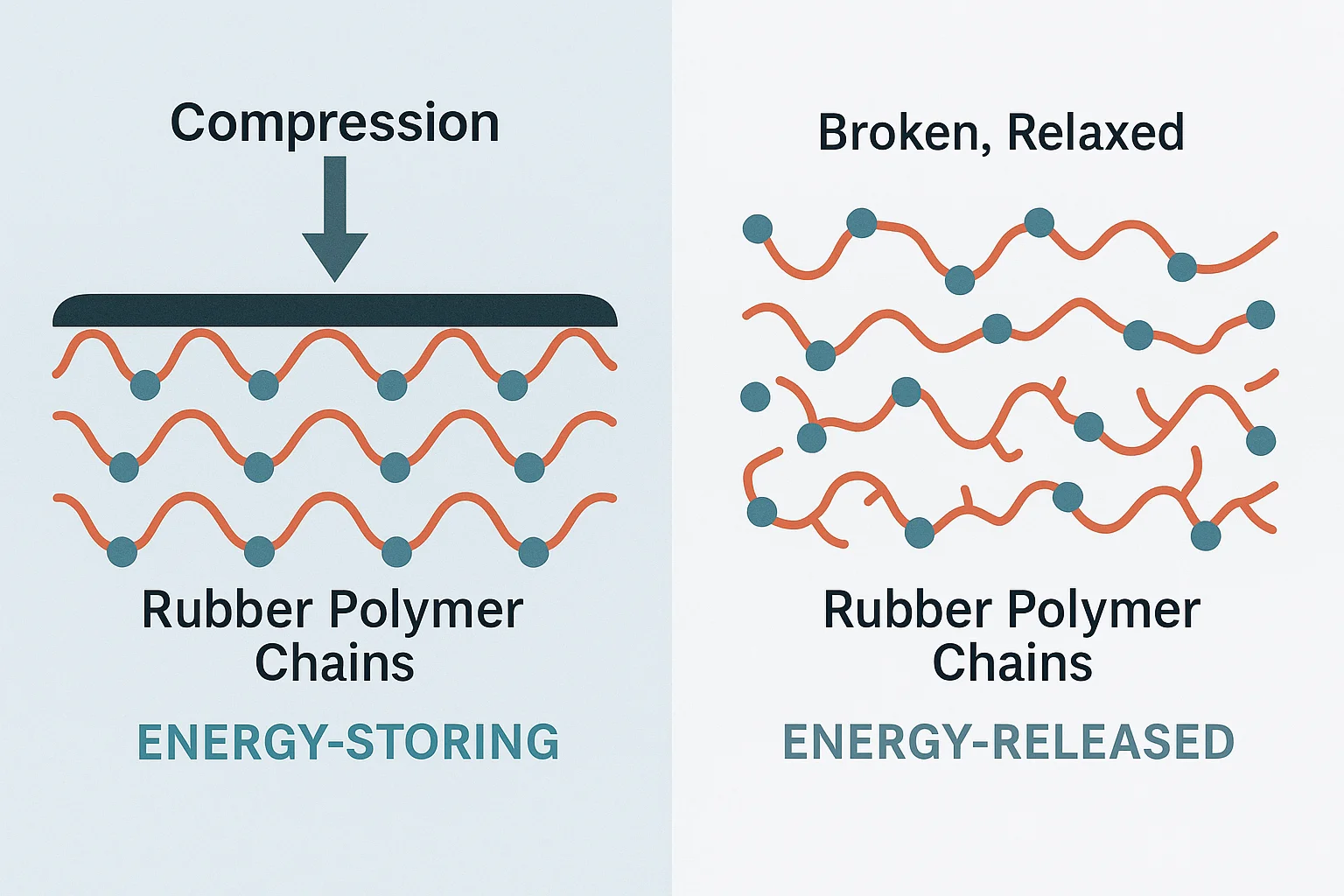

The deformation happens because rubber is a viscoelastic material, meaning it behaves both like a liquid (viscous) and a spring (elastic). Under constant load, the internal molecular chains in the rubber begin to relax and shift, and over time, they lose their ability to bounce back. This leads to gaps in sealing, resulting in leakage or contamination—critical failures in many industrial applications.

Compression deformation is not the same across all rubber types. Factors like the rubber formulation, cross-linking density, filler content, and curing process all influence how much a material will compress and whether it will bounce back. Understanding this behavior helps in selecting the right rubber for each application, especially in seals that must maintain performance over long service lives.

Why Does Rubber Sustain Permanent Deformation?

Rubber sustains permanent deformation mainly due to compression set, which occurs when the material is unable to fully recover its original shape after long-term stress. This issue becomes more pronounced under heat, time, and chemical exposure—all common in sealing applications.

At the molecular level, rubber consists of long polymer chains that are cross-linked. When compressed, these chains stretch and store energy. Ideally, once the force is removed, they return to their original configuration. But with prolonged stress, the internal structure starts to break down. The chains either slip past each other or relax permanently, especially if the temperature softens the rubber. As a result, the seal may appear flattened or distorted and won’t provide the same sealing pressure.

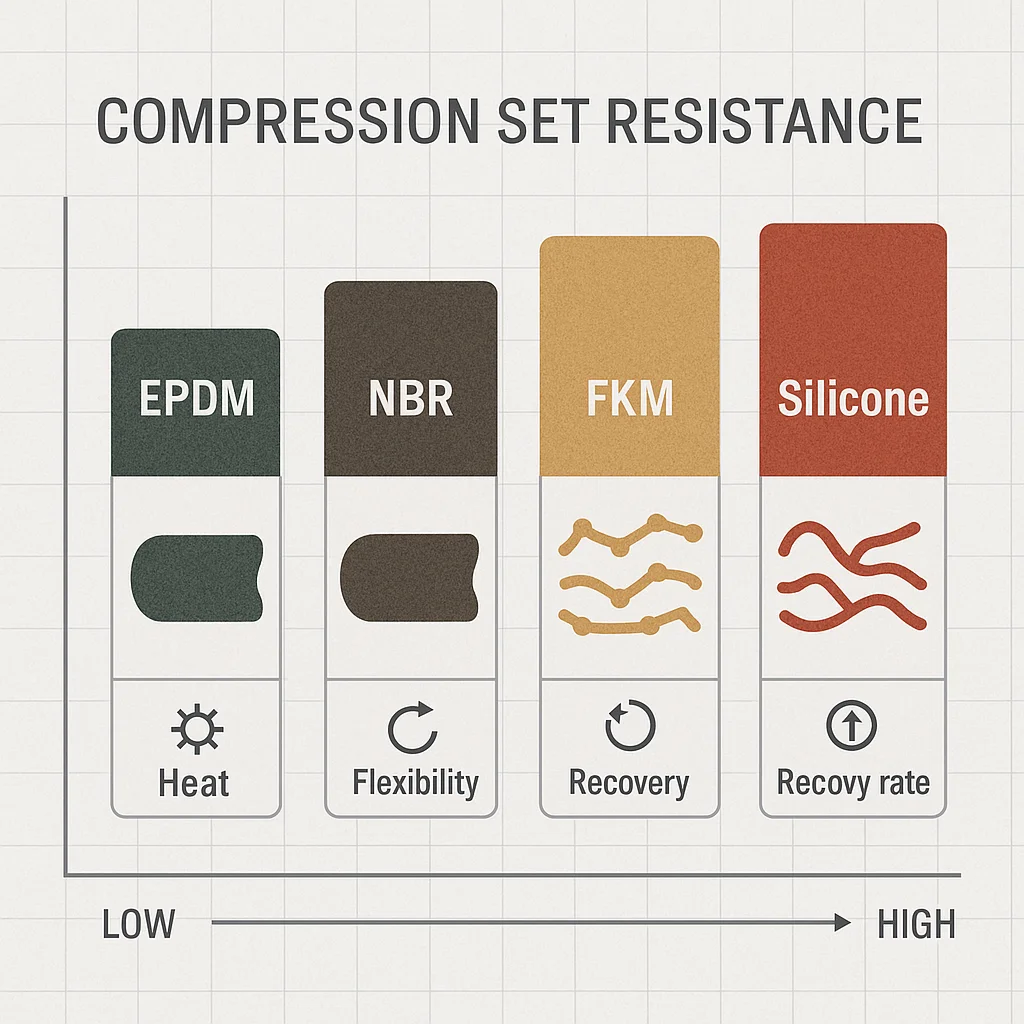

Not all rubber behaves the same. For example, silicone rubber tends to have excellent high-temperature resistance but may suffer from a higher compression set than fluorocarbon (FKM) rubber. Environmental factors like ozone, oils, and UV exposure can also speed up degradation.

In real-world use, this means a seal might work perfectly at first but fail after months of compression. That’s why understanding compression deformation is essential when choosing a material for long-term sealing performance.

Understanding the Compression Set in Rubber Seals

When we talk about compression set in rubber seals, we’re really talking about a seal’s ability to return to its original shape after being squeezed. A good seal compresses to fill gaps and prevent leakage, but once that pressure is removed—during shutdowns or temperature changes—it should rebound. If it doesn’t, the seal has developed a high compression set and may no longer perform its job.

Compression set is usually measured as a percentage. The standard test involves compressing a rubber sample to a fixed deflection, maintaining that compression for a set period (often 22 or 70 hours) at a specific temperature, and then measuring how much it recovers after the load is removed. A lower percentage means better recovery, which is desirable for dynamic sealing applications like O-rings and gaskets.

There are two main testing methods:

- ASTM D395 Method B (constant deflection)

- ISO 815-1 (similar international standard)

A seal with a high compression set might still look intact but could leak under pressure. That’s why compression set is a key performance indicator when evaluating rubber sealing materials, especially in critical systems like hydraulic valves, automotive engines, or chemical processing equipment.

The choice of rubber—whether it’s EPDM, NBR, FKM, or silicone—plays a big role in compression set resistance. So do additives, curing methods, and even storage conditions. When selecting a sealing material, always check the compression set specs under your actual operating conditions.

How Do You Calculate Compression Deflection of Rubber?

To design reliable rubber seals, it’s important to understand how much a material will compress under a specific load. This is known as compression deflection, and while it sounds technical, the principle is quite straightforward.

In simple terms, compression deflection measures how much a rubber part changes in height when a known force is applied. To estimate this, you need to consider the shape factor, Young’s modulus of the rubber, and the load applied.

Here’s a basic formula used in rubber engineering:

Deflection (inches) = Load (psi) / [E × (1 + 2 × Shape Factor²)]

Where:

- E is the Young’s modulus of the rubber (usually measured in psi)

- Shape Factor is the ratio of the loaded area to the free-to-bulge area

For instance, if you’re compressing a rubber pad with a shape factor of 2 and an E-value of 150 psi under a 300 psi load, plug those numbers into the formula to get an approximate deflection.

But in the real world, things aren’t always that linear. Rubber behaves non-linearly—especially at high strain—because of its hyperelastic properties. That’s why many engineers rely on finite element analysis (FEA) or test data when dealing with complex seal geometries or high-precision requirements.

Several online calculators also exist for quick estimations, but always validate your numbers with testing when performance is critical. Accurate deflection prediction helps avoid over-compression and premature seal failure.

Rubber Compression Deformation: Equation and Theory

To fully understand rubber compression deformation, we need to dive into some of the material science behind it. Rubber doesn’t behave like metal or plastic—it’s a hyperelastic material, which means its stress-strain response is non-linear and depends heavily on the type of deformation applied.

One of the most common models used to describe rubber behavior is the Mooney-Rivlin equation. This is a two-parameter model used for predicting how rubber stretches or compresses under load. While complex in its full form, its practical use lies in modeling rubber parts during the design stage:

W = C₁(I₁ – 3) + C₂(I₂ – 3)

Where:

- W is the strain energy

- C₁ and C₂ are material constants

- I₁ and I₂ are strain invariants derived from deformation

In compression, engineers also look at the Young’s modulus—a measure of stiffness. For most rubbers, Young’s modulus ranges from 100 psi to 3000 psi depending on formulation and durometer (hardness).

Then there’s the stress-strain curve, which shows how rubber responds as it’s stretched or compressed. Initially, rubber offers resistance (elastic phase), but beyond a certain point, molecular chains align and soften the material. If stress continues, permanent deformation can occur.

One practical example of applying these theories is during seal design. If you don’t account for the compression load, rebound recovery, and working temperature, the rubber could develop a high compression set or fail entirely.

By combining theoretical equations with empirical data (such as compression set test results), I can select the right rubber compound that delivers both elasticity and long-term durability under real-world pressures.

How to Improve Compression Set in Rubber Materials

If you’re trying to reduce compression set in rubber seals, the first place to look is the material formulation. The type of base polymer used—NBR, EPDM, FKM, silicone—has a huge impact. For instance, fluorocarbon (FKM) rubbers offer better resistance to heat and chemicals, which helps maintain elasticity over time. On the other hand, natural rubber may compress more easily under the same conditions.

Next comes the curing system. Peroxide-cured rubbers often exhibit lower compression set values compared to sulfur-cured ones, especially at elevated temperatures. Adjusting the cross-link density during curing can also improve rebound resilience.

Fillers and plasticizers must be used carefully. Too much filler can make the rubber stiffer and more prone to cracking under compression, while plasticizers might migrate over time, affecting recovery. Additives like anti-aging agents, antioxidants, and UV stabilizers also help extend the life of the rubber in tough environments.

From a design standpoint, avoid over-compression. Many failures come from compressing seals beyond their design limit. Use proper compression stops and select a rubber hardness (durometer) that matches your application load.

Finally, store rubber components in cool, dark, and dry conditions to preserve their performance until use. Even the best materials degrade with poor storage.

Real-World Implications for Seal Design and Procurement

As a manufacturer, I’ve seen firsthand how compression deformation affects real-world sealing performance. For product designers and procurement professionals, ignoring this factor can lead to unexpected costs, recalls, or downtime.

From a design perspective, selecting the wrong rubber can result in seals that lose their shape too quickly under heat or pressure. This is especially critical in systems with static loads, like pipe flanges or hydraulic cylinders, where the seal is compressed for long periods. Using rubber with a poor compression set will almost certainly lead to leaks over time.

For purchasing teams, it’s not just about price—it’s about the material specs. Always request the compression set value (per ASTM D395 or ISO 815) from your supplier. A low-cost rubber may seem appealing but could deform permanently under moderate conditions. That leads to reorders, replacements, or worse—system failure in your end product.

If you’re sourcing seals for applications involving high temperatures, pressure cycles, or chemical exposure, prioritize tested, certified compounds with a low compression set and high rebound resilience. Better yet, work with a supplier (like us) who understands how to balance material properties with your exact application needs.

Summary

Compression deformation is a silent killer in rubber seals, but it’s preventable. By understanding how and why it happens—and choosing the right materials—you can avoid leaks, failures, and downtime. If you need expert help selecting rubber with the right compression set, I’m here to support your sealing success.

References: