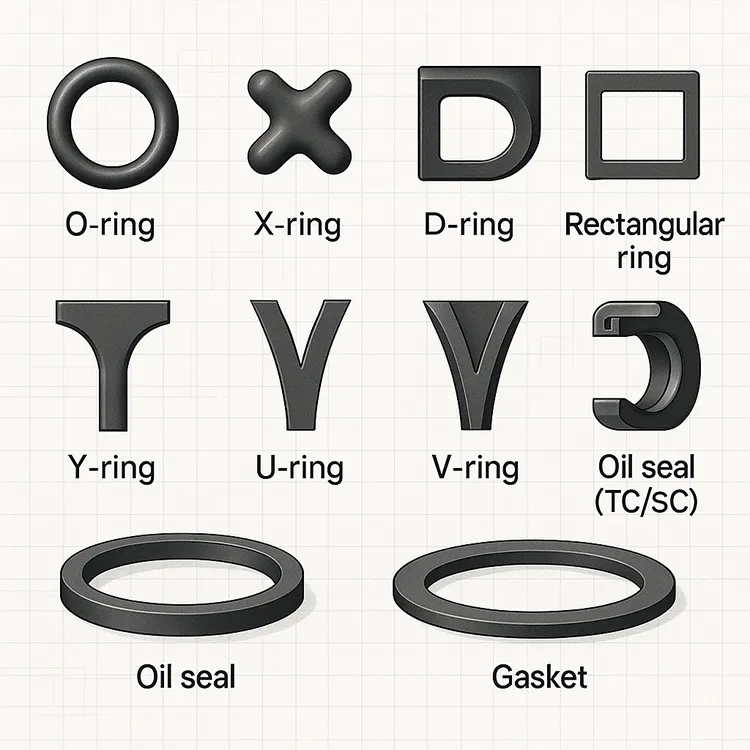

Rubber Seals by Shape and Structure

When I first entered the rubber components industry, I was overwhelmed by how many types of sealing rings there were. But over time, I realized that understanding the basic shapes and structures made things a lot clearer. If you’re a buyer or engineer trying to choose the right seal for your equipment, this section will walk you through the essentials.

O-Rings (O-Ring)

The O-ring is probably the most recognized sealing ring in the world. Its cross-section is a perfect circle, and it’s widely used for both static and dynamic sealing. Whether I’m working on a hydraulic valve or a pipeline joint, the O-ring is often my first choice due to its simplicity, low cost, and ease of installation.

Key applications: Hydraulic systems, pneumatic cylinders, pump shafts, pipe joints.

Y-Rings / U-Rings / V-Rings

These rings have a distinctive lip shape that enhances sealing under motion. Y-rings are commonly used in reciprocating motion, like in hydraulic cylinders. U-rings offer excellent sealing in both directions and are known for their wear resistance. V-rings are often stacked for high-pressure situations.

Real-world tip: For high-pressure reciprocating systems, I often use a Y-ring paired with a dust wiper for maximum effect.

X-Rings (Quad-Rings)

Also called quad-rings, X-rings have a four-lobed profile that provides better stability and reduces the chances of twisting during installation. They offer more sealing surface than standard O-rings and help reduce friction in dynamic applications.

Key use: Dynamic sealing with reduced wear, particularly when O-ring rolling is a concern.

Rectangular Rings

These are flat in profile and are primarily used in static applications. Their broad contact area offers reliable sealing for flange joints and similar settings.

Note: I often specify these for applications where space is tight and high-pressure sealing is essential.

Oil Seals (TC/SC Type)

Oil seals are more complex, often consisting of a rubber outer layer, a spring-loaded lip, and sometimes even a metal reinforcement. TC-type seals have a double lip, while SC-types have a single sealing lip. These are critical in rotating shafts to prevent lubricant leakage and contamination ingress.

Application areas: Gearboxes, motor shafts, crankcases.

D-Rings

These have a flat bottom and rounded top, offering a more stable seating surface compared to O-rings. I’ve found them particularly helpful in aerospace and automotive applications where seal rolling could cause critical failure.

Dust Seals / T-Rings

Dust seals are used to prevent external contaminants like dust, mud, or moisture from entering the sealing area. T-rings are a variant that combines features of backup rings and dust lips for enhanced performance.

Gaskets

Though not rings in the strictest sense, gaskets are flat seals commonly cut from sheet rubber and used to seal flanges and joints. I always include them in conversations around rubber seals because of their role in static sealing.

“Choosing the right rubber seal structure isn’t just about the shape—it’s about matching performance with your specific working environment.”

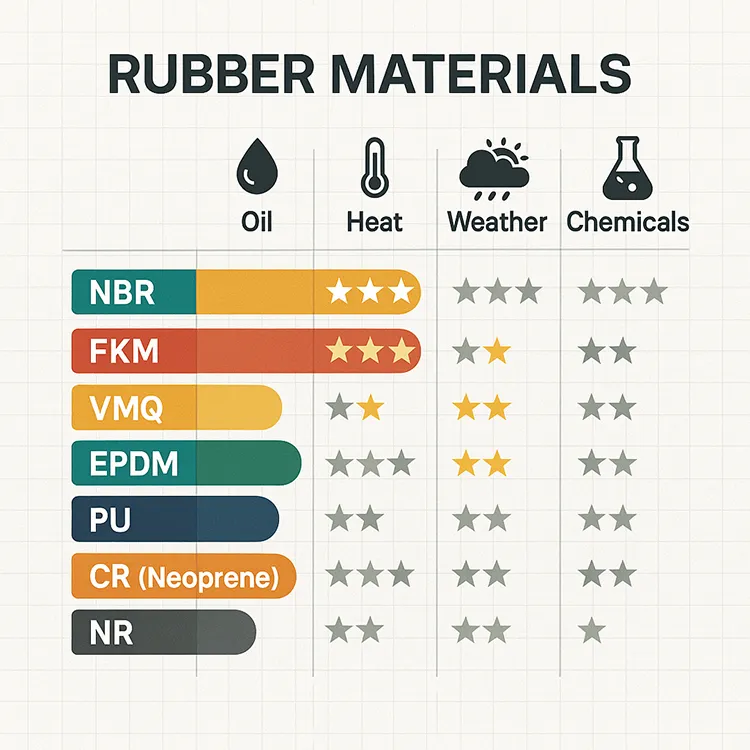

Rubber Seals by Material

Once the shape is settled, the next big decision I make is about the rubber material. Each rubber type has its strengths and weaknesses—what works in a high-heat food-grade pump might completely fail in a chemical plant. Here’s how I break it down when helping clients choose the right material for their sealing rings.

Nitrile Rubber (NBR)

NBR is the go-to material for oil-resistant applications. It’s affordable, durable, and handles a wide temperature range (–40°C to +120°C). I recommend it for general-purpose industrial seals, especially when mineral oils or greases are involved.

Best for: Automotive seals, fuel systems, hydraulic and pneumatic systems.

Fluorocarbon Rubber (FKM/Viton)

When I encounter high temperatures or aggressive chemicals, FKM is my top choice. It resists oils, fuels, acids, and high heat—up to 250°C in some cases. Though more expensive, its durability makes it cost-effective in critical applications.

Used in: Automotive engines, chemical equipment, and aerospace systems.

“If the seal must survive heat, oil, and time—FKM is usually the answer.”

Silicone Rubber (VMQ)

Silicone shines in extreme temperature environments, from –60°C to +200°C. It’s also food-safe and physiologically inert, making it ideal for medical and food processing seals. However, it’s mechanically weaker than other rubbers and not suitable for dynamic, high-pressure sealing.

Applications: Food-grade pumps, beverage processing, ovens, medical equipment.

EPDM Rubber

EPDM resists aging, UV, ozone, and water—making it perfect for outdoor and water-related applications. It’s not oil-resistant, so I avoid it where oils are present, but for weather resistance, it’s hard to beat.

Common uses: Rooftop HVAC seals, water system gaskets, and automotive weatherstripping.

Polyurethane Rubber (PU)

PU combines excellent abrasion resistance with high tensile strength. I often recommend it for hydraulic systems or dynamic applications with wear-and-tear risk. It’s less flexible than other rubbers but can outperform them in longevity.

Good for: Hydraulic cylinders, scraper seals, and shock-absorbing seals.

Neoprene Rubber (CR)

Neoprene is the generalist of rubbers. It has moderate resistance to oils, weather, and chemicals, making it suitable for a wide range of uses without excelling at any one thing. If versatility is the goal, neoprene often checks the box.

Use cases: Refrigeration seals, cable jackets, automotive parts.

Natural Rubber (NR)

With excellent elasticity and resilience, natural rubber is still relevant, especially in applications requiring high stretch and recovery. However, it degrades in oil, UV, and ozone, so I use it cautiously in outdoor or industrial chemical environments.

Typical use: Vibration dampening, shock mounts, and some mechanical seals.

NBR/EPDM Blends

Sometimes, hybrid materials strike the right balance. NBR/EPDM blends combine oil resistance with weatherability, offering a cost-effective solution for automotive seals and general-purpose gaskets.

“The right rubber compound is often the unsung hero behind a leak-free system.”

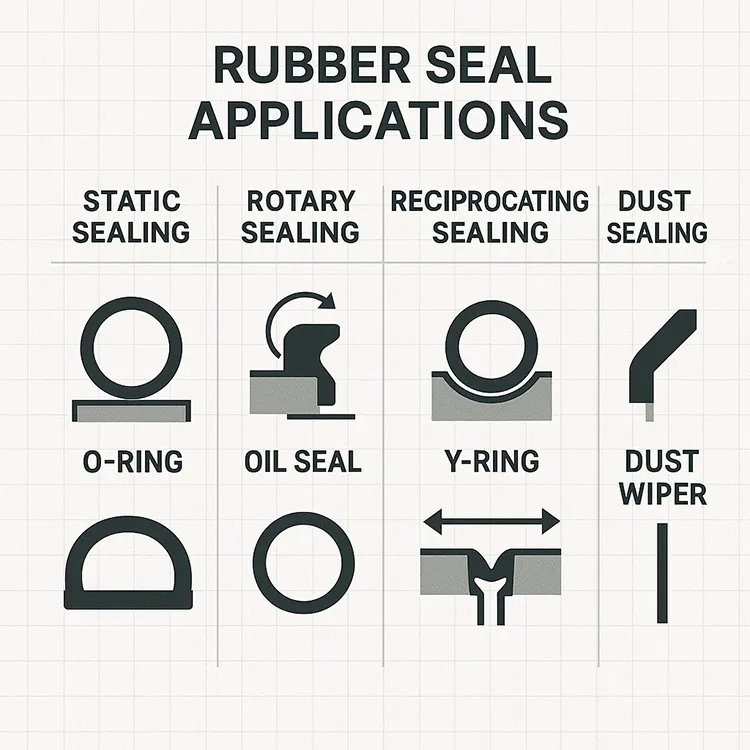

Rubber Seals by Application

Beyond shape and material, the function of a seal often defines its true value. When selecting a sealing ring, I always ask: What is this seal going to do? That one question drives most of my recommendations. Whether it’s holding back hydraulic pressure or keeping out dust, every application has its own requirements.

Static Sealing

Static seals are used in parts that do not move relative to each other. They’re found in flanges, lids, covers, and threaded joints. The sealing performance here depends on compression rather than movement.

My go-to options: O-rings, rectangular rings, and gaskets.

Typical applications: Pipe flange joints, enclosures, fixed housings.

Tip: I always remind clients that even in static sealing, surface finish and compression set resistance matter more than they think.

Dynamic Sealing (Rotary / Reciprocating)

Dynamic sealing involves motion—either rotary (spinning) or reciprocating (sliding back and forth). These seals must endure wear, friction, and fluid turbulence. That’s why material toughness and lip design become key.

- Rotary motion: Here, I recommend oil seals (like TC/SC types), especially when shafts are involved.

- Reciprocating motion: For hydraulic cylinders and pistons, Y-rings, U-rings, and PU seals work best.

Warning: Using a standard O-ring in a dynamic application may result in premature failure due to rolling, cutting, or extrusion.

Dust Sealing

Not all sealing is about fluids—sometimes it’s about keeping things out. Dust seals are designed to block contaminants like sand, dust, or moisture from reaching sensitive parts, such as piston rods or bearings.

Common setup: I pair dust wipers with Y-rings in hydraulic cylinders for dual protection.

Ideal industries: Construction machinery, agricultural equipment, mining gear.

Special Condition Sealing

Some applications push rubber seals to the limit. Think high pressure, vacuum, extreme temperatures, or hygienic requirements. In these cases, seal design and compound selection become non-negotiable.

- Pneumatics: Low-friction seals with minimal leakage, such as T-rings or low-hardness O-rings.

- High-pressure systems: Back-up rings with O-rings, V-ring stacks, or reinforced PTFE-rubber composites.

- Food-grade applications: Silicone or EPDM materials certified under FDA or EU 1935/2004.

“If the operating environment is extreme, the seal must be engineered with that specific reality in mind—there’s no shortcut.”

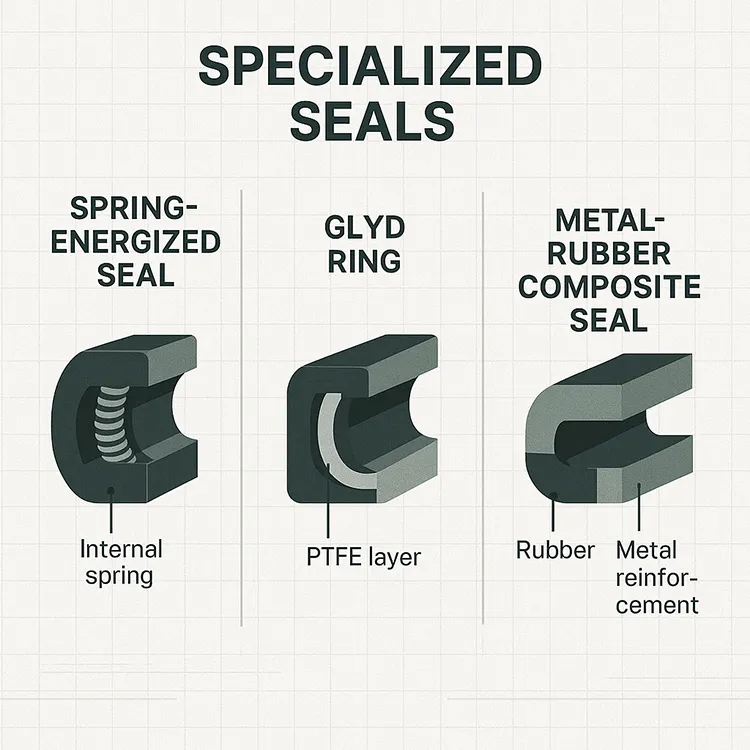

Other Specialized Seal Types

While standard O-rings and lip seals cover a wide range of needs, I often encounter scenarios that demand something more advanced. Over the years, I’ve worked with many specialized sealing solutions tailored for extreme precision, long-term performance, or unusual working conditions. Here are the ones I consider when basic seals just won’t cut it.

Combination Seals (e.g., Glyd Ring, Stepseal)

Combination seals integrate multiple sealing elements into a single unit. Take the Glyd Ring, for instance—it’s a blend of an elastomer energizer and a PTFE-based ring. It offers low friction and high chemical resistance, ideal for dynamic motion.

Use case: I usually specify Glyd Rings for heavy-duty hydraulic pistons or valves with aggressive fluid exposure.

Spring-Energized Seals

These seals combine a polymer sealing lip (like PTFE) with a metal spring inside to maintain consistent sealing force. They shine in high-temperature or cryogenic environments where elastomers can become brittle or lose elasticity.

Applications: Aerospace valves, medical devices, and high-vacuum chambers.

“When temperature swings or pressure extremes are a concern, spring-energized seals provide reliable performance where rubber alone would fail.”

Labyrinth Seals

Unlike contact seals, labyrinth seals use a non-contact, multi-chamber design to reduce leakage. They don’t provide a perfect seal, but they excel at preventing contamination in rotating machinery.

I’ve used them in: Motors, turbines, and pumps where some leakage is tolerable but contact wear must be avoided.

Note: These are typically paired with other seal types for a complete solution.

Metal-Rubber Composite Seals

These hybrid seals combine the elasticity of rubber with the structural support of metal. Common types include bonded washers (sealing washers with rubber inserts) and metal-encased O-rings for high-pressure flange sealing.

Ideal for: Hydraulic connections, fuel systems, and gas-tight environments.

Bonus: Metal parts can be customized in stainless steel, aluminum, or brass depending on corrosion or conductivity needs.

Key Factors When Choosing Rubber Seals

Choosing the right rubber seal isn’t just about picking a shape and material—it’s about aligning the seal’s properties with the demands of the application. Whenever I help clients with sealing solutions, I walk them through a checklist of five critical factors. Skipping any one of these can lead to premature failure or costly downtime.

1. Working Medium (Fluid or Gas)

The first question I ask is: What will the seal be exposed to? Different rubbers react differently to oils, fuels, water, steam, acids, or gases.

- For oil and fuel: I lean toward NBR or FKM.

- For water or steam: EPDM or silicone is more appropriate.

- For aggressive chemicals: I may recommend PTFE or FFKM composites.

Tip: Always check for chemical compatibility using a reference chart or the seal manufacturer’s data sheet.

2. Temperature Range

Rubber seals have defined operating temperature limits. Exceeding them can lead to hardening, cracking, or complete seal failure.

- Low-temp environments (–40°C and below): Silicone and EPDM are my go-to choices.

- High-temp environments (above 150°C): FKM or silicone.

- Cryogenic: I move to specialty seals like spring-energized PTFE.

“A seal that fails at the wrong temperature turns into a liability, not a safeguard.”

3. Pressure Rating

The system’s pressure dictates whether I can use a simple O-ring or need reinforced sealing with backup rings or composite designs.

- Low to medium pressure (up to 10 MPa): Standard O-rings or lip seals are often sufficient.

- High pressure (above 25 MPa): I use PU Y-rings, stacked V-rings, or Glyd Rings with anti-extrusion rings.

4. Movement Type

Seals must be matched to the movement type—static, reciprocating, or rotary.

- Static: O-rings, gaskets.

- Reciprocating: Y-rings, U-cups.

- Rotary: TC-type oil seals or mechanical face seals.

Note: Using a static seal in a dynamic setting is one of the most common causes of early failure I see.

5. Certification and Compliance

For industries like food, pharma, or aerospace, seals must meet strict standards like FDA, EU 1935/2004, or ISO 3601. I always make sure the chosen seal has the proper documentation.

Examples:

- Food-grade: Platinum-cured silicone, EPDM compliant with FDA 21 CFR 177.2600.

- Aerospace: FKM or perfluoroelastomer (FFKM) certified to aerospace standards.

Application Case Examples

To make everything we’ve discussed more tangible, I want to share a few real-world examples that illustrate how I apply seal type, material, and function together. These are drawn from actual customer scenarios I’ve encountered in industrial environments.

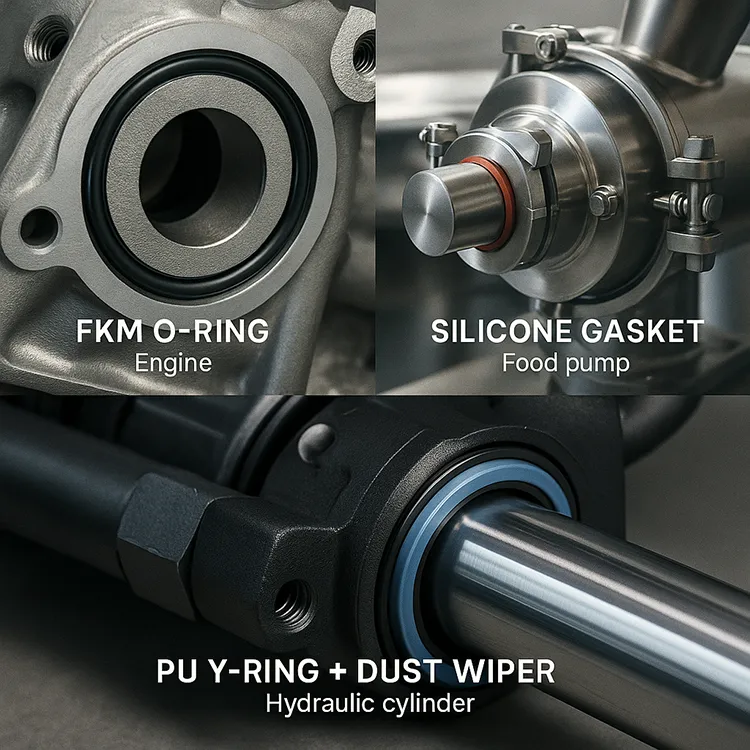

Automotive Engine: FKM O-Rings

In one of our projects with a Tier 1 automotive supplier, we provided FKM O-rings for use in high-temperature engine oil systems. These seals had to withstand continuous exposure to 180°C motor oil without hardening or leaking over a 5-year lifecycle.

- Why FKM: Exceptional oil and heat resistance

- Seal type: Standard O-ring (ISO 3601)

- Result: No failures reported after 1 million cycles of simulated operation

Insight: Even though the O-ring seems simple, choosing the right compound was critical to long-term reliability.

Food Pump: Silicone Gasket

A food processing equipment manufacturer approached us for seals that could meet FDA compliance and withstand cleaning agents. We supplied platinum-cured silicone gaskets for a rotary lobe pump in a yogurt production line.

- Why silicone: Food-safe, odorless, and chemically inert

- Seal type: Custom die-cut gasket

- Result: Zero bacterial buildup, fast approval during audits

Insight: In food-grade applications, documentation and hygiene are just as important as material performance.

Hydraulic Cylinder: PU Y-Ring + Dust Wiper

A heavy machinery client needed seals for their hydraulic cylinders used in excavators. We designed a sealing set composed of a PU Y-ring and a rubber dust wiper to handle muddy, abrasive environments.

- Why PU: High wear resistance and dimensional stability

- Seal type: Y-ring for dynamic sealing, dust seal for contamination protection

- Result: Extended maintenance interval by 40%

“The right seal pairing doesn’t just prevent leaks—it extends equipment life and boosts ROI.”

Conclusion: Matching the Right Seal to the Right Job

Over the years, I’ve come to realize that selecting the right rubber sealing ring is never just about picking something off the shelf. It’s about understanding the full picture—shape, material, function, and environment—and aligning them to the real demands of the application.

Whether I’m helping a client seal an engine, a food-grade pump, or a piece of heavy equipment, the same principle applies: a well-matched seal ensures reliability, safety, and efficiency. The wrong choice can lead to leaks, contamination, system failure—or worse, unplanned downtime that costs far more than the seal itself.

If you’re unsure which seal fits your needs, don’t guess. I’m here to help you make the best choice based on data, experience, and industry standards.

“In sealing, details matter—because even the smallest ring can make or break a system.”

References: