1. Why Tensile Strength Matters in Rubber Applications

Tensile strength is one of the most important mechanical properties in rubber selection. According to ASTM D412, it refers to the maximum stress a rubber material can withstand while being stretched before it breaks. For engineers and designers, this value is a key indicator of a material’s resistance to tearing or failure under load.

When tensile strength is insufficient, rubber components are prone to cracking, tearing, or complete rupture—especially in sealing applications, where even small deformations can lead to leaks or pressure loss. In hoses or gaskets under dynamic loads, inadequate strength may cause early failure, resulting in costly downtime or safety issues.

However, the strongest material isn’t always the best. Rubber must not only resist pulling forces but also retain flexibility, compression recovery, or chemical resistance. That’s why the right tensile strength is about balance—not maximization. Choosing a material that fits the specific stress profile of your application is far more effective than blindly selecting the strongest available option.

2. Comparative Table of Common Rubber Tensile Strengths

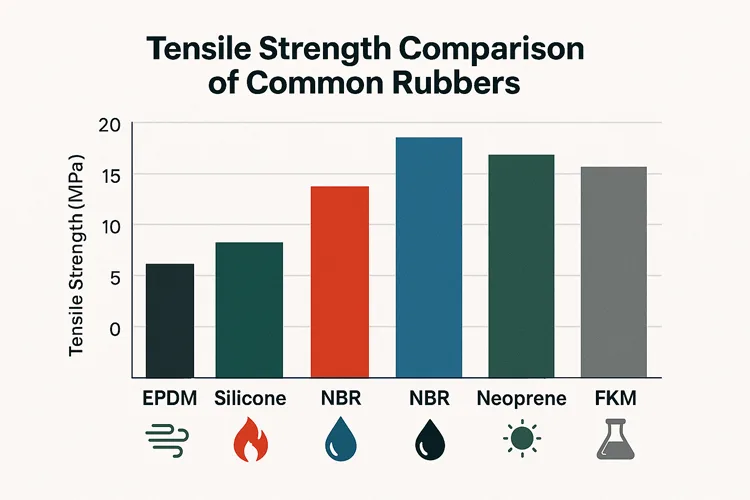

To make material selection easier, I’ve compiled a comparison table of the tensile strength ranges for commonly used industrial rubbers. These values are approximate and based on standard compound grades tested per ASTM D412. Actual values may vary depending on formulation and processing.

| Rubber Type | Tensile Strength Range (MPa) | Key Characteristics |

|---|---|---|

| EPDM | 7–14 | Good weather resistance, medium strength |

| Silicone | 6–12 | Excellent heat resistance, soft texture, lower strength |

| Nitrile (NBR) | 12–20 | Great oil resistance, high strength |

| Neoprene | 8–17 | Good aging resistance, balanced strength |

| Fluoroelastomer (FKM) | 10–18 | Strong chemical resistance, stable strength |

These values offer a quick reference for selecting rubber based on the expected mechanical load of the application. For example, nitrile and FKM tend to be better for oil-sealing components under stress, while EPDM is popular in automotive and weather-sealing parts due to its reliable flexibility and environmental stability.

I recommend visualizing this data as a bar or radar chart to highlight the performance differences across materials at a glance.

3. How to Balance Tensile Strength with Other Properties in Real Applications

Tensile strength is rarely the only performance indicator that matters. In real-world applications, rubber components must endure a combination of forces, environmental stressors, and mechanical movements. Here’s how I typically evaluate tensile strength in context:

3.1 Seals: Strength vs. Softness

In static or dynamic sealing, rubber must conform tightly to mating surfaces. If the tensile strength is too high, the rubber may become too stiff to compress effectively, leading to sealing failure. I often choose softer materials like silicone or lower-durometer EPDM for applications where compression and flexibility are more critical than raw strength.

3.2 Hoses & Tubing: Strength vs. Pressure Resistance

Rubber hoses must handle internal pressure without bursting or collapsing. Materials like NBR, with tensile strength in the 12–20 MPa range, are ideal because they balance elasticity and durability under stress. However, for lightweight or low-pressure systems, moderate-strength rubbers like EPDM may be more cost-effective and sufficient.

3.3 Dynamic Parts: Strength vs. Resilience

In vibration-damping pads, grommets, or suspension mounts, it’s not just tensile strength but rebound and fatigue resistance that matter. Neoprene and silicone—though not the strongest—excel in absorbing repeated motion without permanent deformation. I avoid using overly rigid rubbers in these contexts.

3.4 Harsh Environments: Strength vs. Chemical Resistance

In chemical plants or outdoor settings, rubber strength may degrade over time. FKM stands out for offering both chemical resistance and stable mechanical performance. Even with tensile strength similar to NBR, its long-term reliability often makes it the safer choice.

Tip: Selecting “adequate strength” that fits the job is smarter than chasing the “highest possible number.” Over-engineering can lead to poor sealing, excessive cost, or premature wear.

4. Key Factors That Influence Rubber Tensile Strength

Even within the same rubber type, tensile strength can vary widely based on how the material is formulated and processed. In my experience, the following factors play a crucial role in determining how strong a rubber compound truly is:

• Material Purity and Formulation

The base polymer alone doesn’t define strength. Additives like carbon black, silica, oils, and plasticizers all impact tensile properties. High filler loading can reduce strength, while optimized crosslinking agents and reinforcement fillers enhance it. Purity of raw materials also affects consistency—impurities can create stress concentrators that lead to early failure.

• Curing (Vulcanization) Parameters

The vulcanization process—especially temperature, pressure, and duration—directly affects crosslink density. Under-cured rubber may remain weak and tacky, while over-curing can make it brittle. Each rubber type has an optimal vulcanization window, and I always ensure tight process control to hit that sweet spot.

• Environmental Conditions

Exposure to extreme temperatures, ozone, UV, or aggressive chemicals will gradually degrade the polymer chains. That’s why rubber exposed outdoors or in harsh environments must be formulated for stability, not just strength. Pre-aging tests help predict long-term behavior.

• Service Life & Aging

Even the strongest rubber loses strength over time. Aging tests—like hot air oven aging or immersion in specific chemicals—simulate how tensile properties will evolve after years of use. For mission-critical seals, I always request test data showing post-aging strength retention.

5. How to Interpret a Rubber Tensile Test Report

When selecting rubber materials for engineering use, understanding the test report is just as important as reading a datasheet. Most tensile strength tests follow either ASTM D412 or ISO 37, which involve stretching a dumbbell-shaped rubber specimen until it breaks.

• Key Terms in the Report

- Tensile Strength at Break (MPa): Maximum stress the sample withstands before failure.

- Elongation at Break (%): How far the material stretches before breaking. Indicates flexibility.

- Modulus (100%, 200%, etc.): Stress at specific strain levels—useful for predicting how the material behaves under partial load.

These values are often plotted on a stress-strain curve, where the slope and peak give insights into stiffness and durability.

• Red Flags in Reports

If the report shows a steep drop in strength after heat aging, fluid immersion, or UV exposure, that could signal long-term durability issues. I always compare aged vs. unaged test values to assess whether a material is robust enough for the intended environment.

• Real-World Use Case

Recently, when evaluating rubber seals for a chemical pump, I compared tensile test reports of NBR and FKM. Though both passed initial specs, the FKM retained over 90% strength after acid immersion, while NBR dropped by 40%. That difference made the choice obvious.

A good tensile report does more than show strength—it helps predict performance over time.

6. Material Selection Guide by Application

Rubber selection is always application-specific. Below is a quick reference guide I often use when advising engineers and buyers on material choices based on tensile strength and overall suitability:

| Application Scenario | Recommended Rubber | Reasoning |

|---|---|---|

| Automotive Seals | EPDM | Excellent ozone resistance, cost-effective, moderate strength sufficient for sealing |

| Food-Grade Tubing | Silicone | Non-toxic, high-temperature resistant, compliant with FDA regulations, adequate flexibility |

| Hydraulic Sealing Rings | NBR | Outstanding oil resistance, high tensile strength to handle fluid pressure |

| Chemical Valve Gaskets | FKM | Exceptional chemical stability, retains strength over time in corrosive environments |

I’ve found that trying to use a single rubber type for all applications often backfires. A material that works well in high-heat food processing may fail in oil-laden environments, and vice versa. For example, while silicone is ideal for clean systems, it lacks the tensile strength to perform under heavy mechanical stress.

Always consider material strength in relation to actual stress levels and environmental exposure.

7. Conclusion and Advice

Tensile strength is a core metric when evaluating rubber materials—but it’s never the only one that matters. In my experience, the best-performing rubber components are those chosen based on a comprehensive understanding of the application’s mechanical and environmental demands, not just peak strength values.

A rubber with “the highest strength” might seem impressive on paper, but in practice, it could be too stiff, too brittle, or chemically incompatible. That’s why I always treat tensile strength as a must-check index, not a standalone criterion.

Before finalizing any rubber material, I recommend requesting full test reports, understanding aged performance data, and if possible, validating properties with actual samples or COAs (Certificates of Analysis). Communication with your supplier is key—don’t settle for generic specs if your application has unique requirements.

In short: know your application, understand the trade-offs, and choose a material that performs—not just one that impresses on paper.

References: