1. Introduction

1.1 Why Selection Is the #1 Success Factor

From my experience working with automation engineers and production teams, the success or failure of foam suction cups depends heavily on proper selection. Foam cups outperform standard rubber cups on rough, porous, or inconsistent surfaces—but only when the diameter, hardness, foam thickness, material, and vacuum parameters are correctly matched to the application.

Most issues such as drop-offs, unstable gripping, slow pick-up, and overheating vacuum generators originate from incorrect sizing or material mismatch rather than product defects. If you are already facing those problems, I also recommend consulting our troubleshooting guide, Foam Suction Cups Not Holding? Fix Common Issues.

If you’re new to foam suction cups and need a foundational overview, you can refer to the main guide, Foam Suction Cups: Complete Buyer’s Guide.

To understand how foam cups behave in various industries—such as packaging, labeling, woodworking, electronics, and glass handling—you may find it helpful to review Foam Suction Cup Applications in Industry before continuing with the sizing process.

1.2 What This Guide Covers

In this selection guide, I walk you through a complete, practical, step-by-step approach to choosing the right foam suction cups:

- How to size the correct cup diameter based on weight, acceleration, and surface conditions

- How to choose the correct foam hardness or density depending on surface delicacy, porosity, or rigidity

- How to pick the best foam material (NR, EPDM, NBR, silicone, PU), with deeper material comparison available in

Foam vs Rubber Suction Cups: Material Guide - How to match the cup with the vacuum system, including flow, hose length, manifolds, and filters

- Engineering rules-of-thumb to speed up decision-making

- Real selection scenarios from packaging, electronics, woodworking, and labeling automation

- A printable engineer-friendly checklist for daily use

If your handling challenges involve rough, oily, or dusty surfaces, you may also benefit from the practical reference,

Foam Suction Cups for Rough and Oily Surfaces.

And if your concern involves lifecycle, maintenance cost, or cup wear, the next recommended reading is

Foam Suction Cup Life, Maintenance and Cost.

Foam suction cup selection always begins with correct sizing. In this chapter, I walk you through the engineering logic I use when recommending diameters and foam thicknesses for automated handling systems. If you haven’t yet reviewed practical use cases across industries, you can refer anytime to

Foam Suction Cup Applications in Industry for context.

2. Step-by-Step Sizing Guide

2.1 Determine the Load Requirements

Before choosing a suction cup diameter, I always calculate the required lifting force based on three parameters:

- Object weight (kg)

- Acceleration during motion (robot speed, vertical lift, sudden stops)

- Safety factor — typically 2×–4×, depending on industry and risk tolerance

For high-speed robotic arms or pick-and-place systems, acceleration may exceed the object’s weight force. This is why a cup that works during “slow testing” may fail once the machine accelerates to full production speed.

Key rule:

Higher acceleration = larger diameter requirement.

2.2 Choose the Correct Cup Diameter

Foam suction cups operate with controlled leakage, because their job is to conform to rough or irregular surfaces. This means they rely more on contact area than rubber cups.

A practical way to size diameter is:

- Begin with standard vacuum calculation based on weight

- Increase accordingly for:

- porous surfaces (corrugated cartons, MDF, recycled paper)

- curved or textured surfaces

- inconsistent shapes or soft packaging

For rough or porous materials, I always use the 20% Oversize Rule:

Select a diameter at least 20% larger than the calculated value.

This helps compensate for leakage and micro-gap variations.

If you’re unsure whether the surface should be considered “difficult,” check the dedicated guide

Foam Suction Cups for Rough and Oily Surfaces.

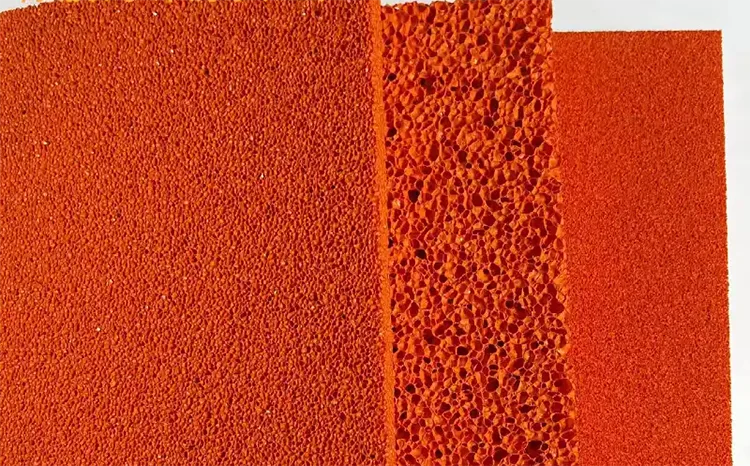

2.3 Select Foam Thickness

Foam thickness plays a major role in how the cup handles height variations, texture depth, and local inconsistencies.

Thin foam layer (2–3 mm):

- Best for smooth, rigid surfaces

- Fastest vacuum response

- Minimal deformation → high precision

Medium foam layer (4–6 mm):

- Most universal option

- Suitable for packaging, labeling, wood panels

- Good balance between sealing and durability

Thick foam layer (7–10 mm):

- For rough, highly porous, or uneven surfaces

- Ideal for corrugated cartons, MDF, textured plastics

- Allows deeper compression and micro-gap sealing

If your production environment is dusty, oily, or highly textured, thickness selection should also consider the vacuum system. Details are covered later in

Foam Suction Cups for Rough and Oily Surfaces.

2.4 Example Sizing Scenarios

Below are simplified versions of the calculations I help customers work through.

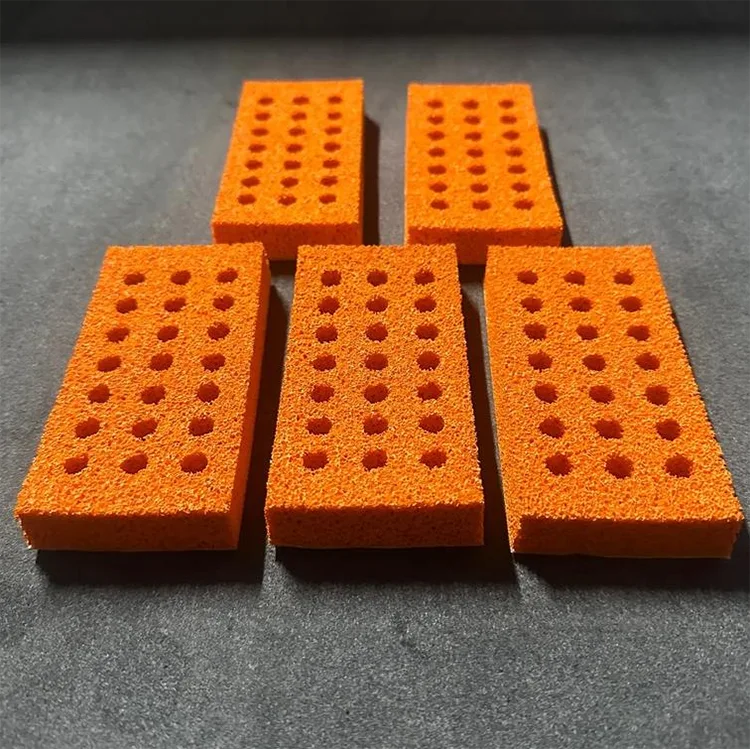

Scenario A — Picking a 3 kg corrugated carton

- Surface: porous carton

- Handling: vertical pick with fast acceleration

- Recommended:

- Larger diameter (oversize rule)

- Medium-thick foam for sealing porosity

- Soft–medium hardness

This is a typical case where rubber cups fail, but foam cups perform consistently after proper sizing.

Scenario B — Handling a lightweight (0.3 kg) plastic electronics housing

- Surface: smooth but delicate

- Handling: precise pick-and-place

- Recommended:

- Smaller diameter for higher precision

- Thin to medium foam layer

- Ultra-soft foam to prevent marking

You can compare this with the special material requirements described in

Foam vs Rubber Suction Cups: Material Guide.

Scenario C — Large MDF wooden panel

- Surface: dusty + porous

- Handling: sheet transfer

- Recommended:

- Large diameter

- Medium to thick foam

- Dust-tolerant material

- Stronger flow vacuum system (covered later)

For deeper analysis of surface difficulties, refer to

Foam Suction Cups for Rough and Oily Surfaces.

Foam hardness (or density) determines how well the suction cup adapts to surface irregularities, how much pressure it exerts on the product, how stable the grip is, and how long the cup lasts.

Choosing it correctly is just as important as selecting the right diameter.

If you need help understanding how hardness affects material choice (NR, EPDM, NBR, silicone, PU), deeper explanations are available in

Foam vs Rubber Suction Cups: Material Guide.

3. Selecting Foam Hardness / Density

3.1 Soft Foam (Best for Delicate Surfaces)

Soft foam has high compressibility and low resistance. This makes it ideal for:

- Delicate or easily scratched products

(e.g., coated plastics, glossy housings, consumer electronics) - Surfaces with slight texture

(e.g., printed cardboard inserts, embossed labels) - Items where marking must be avoided

Soft foam generates the least pressing force, which helps prevent visible rings, dents, or surface deformation.

Pros:

✓ Great surface conformity

✓ Safe on fragile finishes

✓ Reduces marking risk

Cons:

○ Shorter lifespan in abrasive environments

○ Less stable for heavy objects

This softness-marking relationship is also explained in the section on delicate surface handling within

Foam Suction Cups Not Holding? Fix Common Issues.

3.2 Medium Foam (Universal Choice)

Medium hardness is the most commonly recommended option for mixed industrial surfaces, offering a stable blend of durability and adaptability.

Ideal for:

- Packaging & logistics

(corrugated boxes, kraft cartons, recycled materials) - Wood panels

(MDF, particle board, semi-sanded surfaces) - General plastic components

(textured but not fully porous surfaces)

Medium foam resists wear better than soft foam while still offering good conformity.

Pros:

✓ Best overall balance

✓ Good for rough surfaces

✓ Longer life compared to soft foam

Cons:

○ Slightly reduced conformity on extremely porous materials

This hardness category aligns with mixed-use recommendations seen in

Foam Suction Cup Applications in Industry.

3.3 Hard Foam (High Stability for Rigid Parts)

Hard foam is typically used for rigid surfaces where precision outweighs surface adaptability.

Best for:

- Flat, rigid panels

- Heavy objects with stable surfaces

- Precise pick-and-place requirements

- Situations where lateral movement must be minimized

Hard foam behaves closer to a semi-rigid interface, providing excellent positional stability.

Pros:

✓ High stability under acceleration

✓ Good for heavy or rigid parts

✓ Better dimensional consistency

Cons:

○ Poor adaptability to porous or textured surfaces

○ Higher risk of product marking

○ Ineffective on rough cartons or wood

For better surface conformity on rough or oily surfaces, see

Foam Suction Cups for Rough and Oily Surfaces.

3.4 Hardness Selection Table

Below is a simplified, skimmable table I provide to engineers to accelerate the decision process:

| Surface Type | Recommended Hardness | Reason |

|---|---|---|

| Rough / porous cartons | Soft–Medium | Maximum sealing, gap tolerance |

| Smooth plastic surfaces | Medium | Good balance of grip & durability |

| Delicate coated surfaces | Soft | Prevents marking or deformation |

| Heavy rigid parts | Medium–Hard | Stability under load & acceleration |

For special environments (heat, oil, abrasion), hardness must be combined with correct material selection, explained in

Foam vs Rubber Suction Cups: Material Guide.

Choosing the correct foam material is just as critical as selecting diameter and hardness. Each material behaves differently under temperature, humidity, oil exposure, abrasion, and marking sensitivity.

This chapter provides a high-level material overview, while the full comparison—structure, performance, and “if X, choose Y” guidance—is available in

Foam vs Rubber Suction Cups: Material Guide.

4. Material Selection Basics

4.1 NR (Natural Rubber)

NR foam is the most common and versatile material used in foam suction cups. It offers excellent elasticity, making it suitable for a broad range of applications.

Best for:

- Packaging and logistics

- General plastic components

- Woodworking and furniture panels

- Textured but non-oily surfaces

- Medium to rough cartons

Key Advantages:

✓ High elasticity → strong conformity

✓ Very stable grip on porous or inconsistent surfaces

✓ Cost-effective and widely available

Limitations:

○ Not suitable for oil exposure

○ Not recommended for high-temperature environments

4.2 EPDM

EPDM foam is ideal for environments exposed to humidity, water, or outdoor conditions.

Best for:

- Outdoor lines (construction, solar panel assembly)

- High-humidity operations

- Applications with ozone or UV exposure

Key Advantages:

✓ Excellent weather resistance

✓ Superior ozone and UV tolerance

✓ Good overall elasticity

Limitations:

○ Does not perform well with oils or fuels

○ Slightly lower grip performance on very smooth surfaces compared to NR

4.3 NBR (Nitrile Rubber)

NBR foam is the go-to option for oily, greasy, or lubricant-contaminated surfaces, especially in automotive and machining sectors.

Best for:

- Automotive metal parts

- Machining components with residual oil

- Parts exposed to lubricants or fuel vapor

Key Advantages:

✓ Superior oil and grease resistance

✓ Provides more stable grip on oily layers

✓ Ideal for metal handling lines

Limitations:

○ Lower UV and ozone resistance than EPDM

○ Slightly less flexible than NR

For deeper troubleshooting of oily surfaces, see

Foam Suction Cups for Rough and Oily Surfaces.

4.4 Silicone

Silicone foam is used when the environment demands high temperature tolerance or non-marking performance on delicate surfaces.

Best for:

- Electronics assembly

- High-gloss plastics or coated surfaces

- Temperature-sensitive production lines

- Food & medical device components (where non-marking matters)

Key Advantages:

✓ Exceptional heat resistance

✓ Outstanding non-marking performance

✓ Very soft and gentle for fragile parts

Limitations:

○ Not suitable for oily environments

○ Higher material cost

If the primary concern is preventing surface damage, silicone is often the most reliable choice.

4.5 PU (Polyurethane)

PU foam is the top choice for high-wear, high-abrasion, fast-cycle environments.

Best for:

- MDF and wood panel handling

- Abrasive surfaces

- High-speed packaging lines

- Environments requiring maximum durability

Key Advantages:

✓ Longest lifespan among foam materials

✓ Excellent tear resistance

✓ Good structural stability under repeated compression

Limitations:

○ Less soft than silicone → not ideal for delicate surfaces

○ Slightly reduced conformity on extremely irregular shapes

For environments where long-term lifecycle cost matters, this material pairs well with the cost logic explained in

Foam Suction Cup Life, Maintenance and Cost.

4.6 Quick Material Decision Matrix

Below is a simple decision tool I provide to engineers for fast selection:

| Environment / Requirement | Material | Reason |

|---|---|---|

| Rough or porous cartons | NR | High elasticity, best sealing capability |

| Outdoor / humid / UV exposure | EPDM | Weather, ozone, UV resistant |

| Oily or greasy metal parts | NBR | Superior oil resistance |

| High temperature or delicate part | Silicone | Non-marking, excellent heat stability |

| Abrasive or high-wear surfaces | PU | Longest lifespan, tear-resistant |

For full structural comparisons and detailed “if your surface is X, choose Y” logic, refer to:

👉 Foam vs Rubber Suction Cups: Material Guide.

Selecting the right foam suction cup is only half of the job — the other half is making sure the vacuum system is correctly configured. Foam cups behave very differently from standard rubber cups because they intentionally allow controlled leakage to conform to surface irregularities.

This means vacuum systems must be tuned for flow, not just vacuum level.

If you work with rough, porous, dusty, or oily surfaces, you may also want to refer to:

👉 Foam Suction Cups for Rough and Oily Surfaces

which explains many surface–vacuum interactions in greater depth.

5. Matching the Cup with the Vacuum System

5.1 Vacuum Level vs. Flow Rate

This is the most misunderstood part of foam suction cup engineering.

Rubber cups require high vacuum level but low flow.

Foam cups require high flow but moderate vacuum level.

Because foam cups compress into surface irregularities and micro-gaps, they operate with constant micro-leakage. That leakage must be compensated with airflow, otherwise the vacuum level will never rise fast enough to lift the part safely.

Key rules:

- Increasing vacuum level doesn’t fix leaks on rough surfaces.

- Increasing flow rate does.

This difference is also reflected in troubleshooting situations within

Foam Suction Cups Not Holding? Fix Common Issues.

Practical takeaway:

✔ For foam cups, choose a high-flow ejector or vacuum pump.

✘ Avoid deep-vacuum, low-flow systems designed for rubber cups.

5.2 Handling Leakage Properly

Foam cups are not supposed to achieve “airtight perfection.”

They seal by compression and texture conformity, not by forming a perfect rubber boundary.

This means:

- Some leakage is normal

- Leakage is managed, not eliminated

- Performance depends on whether flow can maintain vacuum stability

If your surface is extremely porous (e.g., recycled corrugated cartons or MDF), even a well-sized foam cup may struggle unless the vacuum system is upgraded to a higher flow capacity — a concept explained in detail in the rough-surface guide linked above.

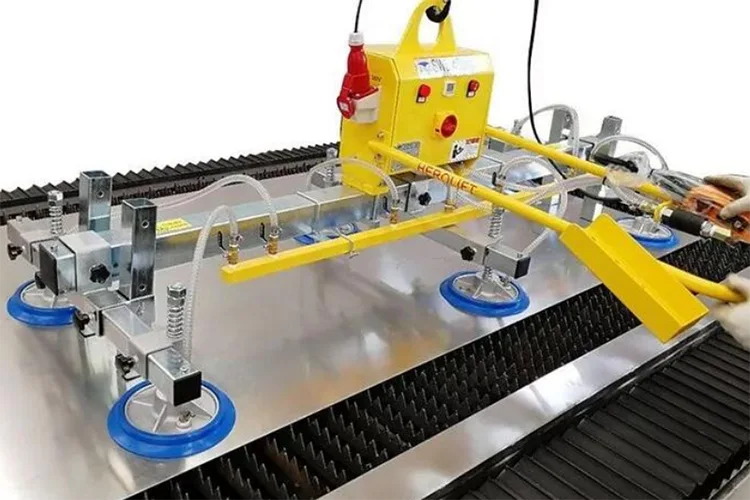

5.3 Choosing Filters and Accessories

Because foam cups can pick up micro-particles from wood, dust, or packaging fibers, filtration is essential to protect your vacuum generator.

Recommended filtration setup:

- Fine filters (for wood dust, paper dust)

- Oil-resistant filters (for automotive or machining environments)

- Easily accessible filter housings (for quick maintenance)

Many vacuum failures come not from the cups but from blocked filters, which reduce flow and cause cups to release parts unexpectedly. This topic is expanded in the maintenance section of

👉 Foam Suction Cup Life, Maintenance and Cost.

5.4 Understanding Manifold & Hose Effects

Vacuum system layout directly affects response time and stability:

Hose length matters

- Long hoses slow down vacuum response.

- Minimize distance between cup and vacuum source whenever possible.

Internal diameter matters

- Narrow hoses restrict airflow.

- Larger internal diameter improves speed and stability — especially important for porous surfaces.

Manifold balancing

In multi-cup systems:

- Cups closer to the vacuum source often receive stronger flow

- Cups farther away may receive insufficient flow → cause drop-offs

- Use balanced manifold designs or flow restrictors to equalize performance

This is especially important when handling large surfaces such as furniture panels, glass, or mixed-shape packages.

For engineers upgrading from rubber to foam cups, troubleshooting vacuum layout is often the fastest path to improvement.

5.5 Choosing the Right Cup Diameter for Vacuum Stability

Cup diameter affects more than just lifting force — it affects how much leakage the system must compensate.

General rules:

- Larger cups = more leakage = higher flow requirement

- Smaller cups = less leakage but reduced stability on rough surfaces

You can refer back to the sizing logic in Chapter 2 or consult application-specific cases in:

👉 Foam Suction Cup Applications in Industry

to see which industries typically require higher-flow systems.

In real industrial environments, engineers and technicians often need fast, reliable shortcuts to make correct decisions without running full calculations. Over the years, I’ve summarized the most practical rules-of-thumb that consistently work for foam suction cups across packaging lines, labeling systems, woodworking operations, electronics assembly, and more.

These rules don’t replace detailed engineering—but they prevent 90% of the common mistakes that lead to drop-offs, poor sealing, or excessive wear.

6. Engineering Rules-of-Thumb for Fast Decisions

6.1 The 20% Oversize Rule (Diameter Selection)

When working with rough, porous, or inconsistent surfaces, the safest approach is:

Always choose a suction cup diameter at least 20% larger than standard smooth-surface calculations.

Why this works:

- Foam cups rely on compression and conformity, not perfect sealing

- Rough or porous materials create more micro-leakage

- Oversizing compensates for leakage and ensures stable vacuum formation

This rule is especially effective on corrugated cartons, recycled packaging, MDF wood, and textured plastics—applications covered in detail in

👉 Foam Suction Cup Applications in Industry.

6.2 The “Hardness vs. Marking” Rule

A very simple but powerful principle:

The softer the product surface, the softer the foam should be.

Use this rule when handling:

- Glossy plastics

- Painted metal housings

- Electronics

- Coated or printed surfaces

- Decorative glass

Hard foam or rubber alternatives may leave visible rings, dents, or surface deformation.

If your current cups are causing marks or scratches, consult:

👉 Foam Suction Cups Not Holding? Fix Common Issues

for adjustment suggestions.

6.3 The Foam Thickness Rule

Foam thickness strengthens sealing performance, especially on inconsistent surfaces.

Use this guideline:

- Thin foam (2–3 mm): precise handling on smooth, rigid parts

- Medium foam (4–6 mm): general-purpose, best overall stability

- Thick foam (7–10 mm): essential for rough cartons, wood, porous materials

A simple heuristics approach:

Rougher or more irregular surfaces = thicker foam layer.

This choice becomes critical when dealing with dusty wood, MDF, or deeply textured packaging—topics further explored in

👉 Foam Suction Cups for Rough and Oily Surfaces.

6.4 The Vacuum Flow Rule

Another principle that dramatically improves success rates:

If increasing cup size doesn’t fix leakage, increase vacuum flow—not vacuum level.

Foam cups operate with controlled leakage, meaning they thrive on:

- High airflow

- Moderate vacuum level

Trying to fix a porous surface by simply raising vacuum pressure almost never works. The solution is to boost airflow through a high-flow ejector or pump.

This rule is especially useful when upgrading from rubber suction cups to foam cups.

For in-depth vacuum system optimization, refer to Chapter 5 or see surface-specific cases in:

👉 Foam Suction Cups for Rough and Oily Surfaces.

6.5 The Material vs. Environment Rule

This quick rule prevents 70% of material-related failures:

- Oil present → NBR foam

- High heat → Silicone foam

- Outdoor / UV / humidity → EPDM foam

- Abrasive surfaces → PU foam

- General packaging surfaces → NR foam

You can find the complete material decision framework in:

👉 Foam vs Rubber Suction Cups: Material Guide.

6.6 The Maintenance Prevention Rule

A simple and effective operational guideline:

If vacuum response is slowing down, check filters, hose length, and foam wear before touching vacuum settings.

Most vacuum inefficiency comes from clogged filters or deteriorated foam—not from vacuum power.

To optimize lifecycle and maintenance cost, refer to:

👉 Foam Suction Cup Life, Maintenance and Cost.

Theory is important, but real-world selection examples make the decision-making process much clearer.

In this chapter, I’ll walk through four practical scenarios from different industries. Each example shows how I analyze:

- Surface type

- Load and acceleration

- Cup diameter

- Foam thickness

- Hardness/density

- Material selection

- Vacuum system considerations

These examples reflect the most common questions engineers ask when choosing foam suction cups for packaging automation, electronics assembly, wood panel handling, and labeling lines.

7. Example Selection Scenarios

7.1 E-Commerce Packaging Line (Rough, Porous Cartons)

Scenario

A pick-and-place robot handles a variety of corrugated boxes at high speed.

Surfaces vary: recycled cartons, kraft boxes, multi-layer cardboard.

Height and stiffness also differ, causing vacuum instability with rubber cups.

Engineering Considerations

- Surface is porous + rough → foam must compensate for micro-gaps

- Load changes with box size

- Fast acceleration requires stronger stability

- Dust and paper fibers may contaminate system

Recommended Selection

- Diameter: Oversized by at least 20% to offset leakage

- Foam Thickness: Medium to thick (4–8 mm)

- Hardness: Medium-soft for roughness adaptability

- Material: NR foam (best elasticity for cartons)

- Vacuum: High-flow ejector or pump

- Add-ons: Fine filter to protect vacuum generator

Why this works

High flow + adaptive foam ensures consistent lifting across inconsistent packaging surfaces.

For deeper surface analysis, see:

👉 Foam Suction Cups for Rough and Oily Surfaces.

7.2 Delicate Electronics Assembly (Glossy Plastic Housings)

Scenario

Automated line handling glossy smartphone housings or consumer electronics.

Surface is sensitive to marks, scratches, or deformation.

Engineering Considerations

- Surface is extremely smooth, delicate, and scratch-prone

- Weight is low (50–300 g)

- Precision alignment required

- Non-marking performance is mandatory

Recommended Selection

- Diameter: Small to medium for precise control

- Foam Thickness: Thin to medium (2–4 mm)

- Hardness: Ultra-soft for zero marking risk

- Material: Silicone foam (non-marking, heat-resistant)

- Vacuum: Moderate vacuum, controlled flow

- Add-ons: Cleanroom-friendly filters if needed

Why this works

Soft silicone conforms gently and eliminates surface damage.

Material guidance available here:

👉 Foam vs Rubber Suction Cups: Material Guide.

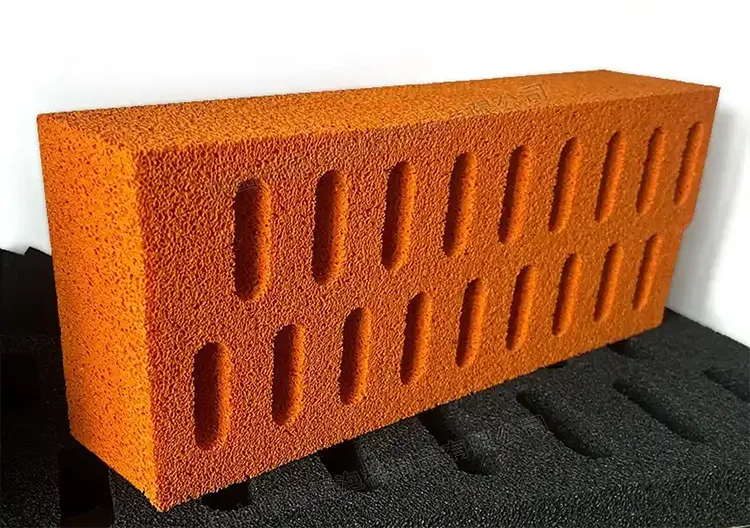

7.3 Wooden Panel Transfer (MDF / Particle Board)

Scenario

A gantry-type system handles MDF, plywood, or particle board panels.

Surfaces are dusty, porous, and sometimes slightly bowed.

Engineering Considerations

- High porosity increases air leakage

- Surface dust reduces sealing efficiency

- Foam must handle local curvature and inconsistent flatness

- Increased wear due to abrasive edges

Recommended Selection

- Diameter: Large for stability on sheet materials

- Foam Thickness: Medium to thick (5–8 mm)

- Hardness: Medium hardness (balance between grip & durability)

- Material: PU foam (wear-resistant)

- Vacuum: High-flow system is mandatory

- Add-ons: High-capacity dust filters

Why this works

PU foam offers longer life under abrasive dust conditions, while increased flow stabilizes vacuum response.

Lifecycle considerations covered in:

👉 Foam Suction Cup Life, Maintenance and Cost.

8. Selection Checklist

Surface & Application

□ What is the surface type?

• Smooth

• Rough

• Porous

• Dusty

• Oily

• Delicate / scratch-sensitive

□ Is the surface consistent or highly variable?

□ Is curvature or height variation present?

(For help analyzing difficult surfaces, refer to

👉 Foam Suction Cups for Rough and Oily Surfaces.)

Load & Motion Requirements

□ Object weight (kg)

□ Acceleration / robot speed

□ Required safety factor (2×–4×)

□ Positioning accuracy required?

Cup Diameter

□ Base diameter from weight calculation

□ Apply 20% oversize rule for rough or porous surfaces

□ Check stability during acceleration

(For application-specific sizing examples, see

👉 Foam Suction Cup Applications in Industry.)

Foam Hardness / Density

□ Soft — delicate or highly textured surfaces

□ Medium — general-purpose, best balance

□ Hard — rigid parts requiring stability

□ Could hardness cause marking?

(If yes → use softer foam or silicone.)

Foam Thickness

□ Thin (2–3 mm) — smooth, rigid parts

□ Medium (4–6 mm) — general surfaces

□ Thick (7–10 mm) — rough or porous surfaces

Material Selection

□ NR — general packaging, high conformity

□ EPDM — outdoor / humid environments

□ NBR — oily or lubricated parts

□ Silicone — delicate, non-marking, high heat

□ PU — abrasive, high-wear environments

(Full material comparison here:

👉 Foam vs Rubber Suction Cups: Material Guide.)

Vacuum System Match

□ High-flow vacuum generator (preferred for foam cups)

□ Adequate airflow for leakage

□ Correct hose length and internal diameter

□ Balanced manifold for multi-cup systems

□ Filters installed?

• Dust filter

• Oil-mist filter

• Fine filter for electronics

Maintenance & Lifecycle

□ Inspect edges, foam wear, compression set

□ Check filters regularly

□ Evaluate cup life under different materials

□ Track vacuum response time and flow

(For cost and lifecycle optimization →

👉 Foam Suction Cup Life, Maintenance and Cost.)

Final Validation

□ Test pick stability

□ Test release speed

□ Verify marking behavior

□ Validate performance at full machine speed

□ Confirm grip consistency across mixed surfaces

At this point, you should have a clear, structured understanding of how to choose the right foam suction cups—whether your priority is sealing performance, stability, non-marking handling, long service life, or compatibility with challenging surfaces such as rough cartons, MDF, oily metal parts, or delicate electronics.

Ready for Custom Solutions?

If your automation equipment or OEM application requires:

- A special cup diameter or thickness

- Non-standard geometry (rectangular, contoured, multi-layer)

- Custom hardness or density

- Custom materials (anti-static, high-temp, oil-resistant, etc.)

- Integration with your EOAT or mounting system

- A consistent long-term supply partner

We provide 2D/3D drawings, prototyping, engineering verification, and stable mass production.

To request a quotation or begin a technical discussion, you can visit our product page:

➡️ Custom Foam Suction Cups

https://www.kinsoe.com/product/custom-foam-suction-cups/

Whether you need standard sizes or full customization, we can help you design the most reliable, cost-effective foam suction cup solution for your automation line.