1. Introduction: Why Dust Boots Matter in Industrial Suspension Systems

If you work in automotive manufacturing, fleet maintenance, or parts procurement, you probably don’t spend much time thinking about dust boots. But in my experience, that’s exactly where costly suspension failures begin—where attention is overlooked.

Shock absorber dust boots, also known as bellows or gaiters, serve as the critical first barrier between the suspension’s working components and the external environment. Mounted over the piston rod of a shock absorber, these boots are designed to shield internal seals and shafts from dust, stones, road salts, water, and chemical contaminants. Once this barrier breaks down, the shock absorber is exposed to premature wear, often leading to seal leakage, rod corrosion, or catastrophic failure under load.

So why should procurement managers, OEM engineers, and industrial fleet operators care?

Because neglecting these small components can quietly destroy the very parts you spend the most money maintaining. And because not all dust boots are created equal—variations in design, material choice, and supplier quality control can mean the difference between a 100,000-km service life and a 10,000-km headache.

In this article, I’ll walk you through the real reasons dust boots fail, what materials work best for different use cases, how to vet suppliers, and what B2B buyers can do to drive down lifecycle costs across suspension systems.

2. Industry Pain Points Related to Dust Boot Performance

2.1 Premature Shock Absorber Failure Due to Boot Wear

One of the most common—and costly—failures I’ve seen in industrial vehicles and commercial fleets is premature shock absorber damage caused by deteriorated or poorly designed dust boots. These boots are meant to form the first layer of defense, shielding the piston rod and internal seal from environmental exposure. But when the boot cracks, tears, or loses elasticity, contaminants like sand, moisture, and salt can infiltrate the shock assembly.

This leads to a vicious cycle: abrasive particles score the chrome rod surface, seals begin to leak, and damping performance degrades—sometimes before the shock itself has reached half its intended lifespan.

2.2 Misalignment Between OEM Requirements and Aftermarket Solutions

For many purchasing teams and service departments, especially those handling mixed or modified fleets, one of the most frustrating pain points is the lack of compatibility between OEM and aftermarket dust boots. Off-the-shelf parts often fail to match specific rod diameters or travel lengths, leading to either a loose fit or excessive tension that compromises boot function. I’ve also encountered complaints around:

- Shortened boot lifespan in chemical-prone or high-UV environments

- Inconsistent chemical resistance from one production batch to another

- Shrinking or hardening of low-grade materials after just a few weeks in service

Without customization or proper material selection, even well-intentioned replacements can accelerate damage rather than prevent it.

2.3 Cost Implications and Downtime

Every hour of downtime matters, especially for logistics providers and off-road operations. A single shock absorber failure may not seem significant—but multiply that across a 50-vehicle fleet, and the ripple effect in labor, parts, and unplanned repairs becomes serious. When dust boots are overlooked, they become a hidden cost driver.

I’ve seen cases where switching to reinforced or custom-fit boots cut shock failures by over 30%, directly reducing MRO expenses and downtime. That kind of gain doesn’t come from just buying cheaper parts—it comes from buying smarter ones.

3. Technical Breakdown: Design, Materials, and Functional Requirements

3.1 Structural Design and How Dust Boots Work

To understand how dust boots protect suspension systems, let’s break down the typical assembly. A shock absorber includes a piston rod that travels in and out of a sealed cylinder filled with hydraulic fluid or gas. The dust boot surrounds this rod, shielding it from debris and abrasion.

Key components involved:

- Shock Rod: The moving element that requires protection from external contaminants.

- Dust Boot: The flexible cover that moves with the rod while keeping out dirt, mud, and water.

- Bump Stop: Often integrated inside the boot, it cushions the suspension during full compression.

- Clamp or Collar: Ensures the boot stays in place at both ends, maintaining a secure seal.

While simple in theory, the dust boot must flex repeatedly without cracking, resist deformation under varying temperatures, and remain sealed even under full suspension travel. Any failure in this setup compromises the entire shock unit.

3.2 Material Options and Engineering Trade-offs

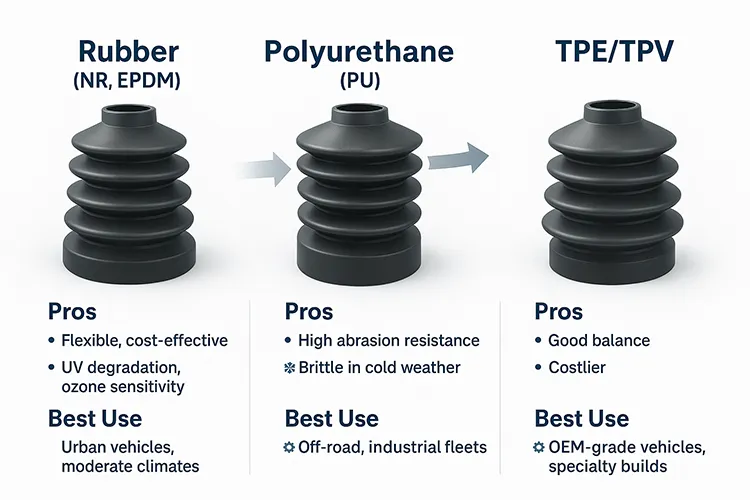

Choosing the right material is not about finding the toughest one—it’s about balancing durability, flexibility, chemical resistance, and cost based on the application.

| Material | Pros | Cons | Best Use Case |

|---|---|---|---|

| Rubber (NR, EPDM) | Flexible, affordable, easy to mold | Susceptible to UV and ozone cracking | City vehicles, moderate weather climates |

| Polyurethane (PU) | Excellent wear and abrasion resistance | Brittle in cold temperatures | Off-road trucks, construction fleets |

| TPE/TPV | UV/chemical resistant, long life | More expensive | OEM-level specs, high-performance builds |

Each material offers unique trade-offs—for instance, a logistics fleet operating in northern climates might favor TPE over PU to avoid cracking in winter months.

3.3 Resistance Requirements

Dust boots operate in a constantly changing environment. They must endure:

- High temperatures from braking systems and engine proximity

- Ozone and UV exposure during long idle periods or outdoor parking

- Chemical attack from road salts, brake dust, fuel mist, or hydraulic oil

Two additional factors often overlooked in specs:

- Compression set resistance: Boots must return to shape after being compressed repeatedly.

- Elastic memory: Allows the boot to stretch and recover as the rod travels—without tearing or deforming.

In real-world use, even the best-designed shock absorber will fail if paired with an inferior boot. That’s why selecting materials with verified performance under lab and field conditions is essential.

4. Sourcing & Supply Chain: What B2B Buyers Should Consider

4.1 OEM vs. Aftermarket: Performance and Interchangeability

As a supplier, I’ve worked with both OEMs and aftermarket distributors—and I’ve seen how easily the performance gap can widen when the wrong dust boot is sourced. OEM boots are typically precision-molded to match exact rod stroke and seal geometry. Aftermarket products, while more cost-effective, often take a universal-fit approach that may compromise sealing tightness or motion range.

When should you use custom or universal boots?

- Choose custom molding for specialty suspensions, harsh environments, or branding needs.

- Opt for universal boots only when the size match is close and performance tolerances allow it.

In either case, confirming compliance with relevant standards like ISO/TS16949 or IATF 16949 ensures the manufacturer has a quality management system suited for automotive applications.

4.2 Key Questions Procurement Teams Should Ask Suppliers

Before locking in a vendor for your dust boot supply, I recommend verifying the following:

- What is the verified service life (in kilometers or duty cycles)?

- Can the supplier provide material data sheets and third-party test reports?

- Are custom moldings or color-coded boots available for part traceability?

- Is the manufacturer familiar with shock absorber dimensions, stroke travel, and sealing compatibility?

These questions aren’t just for compliance—they determine whether a supplier can scale with your product demands or support engineering revisions quickly.

4.3 Customization and Bulk Manufacturing Capabilities

At Kinsoe, we’ve helped clients transition from stock solutions to custom-engineered boots with surprisingly short lead times. One case involved a logistics fleet struggling with premature shock failure in desert operations. By switching to a PU-based custom boot with added bellows for extra travel, they cut boot-related failures by 38% over 12 months.

If you’re considering custom solutions, ask about:

- MOQ (minimum order quantity) flexibility

- Tooling and prototype development time

- Branding options (logo molding, color striping, part number engraving)

A good rubber supplier isn’t just a vendor—they’re an engineering partner who understands application demands and can respond with tailored, timely solutions.

5. Maintenance & Installation Recommendations

For many commercial fleets and industrial operators, dust boot failure goes unnoticed—until the shock absorber starts leaking or the ride quality drops. By that point, the damage has often spread beyond just the boot.

Routine Inspection Tips for Service Teams

I always advise maintenance teams to treat dust boots as frontline indicators. Here’s what to look for during visual inspections:

- Cracks or splits in the accordion folds of the boot

- Boot collapse or deformation, especially near clamp zones

- Signs of contamination inside the boot—oil mist, sand, or corrosion

- Loose or missing clamps, which allow debris to bypass the seal

If any of these are found, it’s time for a replacement—before the shock absorber gets compromised.

Maintenance Intervals for Commercial Fleets

Depending on the operating environment, dust boots should be inspected:

- Every 20,000–30,000 km for on-road logistics fleets

- After every 10,000 km or quarterly for off-road or chemical-heavy operations

Where conditions are extreme—like snowplows, mining vehicles, or salt-hauling trucks—boots may require inspection after each service cycle.

Installation Best Practices

Improper installation can defeat the purpose of even the best-engineered boot. From what I’ve seen in failed field cases, most damage comes from either overtightened clamps or boots stretched beyond their tolerance.

Here are three rules I recommend to every field tech:

- Pre-measure rod travel and match boot length with suspension compression distance.

- Use calibrated clamps or tensioning tools—avoid zip ties or over-crimping.

- Apply silicone-based grease during installation to avoid boot twisting or tearing.

Correct installation not only prolongs the boot’s life but also protects your shock investment.

6. Strategic Value for B2B Collaboration

In B2B procurement, it’s easy to chase the lowest unit cost. But in my experience, this approach often backfires when it comes to components like dust boots—where a $1 saving can lead to a $200 failure down the line.

Why Premium Dust Boots Reduce Total Lifecycle Costs

Think of dust boots not as consumables, but as protective enablers of your suspension investment. By choosing high-grade materials and customized fits, you:

- Extend the operating life of shocks by 30–50%

- Reduce unscheduled downtime and MRO costs

- Minimize secondary damage to adjacent suspension parts (like rods, seals, or mounts)

Over a multi-year fleet lifecycle, these savings compound—especially in harsh or high-frequency usage scenarios.

“One premium-grade component, strategically placed, can protect an entire system’s performance. Dust boots are that component for shock absorbers.”

The Value of Transparent, Long-Term Partnerships

At Kinsoe, we’ve built our reputation not just on rubber parts—but on our ability to respond quickly to redesigns, provide transparent testing data, and collaborate directly with our clients’ engineering teams. That’s where real value lies:

- Fast re-engineering of mold designs when specs change

- Direct access to test results, CAD drawings, and compliance certificates

- Proactive communication during production and fulfillment stages

This kind of partnership becomes especially critical for OEMs, fleet maintenance contractors, and regional distributors managing diverse vehicle platforms.

Supplier Selection Criteria for Industrial Buyers

If you’re sourcing dust boots for B2B operations, don’t just ask for pricing and MOQ. Ask whether the supplier can:

- Deliver batch consistency across production runs

- Support custom formulations for extreme applications

- Integrate into your supply chain with JIT or consignment stock options

- Provide technical co-design support for new vehicle platforms

Strong supplier relationships drive cost-efficiency, product integrity, and faster market response—and for dust boots, that’s the kind of performance that pays off.

7. Conclusion

In today’s demanding automotive landscape, overlooking small components like dust boots can lead to disproportionately large consequences. From premature shock failures to recurring maintenance costs, the ripple effects are real—and avoidable.

Throughout this guide, I’ve shown how quality dust boots protect suspension systems, extend component life, and cut operating costs when chosen correctly. Whether you’re a procurement manager, fleet operator, or OEM designer, understanding the design, materials, and sourcing dynamics behind these parts can help you make smarter, more strategic purchasing decisions.

At Kinsoe, we specialize in helping industrial buyers and engineers source custom-molded, application-specific dust boots built to withstand real-world challenges. We offer:

- Technical drawings and 3D CAD support

- Certified material reports and durability testing

- Branding options and volume-based pricing

If you’re ready to improve your shock system reliability, I invite you to request a quote or sample kit. Let’s engineer a better solution—together.