Intro

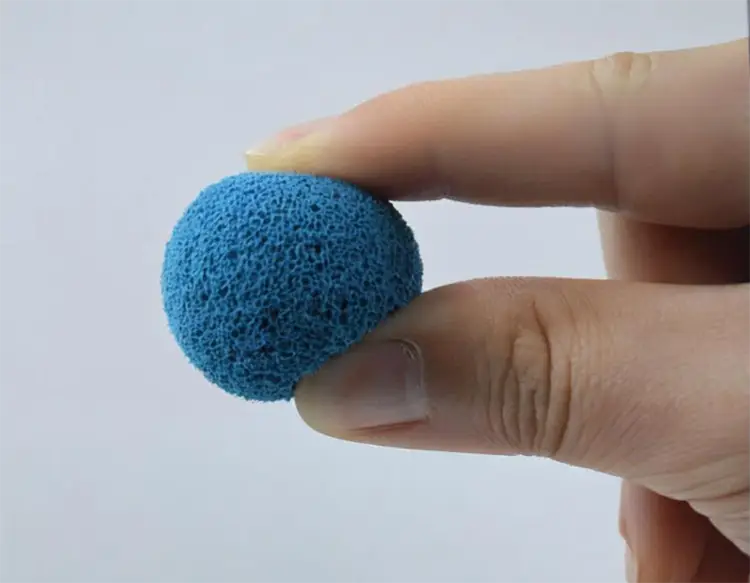

Selecting the right sponge cleaning ball comes down to three core decisions: material (rubber or polyurethane), cell structure (open-cell or closed-cell), and hardness (soft, medium, or hard). These choices directly determine wiping strength, passability through bends and reducers, and how long the ball will last in your system.

This guide gives you a quick, practical decision matrix with clear recommendations for both concrete pipeline cleaning and ATCS condenser/chiller systems.

For full context, you can refer to the main pillar:

https://www.kinsoe.com/sponge-cleaning-balls-fast-buyers-guide/

And for oversize rules and diameter selection, see the Sizing Guide:

https://www.kinsoe.com/sponge-ball-sizing-guide/

Material Basics — Rubber vs. Polyurethane (PU)

Natural Rubber

Natural rubber is the most flexible and elastic option, making it excellent for pipelines with tight bends, reducers, and mixed hose–steel routes. Its natural softness allows it to compress easily and rebound quickly—ideal when the cleaning path is complex or when consistent passability is your top priority.

Best traits:

- High elasticity and conformity

- Predictable compression through elbows

- Excellent general-purpose performance for concrete and mixed industrial lines

Polyurethane (PU)

Polyurethane offers superior abrasion resistance, better shape retention, and longer wear life—especially useful in abrasive environments such as rough steel pipes, older lines, or systems containing fine particulate matter. PU feels firmer than rubber at the same hardness rating, so oversize must be chosen more carefully.

Best traits:

- Outstanding durability and wear resistance

- Maintains diameter over more cycles

- Ideal for smooth tubes, abrasive fines, and long service intervals

When to choose which:

- Choose PU if the line is abrasive, old/rough, or if you want longer life between replacements.

- Choose Rubber if the line has tight bends, reducers, or inconsistent geometry where you need forgiving compression.

Note on chemical compatibility

Most water and slurry environments are rubber-friendly, but if your medium includes additives, solvents, or elevated temperature, check compatibility and aging signs.

For lifespan considerations, see:

Temperature & Reuse: https://www.kinsoe.com/sponge-ball-temperature-reuse/

Cell Structure — Open-Cell vs. Closed-Cell

Open-Cell Sponge Balls

Open-cell structures contain interconnected pores, making the ball highly compressible, responsive, and able to conform closely to uneven surfaces. This gives excellent wiping on concrete hoses, aged steel pipes, and mixed-material lines where interior conditions vary.

Characteristics:

- Excellent compression & rebound

- Adapts well to rough or inconsistent surfaces

- Can carry a small amount of water or slurry (helpful in concrete flush operations)

Best for:

- Concrete pumps

- Mixed hose + steel lines

- Any route with bends, reducers, or ovalized hose sections

Closed-Cell Sponge Balls

Closed-cell balls have sealed internal bubbles, making them less absorbent, slightly firmer, and more dimensionally stable. They glide smoothly in systems where the internal surface is uniform and clean—especially in condensers and chillers.

Characteristics:

- Lower water absorption

- More “seal-like” surface contact

- Predictable compression on smooth walls

Best for:

- Condenser and chiller tubes

- ATCS systems

- High-cycle, smooth-wall cleaning environments

Use-case matching:

- Concrete cleaning & rough interiors → Open-Cell

- Smooth condenser tubes → Closed-Cell (or fine open-cell variants designed for ATCS)

For more on operational behavior, see:

- ATCS Basics: https://www.kinsoe.com/atcs-sponge-ball-cleaning/

- Concrete Methods: https://www.kinsoe.com/concrete-pump-line-cleaning/

Hardness — Soft / Medium / Hard (and What Changes)

Hardness determines how the sponge ball behaves inside your pipe or tube—how easily it compresses, how aggressively it wipes, and how likely it is to hang up at reducers or elbows. Choosing the correct hardness is just as important as choosing the right material.

Soft

Soft balls compress easily, making them the most passable option for lines with complex geometry or tight restrictions. They maintain good wall contact while reducing the risk of jamming.

Best traits:

- Safest in tight bends and reducers

- High conformity and gentle wiping

- Ideal for old, rough, or mixed hose–steel routes

Medium

Medium hardness offers balanced performance. It holds shape better than soft balls but still passes through most geometries without issues. This is the common default for both concrete cleaning and many industrial pipelines.

Best traits:

- Balanced wiping + passability

- Best overall general-purpose choice

- Performs well in moderately complex routes

Hard

Hard sponge balls provide the strongest wiping force, removing stubborn deposits and early scale build-up. However, they also increase the risk of hang-ups, especially in older pipes, reducers, or uneven surfaces.

Best traits:

- Highest wiping aggression

- Best for short, rigid, smooth-walled sections

- Useful for targeted, stubborn residue removal

Hardness + Oversize Interaction

The harder the ball, the less oversize you should use. Oversize ranges typically shift like this:

- Soft: +10–30%

- Medium: +10–20%

- Hard: +5–10%

Oversize details:

Sizing Guide: https://www.kinsoe.com/sponge-ball-sizing-guide/

Decision Matrix (Skimmable)

Use this quick matrix to choose the right Material + Cell Structure + Hardness combination based on your line conditions and cleaning goals. This section distills the entire article into simple, practical recommendations.

Matrix 1 — Material × Hardness (with Typical Cell Guidance)

| Combination | Typical Cell | Best For | Notes |

|---|---|---|---|

| Rubber + Soft + Open-Cell | Open-Cell | Tight bends, reducers, mixed hose–steel routes, concrete flush | Safest passability; excellent conformity |

| Rubber + Medium + Open-Cell | Open-Cell | General concrete line cleaning | Balanced wiping + flexibility |

| Rubber + Hard + Open/Closed | Either | Short, rigid lines needing stronger wipe | Watch reducers; use conservative oversize |

| PU + Soft + Open-Cell | Fine Open-Cell | Rough pipes that still require compression | More durable than rubber in abrasive lines |

| PU + Medium + Closed-Cell | Closed-Cell | Abrasive fines, smoother pipes, longer service life | Excellent shape retention |

| PU + Hard + Closed-Cell | Closed-Cell | Targeted stubborn deposits in smooth sections | Highest hang-up risk—use with caution |

Matrix 2 — Scenario → Recommended Combination

| Scenario | Recommended Combo | Why |

|---|---|---|

| End-of-shift concrete line flush | Rubber + Soft + Open-Cell | High conformity, easy pass-through |

| Old/rough steel lines | PU + Medium + Open/Closed | Better abrasion resistance + stable shape |

| Tight bends / multiple reducers | Rubber + Soft + Open-Cell | Safest for geometry; reduces jamming |

| Smooth condenser/chiller tubes (ATCS) | PU or Rubber + Soft/Medium + Closed-Cell | Predictable compression + reliable recirculation |

| Stubborn residue / early scale | PU + Medium/Hard + Closed-Cell | Stronger wiping, longer cycle life |

| Mixed hose + steel routes | Rubber + Soft/Medium + Open-Cell | Fast rebound and strong conformity |

These matrices give you a practical starting point; you can fine-tune diameter using the oversize rules in the sizing guide:

Sizing Guide: https://www.kinsoe.com/sponge-ball-sizing-guide/

Use-Case Snapshots

Concrete Pumps & Pipeline Cleaning

Concrete hoses and mixed hose–steel pipelines benefit most from combinations that provide high conformity, easy compression, and reliable pass-through. That makes Rubber + Soft/Medium + Open-Cell the most common and practical choice.

Recommended setups:

- Rubber + Soft + Open-Cell → Best for end-of-shift flushes, tight bends, and reducers

- Rubber + Medium + Open-Cell → Best for routine daily cleaning with moderate wiping needs

- PU + Medium → Useful when the pipeline is older, rough, or abrasive, extending service life

If wiping feels weak or residue remains, step up to Medium hardness before increasing diameter.

If hang-ups occur, soften first.

Troubleshooting guide: https://www.kinsoe.com/sponge-ball-troubleshooting/

Concrete cleaning methods: https://www.kinsoe.com/concrete-pump-line-cleaning/

Condensers / ATCS Systems (Chillers, Power Plants)

ATCS systems require balls that move smoothly through smooth tubes and maintain predictable compression under constant recirculation. Closed-cell structures and stable hardness matter here.

Recommended setups:

- PU or Rubber + Soft/Medium + Closed-Cell → Most stable, lowest water uptake, best tube contact

- Fine Open-Cell variants → Provide slightly higher conformity when the system allows it

- Surface options: smooth → fine-ridged → abrasive ring (depending on fouling type)

For ATCS, oversize must stay on the low end (+5–10%) to protect recirculation and capture efficiency.

ATCS fundamentals: https://www.kinsoe.com/atcs-sponge-ball-cleaning/

ATCS ball selection & dosing: https://www.kinsoe.com/atcs-ball-selection-dosing/

Operating Considerations (Quick Checks)

Before finalizing your sponge ball choice, review these operating factors—they often determine whether your selection performs smoothly or causes issues.

Temperature Window

Different rubber and PU formulations tolerate heat differently. Excess temperature can cause hardening, glazing, or slow rebound, reducing wiping performance and shortening lifespan.

For lifespan curves and storage guidance:

Temperature & Reuse: https://www.kinsoe.com/sponge-ball-temperature-reuse/

Chemical / Medium Compatibility

Most applications involve water, slurry, or condensate—conditions in which both rubber and PU perform well.

However, pay attention to:

- Additives (cement slurry agents, corrosion inhibitors, chemicals)

- Solvents or oils in industrial lines

- pH extremes (less common, but relevant in certain process lines)

If compatibility is uncertain, rubber is usually more forgiving; PU tends to be more resistant to abrasion but not necessarily to all chemicals.

Pipe Condition (Scale, Weld Beads, Rough Surfaces)

- Rough/old steel lines: consider PU Medium for longevity.

- Inconsistent or worn hose interiors: choose Rubber Soft/Open-Cell for smooth compression.

- Mixed hose + steel systems: prioritize passability over aggressiveness.

Bends, Reducers, and Line Geometry

Geometry is often more important than material.

- Use Soft/Open-Cell Rubber in systems with multiple or tight bends.

- Keep oversize appropriate, but soften hardness before shrinking diameter.

- In ATCS, favor Closed-Cell Soft/Medium to maintain predictable movement.

These considerations guide whether you should adjust material, cell type, or hardness before changing ball size.

Buyer’s Spec Notes (Copy/Paste)

Use this template when preparing a specification or sending us your requirements. It ensures we recommend the correct material + cell structure + hardness + size for your exact application.

Buyer’s Sponge Ball Specification (Template)

1. Application Type

- Concrete pipeline cleaning

- ATCS condenser/chiller tubes

- Other (describe)

2. Desired Wiping Aggressiveness

- Gentle

- Standard

- Aggressive

3. Material Preference

- Rubber

- Polyurethane (PU)

- No preference (recommend based on conditions)

4. Cell Structure

- Open-Cell

- Closed-Cell

- Fine Open-Cell (ATCS)

- No preference (recommend based on conditions)

5. Hardness Level

- Soft

- Medium

- Hard

(If unsure → we’ll suggest based on geometry)

6. Operating Medium & Temperature

- Water / slurry / condensate

- Temperature range (°C)

7. Pipe/Tube Details

- Actual I.D. measured at all segments

- Reducers? (yes/no)

- Tight bends? (yes/no)

- Mixed hose + steel? (yes/no)

8. Performance Priorities

- Maximum passability

- Highest wiping strength

- Long service life

- Balance of all three

9. Final diameter selection

Use oversize rules from the Sizing Guide:

https://www.kinsoe.com/sponge-ball-sizing-guide/

FAQ

Is PU always better than rubber?

No. PU lasts longer in abrasive or rough lines, but rubber passes tight bends and reducers more reliably because it compresses more easily. Choose based on geometry first, not wear resistance alone.

Does closed-cell always clean better?

Not necessarily. Closed-cell balls give a “seal-like” contact and predictable compression on smooth tubes (ideal for ATCS).

But open-cell balls offer better conformity on rough or uneven surfaces—often delivering better cleaning in concrete hoses or aged pipelines.

If balls stick, should I choose a smaller size?

Shrink diameter only after trying a softer hardness.

Softening maintains proper wiping while improving passability; downsizing too soon reduces cleaning effectiveness.

Troubleshooting guide:

https://www.kinsoe.com/sponge-ball-troubleshooting/

CTA — Choose the Right Material, Cell Structure & Hardness for Your System

Selecting the correct combination of rubber or PU, open-cell or closed-cell, and soft/medium/hard hardness dramatically improves cleaning performance, reduces hang-ups, and extends service life. If you want a tailored recommendation based on your system:

Share these four details with us:

- Pipe or tube I.D. (measure at reducers, elbows, and mixed hose–steel transitions)

- Cleaning purpose (concrete flush / ATCS / other process)

- Preferred wiping level (gentle, standard, aggressive)

- Operating medium & temperature

We’ll suggest the optimal material + cell + hardness + diameter combination for your application.

Ready to Source?

View our high-quality cleaning balls here:

👉 Sponge Cleaning Balls (Product Page)

https://www.kinsoe.com/product/rubber-sponge-cleaning-balls/

Need the Full Overview First?

Start with the main pillar page that connects all 9 articles in this modular series:

👉 Sponge Cleaning Balls: Fast Buyer’s Overview

https://www.kinsoe.com/sponge-cleaning-balls-fast-buyers-guide/

Continue Learning

- Sizing Guide: https://www.kinsoe.com/sponge-ball-sizing-guide/

- Concrete Methods: https://www.kinsoe.com/concrete-pump-line-cleaning/

- ATCS Basics: https://www.kinsoe.com/atcs-sponge-ball-cleaning/

- ATCS Ball Selection & Dosing: https://www.kinsoe.com/atcs-ball-selection-dosing/

- Temperature & Reuse: https://www.kinsoe.com/sponge-ball-temperature-reuse/

- Troubleshooting: https://www.kinsoe.com/sponge-ball-troubleshooting/