I. Introduction

When I first started helping clients with labeling machine rollers, most of them only asked about size, not the sponge material. But here’s what many don’t realize: the type of sponge material in your roller has a direct impact on labeling accuracy, roller lifespan, and overall line efficiency.

A roller that’s perfectly sized but made from the wrong material can lead to costly label misalignment, premature wear, or even damage to delicate packaging.

In this guide, I’ll walk you through the four most common sponge materials used in labeling rollers—so you can confidently choose the one that best suits your application needs.

II. Why Material Choice Matters

At Kinsoe, we’ve seen firsthand how the roller material can make or break a production line. The right sponge material affects:

- Label pressure consistency — for smooth, bubble-free applications

- Durability — especially on fast or continuous production lines

- Chemical and heat resistance — crucial in demanding environments

Choose correctly, and you’ll enjoy longer roller life, fewer reworks, and less downtime. Choose poorly, and you may find yourself battling label jams, roller breakdowns, and production delays.

III. Overview of Common Sponge Materials

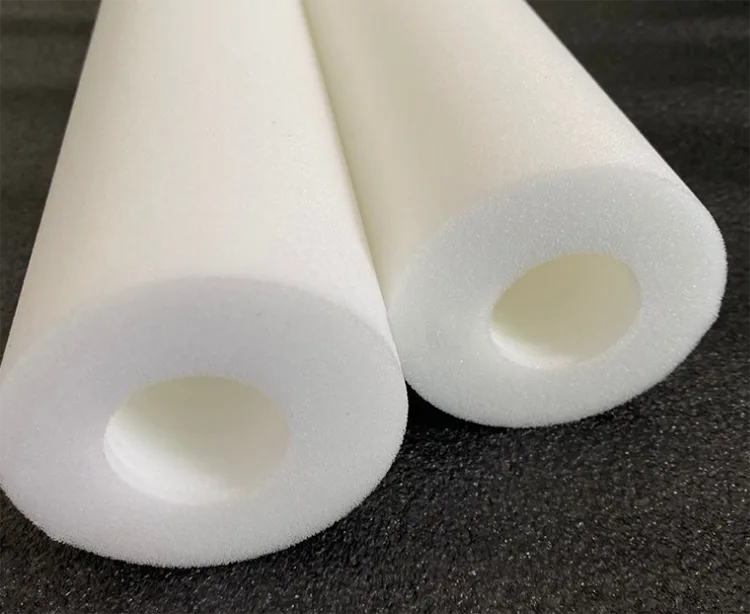

The four most commonly used sponge materials in labeling rollers are:

- Natural Rubber Sponge – popular for general use

- Polyurethane (PU) Foam – known for excellent rebound and abrasion resistance

- Silicone Sponge – ideal for heat and hygiene-sensitive environments

- Nitrile Butadiene Rubber (NBR) Sponge – strong against oils and chemicals

Each one serves different needs. Let’s break them down one by one.

IV. In-Depth Comparison of Each Material

1. Natural Rubber Sponge

Natural rubber sponge is a solid, go-to choice for many general labeling jobs. I’ve recommended it often to buyers looking for a cost-effective, all-rounder solution.

- Pros: Excellent compressibility, good flexibility, and low cost

- Cons: Poor resistance to oil, solvents, and extreme temperatures

- Best for: Paper or plastic labels on standard packaging in dry environments

It’s a smart choice when you need reliable performance on a tight budget.

2. Polyurethane (PU) Foam

If your labeling line runs at high speed or you’re labeling curved or uneven products, PU foam might be your best bet.

- Pros: Very high wear resistance, excellent rebound resilience, and long service life

- Cons: Only moderate heat resistance—can deform in hotter environments

- Best for: High-speed labeling machines or abrasive contact surfaces

I often recommend PU foam for bottling lines and FMCG packaging.

3. Silicone Sponge

Silicone sponge stands out when temperature or cleanliness is a top concern. In my experience, this is the material of choice for pharmaceutical, food, and cosmetic lines.

- Pros: Outstanding heat resistance (up to 200°C), non-stick surface, excellent aging resistance

- Cons: More expensive, can tear more easily under mechanical stress

- Best for: Food-grade, medical-grade, or cleanroom environments

This is where precision meets safety.

4. NBR (Nitrile) Sponge

If your production involves oils, greases, or chemicals, NBR sponge is hard to beat.

- Pros: Exceptional resistance to oil, fuel, and many industrial chemicals

- Cons: Limited UV/weather resistance and not suitable for high-heat lines

- Best for: Harsh environments like automotive, chemical packaging, or oily surfaces

I suggest NBR to customers in industrial applications where exposure to harsh substances is constant.

V. Material Comparison Table

Here’s a quick visual summary I often share with clients during consultations:

| Property | Natural Rubber | PU Foam | Silicone Sponge | NBR Sponge |

|---|---|---|---|---|

| Elasticity | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ |

| Heat Resistance | ★★☆☆☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Abrasion Resistance | ★★☆☆☆ | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ |

| Chemical Resistance | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Cost Efficiency | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ |

| Best Use Case | General Labeling | High-Speed | Food/Cosmetic | Oily Surfaces |

VI. How to Choose Based on Labeling Needs

Let me simplify the decision-making process with a few quick cues:

- Need speed and durability? → Go with PU Foam

- Dealing with high temps or hygiene requirements? → Choose Silicone Sponge

- Facing oily or chemical exposure? → Use NBR Sponge

- Looking for budget-friendly balance? → Stick with Natural Rubber

There’s no one-size-fits-all answer—but there is a right choice for your application.

VII. Conclusion

From years of working with clients across industries, I’ve learned that choosing the right sponge material is just as important as choosing the right size or hardness. It affects everything from label quality to maintenance frequency.

Before you place your next order, take a step back and evaluate your production environment, label type, and equipment speed. If you’re still unsure, don’t worry—I’m here to help.

Contact me at Kinsoe, and I’ll guide you to the best sponge roller material for your specific needs.