When I first started helping clients choose roller materials at Kinsoe, I noticed a recurring challenge: buyers often lump all “rubber rollers” together without realizing the subtle but critical differences between sponge rubber and other materials like solid rubber or silicone.

If you’re in the process of specifying rollers for your machinery—whether it’s a labeling system, printing press, or packaging line—this guide will help you understand where sponge rubber shines, how it compares to other materials, and when it’s the best fit.

What Is Sponge Rubber?

Sponge rubber, also known as foam rubber, is a type of rubber that contains countless tiny air pockets within its structure. These can be either open-cell (allowing air and liquids to pass through) or closed-cell (sealed pockets that resist air and moisture penetration).

This unique cellular design gives sponge rubber its signature softness, compressibility, and lightweight nature—qualities that set it apart from solid rubber.

At Kinsoe, we frequently use sponge rubber for rollers where surface sensitivity and pressure control are key.

Why Choose Sponge Rubber? Key Advantages

1. Superior Cushioning and Shock Absorption

One of the standout features of sponge rubber is its ability to absorb shocks and distribute pressure evenly. This makes it ideal for delicate applications like:

- Applying labels without wrinkling or tearing

- Handling thin films or foils

- Reducing vibration and noise in moving systems

I’ve seen customers in the printing industry switch to sponge rubber rollers specifically to avoid damaging their substrates during high-speed operations.

2. Lightweight Design

Compared to solid rubber, sponge rubber is significantly lighter. This reduces the overall weight of assemblies, which can improve energy efficiency and reduce wear on supporting components.

For example, a lightweight sponge rubber roller can minimize strain on bearings and drive systems in automated equipment.

3. Excellent Flexibility and Conformability

Sponge rubber’s soft surface allows it to conform to irregular shapes and uneven surfaces. This ensures consistent contact across the entire roller width—even if your substrates vary slightly in thickness.

4. Cost Efficiency in Certain Applications

Because sponge rubber uses less material due to its cellular structure, it can offer cost savings in many cases. It also helps reduce product damage, which translates to fewer rejects and higher yields in production.

5. Moderate Heat and Chemical Resistance

While sponge rubber doesn’t match silicone’s extreme temperature tolerance, many closed-cell sponge rubbers can handle moderate heat and resist mild chemicals. This makes them suitable for packaging and light industrial environments.

Sponge Rubber vs Other Materials: A Quick Comparison

| Property | Sponge Rubber | Solid Rubber | Silicone Rubber | EPDM |

|---|---|---|---|---|

| Cushioning | ★★★★★ Excellent | ★★ Poor | ★★★ Moderate | ★★★ Moderate |

| Weight | ★★★★★ Lightweight | ★ Heavy | ★★★★ Light | ★★★★ Light |

| Surface Conformability | ★★★★★ High | ★★ Low | ★★★★★ High | ★★★ Moderate |

| Cost | ★★★★ Moderate | ★★★ Moderate | ★ Expensive | ★★★ Moderate |

| Chemical Resistance | ★★ Limited | ★★★ Good | ★★★★★ Excellent | ★★★★ Good |

| Temperature Resistance | ★★★ Moderate | ★★★★ Good | ★★★★★ Excellent | ★★★★ Good |

This table isn’t meant to crown a “winner” but to highlight that each material has its place. Sponge rubber excels when surface protection and weight savings are priorities.

When to Choose Sponge Rubber Rollers

✅ Ideal For:

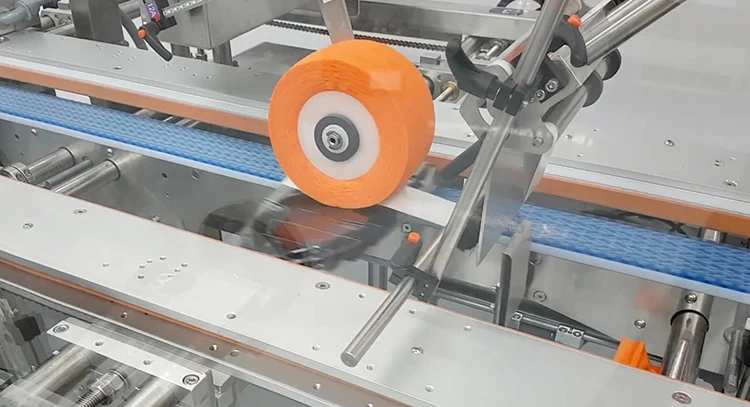

- Label applicators

- Printing presses

- Laminating machines

- Food packaging systems (with FDA-grade sponge rubber)

- Equipment where vibration damping is critical

❌ Consider Alternatives When:

- The application involves abrasive materials or high mechanical stress (solid rubber is better)

- Extreme heat or aggressive chemicals are present (silicone or EPDM may be preferred)

Tips for Maximizing Sponge Rubber Roller Life

- Clean regularly with mild detergents to avoid residue build-up.

- Store properly in a cool, dry place away from direct sunlight to prevent cracking.

- Avoid overloading rollers beyond their designed compression limits.

- Inspect frequently for signs of wear and replace when needed to maintain consistent performance.

Conclusion: The Right Material for the Right Job

Sponge rubber rollers aren’t a one-size-fits-all solution, but when cushioning, flexibility, and lightweight design matter, they’re hard to beat.

At Kinsoe, we’ve helped countless clients select the right roller material for their unique needs. If you’re unsure whether sponge rubber is suitable for your application, we’re here to guide you.

👉 Contact our team today to discuss a custom roller solution tailored to your process.