Introduction

When I first came across sponge tubes in an industrial setting, I thought they were just simple foam pipes used for wrapping or cushioning. But over time, I discovered that sponge tubes are surprisingly versatile—used across everything from automotive trims to gym equipment handles, HVAC insulation to electronics packaging. If you’re in product design, procurement, or even just curious about material choices, understanding sponge tubes is more valuable than it might initially seem.

Sponge tubes are flexible, foam-based cylindrical components made from a variety of rubber and polymer materials. Their role extends far beyond cushioning. They provide thermal insulation, vibration damping, impact protection, and sealing—making them indispensable in both mechanical and consumer product applications. Whether you’re designing ergonomic handle grips or sealing outdoor equipment from the elements, there’s a sponge tube material that fits.

In this guide, I’ll walk you through the essential material types (from EPDM and silicone to EPE and PU), real-world application scenarios, important technical specs to consider, and practical selection tips based on use environment and compliance needs.

Here’s everything you need to know to confidently select the right sponge tube for your project.

1. Common Sponge Tube Materials and Their Properties

When selecting a sponge tube, the first question I ask is: what kind of environment will it be exposed to? Because not all sponge materials perform the same. From UV exposure to heat tolerance, oil resistance to softness—each material has unique strengths. Let me walk you through the most common categories and what they’re best suited for.

Synthetic Rubber-Based Materials

1. EPDM (Ethylene Propylene Diene Monomer)

This is one of my go-to choices for outdoor or automotive applications. EPDM sponge is exceptionally resistant to UV, ozone, and weathering, which makes it perfect for HVAC seals, window gaskets, and outdoor equipment. Its closed-cell structure also provides good thermal insulation and moisture resistance.

2. NBR (Nitrile Rubber)

If oil or chemical exposure is a concern, NBR is a smart pick. It holds up well in contact with fuels, greases, and industrial fluids. That’s why I often see it used in machine enclosures, sealing gaskets, and protective tubing around industrial hoses.

NBR sponge tubing

3. Silicone

Silicone sponge is a premium material—and for good reason. It’s heat resistant up to 230°C, FDA-compliant, and extremely flexible. Ideal for medical, food-grade, and electronics applications. I’ve used it in both kitchen appliance seals and cleanroom tubing where thermal and chemical stability is critical.

4. Neoprene

Neoprene finds a balance between flexibility, flame retardancy, and weather resistance. You’ll often see it in marine applications, HVAC duct padding, and flame-rated cabinet gaskets. It’s moderately priced and performs well in general-purpose industrial use.

Foam & Plastic-Based Materials

1. EPE (Expanded Polyethylene)

When budget and weight matter, EPE is hard to beat. It’s lightweight, cost-effective, and offers decent impact resistance. I often see it in pipe insulation, protective sleeves, and light packaging.

EPE sponge tubing

2. EPP (Expanded Polypropylene)

This material is a step up in toughness. It’s shock-resistant and reusable, making it popular in automotive crash components and returnable packaging systems. I’ve used EPP foam tubes where repeated impact is expected.

3. EVA (Ethylene-Vinyl Acetate)

EVA blends softness and resilience with UV resistance, making it ideal for sports gear, grips, toys, and wearables. Its smooth texture and vibrant color options also make it a favorite in consumer products.

4. PU (Polyurethane Foam)

PU foam can be soft and cushioning or rigid and insulating, depending on its formulation. It’s widely used in furniture arms, gym rollers, and electronic protection cases. I especially like PU for products where tactile comfort and energy absorption are essential.

Comparison Table

| Material | Cell Type | Temperature Range | Resistance Type | Common Uses |

|---|---|---|---|---|

| EPDM | Closed | -40°C to 120°C | Weather, ozone | HVAC seals, outdoor cushions |

| NBR | Closed | -35°C to 100°C | Oil, fuel, abrasion | Machine gaskets, automotive sealing |

| Silicone | Closed | -60°C to 230°C | Heat, chemical | Medical, food-grade tubing, electronics |

| Neoprene | Closed | -40°C to 110°C | Flame, UV, water | HVAC, marine, electrical panel seals |

| EPE | Closed | -50°C to 80°C | Shock, water | Pipe insulation, basic packaging |

| EPP | Closed | -40°C to 120°C | Impact, reuse | Auto parts, returnable packaging |

| EVA | Closed | -30°C to 70°C | UV, impact | Sports grips, handles, toys |

| PU (soft) | Open | -20°C to 80°C | Cushioning | Fitness rollers, chair arms |

Choosing the right material means understanding the application conditions. Each foam behaves differently under pressure, heat, or chemical exposure—so getting this part right is foundational to long-term performance.

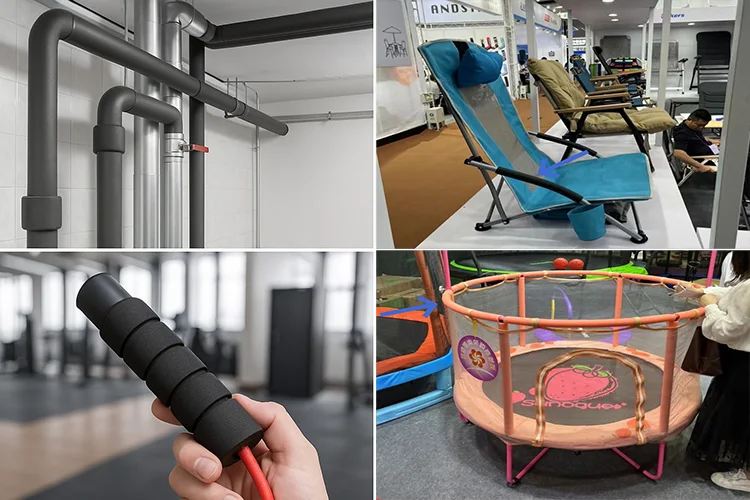

2. Application Scenarios: Industrial and Consumer Uses of Sponge Tubes

When I look at the versatility of sponge tubes across industries, it’s clear they’re not just padding or insulation—they’re problem-solvers. Over the years, I’ve worked on projects ranging from automotive parts to retail packaging, and sponge tubes have played a role in all of them. Let me show you just how broadly they’re used.

Industrial & Mechanical Applications

1. HVAC Pipe and Duct Insulation

Sponge tubes made from EPDM or EPE are widely used in heating and cooling systems. They insulate pipes to prevent heat loss and reduce condensation, helping improve energy efficiency and prevent corrosion. Their closed-cell structure ensures moisture resistance, which is critical in these environments.

2. Vibration Damping and Mechanical Cushioning

I’ve used sponge tubing to isolate vibrations in mechanical assemblies. It’s especially helpful in compressor mounts, panel gaps, and between moving parts—reducing noise, extending equipment life, and preventing wear.

3. Sealing and Gasketing

In enclosures, cabinets, and metal doors, sponge rubber tubes act as compression seals. Materials like neoprene and silicone provide airtight, watertight barriers that also tolerate thermal expansion and compression.

4. Wire and Cable Protection

Slit or hollow-core sponge tubes offer abrasion protection and insulation for sensitive cables and wiring bundles—common in control panels, automotive harnesses, and robotics.

5. Automotive Applications

In vehicles, sponge tubes are used to wrap tubing, absorb shocks, and act as trim seals. EPP and NBR foams are especially popular due to their oil resistance and impact absorption, making them ideal for under-hood and interior components.

Consumer Product Applications

1. Handle Grips

If you’ve ever held a dog leash, skipping rope, or bicycle handle, chances are you’ve felt EVA or NBR sponge tubing. These materials offer a soft touch, non-slip feel, and ergonomic comfort, even in sweaty or outdoor conditions.

2. Furniture and Seating

PU and EPE sponge tubes are used as armrest pads, seat bumpers, and edge wraps on chairs and medical beds. Their cushioning protects both users and equipment from wear or impact.

3. Fitness Equipment and Rehab Tools

Sponge tubing appears in dumbbells, resistance bar grips, and physiotherapy handles. It’s valued for its lightweight and shock-absorbing nature, while still being hygienic and easy to clean.

4. Child Safety Products

EVA and PU sponge tubes are often added to sharp furniture edges and playground bars. Their softness and durability help prevent injury while maintaining clean aesthetics.

5. Toys and DIY Kits

Colorful sponge tubes are frequently used in educational toys, craft kits, and puzzle assemblies. EVA is especially favored for its bright color options, softness, and safety certifications.

Packaging & Protective Applications

1. Edge Protectors for Fragile Items

In shipping glass panels, electronics, or instruments, sponge tubes act as buffer zones that absorb shocks and prevent breakage. Their shape helps them fit around corners and cylindrical parts.

2. Cushioning Sleeves for Instruments

Medical and scientific tools are often packed with silicone or PU sponge tubes, which prevent micro-vibrations during transport and shield delicate surfaces.

3. Reusable Packaging (EPP)

Eco-conscious brands and automotive parts suppliers are turning to EPP sponge tubes in returnable logistics systems. These tubes can be used dozens of times without deformation, supporting sustainability goals.

The application range of sponge tubes is incredibly broad—but every use case shares one goal: protect, seal, or cushion with reliability. Understanding your specific industry environment helps you match the right material to the job.

3. Technical Specifications to Consider

No matter how good the material is, sponge tubes only perform well when their technical specs align with the actual demands of your application. Over the years, I’ve seen projects fail simply because spec mismatches were overlooked—especially in terms of temperature, compression, or cell structure. So in this section, let’s break down the key technical indicators you need to evaluate before making a decision.

1. Cell Structure: Closed-Cell vs. Open-Cell

This is one of the most critical choices.

- Closed-cell sponge has a sealed internal structure that resists moisture, air, and gas penetration. It’s ideal for sealing, insulation, and outdoor use. EPDM, silicone, and EVA often fall into this category.

- Open-cell sponge has interconnected pores, allowing air and fluids to pass through. It offers better cushioning and breathability, often used in padding and sound absorption, such as PU foam rollers.

Quote: “Closed-cell foams seal and block—open-cell foams breathe and cushion.”

2. Shore Hardness

Most sponge tubes are measured using the Shore 00 scale (softer materials) or Shore A scale (denser rubbers).

- For example, EVA tubes used on grips often fall around Shore 40–60 (00), offering a soft yet supportive touch.

- Sealing applications, on the other hand, might require Shore A 20–40 for proper compression without permanent deformation.

The right hardness ensures your sponge tube won’t be too soft to deform under pressure or too hard to lose comfort.

3. Density and Compression Set

Density (kg/m³) affects not just weight, but also strength and durability.

- High-density sponge tubes (e.g., EPP) resist collapse and return to shape after repeated impact—ideal for reusable parts.

- Low-density options (e.g., EPE) are more cost-effective for disposable cushioning or insulation.

Compression set refers to how much the foam fails to rebound after being compressed over time. A lower compression set means better long-term sealing and shock absorption.

4. Environmental Resistance

Your choice of material should reflect the exposure environment:

- Temperature range: Silicone (-60°C to 230°C) for heat; EPE (-50°C to 80°C) for cold pipes.

- UV and ozone resistance: EPDM and EVA are excellent outdoors.

- Oil and chemical resistance: Choose NBR or certain polyurethane blends.

- Water and vapor resistance: Always go for closed-cell materials like EPDM or neoprene.

5. Flame Retardancy and Food Safety

If you’re working on electronics, public transportation, or appliances, you may need:

- UL94 certification (e.g., UL94 V-0 or HF-1) for flame resistance.

- FDA-grade silicone or EVA for kitchen appliances, baby products, or food processing equipment.

Failing to verify these can result in failed audits, product recalls, or unsafe designs.

By understanding these specs—and asking your supplier for test reports and certifications—you make informed, risk-free decisions that stand up to your product’s intended use.

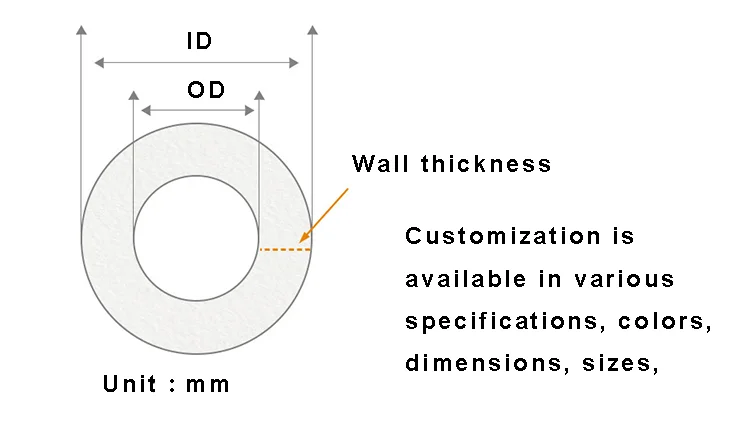

4. Customization and Manufacturing Capabilities

One of the things I appreciate most about sponge tubing is their design flexibility. Whether you need a tube with a slit for easy wrapping, a specific color to match your brand, or precise dimensions for a sealing channel—customization is not only possible, it’s common. And if you’re working in product development or procurement, understanding these manufacturing capabilities can help you design smarter and avoid unnecessary tooling costs.

1. Extrusion Profiles

Most sponge tubes are produced via continuous extrusion, allowing for consistent shapes and long lengths. Common profiles include:

- Round tubes (solid or hollow-core)

- D-shaped profiles (for sealing applications)

- Slit tubes (for wrapping cables or pipes without disassembly)

- Flat-backed or adhesive-backed versions (for one-sided application on surfaces)

Custom profiles can also be developed for OEM projects, provided the right tooling and minimum order quantities are met.

2. Size and Wall Thickness Options

You can typically customize:

- Outer diameter (OD)

- Inner diameter (ID)

- Wall thickness

These parameters are crucial for applications like pipe insulation, mechanical buffers, and ergonomic grips, where fit and comfort depend on millimeter precision.

Our projects at Kinsoe often require tolerances as tight as ±0.05 mm, especially in sealing applications. That’s where high-precision extrusion equipment becomes a necessity.

3. Surface Finishes and Branding

Depending on your industry, surface texture and color may matter:

- Smooth or matte finish for clean aesthetics or branding

- Textured or embossed surfaces for non-slip grips

- Custom colors or logo embossing for brand recognition

Some clients even request color-coding for assembly identification, which helps reduce production errors on large manufacturing lines.

4. Functional Add-ons

You can boost your sponge tube’s performance with:

- Flame-retardant additives for transit or electrical use

- Anti-microbial or anti-static treatments for medical and electronics applications

These add-ons can save labor, meet compliance, or enhance end-user safety—without needing a full redesign.

5. Tooling and MOQ Considerations

Custom tooling is usually required for new profiles, but it’s often a one-time investment that pays off across production cycles. For most extrusion projects:

- MOQ starts at around 500–1,000 meters for standard designs

- Lead time for custom tooling is 5–10 days, depending on complexity

We’ve helped clients reduce cost-per-part by consolidating profiles or tweaking wall thickness to fit multi-application use, all while staying within their MOQ and timeline targets.

Customization isn’t just for branding—it’s a smart way to optimize functionality, reduce assembly steps, and meet compliance at scale. When you know what’s possible, you can build better products from the start.

5. Installation and Handling Tips

Even the best sponge tube won’t perform properly if it’s poorly installed or handled incorrectly. I’ve seen otherwise excellent components fail prematurely simply due to wrong adhesives, over-compression, or improper storage. Whether you’re an installer, technician, or procurement manager specifying product use, these best practices will save you time, labor, and returns.

1. Cutting Methods

Sponge tubes can be cut manually or with precision tools, depending on volume and accuracy needs:

- Manual Cutting: Utility knives or shears work well for on-site adjustments or low-volume use. Always use a clean, sharp blade to avoid deforming the sponge.

- Die-Cutting: Ideal for high-precision, consistent lengths—especially when parts need to align perfectly during assembly.

- Hot Wire Cutting: Useful for PU and EPE foams, this method reduces edge fraying and gives a smooth finish.

For production lines, pre-cut or pre-slit tubing can significantly improve efficiency and minimize waste.

2. Adhesives and Mounting Options

Choosing the right bonding method ensures long-term adhesion without material degradation:

- Double-sided foam tape (e.g., 3M 9448 or 300LSE) is often used for quick and clean installations.

- Silicone-based adhesives are compatible with silicone sponge tubes and resist heat and moisture.

- Mechanical fasteners or clamps are ideal for detachable wraps or when adhesives aren’t feasible due to surface conditions (e.g., oily metals).

Always verify chemical compatibility between the sponge material and the adhesive. For example, NBR reacts poorly with certain solvents, while PU foams may absorb glue and weaken the bond.

3. Assembly Techniques

When integrating sponge tubes into products like grips, seals, or insulation sleeves:

- Ensure proper compression: Over-compression leads to early material fatigue, while under-compression may cause poor sealing.

- Avoid overstretching hollow tubes: Especially for soft materials like EVA or PU, excessive stretching during installation can lead to cracking or permanent deformation.

- Use alignment tools or jigs for repetitive installations to maintain consistency and reduce operator fatigue.

4. Storage and Shelf Life

Environmental exposure during storage can compromise sponge properties, especially if left unprotected:

- Store in cool, dry conditions, away from direct sunlight or UV exposure.

- Avoid stacking heavy items on top of sponge tubes, which may lead to flattening or permanent set.

- First-in, first-out (FIFO) practices should be followed, especially with PU and EVA, which may oxidize or discolor over long periods.

Most sponge materials have a shelf life of 1 to 3 years, depending on formulation and storage conditions. Always request shelf life data and lot tracking from your supplier if long-term inventory storage is involved.

Proper handling preserves product integrity. These simple precautions can prevent installation defects, extend product life, and ensure consistent performance across every unit.

6. Compliance and Certifications

When you’re working with sponge tubes in regulated industries like automotive, medical, or electronics, compliance isn’t optional—it’s essential. I’ve had clients whose entire shipments were delayed or rejected simply because a material didn’t meet flame retardancy or environmental safety standards. Let’s break down the most relevant certifications you need to know before you select or specify sponge tubes.

1. RoHS and REACH

These two are often requested together, especially by European clients:

- RoHS (Restriction of Hazardous Substances) ensures the product does not contain restricted substances like lead, mercury, cadmium, or certain flame retardants.

- REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) covers a broader list of chemical substances and ensures safe usage in consumer and industrial products.

Most EVA, EPE, and silicone sponge tubes used in packaging, toys, or electronics should comply with these standards. Always request a test report or compliance declaration from your supplier.

2. UL94 Flame Retardancy

If your application involves electronics, appliances, or transportation, UL94 rating is a key certification:

- UL94 V-0: Flame extinguishes within 10 seconds on a vertical sample.

- HF-1 or HF-2: Often used for foams in automotive interiors or consumer electronics where flame self-extinguishing is required.

Materials like neoprene, PU, and specially formulated EPDM can be made flame-retardant to meet these requirements.

3. FDA and Food-Grade Certification

For kitchen appliances, beverage equipment, and baby products, FDA or LFGB compliance is necessary:

- FDA CFR 21 177.2600 governs rubber materials in food contact applications.

- Food-grade silicone sponge tubes are a common solution here, offering non-toxicity, heat resistance, and odor neutrality.

When choosing materials for these applications, ensure suppliers can provide third-party certification and traceability for raw materials.

4. ISO/TS16949 or IATF 16949 (Automotive)

If you’re sourcing sponge tubes for automotive manufacturing, IATF 16949 certification is a must. It guarantees:

- Quality management processes

- Traceability across production batches

- Consistency in supply for long-term programs

At Kinsoe, we’ve often worked under these standards when delivering trim seals, impact absorbers, and thermal insulation tubes for tier-1 automotive suppliers.

Compliance isn’t just about passing inspection—it’s about protecting your brand and minimizing project risk. Make certifications part of your spec sheet early in the process, and don’t hesitate to request verification or samples before finalizing orders.

7. How to Choose the Right Sponge Tube

With so many material types, shapes, and specs available, choosing the right sponge tube can feel overwhelming. I’ve worked with clients across dozens of industries—from fitness equipment makers to electronics OEMs—and the best decisions always start by asking the right questions. Here’s a step-by-step framework I use to guide material selection.

1. Define the Primary Function

Start by identifying what the sponge tube is expected to do:

- Sealing against moisture, air, or dust? → Prioritize closed-cell materials like EPDM or neoprene.

- Cushioning for impact or comfort? → Go for soft, energy-absorbing materials like PU or EPE.

- Insulating heat or cold? → Use low-thermal-conductivity foams like EPE or silicone.

- Grip or aesthetics? → Choose tactile, UV-resistant options like EVA or NBR.

This simple step narrows your options by half.

2. Match Material to Environment

Every application lives in its own conditions. You’ll need to consider:

- Temperature range: Silicone or neoprene for high heat; EPE for insulation at low temps.

- UV/Ozone exposure: EPDM and EVA hold up best outdoors.

- Chemical/oil contact: NBR is your top pick here.

- Flame safety: Choose UL94-rated neoprene, PU, or treated EPDM.

- Food or medical contact: Stick with FDA-grade silicone.

Environmental matching is the key to durability. Even the best grip will degrade quickly if the material isn’t suited to its surroundings.

3. Choose Rigidity vs. Flexibility vs. Reusability

- For soft-touch comfort (like gym handles), EVA and PU are excellent.

- For structural strength (like reusable packaging or automotive crash parts), EPP is a better fit.

- For sealing performance, look at compression set and rebound properties—EPDM and silicone excel here.

Also consider installation: Do you need something pliable for wrapping, or firm for snapping into a groove?

4. Consider Production Volume and Budget

- If you’re building low-volume, high-customization products (like medical devices), silicone sponge tubes with tight tolerances may be worth the investment.

- For mass production, EPE or EVA offers cost efficiency with scalable extrusion and easy customization.

- Don’t forget MOQ thresholds—some materials or custom profiles may require 500–1,000 meters minimum.

5. Check Certification Requirements

Before you commit, list any regulatory needs:

- UL94, RoHS, REACH, FDA, IATF?

- Will the product be exported to a region with specific material bans or recycling rules?

Request test reports or compliance documentation early in the sourcing process. At Kinsoe, we always include certification proof with sample submissions to avoid last-minute surprises.

Smart selection means looking at more than just price—it’s about matching the right material to the real-world job. When you clarify your requirements and environment, the right choice often becomes obvious.

Conclusion

Sponge tubes might seem like simple components—but as I’ve shown throughout this guide, their impact on performance, comfort, and product durability is anything but minor. Whether you’re trying to improve HVAC insulation, develop safer packaging, or design ergonomic consumer products, the right sponge tube material can make the difference between a solution that fails quietly and one that excels under real-world conditions.

Here’s a quick recap of what we’ve covered:

- Material Options: From silicone and EPDM to EVA and EPE, each foam offers unique strengths in temperature, flexibility, chemical resistance, and cost.

- Application Diversity: Sponge tubes serve across industries—from automotive seals to baby product grips, from mechanical dampers to reusable logistics packaging.

- Technical Precision: Factors like cell structure, hardness, density, and flame rating aren’t just specs—they’re performance indicators.

- Customization and Installation: Profile shape, adhesives, finishes, and even branding options give you full control over both function and form.

- Regulatory Compliance: Standards like RoHS, UL94, and FDA aren’t just checkboxes—they’re vital to market access and safety.

- Selection Strategy: Focus on function, environment, durability, budget, and required certifications to make the right choice every time.

At Kinsoe, we’ve helped hundreds of businesses—from global OEMs to startup designers—find the sponge tube solutions that actually fit their challenges. And we can do the same for you.

If you’re unsure which material or spec is best for your project, get in touch. We offer engineering support, rapid prototyping, and customization starting from low MOQs. Just reach out—and let’s turn your design into reality.