I. Introduction

Sealing failures are one of those silent threats in industrial systems that can bring operations to a standstill without warning. I’ve seen cases where a small leak from a worn seal led to hours of costly downtime, contaminated entire batches of product, or even created safety hazards for the workforce. Whether it’s a factory assembly line, a high-pressure hydraulic system, or a piece of processing equipment, the integrity of seals directly impacts performance, reliability, and safety.

At Kinsoe, I work with a wide range of customers who rely on seals to keep fluids contained, pressures stable, and contaminants out. Over the years, I’ve noticed that many challenges arise not from the lack of sealing components, but from a lack of understanding of their types, design requirements, and application limits. Misunderstanding the difference between static and dynamic seals, for instance, can lead to early wear, leakage, or complete system failure.

In this article, I’m sharing comprehensive, practical knowledge about static and dynamic seals—from clear definitions and typical applications to essential design principles, material selection, relevant standards, and failure prevention strategies. My goal is to help you select, design, and maintain seals more effectively, ensuring the long-term reliability of your equipment.

II. Understanding the Basics

1. What Is a Seal?

A seal is a component designed to prevent the passage of fluids (liquids or gases) between mating surfaces. In industrial systems, seals are critical for maintaining pressure, preventing leakage, and protecting against contamination. Without proper sealing, equipment efficiency drops, maintenance costs rise, and the risk of operational hazards increases.

Seals work by creating a physical barrier that fills the gap between two surfaces. Depending on the application, this barrier may need to withstand high pressures, extreme temperatures, or aggressive chemicals—often all at once.

2. Static Seals

A static seal is used between two parts that do not move relative to each other. Its purpose is to maintain a tight seal under constant compression, resisting pressure and environmental exposure over time.

Common examples include:

- O-rings in flange joints for pipelines.

- Flat gaskets sealing enclosure covers.

- Metallic ring gaskets in high-pressure oil & gas equipment.

Sealing principle: The seal material deforms under compression, filling any microscopic surface irregularities and forming a tight, continuous barrier. This deformation is essential to creating a leak-free joint.

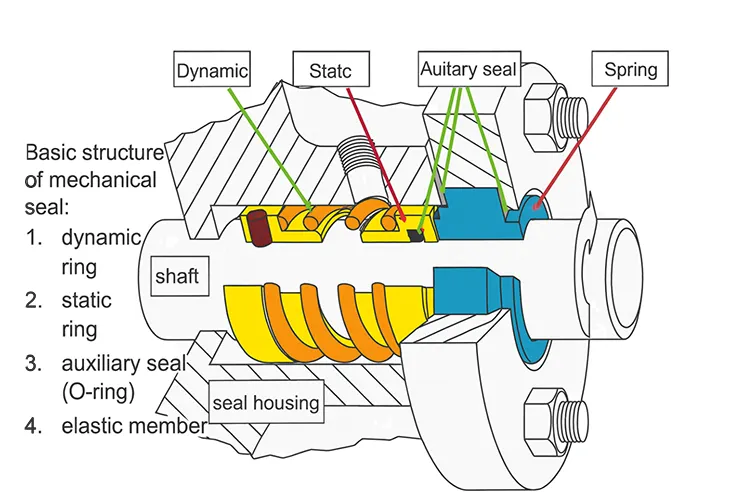

3. Dynamic Seals

A dynamic seal is used between two parts with relative motion, making its job far more complex than a static seal. Movement can be reciprocating (back-and-forth), rotary (spinning), or oscillating (partial rotation).

Common examples include:

- Rod seals in hydraulic cylinders (reciprocating motion).

- Rotary shaft lip seals in gearboxes (rotary motion).

- Mechanical seals in pumps and mixers (rotary motion with fluid contact).

Sealing principle: Unlike static seals, dynamic seals must maintain controlled contact while managing lubrication to reduce friction and wear. They are carefully designed to balance sealing effectiveness with durability, ensuring they perform reliably even under continuous movement.

III. Typical Applications

1. Static Seal Applications

Static seals are used in countless industrial and commercial systems where components remain stationary but still require a tight, reliable seal.

Key examples include:

- Pipe flanges in oil & gas systems: Preventing leaks at high pressures in both upstream and downstream operations.

- Valve bonnet sealing in water systems: Ensuring no leakage from the valve’s internal cavity to the environment.

- Electrical enclosures in harsh environments: Keeping dust, moisture, and chemicals from damaging sensitive electronics.

In these cases, the main priority is long-term sealing stability under constant compression. Selecting the right material and ensuring proper installation are critical for success.

2. Dynamic Seal Applications

Dynamic seals operate under far more demanding conditions because they must handle continuous or intermittent motion while maintaining a tight seal.

Key examples include:

- Hydraulic and pneumatic cylinders: Rod seals prevent fluid leakage while allowing the piston rod to move in and out.

- Pumps, mixers, and agitators: Mechanical seals keep process fluids contained while shafts rotate at high speeds.

- Gearboxes and rotating machinery: Rotary lip seals retain lubricants and keep out contaminants in bearings and shafts.

In these applications, motion, friction, and wear resistance become critical considerations. Lubrication, surface finish, and material properties directly affect the service life of the seal.

IV. Design Fundamentals

1. Compression & Squeeze

Compression, often referred to as “squeeze,” is the percentage the seal is compressed between mating surfaces.

- Static seals generally require a higher squeeze to ensure a tight, long-term seal. The extra compression helps compensate for any minor surface imperfections.

- Dynamic seals need a lower squeeze to minimize friction, reduce heat buildup, and prevent premature wear.

Industry references, such as the Parker O-Ring Handbook, provide proven guidelines for optimal squeeze values depending on seal type, size, and material.

2. Gland Fill and Stretch

A proper gland (groove) design is essential to avoid seal extrusion or excessive stress.

- Gland fill should not exceed 85% of the available groove volume. This ensures space for thermal expansion and swelling without forcing the seal into damaging extrusion gaps.

- Stretch must be controlled—especially for elastomeric O-rings—since too much can weaken the seal or distort its cross-section.

3. PV (Pressure × Velocity) Limit

The PV limit combines operating pressure and sliding velocity into a single value to assess heat generation, friction, and wear potential.

- Elastomers like NBR and EPDM have lower PV limits, suitable for slower dynamic applications.

- Polyurethane (PU) offers higher PV tolerance, making it suitable for hydraulic seals.

- PTFE and filled PTFE excel at very high PV conditions, such as high-speed rotary sealing.

4. Lubrication and Friction

The Stribeck curve describes the three lubrication regimes that influence seal performance:

- Boundary lubrication: Minimal film between surfaces—higher friction and wear risk.

- Mixed lubrication: Partial separation of surfaces—balanced friction and sealing.

- Hydrodynamic lubrication: Full fluid film—lowest friction but may compromise sealing if not controlled.

Choosing the correct lubrication strategy is key to extending seal life.

5. Surface Finish Requirements

Surface texture plays a major role in sealing reliability:

- Rotary lip seals: Require a finish of Ra 0.2–0.8 μm, with no spiral lead pattern that could pump fluid past the seal.

- Dynamic rod seals: Need a hardened, polished surface to minimize abrasion and wear.

Poor surface finishes can quickly shorten seal lifespan, regardless of the material used.

V. Material Selection Guide

1. Static Seals

For static sealing, material selection focuses on compression retention, environmental resistance, and long-term stability. Common choices include:

- Elastomers:

- NBR (Nitrile): Excellent oil resistance, cost-effective, suitable for moderate temperatures.

- EPDM: Superior weather, ozone, and steam resistance; not suitable for petroleum oils.

- FKM (Viton®): Outstanding chemical and high-temperature resistance.

- FFKM: Exceptional chemical and thermal resistance for critical applications.

- Thermoplastics: PTFE and PEEK for high chemical resistance and minimal creep under compression.

- Metals: Stainless steel and copper alloys for extreme temperatures or high-pressure static sealing.

2. Dynamic Seals

Dynamic sealing materials must combine low friction, high wear resistance, and dimensional stability. Options include:

- Low-friction elastomers: Polyurethane (PU) for high wear resistance; FKM blends for heat and chemical resistance.

- PTFE and filled PTFE: For high-speed, low-friction sealing, especially in chemically aggressive environments.

- Specialized materials: Elastomers meeting ISO 23936-2 or NORSOK M-710 for sour gas (H₂S) and rapid gas decompression resistance.

3. Selection Factors

When choosing seal materials, it’s essential to evaluate:

- Temperature range: Both operational and peak exposure limits.

- Media compatibility: Resistance to oils, chemicals, steam, or gases.

- Pressure and motion type: Higher pressures and faster speeds require tougher materials.

- Environmental exposure: UV light, ozone, abrasive dust, and water ingress all influence material longevity.

VI. Relevant Industry Standards

When specifying or manufacturing seals, adhering to recognized industry standards ensures consistent quality, compatibility, and performance. Some of the most widely applied standards include:

- ISO 3601 — Defines O-ring dimensions, tolerances, and quality acceptance criteria, ensuring interchangeability across suppliers.

- AS568 — SAE standard covering O-ring dash sizes widely used in North America.

- ISO 6194 — Outlines requirements and testing for rotary shaft lip seals, including material properties and performance characteristics.

- API 682 — Specifies mechanical seal requirements for pumps in petroleum, chemical, and gas industries.

- ASTM D2000 — Provides a classification system for elastomer compounds, allowing engineers to specify materials based on performance properties.

- ASTM D1414 — Details standard testing methods for O-rings, covering tensile strength, elongation, and hardness.

- ISO 23936-2 / NORSOK M-710 — Defines testing and qualification procedures for elastomers in sour gas service, ensuring resistance to rapid gas decompression (RGD) and chemical degradation.

Following these standards not only guarantees product reliability but also helps meet regulatory and contractual requirements in critical industries.

VII. Common Failure Modes and Prevention

1. Static Seal Failures

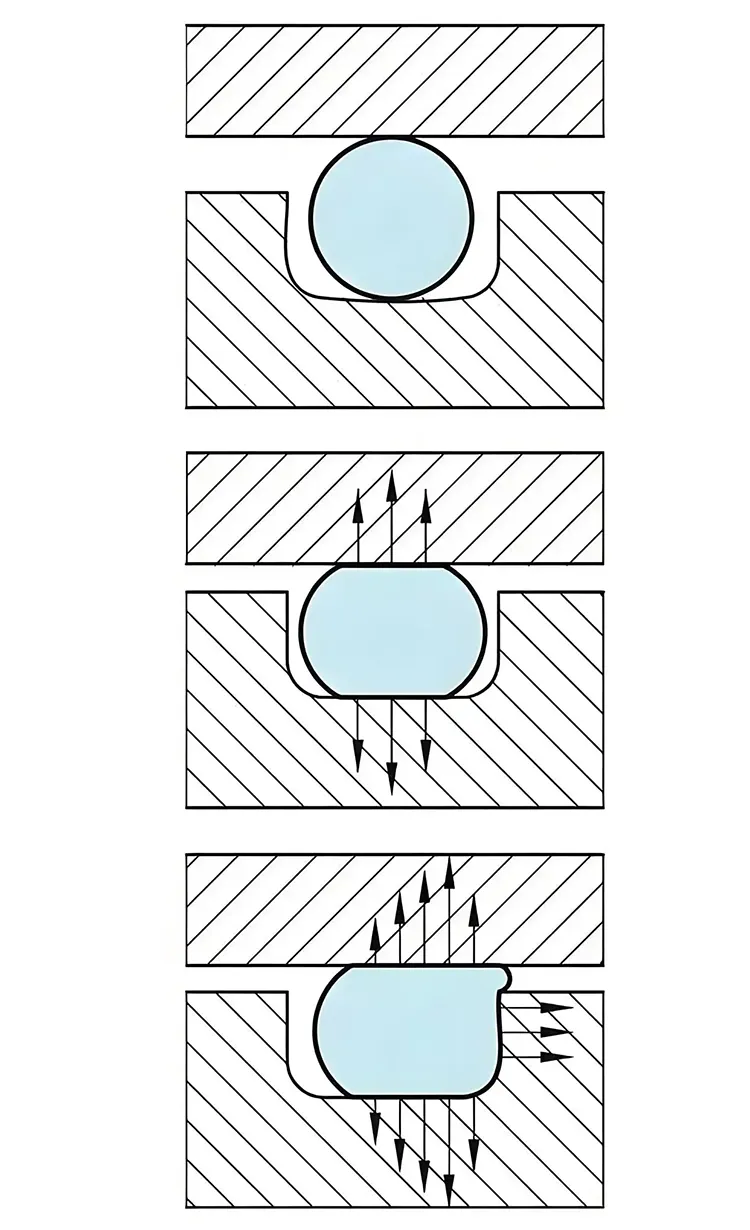

Static seals, while not subject to motion, can still fail due to environmental or installation-related factors. Common issues include:

- Extrusion & nibbling: Seal material is forced into the clearance gap under pressure, causing physical damage.

- Compression set: Permanent deformation from prolonged compression reduces sealing force.

- Chemical swelling & cracking: Incompatible media cause expansion, softening, or embrittlement.

- Installation damage: Nicks, cuts, or twisting during assembly compromise sealing integrity.

Prevention tips:

- Use backup rings to prevent extrusion in high-pressure applications.

- Select materials with proven media compatibility.

- Follow proper installation guidelines, including lubrication and correct tool usage.

2. Dynamic Seal Failures

Dynamic seals face additional challenges from motion, friction, and heat generation. Typical failure modes include:

- Abrasive wear from contamination: Particles scratch or erode sealing surfaces.

- Thermal hardening: Excessive PV conditions cause the material to harden and lose elasticity.

- Spiral wear: Shaft lead or improper finish creates a screw-like path for leakage.

- Lip deformation or cracking: Continuous stress or chemical attack damages the sealing lip.

Prevention tips:

- Maintain effective lubrication and avoid dry running.

- Control shaft or rod surface finish and hardness.

- Stay within the PV limits recommended for the material and application.

VIII. Testing and Quality Assurance

To ensure sealing components perform reliably in the field, rigorous testing and quality checks are essential before shipment or installation.

Leak Testing

- Hydrostatic testing: Uses pressurized water to check for leaks, suitable for high-pressure static applications.

- Pneumatic testing: Uses pressurized air or gas to detect leaks, offering higher sensitivity for small leakage paths.

Compression Set and Hardness Testing

- Evaluates an elastomer’s ability to return to its original shape after compression.

- Hardness (measured in Shore A or D) ensures material consistency across batches.

Rapid Gas Decompression (RGD) Testing

- Critical for seals in oil & gas applications where sudden pressure drops can cause internal blistering or rupture.

- Conducted according to standards such as ISO 23936-2 or NORSOK M-710.

Dimensional Inspection

- Measurements checked against ISO or AS568 tolerances to ensure proper fit.

- Advanced optical or laser measurement systems are often used for precision.

By integrating these tests into production and quality control processes, seal manufacturers and buyers can reduce the risk of premature failures and costly downtime.

IX. Real-World Case Studies

Case 1: Preventing O-Ring Extrusion in High-Pressure Flange Joints

A client in the oil and gas sector faced frequent O-ring failures in a high-pressure pipeline flange. The issue was traced to extrusion caused by excessive clearance between mating parts. By redesigning the groove to meet ISO 3601 specifications and adding PTFE backup rings, we eliminated extrusion damage and extended seal life from three months to over a year.

Case 2: Extending Rotary Lip Seal Life in a Gearbox

A gearbox used in a manufacturing plant suffered from early lip seal wear, leading to lubricant leakage and frequent downtime. Upon inspection, we found that the shaft finish exceeded the Ra 0.8 μm limit and had spiral tool marks. After polishing the shaft to Ra 0.4 μm and replacing the seal with a low-friction FKM lip seal, the service life increased by 250%, significantly reducing maintenance interruptions.

These examples show how careful analysis, proper material choice, and adherence to design guidelines can solve persistent sealing problems and deliver measurable improvements in reliability.

X. Summary & Key Takeaways

Static and dynamic seals may serve the same ultimate purpose—preventing leakage—but their design principles, material requirements, and application challenges are very different. Static seals rely on higher compression to maintain a long-term, motionless barrier, while dynamic seals must balance sealing effectiveness with low friction and wear resistance under movement.

From my experience at Kinsoe, I’ve seen how correct seal selection, precise installation, and adherence to industry standards can make the difference between trouble-free operation and costly downtime. Whether you’re specifying an O-ring for a static flange joint or a rotary lip seal for a gearbox, the fundamentals remain the same:

- Understand the application’s pressure, temperature, and media.

- Choose materials with proven compatibility and performance.

- Follow established design guidelines for compression, gland fill, and PV limits.

- Ensure surfaces meet the required finish specifications.

- Conduct thorough testing and quality checks before deployment.

Reliable sealing is not just about the seal itself—it’s about integrating design, material science, and maintenance practices into every stage of the process. By applying the right knowledge and preventive measures, you can achieve long-lasting sealing performance and safeguard your operations.

XI. References

- Parker O-Ring Handbook (ORD 5700)

- API 682 — Mechanical Seals for Pumps

- ASTM D2000 — Rubber Products Classification

Related Articles

- Types of Rubber Seals by Shape, Material, and Use — Learn about different seal types, their materials, and specific applications to help you make informed design and selection decisions.

- Why Rubber Seals Fail: Compression Set Explained — Understand the causes of compression set in rubber seals, its impact on performance, and effective ways to prevent it.

- How Rubber Hardness Impacts Performance & Reliability — Discover how Shore hardness affects seal flexibility, durability, and suitability for various operating conditions.