Introduction: What Are Thermoplastic Elastomers (TPE)?

Last year, one of my clients asked if TPE was really safe for making baby spoons—and whether it could replace PVC in their shoe soles. That’s when I realized: most people, even buyers and product designers, are still unsure what TPE actually is.

Let’s clear it up.

Thermoplastic Elastomers (TPE) are a class of materials that combine the flexible, rubber-like qualities of elastomers with the processing advantages of thermoplastics. That means they can stretch and bounce back like rubber—but also melt and be remolded like plastic. This dual nature makes them incredibly useful for all kinds of modern applications.

TPEs are not one single material, but rather a family of high-performance polymers. Thanks to their fatigue resistance, softness, and recyclability, they’re now commonly found in products ranging from phone grips and toothbrush handles to automotive seals and shoe soles.

Professionally speaking, TPEs provide a compelling balance between flexibility, durability, and process efficiency. Because they don’t require chemical curing (unlike traditional vulcanized rubber), they’re much easier and faster to work with on an industrial scale.

“TPEs deliver rubber-like behavior with the efficiency of thermoplastics—making them ideal for sustainable, high-performance products.”

But that brings up more questions: Are they safe for contact with skin or food? Do they outperform PVC? And what role do they play in something as demanding as footwear?

Here’s a deep dive into the science, safety, applications, and comparisons that matter when choosing TPEs.

Let’s begin.

1. The Science Behind Thermoplastic Elastomers

1.1 Structure and Composition

To understand why TPEs perform the way they do, we need to look at their molecular structure.

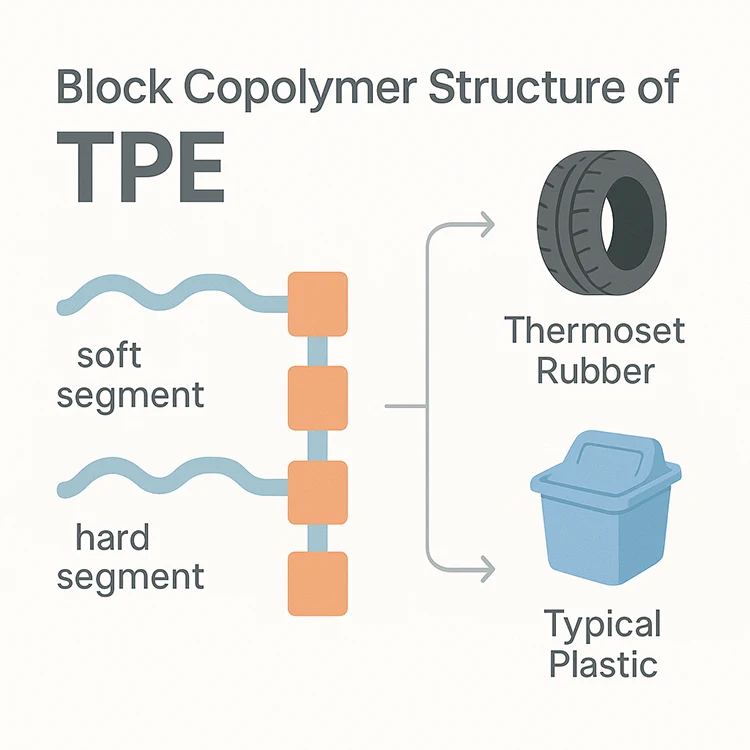

TPEs are typically block copolymers or polymer blends made from soft and hard segments. The soft segments give them rubber-like elasticity, while the hard segments provide mechanical strength and thermal processability. When heated, the hard blocks melt, allowing the material to flow. When cooled, the hard segments re-solidify, locking the elastic structure in place—no chemical vulcanization required.

This reversible physical crosslinking sets TPEs apart from traditional thermoset rubbers, which undergo irreversible curing. Once thermoset rubber is molded, it cannot be melted and reformed. On the other hand, TPE can be reprocessed and remolded multiple times, reducing waste and improving manufacturing flexibility.

Compared to conventional plastics, TPEs are softer, more stretchable, and capable of enduring flex fatigue without cracking or permanent deformation.

In short:

- TPE vs Rubber: TPEs don’t need vulcanization, are recyclable, and process faster.

- TPE vs Plastic: TPEs are soft, flexible, and resilient, unlike rigid plastics.

1.2 Categories of TPE

Not all TPEs are created equal. In fact, there are several subtypes—each engineered for different performance and application needs:

- TPE-S (Styrenic Block Copolymers)

- Most commonly used TPE

- Soft touch, low cost, recyclable

- Common in grips, toys, and household items

- TPE-V (Thermoplastic Vulcanizates)

- Contains dynamically vulcanized rubber particles

- Offers improved heat and oil resistance

- Used in automotive seals and under-the-hood parts

- TPE-U (Thermoplastic Polyurethanes)

- Excellent abrasion resistance, elasticity, and transparency

- Widely used in shoe soles, flexible tubing, and cables

- TPE-E (Thermoplastic Copolyester Elastomers)

- High-temperature resistance and mechanical strength

- Preferred in engineering applications and electrical parts

- TPE-O (Olefinic TPEs) and TPE-A (Polyamide TPEs)

- Used for lightweight, chemical-resistant parts

- TPE-A is often applied in technical or harsh environments

Each type has unique characteristics, but all share a common trait: they merge flexibility with thermal processability, offering manufacturers an edge in design freedom and cost-effectiveness.

3. Is TPE a Good Material for Footwear?

3.1 Functional Advantages in Shoes

Absolutely—TPE has become a go-to material in modern footwear design. It offers a balanced mix of softness, flexibility, and toughness that makes it highly functional for everyday shoes.

Here’s why manufacturers and designers are increasingly choosing TPE over traditional materials like rubber or EVA:

- Shock Absorption: TPE’s inherent elasticity cushions impact and reduces strain on the feet.

- Slip Resistance: Many TPE formulations provide excellent grip on wet or oily surfaces.

- Flexibility and Comfort: It bends easily without cracking, making it ideal for walking and children’s shoes.

- Recyclability: Unlike EVA, TPE can be remelted and remolded—supporting sustainability goals.

For brands targeting eco-conscious consumers, TPE is a smart choice that doesn’t sacrifice performance.

“TPE enables brands to combine comfort, performance, and recyclability in one seamless material.”

3.2 Where TPE Is Used in Footwear

TPEs are not just for soles—they’re found throughout the shoe:

- Outsoles: Durable, grippy, and weather-resistant

- Insoles: Soft and form-fitting for daily wear

- Midsoles: For energy return and light cushioning

- Straps and Overmolds: In sandals, crocs-style shoes, or waterproof boots

They’re especially popular in children’s shoes, work boots, and casual everyday sneakers because of their comfort and safety profile.

3.3 Any Drawbacks in Shoes?

While TPE is incredibly versatile, it’s not a silver bullet for all shoe types. There are a few limitations to consider:

- High-Impact Sportswear: For elite athletic performance, TPE may not offer the energy return or ultra-lightweight advantage that specialized materials like EVA foam or TPU blends provide.

- Long-Term Compression Set: In high-pressure areas (like marathon soles), some TPEs may flatten out over time unless properly engineered.

So while TPE excels in comfort-focused, sustainable, and casual footwear, it may need reinforcement or pairing with other materials for advanced performance wear.

PVC color masterbatch

4. TPE vs. PVC: Which Should You Choose?

4.1 Mechanical & Chemical Performance

When it comes to flexibility, durability, and ease of use, TPE often outperforms PVC in critical ways.

- Flexibility: TPE remains soft and elastic even at low temperatures, whereas PVC can become stiff or brittle, especially in cold climates.

- Abrasion Resistance: TPE offers superior wear resistance, making it more suitable for dynamic applications like soles or gaskets.

- Thermal Stability: TPE generally holds up better under continuous flexing and heat, while PVC may warp or degrade under thermal stress.

In use cases requiring frequent bending, impact absorption, or soft-touch surfaces, TPE is a clear mechanical winner.

4.2 Health and Environmental Considerations

This is where the differences become even more significant.

- TPE is phthalate-free and chlorine-free, making it safer for food contact, skin contact, and eco-conscious products.

- PVC, unless specially formulated, often relies on plasticizers like DEHP (which are restricted in the EU) and contains chlorine—which can release dioxins when burned or processed improperly.

PVC’s life-cycle impact is far greater, both in terms of toxic byproducts and end-of-life recyclability.

“If you’re building a brand around safety, sustainability, or compliance—TPE is the superior material.”

4.3 Manufacturing and Cost Factors

Let’s address the practical side: cost and processing.

- TPE is easier to color, overmold, and bond with other plastics, which simplifies complex designs (like two-shot molding).

- It also has shorter cycle times during molding, increasing production efficiency.

- However, PVC remains cheaper per kilogram and is still used in low-margin mass-market products for this reason.

But here’s the tradeoff: while PVC saves on material cost, it limits recyclability, has higher environmental compliance risk, and lower brand appeal in regulated markets.

For long-term value and future readiness, TPE is often the smarter investment—especially for brands targeting EU, U.S., or green-conscious consumers.

5. Use Cases of TPE

Thermoplastic Elastomers are quietly shaping products all around us. Whether you’re holding a toothbrush, slipping on casual shoes, or using medical tubing—there’s a good chance TPE is at work behind the scenes.

Here are some of the most impactful and growing use cases:

- Automotive Seals and Gaskets

TPEs are widely used in car door weatherstrips, dashboard components, under-the-hood seals, and flexible connectors due to their excellent resistance to oil, heat, and UV exposure. - Consumer Electronics and Wearable Tech

Think of smartwatch straps, phone cases, and ergonomic grips. TPE’s soft-touch feel and moldability make it ideal for stylish, user-friendly designs. - Kitchenware and Food-Grade Items

Because of their food-safe and BPA-free profile, TPEs are used in spatula handles, baby spoons, bottle nipples, and storage container seals. - Footwear Components

As mentioned earlier, TPE finds use in outsoles, insoles, and midsoles—offering flexibility, recyclability, and reliable wear resistance. - Medical Tubing and Flexible Connectors

Certain medical-grade TPEs meet ISO 10993 standards, making them ideal for IV tubing, connectors, surgical grips, and even soft medical devices that need biocompatibility.

“From under the hood to under your feet—TPE is one of the most adaptable materials in modern manufacturing.”

In every one of these industries, TPE replaces heavier, less recyclable, or less safe alternatives, offering better design flexibility, user comfort, and compliance with global safety standards.

Conclusion

After working with various materials in product development and sourcing, I’ve come to respect TPE as one of the most versatile, safe, and forward-looking elastomers available today.

It brings together the best of two worlds: rubber-like elasticity and thermoplastic processability. That makes it a top choice for industries that demand softness, durability, and speed—without compromising on safety or sustainability.

If you’re choosing between TPE and PVC, the answer lies in what your project values most. If you prioritize safety, environmental responsibility, design flexibility, and long-term value, TPE clearly outshines PVC. While it might come with a slightly higher price tag upfront, the performance, compliance, and recyclability it offers pay off over time.

And for footwear? Unless you’re designing for elite athletics, TPE is one of the best materials you can choose, especially if you’re building eco-friendly or comfort-driven products.

In short: TPE isn’t just a trend—it’s a material evolution.

Whether you’re a buyer, product designer, or brand manager, it’s worth taking a closer look at how TPE could elevate your products and streamline your manufacturing.

Curious about how TPE could improve your next product? At KINSOE, we’ve helped clients across industries transition to high-performance elastomers with confidence. From custom gaskets to flexible connectors, our team can support you from concept to delivery.

References: