1. Introduction

A few years ago, one of our industrial clients installed new wind turbines in a coastal region notorious for high humidity and abrasive salt spray. During routine inspections, the team noticed that while many nearby installations had suffered premature bearing failures, theirs continued running smoothly. The secret wasn’t an expensive upgrade or an advanced coating—it was the small, flexible V-Rings mounted on the shafts, quietly protecting the bearings from contaminants.

That story illustrates something I’ve seen countless times in my years at Kinsoe: the simplest sealing components often make the biggest difference. The V-Ring is one such component—a compact, cost-effective elastomer seal designed to defend rotating systems against dirt, dust, and moisture. Despite its unassuming shape, it plays a crucial role in extending equipment life and maintaining operational stability.

In this article, I’ll take a deep dive into the principles, advantages, and applications of V-Rings. I’ll explain how they work, the different types available, how to choose the right size and material, and what factors determine their performance and service life. I’ll also share real-world examples, troubleshooting tips, and a buyer’s checklist to help you make confident, informed decisions.

Understanding V-Rings isn’t just a matter of technical curiosity—it’s a key step toward ensuring long-term reliability in rotating machinery. Here’s what every engineer, buyer, and product manager should know.

2. What Is a V-Ring? Understanding the Principle Behind It

When I describe a V-Ring to new engineers or procurement specialists, I often say it’s the simplest seal you’ll ever install—and the hardest to forget once you see its effectiveness. A V-Ring is an all-rubber, one-piece axial seal designed to protect rotating shafts and bearings from contaminants such as dust, dirt, water, or oil splash. Unlike conventional radial shaft seals that rely on radial interference and housing fits, the V-Ring operates on a pressureless axial sealing principle.

How It Works

The V-Ring consists of three main parts:

- The Body (or Heel): This section fits tightly around the shaft, rotating together with it.

- The Flexible Lip: This part extends axially to lightly contact a counterface—such as a bearing housing or washer—creating a sealing interface.

- The Hinge Section: Between the body and lip lies a thin, flexible hinge that allows the lip to maintain contact even when there’s slight shaft misalignment or runout.

When the shaft rotates, the V-Ring spins with it, and the axial lip rubs gently against the counterface, forming a light contact seal. This action effectively keeps grease in and blocks out dust or liquid ingress. Because it operates without pressure, it is ideal for non-pressurized environments, where contamination control is more critical than fluid containment.

The Centrifugal Lift-Off Effect

At higher rotational speeds, a fascinating phenomenon occurs: centrifugal force causes the lip to slightly lift off the counterface. This reduces friction and heat buildup, extending the seal’s service life. Even during this “lift-off” phase, the V-Ring continues to act as a centrifugal slinger, throwing away water, oil, and debris from the shaft’s path.

In short, a V-Ring serves two roles simultaneously—a dynamic shield and a flexible barrier. Its ingenious design allows it to operate efficiently across a range of speeds, making it one of the most versatile and maintenance-friendly sealing solutions I’ve worked with in industrial and automotive systems alike.

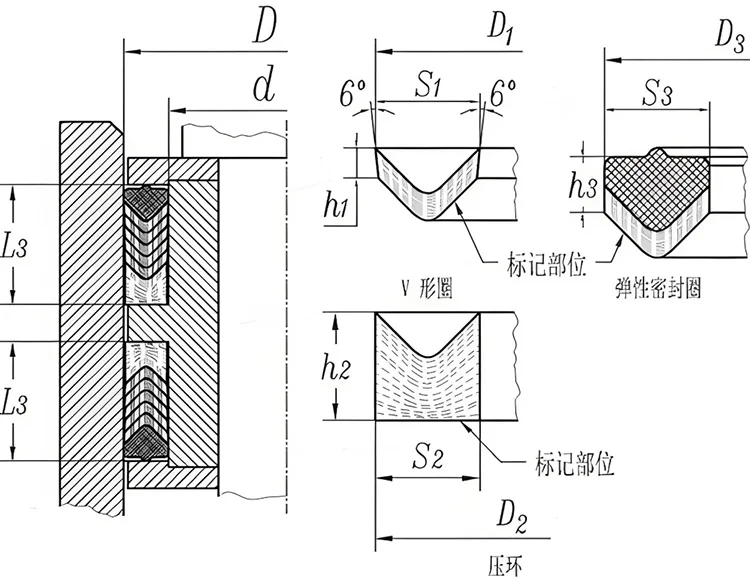

3. V-Ring Types Explained (VA, VS, VL, VE)

Although all V-Rings share the same basic working principle, their geometry and proportions can vary depending on installation conditions. Over time, manufacturers have standardized a few key profiles to cover a wide range of mechanical configurations. At Kinsoe, I’ve often helped customers choose the right type by evaluating available space, shaft size, and environmental exposure. Here’s how the main variants differ.

Overview of Major Types

| Type | ISO/Alternative Code | Profile Characteristics | Typical Applications |

|---|---|---|---|

| VA | VR1 | Standard cross-section with medium-width lip; fits most shafts and housings. | General-purpose sealing in motors, pumps, and bearings. |

| VS | VR2 | Wider cross-section and reinforced body; ensures stronger axial stability. | Heavy-duty applications with higher vibration or runout. |

| VL | VR4 | Low-profile design with a thinner cross-section. | Compact systems with limited radial or axial space. |

| VE | VR3 | Tall body with extended rear face for improved fit and positioning. | Large-diameter shafts and industrial drives. |

Geometrical and Functional Differences

- VA Type (Standard Use):

This is the most commonly used profile. It offers a balanced structure that combines flexibility with sealing stability. Its medium lip pressure works well for shafts ranging from 6 mm to 200 mm, making it a versatile choice for general machinery. - VS Type (Heavy-Duty):

The VS type features a thicker base and a more rigid body. It resists centrifugal deformation better, which helps in large-diameter shafts or equipment with considerable vibration, such as gearboxes or agricultural machinery. - VL Type (Low Cross-Section):

Designed for confined spaces, the VL’s shorter lip minimizes contact pressure and friction. I typically recommend it for small electric motors or compact mechanical assemblies where space is critical but sealing performance can’t be compromised. - VE Type (Extended Body):

The VE version is characterized by its taller heel section, allowing a firmer hold on the shaft. It’s ideal for large industrial shafts or setups requiring enhanced mechanical retention and axial stability.

How to Choose the Right Type

Selecting the appropriate V-Ring depends on more than just shaft diameter. You need to balance operating speed, environmental conditions, and available installation space.

- For general-purpose equipment: choose VA.

- For dusty or vibrating environments: use VS for added durability.

- For tight spaces or low-profile designs: VL is the best fit.

- For large shafts or high mechanical loads: VE ensures secure installation.

When properly matched, the correct V-Ring type can provide years of trouble-free operation, protecting critical components with minimal maintenance effort.

4. Sizing Guidelines and Material Selection

When customers consult me about V-Ring specifications, I often emphasize that selecting the right size and material is the difference between a long-lasting seal and a premature failure. Although V-Rings are flexible and forgiving, their performance depends on fitting accuracy, material compatibility, and environmental conditions.

Sizing Basics

A V-Ring is stretched onto the shaft and relies on this stretch to stay in position during operation. The key parameters are:

- Shaft Diameter (d1): The nominal diameter of the rotating shaft.

- Stretch Percentage: Generally between 2% and 6% for small to medium V-Rings, ensuring a snug fit without overstressing the rubber.

- Counterface Diameter (d2): The surface against which the lip seals—often a stationary component like a bearing housing or cover.

- Axial Preload: A small, controlled compression between the lip and counterface that maintains sealing without generating excess friction.

- Installation Space: Adequate clearance should be left to prevent lip interference with other parts and to allow for shaft movement.

A simple rule I follow: the V-Ring should rotate with the shaft, not slip, and the lip should maintain light, even contact with the counterface.

Material Comparison Chart

Choosing the right material depends on temperature range, media compatibility, and operating conditions. Below is a summary of commonly used elastomers for V-Rings:

| Material | Temperature Range (°C) | Key Features | Typical Applications |

|---|---|---|---|

| NBR (Nitrile Rubber) | -30 to +100 | Excellent oil and grease resistance; affordable. | General-purpose machinery, gearboxes. |

| HNBR (Hydrogenated Nitrile) | -30 to +150 | Improved heat and ozone resistance over NBR. | Automotive and industrial drives. |

| FKM (Viton®) | -20 to +200 | Outstanding chemical, heat, and oil resistance. | High-temperature or chemical processing equipment. |

| EPDM | -40 to +150 | Superior ozone and weather resistance; poor oil compatibility. | Outdoor applications, water systems. |

| Silicone (VMQ) | -60 to +200 | Exceptional flexibility at extreme temperatures. | Food, medical, or climate-controlled environments. |

| AFLAS (FEPM) | 0 to +230 | Excellent resistance to chemicals, acids, and amines. | Aggressive chemical or oilfield environments. |

Special Considerations for Harsh Environments

For high-temperature or aggressive chemical conditions, I often recommend FKM or AFLAS, both capable of enduring extended exposure without hardening or cracking. For outdoor or ozone-prone applications, EPDM remains a reliable and economical choice.

In food or medical systems, where hygiene and thermal stability are critical, silicone is ideal due to its inertness and resistance to both cold and heat.

Ultimately, the goal is to match the elastomer’s chemical and thermal properties to your working environment. Doing so ensures that the V-Ring maintains elasticity, resists wear, and delivers consistent sealing performance over thousands of operating hours.

5. Speed, Friction, and Service Life

In my years of working with rotating systems, I’ve seen countless examples where a seal’s performance was determined not by its material or design—but by how well it handled speed and friction. V-Rings, despite their simplicity, are sensitive to these two factors, and understanding their relationship is the key to achieving long service life.

Relationship Between Speed and Contact Pressure

A V-Ring’s sealing lip maintains light contact with the counterface. As the shaft speed increases, centrifugal force acts on the lip, gradually reducing the contact pressure. At moderate speeds, this creates an optimal balance—sufficient sealing with minimal wear.

However, when the speed exceeds the recommended limit, the lip begins to lift off slightly (known as the centrifugal lift-off effect), transforming the V-Ring into a dynamic slinger that deflects contaminants outward rather than sealing through direct contact.

This self-adjusting mechanism helps prevent heat buildup and excessive wear, but if the speed is too high, the seal may lose full contact, allowing contamination ingress.

Typical Speed Ranges

For most elastomer V-Rings, the recommended surface speed lies between 9–12 m/s, equivalent to roughly 1700–2300 rpm for a 100 mm shaft.

- At low speeds (<6 m/s), the lip maintains stable contact and seals effectively.

- At medium speeds (6–12 m/s), partial lift-off may occur, but sealing remains efficient.

- At high speeds (>15 m/s), the lift-off effect dominates, and sealing efficiency decreases.

Each material behaves differently—FKM and HNBR can tolerate higher temperatures and frictional stress better than NBR or EPDM.

Frictional Power Loss and Heat Generation

Every sealing interface generates frictional heat, and in V-Rings, this depends on:

- Contact pressure between lip and counterface

- Surface finish and lubrication

- Shaft speed and run time

If heat accumulation exceeds the material’s tolerance, the seal may harden, glaze, or lose elasticity. This is why a well-polished counterface (Ra ≤ 0.8 μm) and light lubrication can significantly extend lifespan.

Practical Design Tips to Extend Service Life

- Use the correct preload — Excessive axial compression increases friction and accelerates wear.

- Check surface finish — A smooth, flat counterface ensures even lip contact and minimizes localized heating.

- Control shaft runout — Excessive eccentricity causes vibration and uneven wear.

- Avoid oil starvation — A light film of grease or oil helps reduce friction.

- Consider dual sealing — Combining a V-Ring with a radial seal or labyrinth can enhance both pressure resistance and dirt exclusion.

When properly matched to the operating conditions, a V-Ring can easily achieve thousands of operating hours without maintenance. It’s not an exaggeration to say that in many rotating systems I’ve seen, the V-Ring outlives the bearing it was meant to protect.

6. Proper Installation Methods for Long-Term Reliability

Even the best-designed V-Ring can fail prematurely if it’s not installed correctly. I’ve seen cases where a perfectly good seal lasted only weeks because of incorrect stretching, wrong lip orientation, or poor surface preparation. To achieve the long-term reliability V-Rings are known for, proper installation practices are essential.

1. Orientation of the Lip and Direction of Rotation

A V-Ring’s lip must face the counterface—the surface against which it seals. The ring itself rotates with the shaft, not against it. Unlike conventional radial seals, a V-Ring isn’t fixed into a bore; instead, it’s lightly tensioned on the shaft and uses centrifugal action to assist in sealing.

Key point: The sealing lip should never face away from the contamination source. If reversed, it will fail to exclude contaminants effectively.

2. Recommended Shaft Stretch and Axial Preload

The V-Ring must fit tightly enough to rotate with the shaft but not so tight that it distorts.

- Stretch Ratio: Typically 2%–6% of the shaft diameter.

- Axial Preload: The lip should press lightly—enough to form a seal but not enough to create excessive friction.

I usually confirm this by rotating the shaft manually after installation; it should feel smooth, without binding or scraping.

3. Counterface Surface Finish and Flatness

A poor counterface finish can damage the sealing lip or cause uneven contact. The surface should be:

- Flatness: ≤ 0.03 mm across the sealing area.

- Roughness: Ra ≤ 0.8 µm (polished steel or fine-machined aluminum).

- Cleanliness: Free of burrs, machining residues, or sharp edges that could cut the lip during operation.

In high-speed systems, a finely ground or polished counterface can dramatically reduce wear and heat generation, extending seal life by up to 50%.

4. Installation Steps

- Inspect and clean the shaft and counterface. Remove all dirt, oil residues, and burrs.

- Lightly lubricate the shaft and the lip area using compatible grease or oil.

- Stretch the V-Ring gently over the shaft by hand or with a cone tool. Avoid sharp tools that could tear the lip.

- Slide into position and ensure the lip sits evenly against the counterface.

- Rotate the shaft manually to verify smooth contact before full operation.

5. Common Installation Mistakes and How to Avoid Them

| Mistake | Result | Prevention |

|---|---|---|

| Overstretching the ring | Poor shaft grip or deformation | Follow 2–6% stretch guideline |

| Lip facing wrong direction | Seal fails to exclude contaminants | Always face lip toward contamination source |

| Dirty or rough counterface | Accelerated wear and leakage | Polish and clean before assembly |

| No lubrication | Increased friction and heat | Apply a thin film of grease |

| Uneven pressing | Warped seal and premature failure | Use a uniform axial load when seating |

Installing a V-Ring is not complicated, but it does demand precision. When done correctly, the result is a stable, self-compensating seal that maintains consistent contact and protection throughout its lifespan—even in dusty, wet, or high-vibration environments.

7. Where V-Rings Excel — and Where They Don’t

In my experience, V-Rings are among the most cost-effective and adaptable sealing solutions available, but like every seal type, they have their limitations. Understanding where they shine—and where they fall short—helps prevent misuse and ensures optimal performance.

Key Advantages

- Simple Structure and Low Cost

The V-Ring’s one-piece rubber design eliminates the need for metal housings, springs, or complex assembly. This simplicity not only reduces cost but also minimizes maintenance, making it ideal for OEMs and aftermarket applications alike. - Excellent Contaminant Exclusion

Thanks to its axial sealing lip and centrifugal action, the V-Ring excels at keeping dust, dirt, water, and oil mist away from critical components like bearings and shafts. Even after partial lift-off at higher speeds, it continues to act as a dynamic slinger, flinging away contaminants. - Compatibility with Grease Lubrication

V-Rings perform exceptionally well in grease-lubricated systems, where their flexible lip retains lubrication while preventing external ingress. This makes them a common choice for electric motors, gearboxes, and agricultural machinery. - Easy Installation and Replacement

Because there’s no need for a fixed housing, V-Rings can be installed or replaced without disassembling the shaft assembly. In many maintenance scenarios, this alone saves hours of downtime. - Adaptability to Misalignment and Vibration

The flexible hinge section allows the lip to follow shaft movement and vibration, maintaining consistent contact even under moderate runout conditions.

Quote: “The V-Ring may be small, but in hostile environments, it acts as the first line of defense—often protecting seals that cost ten times more.”

Limitations

- Not Suitable for Pressure Sealing

Unlike radial shaft seals, V-Rings are designed for pressureless environments. They cannot contain fluid pressure and will lift off or deform if exposed to more than a few millibars of differential pressure. - Lift-Off at High Speeds

While centrifugal lift-off reduces friction, excessive speeds can cause complete separation from the counterface, leading to contamination ingress. Always check the speed limits recommended by the manufacturer. - Dependent on Counterface Quality

A poor or uneven counterface surface can cause leakage or premature wear. The seal’s effectiveness depends heavily on flatness, smoothness, and alignment. - Limited Temperature and Chemical Resistance (for NBR types)

Standard nitrile (NBR) V-Rings are not suitable for aggressive chemicals or very high temperatures. In such cases, FKM or AFLAS should be used.

Comparison with Other Seal Types

| Seal Type | Primary Function | Strengths | Weaknesses |

|---|---|---|---|

| V-Ring | Axial dust and splash protection | Simple, flexible, inexpensive | Not pressure-tight |

| Radial Oil Seal | Fluid retention | Good for oil sealing, moderate pressure | More complex, higher cost |

| Labyrinth Seal | Non-contact exclusion | Long life, no wear | Requires tight machining tolerance |

| Mechanical Face Seal | High-load, sealed systems | Excellent durability | Bulky and expensive |

V-Rings shine as auxiliary or secondary seals, often used alongside radial or labyrinth seals to enhance dirt exclusion and prolong system life. In applications where contamination control outweighs pressure retention, their simplicity and performance make them an unmatched choice for long-term reliability.

8. Real-World Applications and Case Studies

I often describe V-Rings as the “silent guardians” of mechanical systems. They don’t call attention to themselves, yet they protect some of the most valuable components in industrial equipment. Over the years at Kinsoe, I’ve seen V-Rings used in every imaginable setting—from precision instruments to massive wind turbines. Their adaptability and efficiency make them indispensable in countless industries.

Common Industries

- Electric Motors

In electric motors, V-Rings are installed on the shaft to protect bearings from dust, moisture, and oil mist. Their low-friction contact ensures that performance remains consistent even at high rotational speeds. They also prevent grease leakage, reducing bearing failures and maintenance costs. - Gearboxes and Pumps

V-Rings are widely used on gearbox shafts and pump drives, where they act as auxiliary seals to shield radial shaft seals from contamination. In particular, they help keep abrasive particles and water out, thereby extending the lifespan of both the oil seals and the lubricant inside. - Wind Turbines and Heavy Machinery

For equipment exposed to harsh weather, such as wind turbines or mining machinery, V-Rings serve as first-line barriers. Their flexibility allows them to accommodate shaft deflection and vibration while continuously flinging away rain, mud, and grit. Even in vertical shaft orientations, they remain effective due to their dynamic slinging action. - Automotive and Industrial Drives

In automotive systems—particularly in axles, transmissions, and pulley assemblies—V-Rings protect bearings and shafts from road dust and water spray. They also appear in conveyor systems, fans, and industrial drive motors that operate in dusty or humid environments.

Integration with Other Seals

In most systems, a V-Ring doesn’t work alone. It’s often part of a multi-stage sealing system, combining with:

- Radial oil seals, which retain lubricants and resist internal pressure.

- Bearing shields, which block larger contaminants.

- Labyrinth seals, which handle non-contact exclusion in high-speed applications.

When combined correctly, these elements create a layered defense—each seal focusing on its specific function. The V-Ring, positioned externally, prevents contaminants from ever reaching the inner sealing elements.

Case Study: Gearbox Bearing Protection in a Quarry Conveyor

A few years ago, one of our industrial customers operated a stone crushing plant where conveyors worked under constant dust exposure. Their primary bearings failed every six months, even after switching to higher-grade lubricants and seals.

When we reviewed the system, we noticed that the existing radial seals were performing well internally, but no external barrier existed to stop dust ingress. We recommended adding V-Rings (Type VS, NBR) on the exposed shaft ends.

After installation, the plant reported a dramatic improvement:

- Bearing life extended from 6 months to over 18 months.

- Maintenance frequency reduced by 65%.

- Overall sealing cost per year decreased, despite the addition of new components.

The success came from the V-Ring’s ability to block dust and deflect debris before it ever reached the critical sealing surfaces.

From precision electric motors to massive industrial conveyors, V-Rings have proven that even small components can deliver large-scale protection and savings. Their combination of simplicity, flexibility, and durability makes them a preferred choice wherever environmental sealing is critical but pressure retention is not.

9. Troubleshooting Guide — Solving Common V-Ring Problems

Even though V-Rings are simple and robust, I’ve seen many failures that could have been avoided with proper setup and inspection. Understanding the common issues and their root causes allows engineers and maintenance teams to restore sealing performance quickly without unnecessary downtime.

1. Overheating

Symptoms:

- Rubber surface hardening or glazing

- Burn marks near the lip

- Noticeable odor of heated rubber

Causes:

- Excessive axial preload causing high friction

- Shaft speed exceeding recommended limits

- Poor lubrication or dry counterface

- Rough or uneven surface finish

Solutions:

- Reduce preload and verify the lip contact pressure

- Ensure shaft speed stays within 9–12 m/s

- Apply a thin layer of compatible grease or oil

- Polish the counterface to ≤ Ra 0.8 µm

Tip: In high-speed applications, a partial lift-off of the lip is normal and helps prevent overheating.

2. Premature Wear

Symptoms:

- Uneven lip wear

- Cracks or tears at the hinge section

- Rapid reduction in sealing effectiveness

Causes:

- Shaft misalignment or excessive runout

- Contaminant buildup at the lip edge

- Use of incorrect material for temperature or media

- Improper installation or overstretching

Solutions:

- Check shaft concentricity and runout (≤ 0.2 mm recommended)

- Clean sealing area regularly during maintenance

- Choose a more suitable material (e.g., FKM for high heat)

- Replace worn V-Rings with new ones and follow stretch guidelines

3. Leakage or Contaminant Ingress

Symptoms:

- Visible dust, oil, or water inside the housing

- Grease leakage around the shaft end

- Reduced bearing life or corrosion signs

Causes:

- Lip lift-off due to high speed or incorrect preload

- Lip facing wrong direction

- Damaged or warped counterface

- Use of wrong type (e.g., VL instead of VS for heavy duty)

Solutions:

- Reinstall with correct orientation—lip must face the contamination source

- Verify surface flatness and finish

- Select the right V-Ring type based on application

- Consider pairing with a radial seal for added protection

4. Noise and Vibration

Symptoms:

- Whistling or squealing sounds at start-up

- Vibration felt along the shaft or housing

Causes:

- Excess friction due to dry installation

- Lip chatter caused by uneven contact pressure

- Shaft imbalance or eccentric motion

Solutions:

- Apply a thin film of lubricant before installation

- Inspect the counterface for waviness or burrs

- Balance the rotating components if necessary

Quick Diagnostic Table

| Issue | Likely Cause | Recommended Fix |

|---|---|---|

| Overheating | Too much preload, high speed | Reduce preload, check lubrication |

| Premature wear | Misalignment, dirt, wrong material | Realign shaft, clean area, use proper elastomer |

| Leakage | Wrong orientation, lift-off | Reinstall correctly, verify speed |

| Noise | Dry contact, rough surface | Lubricate, polish counterface |

The key to reliable sealing is consistent inspection. V-Rings rarely fail without warning—subtle signs like a dry lip, uneven wear, or increased noise often appear first. By addressing these early, you can prevent full-scale equipment failures and ensure that your sealing system continues to perform as intended.

10. Buyer’s Selection Checklist

Whenever I help customers choose a V-Ring, I remind them that a correct selection isn’t just about size—it’s about matching design, material, and environment to achieve long-term sealing reliability. To simplify the process, I’ve prepared a practical checklist that covers all the critical factors you should verify before purchase or installation.

1. Shaft Diameter and Speed

- Confirm the nominal shaft diameter (d1) matches the manufacturer’s range.

- Check for stretch allowance (2–6%) to ensure proper fit.

- Verify the shaft surface speed does not exceed material limits (typically 9–12 m/s).

- If speeds are higher, consider a dual-seal configuration or additional shielding.

2. Operating Environment

Evaluate the conditions the seal will face daily:

- Temperature: From freezing outdoor climates to high-temperature machinery, select a suitable elastomer (e.g., EPDM for weathering, FKM for heat).

- Media: Determine exposure to water, oils, grease, or chemicals.

- Contaminants: Assess dust levels, mud, or water splashing, especially in heavy-duty or outdoor operations.

- Humidity or UV exposure: EPDM or Silicone are excellent for such conditions.

3. Installation Space and Orientation

- Measure available axial and radial space around the shaft.

- Choose compact profiles (like VL type) for tight assemblies.

- Ensure the lip orientation faces the contamination source—an incorrect direction drastically reduces effectiveness.

- Check for possible shaft misalignment or runout, which may affect contact uniformity.

4. Material and Type Selection

| Material | Advantages | Recommended Use |

|---|---|---|

| NBR | Low cost, good oil resistance | General-purpose machinery |

| HNBR | Heat and ozone resistant | Automotive and drive systems |

| FKM (Viton) | High heat and chemical stability | High-speed or chemical processing |

| EPDM | Excellent weather resistance | Outdoor and water systems |

| Silicone | Flexible in extreme cold or heat | Food, pharma, and cleanroom environments |

| AFLAS | Exceptional chemical resistance | Oil & gas, chemical plants |

Pair this with the correct profile type (VA, VS, VL, VE) based on your space, load, and vibration conditions.

5. Counterface Condition

Before final assembly, confirm the counterface meets the following:

- Flatness: ≤ 0.03 mm

- Surface Roughness: Ra ≤ 0.8 µm

- Material: Machined steel, stainless, or hard aluminum preferred

- Cleanliness: Free of burrs, dust, or oil residues

A smooth, well-prepared counterface not only improves sealing performance but also reduces wear and energy loss.

6. Quantity and Standards

- Verify minimum order quantities and compliance with ISO 6194 or DIN 3760 standards.

- For OEM projects, request sample validation or a trial batch to confirm performance before full production.

- If sourcing from overseas, ensure suppliers provide dimensional and material test reports.

11. Frequently Asked Questions (FAQ)

Over the years, I’ve received countless questions about V-Rings from engineers, buyers, and maintenance teams. Below, I’ve compiled the most common ones to clarify how these seals function and where they’re most effective.

1. Can a V-Ring handle pressure?

No. V-Rings are designed for pressureless sealing applications. Their flexible axial lip provides excellent protection against contaminants but cannot resist internal fluid pressure. If your system requires pressure containment, a radial shaft seal or mechanical face seal should be used in combination.

2. What is the maximum speed a V-Ring can run at?

In most cases, the safe limit is around 9–12 m/s surface speed. Beyond this range, the lip tends to lift off the counterface due to centrifugal force. However, this lift-off doesn’t mean complete failure—it simply transitions the V-Ring into a deflective slinger, still providing partial protection against contaminants.

For higher speeds, I recommend using low-friction materials (like FKM or HNBR) and ensuring proper lubrication to prevent heat buildup.

3. Which material is best for hot water or chemical exposure?

- For hot water, EPDM is the most reliable choice due to its resistance to steam, ozone, and oxidation.

- For chemically aggressive media, FKM (Viton) or AFLAS (FEPM) provides superior performance.

- If the environment involves both temperature extremes and exposure to mild chemicals, HNBR offers a balanced solution.

4. How tight should a V-Ring fit the shaft?

The V-Ring should be stretched about 2–6% of the shaft diameter. This ensures a secure grip without overstressing the rubber. A correctly fitted ring rotates smoothly with the shaft without slipping or wrinkling. Overstretching can deform the lip and shorten service life.

5. Can a V-Ring replace a labyrinth seal?

Not entirely. While both serve as non-contact or low-pressure barriers, their functions differ:

- V-Rings rely on light contact and centrifugal slinging to block contaminants.

- Labyrinth seals use a series of non-contact grooves to create a tortuous path for contaminants.

In many designs, these two are used together—a V-Ring provides the first line of defense, while the labyrinth handles deeper exclusion.

6. What counterface finish is required for proper sealing?

The counterface should be flat and smooth, typically Ra ≤ 0.8 μm.

If the surface is rough or uneven, it causes lip wear, noise, and heat generation. A finely ground steel or anodized aluminum surface ensures consistent contact and extended service life.

7. Do V-Rings need lubrication?

Yes, but only a thin film of compatible grease or oil. Over-lubrication can cause the ring to hydroplane and slip. The goal is to reduce friction during break-in and prevent dry running during the first few hours of operation.

8. Can a V-Ring be reused after disassembly?

I don’t recommend it. Once removed, the V-Ring may lose its original tension or suffer micro-tears that aren’t visible to the eye. Reusing it risks leakage and inconsistent sealing performance. Always replace V-Rings during scheduled maintenance—it’s a small cost for major reliability gains.

These practical answers summarize years of field experience. A well-selected and properly maintained V-Ring can provide reliable, long-term protection—but only when its physical limitations and best practices are respected.

12. Conclusion

Through years of experience in sealing technology, I’ve learned that small components often determine the fate of big machines—and the V-Ring is one of those unsung heroes. Despite its simple shape, it delivers impressive performance across countless industries, offering dependable protection where contamination control is critical but pressure sealing isn’t required.

The V-Ring operates on a pressureless axial sealing principle, rotating with the shaft and forming a flexible barrier against dust, water, and oil splash. Its genius lies in its simplicity—no metal case, no spring, yet it can dramatically extend bearing and shaft life.

Across electric motors, gearboxes, pumps, and wind turbines, V-Rings demonstrate consistent advantages:

- Low cost and easy installation

- Excellent contamination resistance

- Adaptability to misalignment and vibration

- Compatibility with grease lubrication

While not suited for pressure sealing or extreme speeds, their versatility makes them a reliable companion for radial and labyrinth seals. Whether used as a primary barrier or secondary defense, V-Rings remain one of the most practical solutions for non-pressurized systems.

If you’re designing or maintaining rotating machinery, take a moment to evaluate whether your current sealing setup includes proper external protection. Adding a V-Ring could prevent countless failures caused by contamination—and it often costs just a fraction of a full system repair.

At Kinsoe, I specialize in developing custom rubber seals and components that meet rigorous industrial standards. From NBR to FKM and AFLAS V-Rings, we can tailor each design to your shaft size, operating speed, and environment.