I. Introduction

In my years working with industrial sealing solutions, I’ve learned that valve sealing is far more than just a mechanical detail—it’s a critical safeguard for operational reliability. Whether in power plants, chemical processing, or water treatment, valve seals ensure that fluids, gases, or steam remain exactly where they should be. They prevent both internal and external leakage, protecting equipment from damage, conserving resources, and maintaining system safety.

In this article, I’ll walk you through the essentials of valve sealing: the different types, the materials most commonly used, the factors that affect their performance, and how to choose the right one for your application. I’ll also share common causes of seal failures and the best practices I follow to maximize service life.

II. The Role of Valve Seals

A valve seal is the component that ensures a tight closure between critical contact surfaces within a valve. Its role goes beyond simply plugging gaps—it’s about controlling the flow of media under varying pressures, temperatures, and chemical conditions.

Key functions include:

- Preventing media leakage to maintain process integrity.

- Ensuring operational safety by avoiding dangerous leaks.

- Maintaining process efficiency through stable pressure and flow control.

In short, a good valve seal is a silent guardian that works continuously in the background.

III. Types of Valve Seals

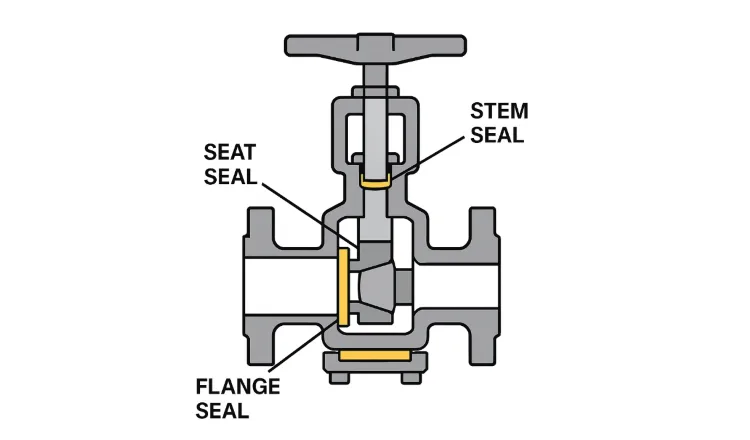

1. Seat Seal

Positioned between the valve disc and the seat, the seat seal is responsible for ensuring complete shutoff when the valve is closed.

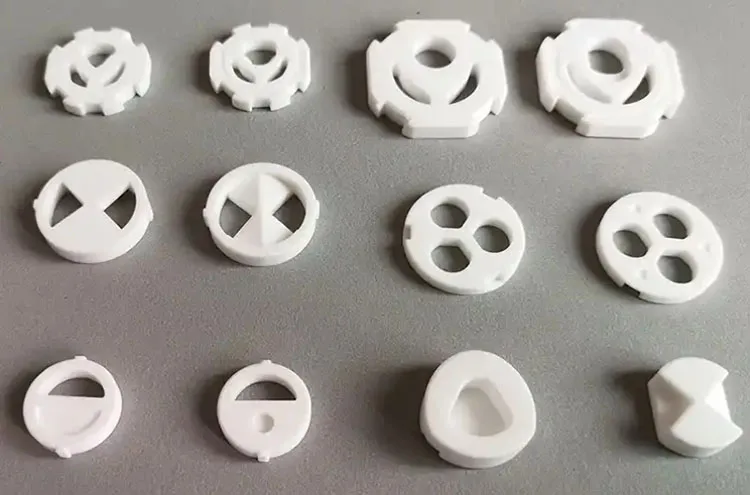

- Soft seat seals (rubber, PTFE) offer superior sealing performance, even with slight misalignments.

- Hard seat seals (metal, ceramic) excel in high-temperature, abrasive, or high-pressure conditions.

These are widely used in ball, butterfly, and gate valves.

2. Stem Seal

Located around the valve stem, these seals prevent leakage along the moving shaft.

- Common designs include packing glands, O-rings, and bellows seals.

- They are essential for valves with frequent actuation, where dynamic sealing is required.

3. Flange Seal

Found at the connection between a valve and the pipeline, flange seals typically use gaskets to ensure tight joints.

- Gasket materials range from compressed fiber to spiral-wound metal.

- They are critical in high-pressure and high-temperature service lines.

IV. Common Sealing Materials

| Material | Key Properties | Common Applications | Temperature Range |

|---|---|---|---|

| Rubber (NBR, EPDM, FKM) | Good elasticity, strong sealing | Water, low-pressure gases | -40°C to +200°C |

| PTFE | Excellent chemical resistance, low friction | Corrosive media, food-grade systems | -180°C to +260°C |

| Metal (SS, Stellite) | High temperature and pressure resistance | Steam, petrochemical | Up to +600°C |

| Graphite | High-temp, corrosion resistance | High-pressure valves, power plants | -200°C to +450°C (up to 650°C in some conditions) |

V. Soft vs. Hard Seals

- Soft seals

- Advantages: Excellent sealing, compensates for small surface irregularities.

- Limitations: Lower resistance to extreme temperatures and pressures.

- Hard seals

- Advantages: Highly durable, ideal for demanding conditions.

- Limitations: Require precise machining and alignment.

VI. Factors Affecting Seal Performance

From my experience, a high-quality material alone won’t guarantee reliable sealing. Performance depends on:

- Surface finish and machining accuracy — rough or uneven surfaces reduce seal efficiency.

- Material compatibility with the process medium.

- Installation quality and correct preload — improper tightening can cause leaks.

- Medium properties such as temperature, pressure, and corrosiveness.

- Wear, abrasion, and aging over time.

VII. Common Seal Failures and Causes

I’ve seen seals fail for reasons that could have been prevented with proper attention:

- Seal face damage from erosion or foreign particles.

- Material aging or hardening due to heat or chemicals.

- Improper installation leading to uneven stress.

- Incorrect material selection causing swelling, shrinkage, or chemical attack.

VIII. Best Practices for Seal Selection

When choosing a valve seal, I always recommend:

- Matching material to the exact operating conditions (temperature, pressure, and media).

- Considering maintenance needs and how easily the seal can be replaced.

- Evaluating total lifecycle cost, not just the upfront price.

- Referring to industry standards like API or ASME for guidance.

IX. Conclusion

Valve seals may be small, but their impact on system safety, efficiency, and cost-effectiveness is enormous. By selecting the right type and material, installing it correctly, and maintaining it proactively, you can avoid costly downtime and safety hazards.

At Kinsoe, I’ve helped clients across industries—from petrochemical plants to water treatment facilities—find sealing solutions that work flawlessly under their unique conditions. If you want expert advice on your next valve sealing project, I’m here to help you make the right choice for lasting performance.