Understanding the Problem

Vibration in mechanical systems can lead to noise, fatigue, wear, and eventual failure. This creates real challenges for industries and consumers alike. Whether it’s in HVAC systems, automotive components, or heavy machinery, the demand for a solution that dampens vibration and prolongs lifespan is growing. Enter vibration-reducing gaskets.

MY Answer

Vibration-reducing gaskets are specially engineered seals made from rubber-like materials such as neoprene or silicone. They absorb mechanical vibrations and dampen noise, often used in HVAC, automotive, and heavy machinery applications. These gaskets are extruded by forcing heated rubber through a shaped die, forming continuous profiles tailored to specific industrial needs.

Why It Matters

The importance of vibration-reducing gaskets goes beyond mere noise suppression—they are critical to preserving the operational integrity of machines and systems over time. Unmanaged vibration accelerates wear, degrades connections, and can compromise safety in both consumer products and industrial machinery.

Let’s take examples:

- In automotive engineering, vibration-damping gaskets are used around dashboard electronics, headlamps, and engine compartments. Without them, oscillations from the road or engine can damage sensitive components, loosen connectors, and increase driver fatigue due to cabin noise.

- In HVAC systems, rubber gaskets absorb motor-generated pulses that might otherwise travel through ductwork, loosening screws, cracking joints, or creating humming noises that disrupt occupant comfort.

- In manufacturing equipment, consistent vibration can throw off calibration of precision tools, reduce the life of bearings and shafts, or cause fatigue failure in structural components.

From an economic perspective, proper vibration control directly reduces maintenance costs, lowers warranty claims, and extends equipment life. For example, studies in mechanical maintenance have shown that even modest vibration isolation can increase the lifespan of mounted electric motors by up to 25–40% in high-duty cycles.

Whether you’re an engineer, procurement specialist, or OEM manager, understanding the role of vibration-reducing gaskets allows you to make smarter material and design decisions that directly affect system performance and operational costs.

What Is the Process of Gasket Molding?

Gasket molding is a precision manufacturing process used to form rubber gaskets into specific shapes and dimensions using heat and pressure. Unlike extrusion, which creates continuous profiles, molding is ideal for producing fully enclosed, detailed, and often complex gasket geometries.

The Main Types of Gasket Molding:

- Compression Molding

This is the most widely used method for rubber gaskets. It involves:- Placing a pre-measured amount of uncured rubber (called a preform) into a heated mold cavity.

- Closing the mold and applying pressure, forcing the rubber to fill the mold shape.

- Curing (vulcanizing) the rubber under heat and pressure to create a stable, elastic part.

- Opening the mold and removing the finished gasket.

Best for: Medium-to-large gaskets, flat or simple shapes, high-durometer rubbers.

- Transfer Molding

In this method:- Rubber is placed in a pot and forced through sprues into closed cavities under pressure.

- The material flows more evenly than in compression molding, allowing for better detail and dimensional accuracy.

- It is cured and then removed from the mold.

Best for: Medium-complexity shapes, tighter tolerances, embedded inserts.

- Injection Molding

This highly automated process involves:- Forcing preheated rubber into a closed mold via a screw mechanism.

- The rubber fills multiple cavities rapidly and cures inside the mold.

- After curing, the mold opens and the gaskets are ejected.

Best for: High-volume production, complex geometries, tight tolerances, small parts.

Key Process Considerations:

- Material selection: Silicone, EPDM, nitrile, and FKM (Viton) are commonly used depending on temperature, chemical, or mechanical requirements.

- Cure time and temperature: Must be carefully controlled to avoid over-curing (brittleness) or under-curing (weakness).

- Mold design: Impacts flow, air entrapment, and shrinkage. Venting and gating systems are critical to part quality.

- Post-molding operations: May include deflashing, inspection, adhesive backing, or secondary curing for high-performance seals.

Why Use Molding for Gaskets?

- Complex shapes: Molding supports intricate geometries and tight seal paths.

- High precision: Critical in applications where dimensional control and sealing performance are paramount.

- Material flexibility: Allows use of high-performance elastomers and compound variations for demanding environments.

By mastering the molding process, manufacturers like Kinsoe can deliver precise, repeatable gasket solutions that meet both sealing and vibration control demands across industries.

What Is the Best Rubber to Absorb Vibrations?

Neoprene is widely regarded as one of the best rubber materials for absorbing vibration—and for good reason. It offers a rare balance between mechanical resilience and environmental durability, making it suitable for a broad range of industrial applications.

Why Neoprene Stands Out:

- Viscoelastic Behavior

Neoprene exhibits both viscous and elastic properties. This allows it to deform under load, absorb mechanical energy, and then gradually return to its original shape. This internal energy conversion—known as hysteresis—is essential to damping vibration. - Cellular Structure

Closed-cell neoprene variants trap air within the material, increasing its compressibility and improving its shock-absorbing capabilities. This makes it particularly effective for gaskets used between vibrating mechanical parts. - Chemical and Oil Resistance

Neoprene resists many industrial oils, greases, and mild acids, maintaining its structural integrity even in harsh environments. That’s why it’s often chosen for engine compartments, industrial pumps, and HVAC systems. - Durability in Outdoor Conditions

Neoprene also holds up well under UV exposure, ozone, and temperature fluctuations (from -40°C to +120°C), making it reliable in both indoor and outdoor settings.

Example Use Case:

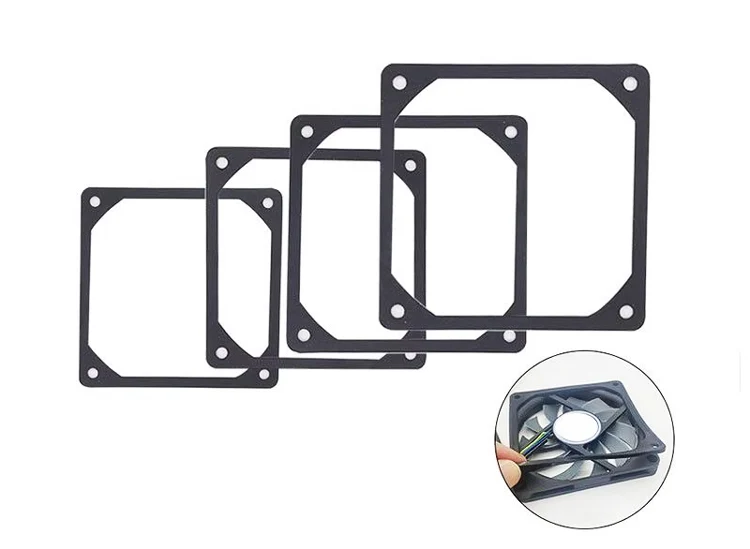

In a high-speed industrial fan system, neoprene gaskets are used between the fan housing and mounting brackets. These gaskets not only prevent the transfer of vibration to the surrounding structure but also ensure a firm seal against air leaks. Over time, this helps reduce operational noise and prevent loosening of nearby fasteners.

“Neoprene’s resilience makes it a cornerstone material for isolating mechanical components from harmful vibration.” – Materials Science Handbook

While other materials like silicone or EPDM may outperform neoprene in specific environments (e.g., high heat or UV exposure), neoprene remains a top general-purpose choice for vibration damping across industries.

What Is the Best Material to Reduce Vibration?

Rubber remains the most effective and versatile material for reducing vibration, thanks to its inherent elasticity, internal damping, and adaptability to different operating environments.

How Rubber Works as a Damping Material

Rubber absorbs vibration by deforming under dynamic stress. Its molecular chains stretch and then slowly revert to their original configuration, converting a portion of the mechanical energy into heat. This process—known as viscoelastic damping—helps minimize the transmission of vibrational energy from one component to another.

The effectiveness of a rubber gasket depends on three main properties:

- Modulus of elasticity – determines how much the material deforms under stress.

- Damping coefficient – governs how much energy is absorbed and dissipated.

- Compression set – indicates how well the material rebounds after being compressed.

Common Rubber Compounds and Their Vibration Properties:

| Rubber Type | Strengths for Vibration Reduction | Typical Use Cases |

|---|---|---|

| EPDM | Excellent outdoor and ozone resistance; good flexibility | HVAC mounts, outdoor electrical enclosures |

| Neoprene | Balanced damping, chemical and oil resistance | Machinery gaskets, engine seals |

| Silicone | High temperature tolerance, soft and resilient | Electronics, cleanroom, aerospace |

| Nitrile (NBR) | Oil and fuel resistance; moderate damping | Automotive fuel system mounts |

| Natural Rubber | High elasticity and rebound; best at shock absorption | Industrial shock mounts, anti-vibration pads |

Each compound can be modified by fillers, plasticizers, or foam structuring (open-cell vs. closed-cell) to fine-tune performance.

Engineering Insight:

A poorly matched rubber material might offer good sealing but poor damping—or vice versa. That’s why vibration gaskets must be engineered with an understanding of dynamic forces, environmental exposure, and compression behavior.

In high-vibration environments—like electric motors, diesel generators, or industrial presses—rubber’s ability to isolate and cushion movement can be the difference between a system that runs reliably for years and one plagued by maintenance issues.

How Does Rubber Reduce Vibration?

Rubber reduces vibration through a combination of elastic deformation and internal damping—a process rooted in its molecular structure and physical behavior under load.

The Science Behind the Damping

When rubber is subjected to mechanical stress (e.g., impact, shaking, oscillation), its flexible polymer chains stretch and shift. Instead of transmitting that energy through to adjacent components, the rubber temporarily stores the energy as strain. As the load is released, part of that energy is dissipated as low-grade heat, and the material gradually returns to its original shape.

This ability to deform and rebound—known as viscoelasticity—is central to vibration reduction.

Key Factors That Influence Rubber’s Damping Performance:

- Hardness (Shore A)

Softer rubber compounds tend to absorb more vibration but may compress too easily under high loads. Harder compounds offer structural stability but may transfer more energy. Selecting the right Shore A value is critical for balancing damping and support. - Material Density and Structure

Closed-cell foams (like neoprene sponge) trap air, enhancing cushioning while resisting water and dust. Solid rubber, while heavier and denser, provides higher strength and better compression recovery. - Temperature Behavior

The performance of rubber changes with temperature. Silicone, for example, retains its damping properties in extreme cold or heat, while natural rubber becomes brittle in cold environments.

Example:

In an air conditioning unit, the compressor generates continuous vibrations. Without a gasket or mount made of properly selected rubber, the vibration could resonate into the metal housing, causing loud buzzing and loosening of bolts. With a silicone or neoprene vibration gasket in place, those energy waves are absorbed, preventing them from traveling into the frame and reducing both noise and structural fatigue.

Summary Insight:

“Rubber doesn’t just block vibration—it transforms it.”

Through energy conversion and mechanical cushioning, rubber turns dynamic motion into a manageable, silent process that protects machines, structures, and people.

What Materials Are Used in Vibration-Reducing Gaskets?

The effectiveness of a vibration-reducing gasket depends heavily on the material composition. These gaskets must not only cushion mechanical vibrations, but also withstand environmental conditions like temperature extremes, oil exposure, UV rays, and compression stress.

Here are the most commonly used materials and their properties:

1. Neoprene (CR)

- Strengths: Excellent damping, good resistance to oil, UV, ozone, and aging. Also adhesive-friendly for bonding to metal surfaces.

- Applications: HVAC mounts, automotive engine bay seals, and general-purpose machinery.

2. Silicone Rubber

- Strengths: Outstanding flexibility across a wide temperature range (-60°C to +230°C). Also resists many chemicals and microbial growth.

- Applications: Aerospace, electronics, food-grade seals, and high-heat environments.

3. EPDM Rubber

- Strengths: Excellent weather, ozone, and UV resistance. Good flexibility and stability in outdoor or marine conditions.

- Applications: Solar energy systems, outdoor enclosures, rooftop HVAC seals.

4. Nitrile Rubber (NBR)

- Strengths: Superior oil and fuel resistance. Moderate vibration control.

- Applications: Fuel systems, hydraulic equipment, vibration-isolated mounts in engines.

5. Natural Rubber

- Strengths: High tensile strength and elasticity; superior performance in dynamic damping.

- Limitations: Poor resistance to oil, ozone, and UV exposure.

- Applications: Shock mounts and isolators for indoor, dry environments.

6. Sponge Rubber (Closed-Cell or Open-Cell)

- Strengths: Provides cushioning, lightweight design, seals out moisture and air.

- Applications: HVAC ducts, marine hatches, enclosures needing both seal and vibration isolation.

Material Selection Tip:

Always align material choice with operating environment and mechanical demands. For example:

- In high-temperature conditions (like ovens or engine bays), use silicone.

- For oil-heavy environments, go with nitrile or neoprene.

- For outdoor exposure, opt for EPDM.

By understanding these materials’ strengths and limitations, you can select the right vibration gasket that offers both longevity and reliable performance in the field.

Molding Rubber Gaskets in Industry

Molded rubber gaskets play a crucial role in industrial systems by delivering precise, durable, and application-specific sealing solutions. Unlike extruded profiles, molded gaskets are produced in closed molds, allowing for greater dimensional control, complex shapes, and integrated features that are essential in high-performance and safety-critical environments.

Key Industry Applications:

1. Automotive Sector

Molded gaskets are used extensively in:

- Cylinder heads, oil pans, and transmission systems—where sealing must withstand high temperatures, pressure cycles, and exposure to oil and fuel.

- Vibration-damping mounts between engine components and vehicle frames.

- Door and window seals that require three-dimensional shapes and consistent compression performance.

Because vehicle systems involve constant motion and heat cycling, molded gaskets are designed to maintain elasticity and sealing integrity under extreme conditions.

2. HVAC & Mechanical Systems

In HVAC applications, molded rubber gaskets are critical for:

- Sealing flanges, valves, and ducts to prevent air leaks and absorb vibration.

- Isolating compressors or fans from mounting brackets to reduce noise and structural fatigue.

The molded process allows manufacturers to create gaskets that fit irregular or multi-hole patterns perfectly—something extrusion cannot achieve with accuracy.

3. Industrial Machinery

In heavy equipment and automated systems:

- Molded gaskets seal joints in pumps, gearboxes, and fluid power systems.

- They help isolate vibrations in mounting assemblies or between rotating and stationary parts.

- Custom geometries (e.g., grommets, diaphragms, lip seals) are possible through molding for specialized performance under compression, torque, or movement.

4. Aerospace & Electronics

Aerospace applications demand high-reliability sealing at low weight. Molded silicone and fluorosilicone gaskets are common in:

- Avionics enclosures to resist EMI and temperature swings.

- Cabin pressure systems where exact fit and compression recovery are critical.

In electronics, molded gaskets are used for sealed keypads, camera housings, and sensor interfaces, often designed to IP67 or higher standards.

Why Industry Relies on Molding:

- Consistency: Each part is formed identically under high precision.

- Complex Geometry: Allows integration of ribs, holes, or multi-level surfaces.

- Material Versatility: Supports a range of rubber compounds tailored to specific conditions—heat, oil, vibration, chemicals.

- Low to Mid-Volume Efficiency: Perfect for OEM parts, replacement components, and specialized machinery.

Molded gaskets offer engineered performance that extrusion simply cannot replicate when sealing, fit, and mechanical endurance are mission-critical.

Neoprene vs Silicone: Which Is Better for Vibration Gaskets?

When it comes to vibration-reducing gaskets, neoprene and silicone stand out as two of the most widely used elastomers. Each brings a distinct set of mechanical, environmental, and economic advantages, making the choice highly application-specific.

Comparative Overview:

| Feature | Neoprene (CR) | Silicone Rubber |

|---|---|---|

| Temperature Range | -40°C to +120°C | -60°C to +230°C |

| Oil & Chemical Resistance | Good | Moderate (selective) |

| UV & Ozone Resistance | Excellent | Excellent |

| Elasticity | Medium | High |

| Compression Set | Moderate | Low (maintains shape better) |

| Cost | Lower | Higher |

| Certifications | Common in industrial/commercial | Common in FDA, aerospace, medical |

| Adhesion to Metal | Excellent | Moderate (requires primers) |

Neoprene: The All-Purpose Workhorse

Neoprene is favored in industrial and automotive applications for its:

- Balanced damping and strength

- Excellent adhesion to substrates

- Resistance to oils and greases

It’s particularly well-suited for engine bays, HVAC systems, and equipment enclosures where moderate temperature and oil resistance are needed.

Silicone: The High-Performance Specialist

Silicone excels where:

- High or low temperatures are a factor (e.g., -60°C to +230°C)

- Flexibility and rebound are crucial

- Chemical cleanliness or FDA compliance is required

That’s why silicone is common in aerospace, cleanrooms, electronics, and medical devices where both reliability and compliance are paramount.

Choosing Between Them:

- Use neoprene for cost-effective, general-purpose damping, especially in oil-rich or moderately demanding environments.

- Choose silicone for temperature extremes, low compression set, or hygienic conditions where longevity and thermal resilience matter most.

“The right choice isn’t about which material is ‘better’—it’s about what fits your operating conditions best.”

Design Considerations for Industrial Gasket Molding

Designing molded rubber gaskets for industrial use requires a careful balance of material science, geometry, process control, and performance expectations. Unlike extrusion, which is limited to uniform cross-sectional profiles, molding allows for complex three-dimensional forms—but this flexibility comes with added design responsibilities.

1. Part Geometry and Functional Requirements

- Shape complexity: Molding supports features like grooves, lips, raised surfaces, holes, and varying wall thicknesses.

- Compression zones: Engineers must define which areas will compress and seal, and which must remain dimensionally stable.

- Flash and parting lines: Mold parting surfaces must be planned to avoid flash in critical sealing zones. Design should facilitate easy demolding.

Example: A gasket used in a valve cover may include raised ribs for sealing, bolt holes for mounting, and curved walls to match the housing contour—all molded in a single shot.

2. Material Selection and Compound Matching

Choosing the right rubber compound depends on:

- Temperature range: e.g., silicone for -60°C to +230°C, EPDM for weather and UV.

- Chemical exposure: nitrile for oil/fuel; FKM for aggressive chemicals.

- Mechanical demands: hardness (Shore A), elongation, and tensile strength must match the application.

Molded gaskets often require low compression set and high rebound resilience to maintain seal performance over time.

3. Mold Design and Tolerance Control

- Cavity layout: Must ensure even flow of rubber into all features without trapping air or under-filling.

- Shrinkage compensation: Rubber shrinks upon curing—designers must anticipate and offset these changes.

- Venting and gating: Proper venting avoids air pockets; gate positioning controls fill direction and pressure distribution.

4. Curing Time and Cycle Efficiency

Cure time depends on:

- Rubber type (e.g., peroxide-cured silicone vs sulfur-cured EPDM)

- Part thickness

- Molding method (compression, transfer, or injection)

Designers must avoid thick areas that lead to undercured cores, which can affect elasticity and strength.

5. Post-Molding Operations

Some molded gaskets require:

- Deflashing: Trimming excess rubber (flash) around edges.

- Adhesive application: For gaskets that must bond to surfaces.

- Secondary curing or post-baking: Especially for silicone, to remove volatiles and stabilize properties.

6. Prototyping and Design Validation

Before full production, molded gasket designs should be validated via:

- Rapid tooling or 3D-printed mold inserts

- Compression tests

- Finite Element Analysis (FEA) for deformation under load

A well-designed molded gasket ensures long-term sealing reliability, reduced maintenance, and compliance with safety standards. At Kinsoe, we collaborate closely with engineers to optimize every aspect of gasket performance—from material blend to final mold parting geometry.

Conclusion

Vibration-reducing gaskets do much more than seal—they serve as critical vibration control systems that protect equipment, ensure mechanical stability, and extend service life. From high-speed machinery and HVAC systems to automotive and aerospace environments, these engineered components absorb disruptive energy that would otherwise degrade performance and shorten equipment lifespan.

Recap of Core Insights:

- Rubber’s viscoelastic properties make it ideal for vibration damping.

- Materials like neoprene, silicone, and EPDM each serve distinct roles based on environmental and mechanical demands.

- Extrusion technology enables cost-effective, customizable gasket profiles that meet tight tolerances and performance specs.

- Thoughtful design—from cross-sectional geometry to material hardness—ensures the right balance of flexibility, durability, and vibration isolation.

Whether you’re a system designer looking for optimal material specs or a procurement engineer evaluating gasket suppliers, understanding the fundamentals of rubber extrusion and vibration control equips you to make smarter, longer-lasting choices.

At Kinsoe, we specialize in custom-molding rubber gaskets tailored to specific vibration and sealing challenges. With over 20 years of expertise, precision prototyping capabilities, and materials engineered for tough conditions, we’re ready to help you reduce downtime, improve safety, and ensure smoother operation across your entire system.

Need help identifying the right gasket for your application?

Contact us or send in your system requirements for expert recommendations.

References: