1. Introduction

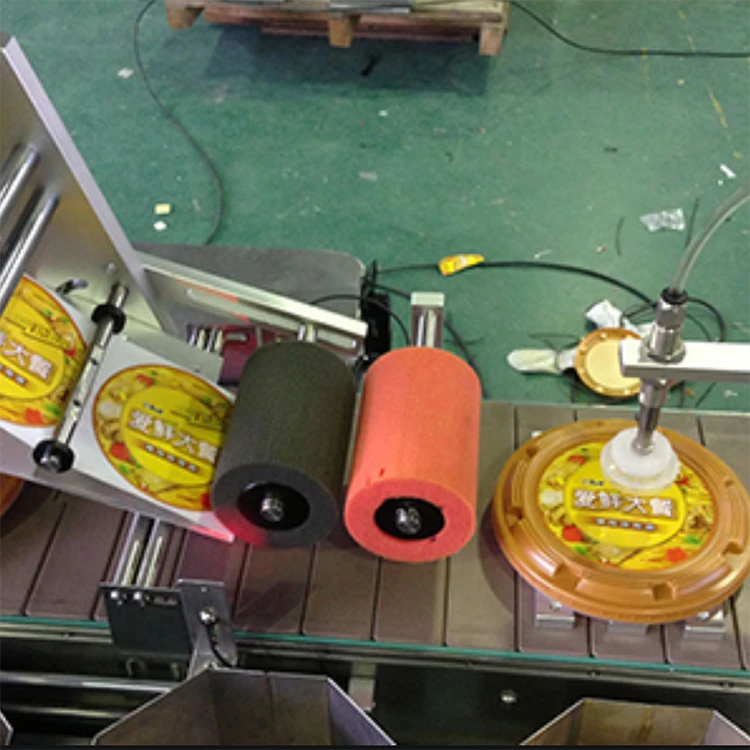

Have you ever wondered how labels are applied so precisely on products—whether it’s a water bottle, a can of soda, or a shampoo tube? The secret often lies in an unassuming but critical component: the sponge labeling roller. Without it, labels would peel, wrinkle, or misalign during production. I used to think labeling was just about sticking a sticker onto a product. But after entering the manufacturing world, I quickly realized it’s a complex dance between pressure, speed, and material control.

If you’re in procurement or production management, you’ve likely encountered issues with label misplacement, machine wear, or inconsistent adhesion. That’s where the choice of sponge roller comes in. It might look like a simple foam cylinder, but the right roller can dramatically improve labeling efficiency, precision, and durability across various packaging lines.

In this article, I’ll walk you through everything you need to know about sponge labeling rollers—from their definition and core function to the material options and real-world applications. Whether you’re a buyer looking for reliable parts or a curious reader, this guide will offer clarity and practical insights.

Here’s what matters most when it comes to sponge labeling roller

2. What Is a Sponge Labeling Roller?

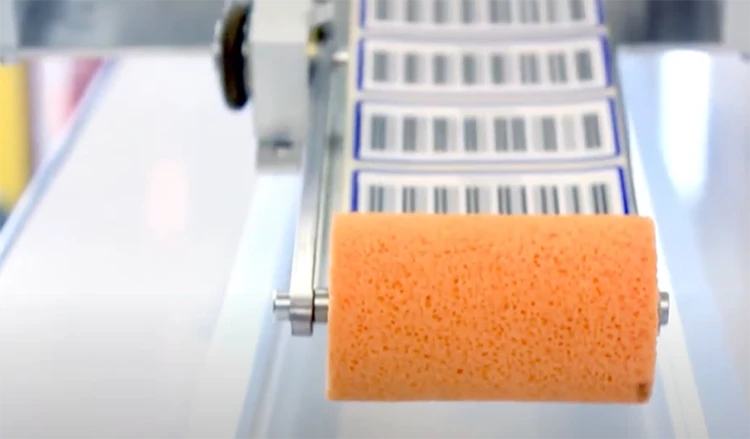

Sponge labeling roller—also known as a sponge roller, rubber sponge roller, or label applicator roller—is a specialized cylindrical component used in automatic labeling machines to assist with the precise application of adhesive labels onto products. Typically made from compressible sponge materials such as natural rubber, polyurethane (PU) foam, or silicone, these rollers act as pressure applicators, pressing the label smoothly onto the product surface without causing air bubbles, folds, or misalignment.

When I first examined one up close, I was surprised at how simple it looked—but the engineering behind it is anything but basic. A sponge labeling roller must strike a delicate balance: it needs to be soft enough to conform to the product’s shape, yet firm enough to maintain consistent pressure. If it’s too hard, labels may not stick evenly. If it’s too soft, the roller might wear out quickly or deform under high-speed use.

In most labeling machines, the sponge roller works in sync with a driven or idle shaft and a label dispensing mechanism. As the product passes through, the roller applies even pressure across the label, ensuring perfect adhesion every time.

“The right sponge roller ensures accuracy, speed, and durability in modern labeling lines.”

That’s why choosing the right type of sponge and specifications is key to long-term performance. From beverage bottles to cosmetic containers, this humble roller plays a major role in packaging perfection.

3. Why Sponge Rollers Matter in Labeling Machines

At first glance, it’s easy to overlook the role of a sponge labeling roller. But once I saw how critical it is to the success of an entire packaging line, I started to pay close attention. A poorly chosen or worn-out roller can result in misapplied labels, machine downtime, and product rework—all of which increase operational costs.

Here’s why these rollers matter so much:

- Precise Label Positioning: The sponge surface adapts to slight variations in product shape, ensuring the label is pressed uniformly onto the surface without wrinkles or bubbles.

- Consistent Pressure Distribution: In fast-moving automatic lines, rollers must deliver steady, even pressure to avoid slippage or partial adhesion.

- Vibration Absorption: Sponge rollers help reduce mechanical vibration in high-speed machines, protecting both the product and the equipment.

- Gentle Contact: For fragile or irregular-shaped items, the soft compression prevents cracking or cosmetic damage.

I’ve worked with clients who were experiencing label misalignment issues despite using high-end labeling machines. In most cases, the problem traced back to the roller—not the electronics or software. Swapping in a high-quality sponge roller with the right density solved the problem immediately.

If you’re trying to boost packaging quality or reduce labeling waste, upgrading your sponge roller may be the most cost-effective fix available. It’s one of those “small parts, big impact” components in industrial automation.

4. Common Materials and Their Differences

Not all sponge labeling rollers are created equal. The material you choose affects everything from roller lifespan to how well it handles specific products. Over the years, I’ve tested various sponge types in different labeling environments—and each one offers unique benefits and trade-offs.

Let me break down the three most commonly used materials:

4.1 Natural Rubber Sponge

Natural rubber sponge rollers are known for their high elasticity and excellent recovery. They compress easily and bounce back quickly, making them ideal for rapid labeling lines where flexibility is essential.

Key Advantages:

- Great for medium-speed and high-volume applications

- Operates well within a wide temperature range (typically -60°C to 120°C)

- Strong grip and durability under repeated compression

However, they may degrade faster when exposed to oils, solvents, or certain chemicals. So if your application involves aggressive substances, it might not be the best choice.

4.2 PU (Polyurethane) Foam

PU foam rollers are valued for their abrasion resistance and customizable hardness. I often recommend PU foam for clients handling heavy-duty or high-speed labeling jobs.

Key Advantages:

- Longer lifespan compared to natural rubber

- Available in a range of densities for specific pressure needs

- Better resistance to wear, tear, and mechanical fatigue

Still, PU may lose elasticity over time, especially in high-humidity environments or when compressed continuously.

4.3 Silicone Sponge

Silicone sponge rollers are the go-to choice when heat resistance and chemical stability are top priorities. I’ve seen them perform flawlessly in labeling applications involving hot-fill containers or chemical packaging.

Key Advantages:

- Withstands temperatures up to 250°C

- Excellent for food-grade or pharmaceutical packaging lines

- Non-reactive and safe for sensitive products

The main downside? Cost. Silicone sponges are typically more expensive, so they’re best used where their unique properties are absolutely necessary.

Material Comparison Table

| Feature / Material | Natural Rubber Sponge | PU (Polyurethane) Foam | Silicone Sponge |

|---|---|---|---|

| Elasticity | Very high | Moderate to high | Moderate |

| Temperature Resistance | -60°C to 120°C (up to 130°C short-term) | Up to 100°C | Up to 250°C |

| Chemical Resistance | Poor to moderate | Good | Excellent |

| Wear Resistance | Moderate | Excellent | Good |

| Cost | Economical | Moderate | High |

| Application Fit | General-purpose labeling | High-speed and durable labeling | Heat- or chemical-sensitive applications |

“Match the material to your specific operating environment—not just your budget.”

This table should help you narrow down your options based on your labeling conditions, product type, and performance requirements. Ready to find the best fit? In the next section, I’ll walk you through how to choose the right sponge labeling roller for your machine.

5. How to Choose the Right Sponge Labeling Roller

Choosing the right sponge labeling roller isn’t just about picking the softest or cheapest option. It’s about finding the perfect balance between your machine’s design, the product’s surface, and your production environment. I’ve helped many customers troubleshoot labeling failures, and nine times out of ten, the issue traces back to one of these three factors.

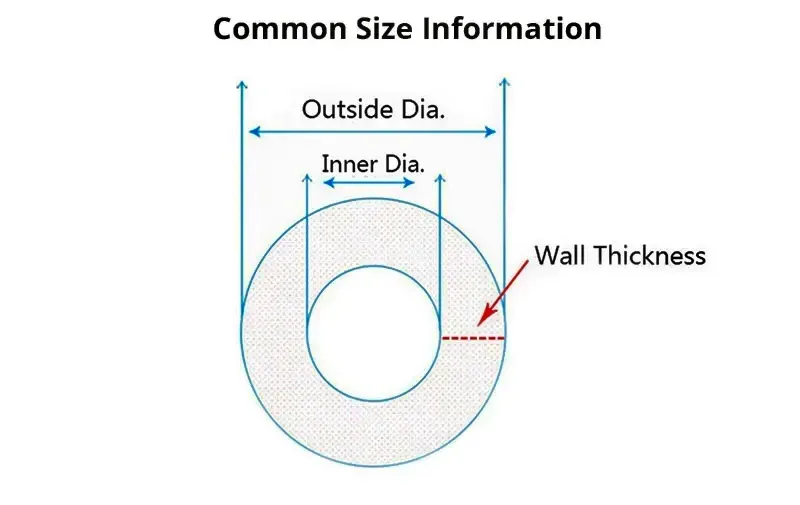

5.1 Size and Shape

Roller size must match your machine and product dimensions. Too small, and it won’t provide enough contact area. Too large, and it could cause uneven pressure or interfere with surrounding components.

- Diameter: Affects the pressure zone and labeling accuracy

- Width: Must align with the label size and the product path

- Core hole size: Must fit precisely on the shaft or bracket

Custom sizing is often required for non-standard machines or oddly shaped containers. That’s why I always ask clients to provide machine specs or product drawings before recommending a roller.

5.2 Hardness and Compression

This is one of the most critical aspects. The hardness (measured in Shore A) determines how much the roller compresses under pressure. A roller that’s too soft might deform or wear out quickly. Too hard, and it could damage the product or cause label bubbling.

- Soft (20–30 Shore A): Great for delicate surfaces or uneven shapes

- Medium (30–45 Shore A): Suitable for general-purpose labeling

- Hard (45–60 Shore A): Ideal for high-speed, flat-surface labeling

I often suggest clients test different hardness levels in their actual production line before committing to a bulk order.

5.3 Heat and Chemical Resistance

If your labeling process involves high temperatures (like hot-fill bottling) or exposure to solvents, oils, or alcohol, then resistance becomes a must-have feature.

- High-temp environments → Go with silicone sponge

- Chemically aggressive settings → PU or silicone is better

- Room temperature, clean environments → Natural rubber performs well

Tip: Always communicate the operating conditions with your supplier. It ensures the roller performs reliably under real use—not just in theory.

“A well-matched roller isn’t just a component—it’s a guarantee of efficiency, longevity, and reduced rework.”

Now that you know how to select the right roller, let’s explore where these rollers are commonly used across different industries.

6. Where Are Sponge Labeling Rollers Used?

You might be surprised at just how many industries rely on sponge labeling rollers. From the drinks you sip to the medicine you take, chances are a sponge roller played a part in packaging that product. In my experience, buyers from various sectors often look for the same three things: labeling precision, material durability, and compatibility with high-speed machines. Here’s where these rollers show up most often:

6.1 Beverage Industry

Think bottled water, soda, beer, and juice—especially those moving down high-speed production lines. In this space, sponge rollers must be fast-recovering, temperature-resistant, and capable of handling moisture or condensation without losing grip.

- Used for PET bottles, glass bottles, and aluminum cans

- Rollers must perform under high-speed, high-humidity environments

- Silicone or PU foam rollers are preferred for their stability

One of my clients in a bottled tea factory switched from standard rubber rollers to custom PU foam types and immediately saw a drop in label rejection rates from 5% to under 1%.

6.2 Food and Packaging

From sauces and condiments to snacks and frozen foods, labeling is a key step in the packaging process. The challenge here is that many containers are oddly shaped—think squeezable ketchup bottles or vacuum-sealed pouches.

- Requires rollers that conform to curves and uneven surfaces

- Food-grade material (like silicone) is often required

- Natural rubber is still widely used due to its cost-efficiency

In this sector, roller shape and softness often matter more than high-speed tolerance. It’s all about adaptability to complex contours.

6.3 Cosmetics and Pharmaceuticals

Cosmetic jars, serum bottles, pill containers, and medical vials require flawless label application to maintain brand image and meet strict compliance standards.

- Small products demand high-precision, small-diameter rollers

- Low residue and non-reactivity are crucial—especially in pharma

- Silicone rollers dominate due to their clean and stable properties

I recall a pharmaceutical supplier who needed a roller that wouldn’t off-gas or flake over time. We provided a platinum-cured silicone roller, and it passed both FDA and ISO cleanroom compatibility tests.

“No matter the industry, the goal is the same: consistent, professional label application that never compromises your product.”

Next up, let’s tackle the most frequently asked questions I hear from buyers and engineers about sponge labeling rollers.

7. FAQs About Sponge Labeling Rollers

Over the years, I’ve received countless questions from clients who were either sourcing rollers for the first time or troubleshooting issues on their labeling lines. Below are the most common questions—and the answers that help clear up confusion:

Q1: How long does a sponge labeling roller typically last?

That depends on the material and usage intensity. Natural rubber rollers may last for a few months under regular use, while PU and silicone rollers can last much longer—especially in high-speed environments. If you’re labeling thousands of units per day, plan to inspect or replace rollers regularly to maintain accuracy.

Q2: Can sponge rollers be cleaned and reused?

Yes, most rollers can be gently cleaned with mild soap and water or alcohol wipes, depending on the material. Avoid harsh solvents unless you’re sure the sponge type can handle them. Silicone rollers are especially resistant to cleaning agents and can be reused many times without degrading.

Q3: What causes label bubbling or wrinkling?

This is usually caused by incorrect pressure, worn-out rollers, or mismatched hardness. A roller that’s too soft may not press the label firmly, while one that’s too hard can’t conform to curves. It’s also worth checking machine alignment and speed synchronization.

Q4: Can I request a custom-made sponge labeling roller for my equipment?

Absolutely. In fact, custom rollers are often the best solution when working with non-standard containers, unique machine models, or specific industry requirements. At Kinsoe, we regularly provide OEM-style rollers based on technical drawings or machine specifications.

Q5: Do sponge rollers come in anti-static or conductive versions?

Yes. For industries like electronics or cosmetics packaging—where static can cause label misplacement or dust attraction—anti-static sponge materials can be used to prevent charge buildup.

“Asking the right questions about sponge rollers can save you time, money, and endless production headaches.”

Still unsure if a standard or custom roller is right for your project? That’s where customization comes in—let me walk you through what’s possible.

8. Customization Options for Buyers

If you’re managing an automated labeling line or working with specialty packaging, off-the-shelf rollers won’t always cut it. That’s why I always recommend exploring custom sponge labeling roller options—especially if you’re facing recurring problems like poor label adhesion or rapid wear and tear.

Here’s what you can typically customize:

1. Dimensions

From micro rollers used for vials to wide-format rollers for industrial drums, every machine has its own size requirements.

- Outer diameter, inner bore, and width can all be tailored

- Tolerances as tight as ±0.05 mm are achievable with CNC precision

- Custom groove patterns or taper shapes can be applied if needed

2. Material Composition

Choosing the right sponge base material—natural rubber, PU, or silicone—is just the start. You can also request:

- Anti-static formulas for electronics or cleanrooms

- FDA-grade materials for food or pharmaceutical labeling

- Oil- and solvent-resistant blends for chemical packaging

3. Surface Finish

Some labeling lines benefit from a roller with added texture or grip. Others require a smooth, low-friction finish.

- Polished or micro-textured surfaces

- Color-coding by material type or hardness level

4. Core and Shaft Fittings

The inner core of the roller must match your equipment precisely.

- Plastic, aluminum, or stainless steel inserts

- Compatibility with both driven and idle shaft mechanisms

One of my clients in the cosmetics industry needed a roller with a soft-touch grip, FDA-compliant silicone, and a 6 mm bore to fit a Japanese-made applicator. We delivered a fully customized batch within 10 days, and they saw a 40% reduction in labeling defects.

“Customization is not just a premium option—it’s often a necessity for modern production environments.”

9. Conclusion

Sponge labeling rollers may look simple, but as I’ve shown you, they’re one of the most vital components in ensuring smooth, precise, and high-speed label application. From material selection and size configuration to compression strength and custom finishes, every detail affects your production line’s efficiency and your product’s presentation.

Whether you’re in food packaging, cosmetics, or pharmaceuticals, choosing the right sponge roller can reduce waste, improve labeling consistency, and cut downtime. I’ve seen it happen time and again—just a small upgrade in roller quality or design results in big performance gains across the board.

To recap, here’s what you should take away from this guide:

- Understand the basic structure and function of a sponge labeling roller

- Know the strengths and limitations of each sponge material

- Match roller properties (size, hardness, resistance) with your production needs

- Don’t hesitate to customize—especially if your equipment or product is non-standard

- Ask smart questions before buying, and test before scaling

If you’re currently sourcing sponge labeling rollers or want to improve your line’s output, I’d be happy to help. At Kinsoe, we specialize in customized rubber and sponge solutions, including high-performance labeling rollers tailored to your exact needs.

Contact us today to request a sample, share your machine specifications, or get expert advice on selecting the right sponge roller.