Introduction

Have you ever wondered why certain rubbers remain flexible outdoors, despite constant exposure to sun, rain, and extreme temperatures? That’s where EPDM rubber comes into play. EPDM, short for Ethylene Propylene Diene Monomer, is a synthetic rubber widely praised for its exceptional durability and weather resistance, making it one of the most preferred elastomers in the industry today.

Unlike natural rubber or nitrile rubber (NBR), which tend to degrade when exposed to harsh environmental conditions, EPDM rubber thrives in tough weather and UV exposure. This makes it invaluable in outdoor applications, ranging from automotive seals and roofing membranes to flexible connectors in HVAC systems.

In this comprehensive guide, I’ll dive into the specific properties that set EPDM apart, explore its common uses, and help you understand how it compares to other popular elastomers. Whether you’re a product designer selecting materials, an industrial buyer seeking the right rubber solution, or simply curious about the science behind synthetic rubber, this article will provide all the essential details you need. Here’s a closer look at what makes EPDM rubber uniquely valuable in a world full of synthetic rubber alternatives.

1. What Is EPDM Rubber Made Of?

To truly understand why EPDM rubber is so versatile and durable, it’s crucial to explore its chemical makeup. EPDM stands for Ethylene Propylene Diene Monomer, clearly indicating the three primary chemical components involved:

- Ethylene (45%-75%) – Provides mechanical strength and rigidity.

- Propylene (25%-55%) – Adds flexibility and resilience.

- Diene Monomer (1%-10%) – Enables crosslinking through vulcanization, significantly enhancing durability and elasticity.

The presence of a diene monomer is particularly important. Unlike regular ethylene-propylene rubber (EPR), EPDM includes this diene component, allowing for effective vulcanization—a process that chemically binds polymer chains, greatly improving heat resistance, elasticity, and strength.

Role of Diene in Crosslinking Flexibility

Diene monomers, such as ethylidene norbornene (ENB) or dicyclopentadiene (DCPD), facilitate crosslinking during vulcanization. This crosslinking provides EPDM rubber with exceptional flexibility and resilience, even under repeated mechanical stresses. It also contributes to EPDM’s impressive durability against environmental factors like UV rays, ozone, and extreme temperatures.

Comparison with Other Elastomers: EPDM vs. NBR vs. Silicone

Here’s a quick look at how EPDM compares to other popular elastomers:

- EPDM vs. NBR (Nitrile Rubber):

EPDM excels in weather and ozone resistance but fails in contact with petroleum-based products. NBR, on the other hand, boasts superior oil resistance but is vulnerable to UV and ozone degradation. - EPDM vs. Silicone Rubber:

Silicone rubber offers a broader temperature range and excellent UV resistance but at a significantly higher cost. EPDM provides a balance of affordability and excellent weathering characteristics, though it doesn’t match silicone’s extreme heat resistance or medical-grade purity.

Understanding these subtle differences ensures you choose the right rubber material tailored to your application, enhancing the overall performance and lifespan of your products.

2. Key Properties of EPDM Rubber

To effectively leverage EPDM in your projects or applications, understanding its specific properties is critical. Below, I’ve organized the key characteristics of EPDM rubber into a clear, concise table to illustrate why it has become a preferred choice in various industries:

| Property | Description |

|---|---|

| Weather Resistance | Exceptional resistance to UV radiation, ozone degradation, rain, snow, and extreme outdoor conditions. |

| Temperature Range | Performs reliably from -50°C to +150°C (with specialized grades enduring up to 180°C). |

| Water Resistance | Highly hydrophobic, making it ideal for waterproof sealing, roofing, and outdoor gaskets. |

| Electrical Insulation | Exhibits low electrical conductivity, frequently used in wire and cable insulation due to its dielectric strength. |

| Elasticity | Maintains flexibility and structural integrity over extended periods, even under mechanical stress. |

| Chemical Compatibility | Shows strong resistance to many acids, alkalis, and ketones but is not suitable for petroleum-based oils or hydrocarbons. |

Among these, the weather resistance of EPDM rubber stands out as a core advantage. Its resilience to environmental stressors ensures minimal degradation over time, resulting in significantly reduced maintenance and replacement costs.

Furthermore, the broad temperature range of EPDM ensures reliable performance in both very cold and hot climates. Its ability to maintain flexibility at extreme temperatures ensures seals and gaskets remain effective even under harsh conditions.

Finally, its excellent electrical insulation properties make EPDM indispensable in electronics and electrical engineering, safeguarding cables and sensitive equipment from electrical damage and environmental stress.

These comprehensive attributes collectively explain why EPDM rubber is consistently the first choice for product designers and industrial procurement professionals seeking durability, versatility, and cost-effectiveness.

3. Limitations You Should Know

While EPDM rubber offers numerous impressive advantages, it’s equally important to recognize its limitations. Knowing these restrictions upfront ensures you make informed decisions and avoid costly mistakes in product selection or design.

Not Suitable for Oil or Fuel Environments

EPDM rubber’s chemical structure makes it inherently vulnerable to degradation from petroleum-based substances, oils, fuels, and hydrocarbons. Exposure to these substances will cause EPDM components to swell, lose mechanical integrity, and eventually fail. For applications involving continuous or even occasional exposure to oil or fuel, alternative materials like NBR (Nitrile Rubber) or FKM (Fluorocarbon Rubber) should be selected instead.

Poor Adhesion to Metal without Surface Treatment

EPDM typically exhibits poor bonding characteristics with metallic surfaces unless specific surface treatments or adhesive primers are applied. This inherent limitation means additional processing steps and costs must be considered if your project involves EPDM-to-metal bonding, such as automotive weatherstripping or industrial sealing applications.

Limited Flame Resistance Unless Modified

EPDM rubber, in its standard form, has limited flame resistance and can combust or degrade under direct flame exposure. However, flame-retardant grades of EPDM are available, specifically formulated by adding flame-retardant additives or fillers. If your application demands fire safety or stringent flame-resistance regulations, always opt for specialized flame-retardant EPDM varieties.

Being fully aware of these limitations will enable you to accurately evaluate whether EPDM is indeed the optimal choice for your specific application—or whether a different rubber type might better suit your project’s unique requirements.

4. EPDM Grades & Processing

When selecting EPDM rubber, it’s essential to consider the various grades and processing methods available, as these choices directly impact the performance, cost, and suitability of the final product.

Solid vs. Sponge EPDM

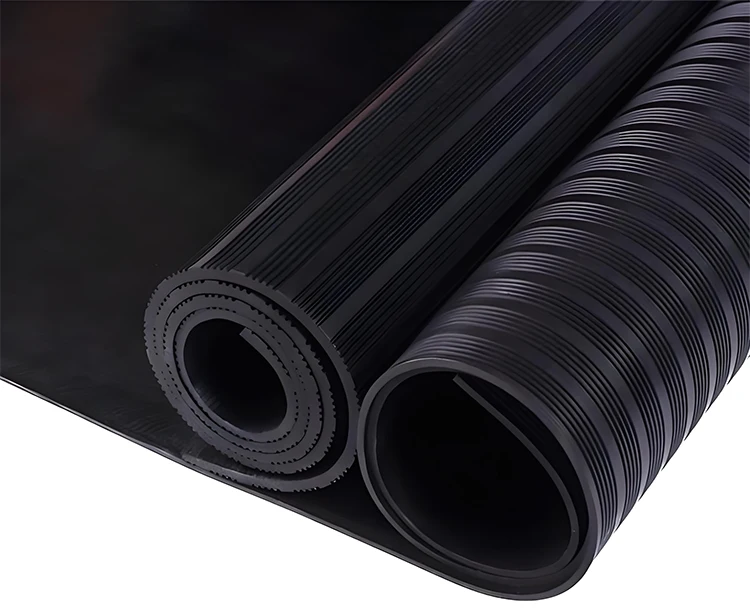

- Solid EPDM:

Solid EPDM rubber is dense, strong, and typically used where sealing strength, durability, and resistance to compression are paramount. It’s commonly used for automotive weather seals, industrial gaskets, and waterproof membranes. - Sponge EPDM:

Sponge EPDM, on the other hand, is lighter, compressible, and ideal for cushioning, vibration isolation, and thermal insulation applications. Its cellular structure allows for greater flexibility and improved thermal performance, making it popular in window seals, thermal insulation pads, and acoustic applications.

Sulfur vs. Peroxide Curing

- Sulfur Curing:

Traditional sulfur-cured EPDM is cost-effective and provides excellent flexibility. However, it has limitations such as slightly lower heat resistance and less color stability (may yellow over time). - Peroxide Curing:

Peroxide-cured EPDM provides superior heat stability, better compression set resistance, and enhanced color stability. This method is preferred for high-performance applications in automotive or electrical industries, though it typically involves higher material and processing costs.

Common Molding Techniques

The versatility of EPDM allows it to be processed via multiple molding techniques, including:

- Extrusion:

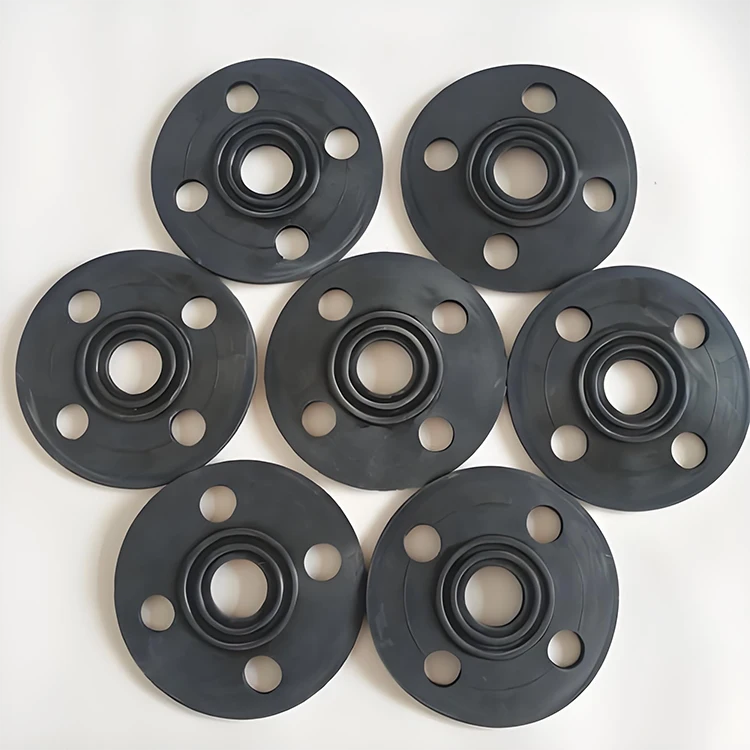

Widely used for continuous profiles such as tubing, seals, cords, and strips. Ideal for mass production of uniform cross-sectional shapes. - Compression Molding:

Suitable for manufacturing complex or large products such as seals, gaskets, diaphragms, and custom-shaped components, offering high dimensional accuracy. - Injection Molding:

Best suited for high-volume, precision parts due to rapid processing speeds and tight tolerances. Commonly utilized in automotive parts and precision industrial components.

Food-grade, Construction-grade, High-temp Variants

Depending on the specific industry and application, EPDM is available in specialized grades:

- Food-grade EPDM:

Meets FDA and other regulatory standards, suitable for food processing equipment, beverage tubing, and hygienic seals. - Construction-grade EPDM:

Formulated to provide superior UV, ozone, and water resistance, ideal for roofing membranes, window seals, and expansion joints. - High-temperature EPDM:

Engineered to withstand sustained exposure up to 180°C, perfect for demanding automotive, industrial, or electronic applications where standard grades would degrade prematurely.

Clearly understanding these distinctions among EPDM types and processing methods enables you to select the most suitable option tailored precisely to your project’s requirements, ensuring optimum performance, durability, and cost-effectiveness.

5. EPDM Rubber Applications (With Real Cases)

EPDM’s unique combination of resilience, durability, and versatility has made it a go-to material across a broad spectrum of industries. To help illustrate exactly why EPDM rubber is so highly valued, I’ve compiled practical examples of common industry applications, along with the reasons EPDM excels in each scenario.

| Industry | Typical Products | Why EPDM Works Well |

|---|---|---|

| Automotive | Weatherstrips, radiator hoses, window gaskets | Outstanding weather resistance, flexibility, and long-term durability in varying temperatures |

| Construction | Roofing membranes, expansion joints, garage door seals | Exceptional resistance to UV, ozone, and moisture, ensuring longevity in harsh outdoor environments |

| HVAC | Flexible duct connectors, insulation sleeves, air seals | Reliable temperature resistance and excellent airtight sealing capabilities |

| Electrical | Cable jackets, panel grommets, insulation tubes | Superior electrical insulation, elasticity, and long-term flexibility |

Case Example: Automotive Weatherstripping

Take automotive weatherstrips as an illustrative case: Major automotive manufacturers, such as Ford, Toyota, and BMW, extensively utilize EPDM for door and window sealing applications. The reason is simple: vehicles need consistent sealing performance to keep out water, dust, noise, and temperature extremes. EPDM weatherstrips excel in providing reliable seals that maintain elasticity, weather resistance, and structural integrity throughout the vehicle’s lifetime, significantly reducing warranty claims related to sealing failures.

Case Example: EPDM Roofing Membranes

In construction, EPDM rubber roofing membranes are widely recognized for their proven track record of durability. Buildings equipped with EPDM roofing—such as large commercial facilities, warehouses, and residential complexes—experience dramatically reduced maintenance costs, thanks to EPDM’s excellent resistance to UV rays, ozone, and extreme weather conditions. Typically, EPDM roofing membranes have a lifespan exceeding 25 years, offering excellent value for building owners.

Case Example: HVAC Flexible Connectors

HVAC systems demand materials that withstand temperature fluctuations, vibration, and constant airflow without losing flexibility. EPDM flexible connectors used in ventilation systems effectively reduce mechanical stress and vibration between ducts, ensuring reliable performance and improving energy efficiency. Companies like Johnson Controls and Honeywell regularly employ EPDM for these critical HVAC components because of its consistent performance over decades of use.

Through these real-world examples, it’s clear how EPDM rubber consistently meets and exceeds the stringent requirements of multiple industries, making it an ideal choice for applications demanding reliability, longevity, and exceptional performance.

6. How to Choose the Right EPDM Rubber

Selecting the right EPDM rubber variant involves carefully evaluating your project’s specific requirements. By considering essential factors such as temperature exposure, shape, chemical resistance, and mechanical demands, you can ensure optimal product performance and longevity. Here’s a practical guide to help you pinpoint exactly which type of EPDM is best suited for your application:

Based on Temperature: Standard vs. High-temp EPDM

- Standard EPDM:

- Ideal for general-purpose applications ranging from -50°C to +150°C.

- Common in construction seals, automotive weatherstrips, and standard HVAC connectors.

- High-temp EPDM:

- Specifically formulated to withstand temperatures up to 180°C.

- Crucial for automotive engine components, industrial seals, and electrical insulation requiring exceptional thermal stability.

Based on Shape: Extrusion vs. Molded

- Extruded EPDM:

- Suitable for continuous profiles like tubing, strips, cords, and weatherstripping.

- Ideal when cost-effectiveness, consistency, and volume production are key considerations.

- Molded EPDM:

- Recommended for complex, custom-shaped, or precision parts.

- Used in applications such as custom gaskets, diaphragms, seals, and specialized industrial components.

Based on Exposure: Chemical Resistance or Ozone Resistance?

- Chemical-Resistant EPDM:

- Enhanced formulation providing resistance to acids, alkalis, and other chemicals.

- Best suited for chemical processing equipment, laboratory seals, and wastewater handling.

- Ozone-Resistant EPDM:

- Standard EPDM inherently excels in ozone and UV resistance.

- Optimal for outdoor applications like roofing membranes, automotive window seals, and exterior cable covers.

Based on Compression Set or Elongation Needs

- Low Compression Set EPDM:

- Offers superior resilience and retains sealing effectiveness after prolonged compression.

- Ideal for long-lasting sealing applications like automotive door seals, HVAC gaskets, and flange seals.

- High-Elongation EPDM:

- Provides exceptional flexibility, elongation, and recovery.

- Perfect for dynamic applications such as expansion joints, movement seals, and vibration isolation pads.

By systematically evaluating these criteria, you’ll accurately identify the right EPDM rubber grade and processing method for your unique application, ensuring dependable performance and maximizing your investment’s value.

7. EPDM vs. Other Rubber Types: Quick Comparison

Choosing between EPDM and other popular rubber types like Nitrile (NBR) or Silicone often hinges on specific performance needs. To simplify your selection process, here’s a straightforward comparison that highlights essential characteristics and differences between these elastomers:

| Feature | EPDM | NBR (Nitrile) | Silicone |

|---|---|---|---|

| Oil Resistance | ❌ Not oil-resistant | ✅ Excellent | ✅ Good |

| UV/Ozone | ✅ Exceptional | ❌ Poor | ✅ Excellent |

| Temperature Range | ✅ -50°C to 150°C (high-temp to 180°C) | ⚠️ -30°C to 120°C | ✅✅ -60°C to 230°C |

| Water Resistance | ✅ Excellent | ⚠️ Moderate | ✅ Excellent |

| Electrical Insulation | ✅ Excellent | ⚠️ Moderate | ✅✅ Superior |

| Cost | ✅ Affordable | ✅ Affordable | ❌ More expensive |

- EPDM:

- Ideal choice for outdoor, automotive, construction, and electrical insulation due to its outstanding weather resistance, affordability, and good temperature range.

- Avoid using in contact with oils or fuels.

- NBR (Nitrile):

- Best suited for automotive and industrial sealing applications involving petroleum-based oils, fuels, and lubricants.

- Poor choice for outdoor exposure and UV-sensitive environments.

- Silicone Rubber:

- Preferred for medical, food-grade, and extreme-temperature applications requiring higher purity, flexibility, and broad temperature performance.

- Higher costs can limit use in general industrial scenarios.

By clearly understanding these comparative factors, you’ll easily pinpoint whether EPDM, NBR, or Silicone aligns best with your project’s performance criteria and budget constraints, leading to optimal functionality and durability in your final product.

FAQ: Frequently Asked Questions About EPDM

Here are clear answers to some of the most common questions I often encounter regarding EPDM rubber. These insights will help address frequent misconceptions and provide practical knowledge to better guide your purchasing and design decisions.

1. Is EPDM the same as rubber?

EPDM is indeed a type of rubber, but specifically a synthetic elastomer. Unlike natural rubber, EPDM is engineered chemically from ethylene, propylene, and a diene monomer. This synthetic composition gives EPDM its distinctive weather resistance, durability, and versatility, which natural rubber lacks.

2. Can EPDM be used with petroleum?

No. EPDM rubber should not be used in petroleum-based applications. Contact with oils, fuels, and hydrocarbon solvents will cause EPDM to swell and deteriorate. For petroleum-based environments, materials like NBR (nitrile rubber) or FKM (fluorocarbon rubber) are much better choices.

3. How long does EPDM roofing last?

Typically, EPDM roofing membranes have an impressive service life of approximately 25-30 years or even more, depending on climate, installation quality, and maintenance. Regular inspections and minor maintenance can extend this lifespan significantly.

4. What’s the difference between sponge and solid EPDM?

- Solid EPDM: Dense, strong, and durable, it provides excellent sealing and structural integrity, ideal for heavy-duty applications.

- Sponge EPDM: Has a cellular structure that offers cushioning, insulation, and flexibility. It’s commonly used for thermal insulation, weatherstripping, and vibration reduction.

Understanding these nuances helps ensure you select the right type of EPDM, precisely matching your project’s unique requirements and constraints.

Conclusion

EPDM rubber stands out in the world of synthetic elastomers due to its unparalleled combination of durability, versatility, and cost-effectiveness. Whether your project involves automotive weather seals, robust roofing membranes, HVAC components, or electrical insulation, EPDM reliably delivers exceptional performance in demanding environments. Its resistance to UV, ozone, water, and extreme temperatures ensures longevity, minimizing maintenance costs and maximizing your product’s lifecycle.

However, being mindful of its limitations—such as incompatibility with petroleum-based substances—is crucial to ensure appropriate material selection. By carefully considering specific application requirements, processing techniques, and available EPDM grades, you can optimize your product design, reduce risks, and achieve outstanding results.

If you need guidance selecting the right EPDM product or wish to explore customized rubber solutions for your project, don’t hesitate to contact Kinsoe. With over two decades of experience in crafting precision-engineered EPDM solutions, Kinsoe can support your projects from concept through completion, ensuring that your materials consistently meet and exceed expectations.

Discover how EPDM can elevate your project—reach out today!

References: