1. Introduction

Polyurethane foam cylinders may look simple, but they play a critical role in modern mechanical design, industrial equipment, automotive systems, HVAC components, and even precision electronics. These cylindrical foam components are designed to absorb impact, reduce vibration, control noise, stabilize assemblies, and compensate for tolerances—all while being lightweight, durable, and easy to integrate into different systems.

Across industries, engineers are increasingly turning to polyurethane foam cylinders because traditional solutions—such as metal springs, solid rubber pads, or rigid plastic stoppers—cannot deliver the same combination of controlled compression, progressive damping, and noise reduction.

At Kinsoe, we work with engineers, project managers, and OEM buyers who need reliable damping components that are simple to customize, stable under repeated cycles, and cost-effective for mass production. Whether the requirement involves cushioning a robotic arm’s end-stop, isolating vibration in a fan motor, or minimizing noise in an automotive compartment, polyurethane foam cylinders often provide the ideal balance of performance and efficiency.

This article serves as the foundation of the full content cluster. You’ll learn:

- What polyurethane foam actually is

- What a foam cylinder looks like and how it functions

- Internal structures, density choices, and geometry options

- Key performance characteristics such as compression, elasticity, and stability

- How these cylinders are manufactured (including laser cutting)

- Where they are used across industries

- How they compare to other materials and how to begin choosing the right specification

If you later want to explore more, you can jump directly to:

- Applications → Top Applications of Polyurethane Foam Cylinders

- Material comparison → Polyurethane vs Other Foam Materials

- Engineering selection guide → How to Select the Right Polyurethane Foam Cylinder

2. What Is Polyurethane Foam?

2.1 Polyurethane as an Engineering Polymer

Polyurethane (PU) is a highly adaptable polymer family used in elastomers, foams, coatings, adhesives, and structural materials. When formulated as a foam, polyurethane becomes lightweight, resilient, and energy-absorbing—making it ideal for damping, cushioning, sealing, and insulation.

Unlike solid polyurethane elastomers (used for wheels, bushings, etc.), PU foam contains millions of micro-cells that control compression, rebound, and energy absorption. This cellular structure is what makes foam cylinders capable of soft deformation while maintaining mechanical stability.

2.2 Open-Cell vs Closed-Cell PU Foam

Polyurethane foams typically fall into two categories:

Open-Cell Foam

- Interconnected cell structure

- Softer and more breathable

- Excellent for vibration damping

- Better for applications requiring quiet, soft compression

Closed-Cell Foam

- Independent sealed cells

- Higher stiffness

- Better barrier to air and moisture

- Preferred for insulation and structural spacing

For foam cylinders used in damping, most projects favor high-density open-cell polyurethane, while some insulation or sealing applications may require closed-cell.

3. What Is a Polyurethane Foam Cylinder? (Core Definition)

3.1 Basic Form and Geometry

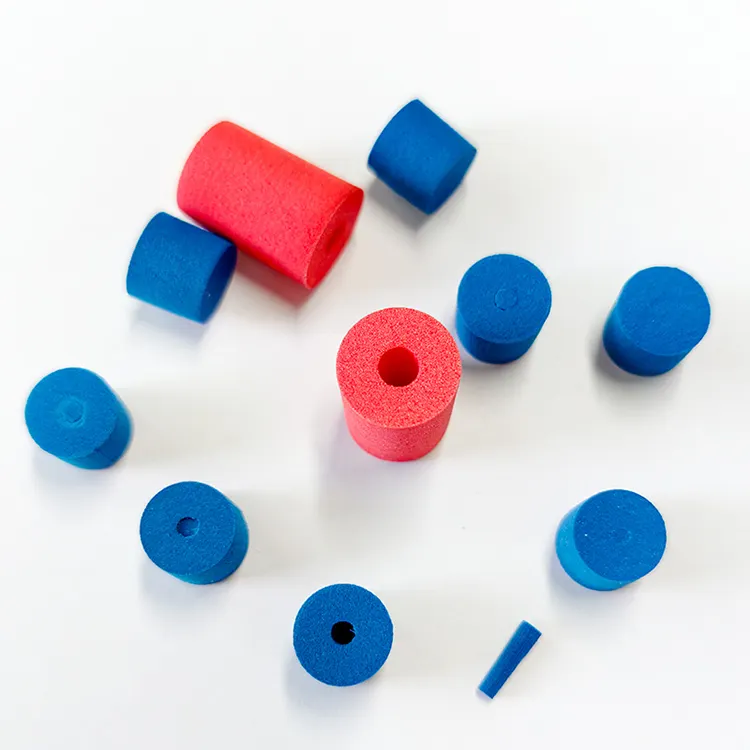

A polyurethane foam cylinder is simply a cylindrical component cut or molded from high-density PU foam. The geometry allows the part to fit easily into mounts, housings, shafts, brackets, or any assembly requiring controlled compression.

Main formats include:

- Solid Cylinder:

Completely filled, no internal bore.

Used for direct impact absorption or heavy compression. - Hollow / Concentric Cylinder:

Features a central bore running through the length.

Provides more progressive damping and is ideal for mounting over rods, shafts, or bolts.

3.2 Functional Role in Systems

PU foam cylinders typically provide one or more of the following functions:

- Shock absorber for machinery, robotic arms, or packaging

- Vibration damper for motors, fans, or compressors

- Soft stop or bumper in automotive and industrial assemblies

- Spacer or alignment buffer

- Noise reduction element

- Thermal or acoustic insulation

Their compact shape and predictable compression profile make them easier to integrate than blocks, sheets, or irregular foam parts.

4. Internal Structure and Geometry Options

4.1 Solid vs Hollow Cylinders

Solid Foam Cylinder

- Highest load capacity

- Uniform compression

- Ideal for direct impact zones

Hollow (Concentric) Foam Cylinder

- Controlled multi-stage deformation

- Lower weight

- Can be installed over screws, shafts, pipes

- Excellent for HVAC vibration support, electronics, and automotive interior mechanisms

4.2 High-Density vs Medium-Density Foam

PU foam cylinders commonly come in densities between 200–600 kg/m³:

- 200–300 kg/m³: Soft, high damping; ideal for automotive, HVAC

- 300–450 kg/m³: Balanced stiffness; used for general industrial damping

- 450–600 kg/m³: High load resistance; used in heavy machinery or repetitive impact zones

Higher density increases stiffness, durability, and load-bearing capability.

4.3 Diameter, Length, and Tolerances

Foam cylinders can be made in virtually any dimension. Typical tolerances range from ±0.5 mm to ±1.5 mm, depending on OD/ID and cutting method.

Precision is important when cylinders must:

- Fit tightly into housings

- Slide onto shafts

- Maintain alignment or preload

- Provide consistent force-displacement behavior

5. Key Performance Properties of PU Foam Cylinders

5.1 Compression and Energy Absorption

One of the biggest advantages of PU foam is its progressive compression curve:

- Initial compression is soft

- Mid-range exhibits strong energy absorption

- Final compression protects equipment from impact shock

This makes it suitable for machinery end-stops, robotic arms, and dynamic applications.

5.2 Wear Resistance and Fatigue Life

Polyurethane offers better abrasion resistance than many foams (such as EVA or PE), meaning it maintains performance over thousands or millions of cycles.

5.3 Elasticity and Shape Recovery

Fast elastic recovery allows foam cylinders to quickly return to shape after compression, ensuring consistent performance in:

- Fans

- Motors

- Reciprocating equipment

- Moving panels

5.4 Acoustic and Thermal Behavior

PU foam cylinders help:

- Reduce noise caused by vibration

- Prevent noise transmission between surfaces

- Provide thermal insulation when used as spacers or supports

6. How Polyurethane Foam Cylinders Are Manufactured

6.1 From Foam Block to Finished Cylinder

General steps:

- PU foam is produced in blocks or sheets.

- Blocks are cured and stabilized.

- Cylinders are cut, cored, or shaped according to required geometry.

6.2 Cutting Technologies (Including Laser Cutting)

Traditional Methods:

- Saw cutting

- Die cutting

- Lathe cutting

High-Precision Laser Cutting:

- Clean edges with minimal deformation

- Extremely accurate OD/ID concentricity

- Perfect for custom shapes and tight tolerances

- Preferred for advanced OEM specifications

Kinsoe often uses laser cutting for cylinders requiring high precision.

6.3 Customization Options

Customizable attributes include:

- OD, ID, length

- Density and hardness

- Color coding

- Chamfered edges

- Adhesive backing

- Grooved or contoured surfaces

7. Typical Forms, Sizes, and Variants Offered

7.1 Standard Sizes

Available in common diameters such as:

- 10 mm

- 15 mm

- 20 mm

- 25 mm

- 30–60 mm for industrial use

Lengths may range from 5 mm to over 200 mm.

7.2 Custom Cylinders for OEM Projects

For customers requiring application-specific dimensions, Kinsoe provides:

- Made-to-drawing cylinders

- Modified compression profiles

- Custom inner/outer tolerances

- Color-coded hardness

7.3 Related Shapes

From the same polyurethane foam blocks, Kinsoe can also produce:

- Pads

- Washers

- Rings

- Blocks

- Strips

All with similar performance characteristics.

8. Where Polyurethane Foam Cylinders Are Used

8.1 Industrial Machinery & Automation

- CNC damping blocks

- End-stop buffers for robotic arms

- Vibration isolation mounts

8.2 Automotive & Transport

- Interior soft stops

- Rattle-elimination cushions

- Car refrigerator vibration supports

8.3 HVAC & Construction

- Fan motor vibration dampers

- Pipe spacers and supports

- Acoustic control points

8.4 Electronics & Appliances

- Anti-vibration mounts

- PCB motor cushions

- Shock absorbers for portabl-e devices

To explore real use cases across five major industries, visit the full application guide:

👉 Top Applications of Polyurethane Foam Cylinders

9. Advantages of Polyurethane Foam Cylinders vs Other Solutions

9.1 Compared to Solid Rubber or Metal Springs

- Much lower noise

- More gradual compression

- Lighter and easier to install

- Better for precision assemblies requiring soft engagement

9.2 Compared to Other Foam Materials

Polyurethane provides:

- Superior abrasion resistance

- Better compression recovery

- Longer fatigue life

- More density options

Alternatives like EVA, PE, or silicone are typically selected only for cost-sensitive, waterproofing, or high-temperature scenarios.

9.3 When Polyurethane Is Not the Best Choice

PU may not be ideal in:

- Continuous high-temperature areas (silicone is better)

- Environments exposed to heavy oils or certain chemicals (NBR foam is better)

- Applications requiring extremely rigid structural foam

For a full comparison, see:

👉 Polyurethane vs Other Foam Materials

10. Key Parameters to Consider When Choosing a Foam Cylinder

10.1 Load & Stroke Requirements

Determine:

- Max load

- Expected compression range

- Required stiffness

10.2 Density & Hardness

Density affects energy absorption; hardness affects “feel” during compression.

10.3 Operating Environment

Consider:

- Temperature

- Humidity

- Oil exposure

- UV exposure

10.4 Fit & Mounting

Ensure correct:

- Bore size

- Clearance

- Length

- Preload

For deeper engineering guidance, see:

👉 Engineering Guide: How to Select the Right PU Foam Cylinder

11. What Buyers Should Prepare Before Contacting a Supplier

11.1 Technical Data Needed

- Load, stroke, operating frequency

- OD/ID/length

- Current failure issues (noise, wear, vibration)

11.2 Questions Kinsoe Will Ask

- Application

- Target compression behavior

- Load profile

- Any industry standards to follow

11.3 Benefits of Working with a Specialist

Kinsoe provides:

- Custom density tuning

- Precision laser cutting

- Rapid prototyping

- Large-scale OEM production

12. Summary

Polyurethane foam cylinders are reliable, adaptable components that play a significant role in managing vibration, cushioning impact, and reducing noise across many industries. With tunable density, customizable geometry, and excellent fatigue resistance, they offer a strong balance of performance and cost-effectiveness.

Recommended Next Reads

- Applications:

https://www.kinsoe.com/polyurethane-foam-cylinder-applications/ - Material comparison:

https://www.kinsoe.com/polyurethane-vs-other-foam-cylinders/ - Engineering selection:

https://www.kinsoe.com/polyurethane-foam-cylinder-selection-guide/

If you need custom polyurethane foam cylinders for industrial, automotive, HVAC, or specialty applications, visit our product page

Or send your drawings and requirements for a tailored solution.